Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Solar Installation Manual

Caricato da

dineshDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Solar Installation Manual

Caricato da

dineshCopyright:

Formati disponibili

Jiangsu Linyang Solarfun Co., Ltd.

October 1, 2010

Installation Guide

Standard modules

SF160-24-1Mxxx, SF160-24-Mxxx

SF160-24-1Pxxx, SF160-24-Pxxx

SF190-27-1Mxxx, SF190-27-Mxxx

SF190-27-1Pxxx, SF190-27-Pxxx

SF220-30-1Mxxx, SF220-30-Mxxx

SF220-30-1Pxxx, SF220-30-Pxxx

SF260-36-1Mxxx, SF260-36-Mxxx

SF260-36-1Pxxx, SF260-36-Pxxx

Black diamond modules

SF160-24-1MxxxB, SF160-24-MxxxB

SF160-24-1PxxxB, SF160-24-PxxxB

SF190-27-1MxxxB, SF190-27-MxxxB

SF190-27-1PxxxB, SF190-27-MxxxB

SF220-30-1MxxxB, SF220-30-MxxxB

SF220-30-1PxxxB, SF220-30-PxxxB

SF260-36-1MxxxB, SF260-36-MxxxB

SF260-36-1PxxxB, SF260-36-PxxxB

Jiangsu Linyang Solarfun Co., Ltd.

888 Linyang Road, Qidong

Jiangsu 226200, China

www.solarfun-power.com

sales@solarfun-power.com

Note: 1. “xxx” indicates nominal power output

2. Digit 1 in module type means IEC product.

Installation guide/ Version 3.0 Page 1 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

INTRODUCTION

Solarfun is a leading manufacturer of silicon ingots, wafers, PV cells and modules, delivering reliability and

competitive pricing on a global scale. We provide world-class PV technology, streamlined manufacturing, and

local customer support.

We are committed to providing technical and installation support for our customers, worldwide.

This Installation Guide covers installation of the following Solarfun modules:

Standard modules

SF160-24-1M/Mxxx - SF160-24-1P/Pxxx - SF190-27-1M/Mxxx - SF190-27-1P/Pxxx - SF220-30-1M/Mxxx

SF220-30-1P/Pxxx - SF260-36-1M/Mxxx - SF260-36-1P/Pxxx

Black Diamond modules

SF160-24-1M/MxxxB - SF160-24-1P/PxxxB - SF190-27-1M/MxxxB - SF190-27-1P/PxxxB - SF220-30-1M/MxxxB

SF220-30-1P/PxxxB - SF260-36-1M/MxxxB - SF260-36-1P/PxxxB

PURPOSE OF THIS GUIDE

This guide contains important information regarding the installation, safe handling and maintenance of

photovoltaic modules made by Jiangsu Linyang Solarfun Co., Ltd. Jiangsu Linyang Solarfun Co., Ltd hereafter is

referred to as “Solarfun.” The word “module” as used in this guide refers to one or more PV modules.

All instructions should be read and understood prior to installing the modules. The installer should conform to all

the safety precautions in this guide when installing the modules. Local standards and regulations should also be

followed during installation. Before installing a photovoltaic system, the installer must be familiar with the

mechanical and electrical requirements for such a PV system. Keep this guide in a safe place for future reference.

Solarfun provides technical support worldwide. Visit www.solarfun-power.com for contact information.

DISCLAIMER OF LIABILITY

The installation techniques, handling and use of the product are beyond company control. Therefore, Solarfun

assumes no responsibility for loss, damage or expense resulting from improper installation, handling or misuse.

Ensure that the module is used only in applications for which it is suitable (see “Installing Module”). All work on a

PV system (installation, setup, maintenance) must be carried out only by appropriately qualified and authorized

engineers. The appropriate DIN standards, construction rules and safety instructions must be followed during

installation.

IEC/EN61730 INFORMATION

Solarfun module is designed to fulfill the criteria of Application Class A requirements according to

IEC/EN61730-part1.

The modules are qualified for application class A: Hazardous voltage (IEC61730: higher than 50V DC; EN61730:

higher than 120V), hazardous power applications (higher than 240W) where general contact access is anticipated

(Modules qualified for safety through EN IEC61730-1 and EN IEC61730-2 within this application class are

considered to meet the requirements for Safety ClassⅡ).

UL LISTING INFORMATION

1. Rated electrical characteristics are within 10% of measured values at Standard Test Conditions of:

1000W/m2, 25℃ cell temperature and solar spectral irradiance per ASTM E892 or irradiance of AM 1.5

spectrum.

2. The standoff height should be at least 7.9 in. If other mounting means are employed, this may affect the UL

Listing.

3. The modules have been evaluated by UL for a maximum positive or negative design loading of 30 lbs/ft2.

4. Wiring methods should be in accordance with the NEC.

5. For installations in Canada, the installation shall also be in accordance with CSA C22.1, safety Standards for

Electrical Installations, Canadian Electrical Code, Part 1.

6. The use of the following hardware is required in order to provide a reliable grounding connection to the

module frame: a combination of the following stainless steel hardware: Serrated washer, Spring washer, flat

washer, a size M4 nut, and bolt M4x30mm -- (see illustration grounding for details).

Installation guide/ Version 3.0 Page 2 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

WARNING!

PV modules generate electricity as soon as they are exposed to sunlight. One module generates a safe, extra low

voltage level, but multiple modules connected in series (summing the voltage) or in parallel (summing the current)

represent a danger. The following points must be noted when handling the solar modules to avoid the risk of fire,

sparking and fatal electric shock.

Do not insert any electrically conducting materials into the plugs or sockets.

Do not fit solar modules and wiring with wet plugs and sockets.

Make sure to use proper safety equipments (insulated tools, insulated gloves, etc.)

when wiring.

Make sure that the connection is made when the circuit is cut off. Do not disconnect

under load.

To avoid the generation of an electric arc, ensure the connectors are clean and have

not been contaminated, and that the electrical connection and mechanical joint are

good.

UNPACKING AND STORING MODULE:

Utmost attention is required when handling module. The following guidelines should be followed with caution

while unpacking, transporting and storing the modules:

Do not strike or physically damage the module.

Carry modules with both hands. Do not use the connection socket as a handle;

Avoid cutting and damaging the frame during handling and installation.

Do not stand on the module.

Do not twist the module.

Do not mark on the rear of the module using sharp objects.

Installation guide/ Version 3.0 Page 3 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

SYSTEM DESIGN, MOUNTING AND INSTALLATION:

System Design

Before installing your solar system, contact local authorities to determine the necessary permit, installation and

inspection requirements that must be followed.

System should be installed by qualified personnel only. The system involves electricity, and can be dangerous if

the personnel are not familiar with the appropriate safety procedures.

PV modules should be mounted in a location where they will receive maximum sunlight throughout the year.

Specially, in the Northern Hemisphere, the modules should face South. And in the Southern Hemisphere, the

modules should face North.

In order to achieve maximum annual yield, optimum orientation and tilt of

PV module is necessary. Sunlight shining vertically and completely onto

PV module is the best condition to generate maximum power.

Artificially concentrated sunlight shall not be directed on the module.

Very hot module(s) can reduce power output performance.

Ensure the module has good ventilation conditions to prevent overheating.

The maximum load on module must not exceed 2.4KN/m2.

Site-specific environment loads such as wind and snow should be taken

into account to avoid exceeding the maximum load.

When designing the system, please pay attention to the total voltage

(if connected in series) and current (if connected in parallel).

We recommend the maximum number of modules in parallel should be

no more than four (4), and while in series, no more than the ratio of

module`s maximum system voltage to open circuit voltage.

(Maximum system voltage: 1000V for IEC product and 600V for UL product)

The module must not be installed close to fire or flammable materials.

Completely cover the module with an opaque material during

installation to keep electricity from being generated.

Mechanical Mounting

The basis for durable and safe mounting is an assembly frame which corresponds to the appropriate structural

requirements, which is securely anchored to the ground, to the roof, or to a façade, and whose long-term stability

is guaranteed. The mounting structure and the module attachments must be designed in accordance with the

local wind and snow loads. Ensure that the modules are mounted over a fire resistant roof covering rated for the

application.

To prevent bending, vibration, mechanical stress or warpage, mount the module onto a flat contact surface.

Secure the module along the long edges with the correct number of clamps. The minimal distance between

mounted modules should be no less than 20 mm. Use all the mounting points provided and avoid direct contact

between glass and metal (e.g. mounting rails).

The junction box should be located in upper or lateral area of the module and the cables should hang

downwards.

Installation guide/ Version 3.0 Page 4 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

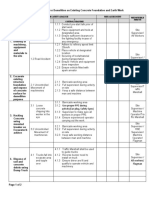

MOUNTING METHODS FOR SOLARFUN MODULES

Option 1: Clamping mounting Option 2: Bolting mounting

The module may be clamped only in the permitted Use the existing installation holes instead of drilling

clamping areas as indicated on following drawings. additional holes for installation (Drilling holes shall

And the module clamps must not overlap the glass or against the reliability and warranty of the module).

shade the module surface. The installation and attachment materials (nuts,

Recommended tightening torque: 5Nm. bolts, etc.) must be corrosion-resistant.

Recommended tightening torque: 5Nm.

Method 1 Method 2 Method 3

Standard Mounting Mounting on short side Triangle Mounting

Product Frame Method 1 Method 2 Method 3

SF160M/P, SF160M/P-B 45&40mm △ ×

SF190M/P, SF190M/P-B 45&40mm △ ×

SF220M/P, SF220M/P-B 50mm × ×

SF260M/P, SF260M/P-B 50mm × ×

Note: 1. “” indicates5400pa is available; “△ ” indicates 2400pa is available; “×” indicates no permission

2. Different frame height should choose appropriated clamp and bolt.

3. Mechanical load test performed according to IEC standard, not applicable for UL products.

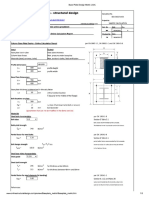

Mounting details

1. Clamping drawing

20mm

R4.5

R4.5

40mm

40mm

26mm

45mm 35mm

Stainless steel M8 bolt

Stainless steel M8 nut

Stainless steel flat washer

Aluminum-alloy clamp

h value depends on frame height

Installation guide/ Version 3.0 Page 5 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

Module type: SF160-24-1M/M, SF160-24-1P/P, SF160-24-1M/M-B, SF160-24-1P/P-B

100 150

Clamping area

Clamping area

150 100

Module type: SF190-27-1M/M, SF190-27-1P/P, SF190-27-1M/M-B, SF190-27-1P/P-B

150

100

Clamping area

Clamping area

100

150

Installation guide/ Version 3.0 Page 6 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

Module type: SF220-30-1M/M, SF220-30-1P/P, SF220-30-1M/M-B, SF220-30-1P/P-B

250

100

Clamping area

Clamping area

100

250

Module type: SF260-36-1M/M, SF260-36-1P/P, SF260-36-1M/M-B, SF260-36-1P/P-B

250

100

Clamping area

Clamping area

100

250

Installation guide/ Version 3.0 Page 7 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

2. Bolting drawing

Min. 20

olt Stainless steel M8 t-head bolt

amp Stainless steel M8 nut

ut Stainless steel Flat washer

at washer Stainless steel Spring washer

Module type: SF160-24-1M/M, SF160-24-1P/P, SF160-24-1M/M-B, SF160-24-1P/P-B

Installation guide/ Version 3.0 Page 8 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

Module type: SF190-27-1M/M, SF190-27-1P/P, SF190-27-1M/M-B, SF190-27-1P/P-B

Module type: SF220-30-1M/M, SF220-30-1P/P, SF220-30-1M/M-B, SF220-30-1P/P-B

Installation guide/ Version 3.0 Page 9 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

Module type: SF260-36-1M/M, SF260-36-1P/P, SF260-36-1M/M-B, SF260-36-1P/P-B

ELECTRICAL INSTALLATION-WIRING

Correct wiring scheme

To minimize the risk of indirect lighting strike, avoid forming closed loops when designing the system. Check that

wiring is correct before starting the generator. If the measured open circuit voltage (Uoc) and short-circuit

current (Isc) differ from the specifications, there may be a wiring fault.

Correct connection plug connectors

The area of the cable mated with the connector is recommended to be 4~6 mm2, length: 900mm, temperature

range:-40℃-90℃. The plug connector has its own polarity. Make sure that the connection is safe and tight. The

plug connector should not receive external stress. Connectors should only be used to connect the circuit, but

never used to turn the circuit on or off.

Use of proper components

Use cable extensions and plugs that are designed for outdoor applications. Ensure that they are in good

electrical and mechanical condition. Only cables with one conductor are to be used.

Ensure that all materials meet the requirements of the systems` maximum voltage, current, moisture, and

temperature when they are exposed to sunlight.

Under normal conditions, a photovoltaic module is likely to produce more current and/or voltage than that

reported under Standard Test Conditions. Accordingly, the values of Isc and Voc marked on the module should

be multiplied by a factor of 1.25 when selecting electrical components voltage ratings, conductor capacities,

fuse type, and type of control components connected to the PV output. Refer to Section 690-8 of the U.S.

National Electric Code for an additional multiplying factor of 1.25 which may be applicable.

The maximum series fuse rating is 10A(module with Solarfun 125x125 cells)or 15A (module with Solarfun

156x156 cells). And the maximum reverse current is known as series fuse rating multiplied by a factor of 1.35.

Each module (or series string of modules so connected) shall be provided with the maximum series fuse as

specified.

Installation guide/ Version 3.0 Page 10 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

Bypass Diodes

When modules in series are partially shaded, it may cause reverse voltage across cells or modules, this may

cause undesirable heating to occur. The use of a diode to bypass the shaded area can minimize both heating

and array current reduction.

All Solarfun modules are equipped with factory installed bypass diodes. The factory installed diodes provide

proper circuit protection for the system.

Others

During installation, be sure to tie the cable from the junction box to the mounting substructure with nylon line,

etc. to avoid direct contact of the cable with the back surface of the module.

GROUNDING:

To avoid the risk of electrical shock or fire, the module frame should be grounded before the electrical

connection of the modules is operated.

The frame shall be grounded in accordance with NEC Article 250 (USA) or CEC in Canada.

A good connection between the grounding hardware is essential for an effective ground. The anodization on a

module frame provides a coating to minimize the corrosion due to weather and it acts as a barrier that reduces

the effectiveness of the grounding connection. For an adequate ground, the grounding hardware should

penetrate the anodization layer.

For bonding to ground only UL listed equipment should be used.

The following hardware is recommended:

LIMITED ENVIRONMENTAL CONDITIONS

Solarfun`s Limited Warranty for module is based upon modules being mounted in accordance with following

conditions.

Operating conditions

The operating temperature of Solarfun module should be within -40℃ (-40ºF) to 85℃ (185ºF).

Ensure adequate ventilation behind the module, especially in hot environments.

Corrosion due to exposure to salt, it is recommended that modules be installed at least 500m from the sea.

Sulfur (from sulfur sources such as volcanoes) can also lead to corrosion and performance degradation and

should be avoided.

Location conditions

The following locations should be avoided when installing a module:

1. Location with potential for extreme sand and dust damage

2. Location with extreme air pollution, chemical vapors, acid rain, and/or soot, etc.

3. Location with extreme hail and/or snow

4. Location with potential extreme salt damage

MAINTENANCE AND CARE

Dirt on the surface of solar module may decrease the power generation. Solarfun modules have a self-cleaning

function under rainfall weather condition. Module with a mounted tilt angle more than 15°is more effective

than other mounting angle. If heavy soiling build-up is excessive on module glass, use a soft cloth and water for

cleaning. CAUTION: DON`T USE ABRASIVE DETERGENTS. Please consult with system designer to decide the

cleaning frequency according to local environmental conditions. Once a year, check the electrical and

mechanical devices to ensure every connection is tight. The system must be periodically inspected.

Installation guide/ Version 3.0 Page 11 / 12

Jiangsu Linyang Solarfun Co., Ltd. October 1, 2010

Visit www.solarfun-power.com for more information.

Solarfun provides detailed technical support, worldwide.

International Sales Office Solarfun – Spain

218 Wusong Road 26th Floor Notari Badia, n4 - Local 11

BM Tower 08221 Terrassa

Shanghai, China 200080 Barcelona, Spain

Tel: +86 212 602 2888 Tel: +34 931 93 97 63

Solarfun Power Deutschland GmbH Solarfun – Korea

Oskar Messter Straße 13 10th Floor, Room 1016

85737 Ismaning Hanshin Intervally West Bldg 707-24

Deutschland Yeoksam-dong, Gangnam-gu

Tel: +49 89 21 75 667-30 Seoul, Korea

Tel: +82 2 2183 0168

Solarfun – Australia Solarfun – USA

Sydney, Australia 3135 Kashiwa Street, Unit B

Tel: +61 405 717 848 Torrance, CA 90506

Tel: +1-310-257-8853

Installation guide/ Version 3.0 Page 12 / 12

Potrebbero piacerti anche

- REF FuseApplicationGuide PDFDocumento17 pagineREF FuseApplicationGuide PDFyetignrNessuna valutazione finora

- MW Onix Solar Project Report PDFDocumento13 pagineMW Onix Solar Project Report PDFankitNessuna valutazione finora

- Estimating Power from Diesel Engine Converted to LPG OperationDocumento6 pagineEstimating Power from Diesel Engine Converted to LPG OperationAmol TembhareNessuna valutazione finora

- Solar Energy BrochureDocumento8 pagineSolar Energy Brochurejamilahmed00Nessuna valutazione finora

- SSFA Market UpdateDocumento34 pagineSSFA Market UpdatelawrgeoNessuna valutazione finora

- Types and Applications of Hydropower PlantsDocumento9 pagineTypes and Applications of Hydropower PlantsCendolz IssZulNessuna valutazione finora

- RENEWABLE ENERGY Market & Policy Trends in IEA CountriesDocumento382 pagineRENEWABLE ENERGY Market & Policy Trends in IEA CountriesagbekasNessuna valutazione finora

- Tender 10 KW Rooftop SolarDocumento14 pagineTender 10 KW Rooftop Solarsrirajt4uNessuna valutazione finora

- 0.5MW PV Solar Plant CameroonDocumento4 pagine0.5MW PV Solar Plant CameroonMuhammad Asif ShafiqNessuna valutazione finora

- Monsson Group - ServicesDocumento20 pagineMonsson Group - ServicesAlexandru HalauNessuna valutazione finora

- Customer Satisfaction Project of Green TechDocumento52 pagineCustomer Satisfaction Project of Green TechRajkamalChichaNessuna valutazione finora

- CEA Water RequirementDocumento52 pagineCEA Water RequirementtozirconNessuna valutazione finora

- IEA PVPS Trends Report 2020-1Documento88 pagineIEA PVPS Trends Report 2020-1David GarciaNessuna valutazione finora

- Swot Analysis of Flow BatteriesDocumento5 pagineSwot Analysis of Flow BatteriesJp GuptaNessuna valutazione finora

- 50kWp Roof Top Solar Project for Govt Polytechnic CollegeDocumento22 pagine50kWp Roof Top Solar Project for Govt Polytechnic CollegeBADRI VENKATESHNessuna valutazione finora

- SolarPro 7.6Documento88 pagineSolarPro 7.6HanyNessuna valutazione finora

- Buses Diesel A CNGDocumento39 pagineBuses Diesel A CNGCarlos Loler NavarroNessuna valutazione finora

- Renewable Energy in IndiaDocumento20 pagineRenewable Energy in IndiabenoypNessuna valutazione finora

- 0141 - 30kWp To 100kWp Solar Photovoltaic Power Plants - CREDADocumento22 pagine0141 - 30kWp To 100kWp Solar Photovoltaic Power Plants - CREDAPranavateja ChilukuriNessuna valutazione finora

- Prepaid Energy Meter Using Smart CardDocumento14 paginePrepaid Energy Meter Using Smart CardanjalikaranNessuna valutazione finora

- Solar PV System GuideDocumento32 pagineSolar PV System GuidelokendraNessuna valutazione finora

- Development of Bidirectional Net Meter in Grid Connected Solar PV System For Domestic ConsumersDocumento5 pagineDevelopment of Bidirectional Net Meter in Grid Connected Solar PV System For Domestic ConsumersHariprasad RNessuna valutazione finora

- Solar 3Documento12 pagineSolar 3ar.ryanortigasNessuna valutazione finora

- CNG 101: Questions about Natural Gas as a Transportation FuelDocumento2 pagineCNG 101: Questions about Natural Gas as a Transportation FuelPawan ChaturvediNessuna valutazione finora

- NREL Wind To Hydrogen Project - Renewable Hydrogen Production For Energy Storage & Transportation PDFDocumento26 pagineNREL Wind To Hydrogen Project - Renewable Hydrogen Production For Energy Storage & Transportation PDFJosePPMolinaNessuna valutazione finora

- ST548KWH-250: Storage SystemDocumento2 pagineST548KWH-250: Storage Systemsubkhan100% (1)

- Building & Inspecting PV Systems Nec PDFDocumento26 pagineBuilding & Inspecting PV Systems Nec PDFHaytham BafoNessuna valutazione finora

- Solar Power Plant Setup - Frequently Asked Questions - EfficientCarbonDocumento15 pagineSolar Power Plant Setup - Frequently Asked Questions - EfficientCarbon08mpe026Nessuna valutazione finora

- D4 1 Specification For Minimum Requirements For Charging Spots V6 1 SubmittedDocumento173 pagineD4 1 Specification For Minimum Requirements For Charging Spots V6 1 Submittedaquel1983100% (1)

- PV150 Installation Test KitDocumento3 paginePV150 Installation Test Kitabdalrhman alqatawnehNessuna valutazione finora

- EU Solar PV Business ModelsDocumento78 pagineEU Solar PV Business ModelsAdrian Fratean100% (1)

- Photovoltaic PlantDocumento37 paginePhotovoltaic PlantenerconNessuna valutazione finora

- Annexe 2 - ESKOM Cost Estimate Letter No IPP293459467 - Legoko 3 PV PlantDocumento46 pagineAnnexe 2 - ESKOM Cost Estimate Letter No IPP293459467 - Legoko 3 PV PlantalfredoNessuna valutazione finora

- 1MW/1.25MW PV Inverter ManualDocumento41 pagine1MW/1.25MW PV Inverter Manualcrazyshiva100% (5)

- Solar Panel ManufacturingDocumento11 pagineSolar Panel ManufacturingKhalil Ibrahim AhmedNessuna valutazione finora

- Evaluation of islanding detection methods for PV systemsDocumento59 pagineEvaluation of islanding detection methods for PV systemsanu17008Nessuna valutazione finora

- BYD Battery-Box Operating Manual LVL 15.4: PremiumDocumento37 pagineBYD Battery-Box Operating Manual LVL 15.4: PremiumDINONessuna valutazione finora

- Breakout Session 1: Asset Management and O&M Standardization: Process, Status Quo and Next StepsDocumento14 pagineBreakout Session 1: Asset Management and O&M Standardization: Process, Status Quo and Next StepsLaima KlemasNessuna valutazione finora

- Electric Vehicles Unplugged Global Marketing AnalysisDocumento36 pagineElectric Vehicles Unplugged Global Marketing AnalysisFater Saadat NiakiNessuna valutazione finora

- First Solar 2014 Annual Report Bookmark - FinalDocumento188 pagineFirst Solar 2014 Annual Report Bookmark - FinalFabián OrccónNessuna valutazione finora

- Solar TrackerDocumento6 pagineSolar Trackerapratim mandalNessuna valutazione finora

- Middle East and Africa Uninterruptible Power Supply (UPS) Systems Market (2020-2026) - Sample PagesDocumento64 pagineMiddle East and Africa Uninterruptible Power Supply (UPS) Systems Market (2020-2026) - Sample PagesSurbhi SabharwalNessuna valutazione finora

- BEES MatlabDocumento54 pagineBEES Matlabcracking khalif100% (1)

- Solar Power TransformersDocumento2 pagineSolar Power TransformerskelvinchanNessuna valutazione finora

- Amplus SolarDocumento4 pagineAmplus SolarAbhishek AbhiNessuna valutazione finora

- Solar Power Plant in MoroccoDocumento2 pagineSolar Power Plant in MoroccoUSMAN IBRAHIM0% (1)

- Switching From DieselDocumento2 pagineSwitching From DieseljohnribarNessuna valutazione finora

- Powerful lithium batteries for long runtimeDocumento4 paginePowerful lithium batteries for long runtimevaseemalikhanNessuna valutazione finora

- Floating Photovoltaic Power Plant A ReviewDocumento10 pagineFloating Photovoltaic Power Plant A ReviewTaufiq Byomantoro100% (1)

- Solar Bankability - d1.1 - d2.1 - Technical Risks in PV Projects PDFDocumento139 pagineSolar Bankability - d1.1 - d2.1 - Technical Risks in PV Projects PDFSyed Furqan RafiqueNessuna valutazione finora

- Solar PV Module Reliability Scorecard 2016-2-1473940821Documento21 pagineSolar PV Module Reliability Scorecard 2016-2-1473940821Ankit SahaNessuna valutazione finora

- Solar Farm Diagramnov17 2014Documento1 paginaSolar Farm Diagramnov17 2014Sikumbang MobilNessuna valutazione finora

- Solar Inverter SystemDocumento32 pagineSolar Inverter Systemabel tibebuNessuna valutazione finora

- Vestige Sharp Air PurifierDocumento6 pagineVestige Sharp Air PurifierSamir K MishraNessuna valutazione finora

- Revised DMS ProposalDocumento17 pagineRevised DMS ProposalApril UyanNessuna valutazione finora

- 3D Photovoltaic Devices Complete Self-Assessment GuideDa Everand3D Photovoltaic Devices Complete Self-Assessment GuideNessuna valutazione finora

- Sunshine, Blue Skies ... At Home with Wind and Solar EnergyDa EverandSunshine, Blue Skies ... At Home with Wind and Solar EnergyNessuna valutazione finora

- Deployment of Hybrid Renewable Energy Systems in MinigridsDa EverandDeployment of Hybrid Renewable Energy Systems in MinigridsNessuna valutazione finora

- HDPEDocumento4 pagineHDPEdineshNessuna valutazione finora

- Edoc - Pub - Transformer Foundation DesignDocumento26 pagineEdoc - Pub - Transformer Foundation DesigndineshNessuna valutazione finora

- 8448-Article Text-27459-1-10-20211115Documento17 pagine8448-Article Text-27459-1-10-20211115dineshNessuna valutazione finora

- Calculating Seismic Protection of Dampers and AbsorbersDocumento4 pagineCalculating Seismic Protection of Dampers and AbsorbersdineshNessuna valutazione finora

- Design of Foundation For 220 KV ElectricalDocumento7 pagineDesign of Foundation For 220 KV ElectricaldineshNessuna valutazione finora

- Redundancy of Structural Systems in The Context of Structural SafetyDocumento7 pagineRedundancy of Structural Systems in The Context of Structural SafetyNishan GajurelNessuna valutazione finora

- On The Correlation of Seismic Intensity Scale WithDocumento25 pagineOn The Correlation of Seismic Intensity Scale WithdineshNessuna valutazione finora

- Comparison of Seismic Risk Assessment Based On Macroseismic Intensity and S (Ectrum Approaches Using SeisVARADocumento15 pagineComparison of Seismic Risk Assessment Based On Macroseismic Intensity and S (Ectrum Approaches Using SeisVARAdharmNessuna valutazione finora

- MSP 2018-2023 Final AdoptedDocumento28 pagineMSP 2018-2023 Final AdopteddineshNessuna valutazione finora

- Seismic Risk Mapping For UzbekistanDocumento20 pagineSeismic Risk Mapping For UzbekistandineshNessuna valutazione finora

- Transformer assembly diagramDocumento3 pagineTransformer assembly diagramdineshNessuna valutazione finora

- Base Plate Design Metric UnitsDocumento3 pagineBase Plate Design Metric UnitsdineshNessuna valutazione finora

- Probabilistic Seismic Hazard Analysis For YemenDocumento16 pagineProbabilistic Seismic Hazard Analysis For YemendineshNessuna valutazione finora

- Seismic Risk Assessment of Built Environment in PakistanDocumento10 pagineSeismic Risk Assessment of Built Environment in PakistandineshNessuna valutazione finora

- Geodesy and GeodynamicsDocumento20 pagineGeodesy and GeodynamicsJoan Vega EspinozaNessuna valutazione finora

- Performing Code Check in STAAD per AISC 9th EditionDocumento9 paginePerforming Code Check in STAAD per AISC 9th EditiondineshNessuna valutazione finora

- RAM Connection Standalone CE Report - 11Documento2 pagineRAM Connection Standalone CE Report - 11dineshNessuna valutazione finora

- Design Parameter EC3Documento20 pagineDesign Parameter EC3dineshNessuna valutazione finora

- Irc 112-2019 - 06-03-2019Documento240 pagineIrc 112-2019 - 06-03-2019Varun Verma85% (20)

- Schedule 80 Mild Steel Pipe Sizes - Dimensions - Weight and PriceDocumento10 pagineSchedule 80 Mild Steel Pipe Sizes - Dimensions - Weight and PricedineshNessuna valutazione finora

- Annexure-6 FOSROC - Lokfix & Nitobond Technical DataDocumento10 pagineAnnexure-6 FOSROC - Lokfix & Nitobond Technical DatadineshNessuna valutazione finora

- Steel Design Parameter - EuroDocumento11 pagineSteel Design Parameter - EurodineshNessuna valutazione finora

- Seismic Code Developments For Steel & Composite StructuresDocumento23 pagineSeismic Code Developments For Steel & Composite StructuresdineshNessuna valutazione finora

- BS en ISO 12944-1 2017 Paints and Varnishes-Corrosion Pro. Steel - General IntroductionDocumento18 pagineBS en ISO 12944-1 2017 Paints and Varnishes-Corrosion Pro. Steel - General Introductionssebastian8177100% (7)

- Comparative Study of Diagrid Structures With and Without Corner ColumnsDocumento6 pagineComparative Study of Diagrid Structures With and Without Corner ColumnsdineshNessuna valutazione finora

- METSEC Purlins SystemsDocumento84 pagineMETSEC Purlins SystemsIvan KlyuchkaNessuna valutazione finora

- Nuclear CodesDocumento4 pagineNuclear CodesdineshNessuna valutazione finora

- Cross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3Documento12 pagineCross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3dineshNessuna valutazione finora

- Fosroc Nitobond EP - Epoxy bonding agent for concreteDocumento4 pagineFosroc Nitobond EP - Epoxy bonding agent for concreteSanjeev KumarNessuna valutazione finora

- Bored CIP Piles - Capacity Calculation - International Practice - Updated-1Documento13 pagineBored CIP Piles - Capacity Calculation - International Practice - Updated-1dineshNessuna valutazione finora

- PW DebugDocumento2 paginePW DebugAimeeFieldsNessuna valutazione finora

- RGD AccessAbility Handbook 2015 ForWebFINAL-s PDFDocumento32 pagineRGD AccessAbility Handbook 2015 ForWebFINAL-s PDFtiago87pintoNessuna valutazione finora

- 20&604 WDSeriesDocumento2 pagine20&604 WDSeriesbiteme99Nessuna valutazione finora

- DISCOVERY SP-ENG V. 0.6 - Leonali 1463Documento30 pagineDISCOVERY SP-ENG V. 0.6 - Leonali 1463Hanz RodriguezNessuna valutazione finora

- Kitchen Equipment Dimensions and SpecsDocumento25 pagineKitchen Equipment Dimensions and SpecselektrikCi124Nessuna valutazione finora

- SemaphoreDocumento29 pagineSemaphoreSaranya ThangarajNessuna valutazione finora

- 2012 JBLM MILCON Tacoma Chamber of Commerce Oct2012Documento13 pagine2012 JBLM MILCON Tacoma Chamber of Commerce Oct2012Brackett427Nessuna valutazione finora

- Monthly Internship Report 2 (Biniyam Assefa and Tensae Degu)Documento9 pagineMonthly Internship Report 2 (Biniyam Assefa and Tensae Degu)biniyam assefaNessuna valutazione finora

- Alcatel Support Document For Cable System in CubaDocumento11 pagineAlcatel Support Document For Cable System in CubaDEGNISSODENessuna valutazione finora

- ULSADO-JSA-Demolation Existing Concrete FoundationDocumento2 pagineULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- Technical Guidance Notes: Level 2, No. 13Documento4 pagineTechnical Guidance Notes: Level 2, No. 13Τε ΧνηNessuna valutazione finora

- Astm B187Documento9 pagineAstm B187Plata Elpidio100% (3)

- Description Wincc Project Scanner enDocumento9 pagineDescription Wincc Project Scanner enDugPigeonNessuna valutazione finora

- Cantonk HD-Analog Cameras Price List V201407BDocumento7 pagineCantonk HD-Analog Cameras Price List V201407BCatalin StefanutNessuna valutazione finora

- Chrome Group PolicyDocumento37 pagineChrome Group PolicyvksatyanNessuna valutazione finora

- Spec Oem National 300qDocumento2 pagineSpec Oem National 300qJose Javier GamaNessuna valutazione finora

- PMOS RunsheetDocumento3 paginePMOS Runsheetkrishna_singhalNessuna valutazione finora

- Automated Discovery of Custom Instructions for Extensible ProcessorsDocumento8 pagineAutomated Discovery of Custom Instructions for Extensible Processorsinr0000zhaNessuna valutazione finora

- Planning - THERM - Timber - H-I - H-V - 2016 (RAICO)Documento542 paginePlanning - THERM - Timber - H-I - H-V - 2016 (RAICO)AnrStukNessuna valutazione finora

- MPTO Charts566662Documento25 pagineMPTO Charts566662andres ortizNessuna valutazione finora

- Data Scrambling: A Net 2000 Ltd. White PaperDocumento12 pagineData Scrambling: A Net 2000 Ltd. White PapernassarsubNessuna valutazione finora

- Ccsviiid1 2029-3Documento2 pagineCcsviiid1 2029-3DieguitoOmarMoralesNessuna valutazione finora

- Mastertop TC 458 PDFDocumento3 pagineMastertop TC 458 PDFFrancois-Nessuna valutazione finora

- SailPointCustomConnectors PDFDocumento17 pagineSailPointCustomConnectors PDFprudhvi reddy0% (1)

- Pilot Operated Safety Relief ValvesDocumento6 paginePilot Operated Safety Relief ValvesfabioNessuna valutazione finora

- ITU Rec. BT.709-5 Defines Parameters for HDTV StandardsDocumento31 pagineITU Rec. BT.709-5 Defines Parameters for HDTV StandardsHarold Coila VillenaNessuna valutazione finora

- HTML DOM TutorialDocumento11 pagineHTML DOM Tutorialapi-3819971100% (1)

- Competency-Check-H e I ADocumento20 pagineCompetency-Check-H e I Abaldo yellow4Nessuna valutazione finora

- Supports For Pipelines 1758uk 7-03-15 PDFDocumento46 pagineSupports For Pipelines 1758uk 7-03-15 PDFAndor MolitoriszNessuna valutazione finora

- RC2 Series Screw Compressor Maintenance ManualDocumento161 pagineRC2 Series Screw Compressor Maintenance ManualMichele CassiniNessuna valutazione finora