Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Factor of Evaporation

Caricato da

rajakongTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Factor of Evaporation

Caricato da

rajakongCopyright:

Formati disponibili

Factor of Evaporation

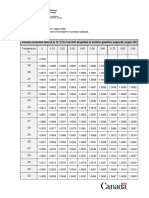

The factor of Evaporation is used to adjust rated boiler output (from and at 212 degrees F) to actual job or operating

conditions. Available feedwater temperature and expected boiler operating pressure (psig) affect- the boiler output ratings

which are based on "from and at 212 degrees F."

Example: A boiler is to have an output of 3060 pounds of steam/ hour when operating at 10 psig with feedwater at 100

degrees F. What should the boiler rating be on the basis of from and at 212 degrees F?

From the following chart, at 100 degrees F and 10 psig, we obtain the factor 30.6 pounds of steam/BHp. This factor is

used to convert to the "from and at 212 degrees F" rating basis.

3060

-------- = 100 hp rated boiler should be selected.

30.6

POUNDS OF DRY SATURATED STEAM PER BOILER HORSEPOWER

Feed Gauge Pressure - psig

water

temp 0 2 10 15 20 40 50 60 80 100 120 140 150 160 180 200 220 240

30 29.0 29.0 28.8 28.7 28.6 28.4 28.3 28.2 28.2 28.1 28.0 28.0 27.9 27.9 27.9 27.9 27.9 27.8

40 29.3 29.2 29.1 29.0 28.9 28.7 28.6 28.5 28.4 28.3 28.2 28.2 28.2 28.2 28.2 28.1 28.1 28.1

50 29.6 29.5 29.3 29.2 29.1 28.9 28.8 28.8 28.7 28.6 28.5 28.5 28.4 28.4 28.4 28.3 28.3 28.3

60 29.8 29.8 29.6 29.5 29.4 29.2 29.1 29.0 28.9 28.8 28.8 28.7 28.7 28.6 28.6 28.6 28.6 28.5

70 30.1 30.0 29.9 29.8 29.7 29.5 29.4 29.3 29.2 29.1 29.0 29.0 28.9 28.9 28.9 28.8 28.8 28.8

80 30.4 30.3 30.1 30.0 30.0 29.8 29.6 29.6 29.5 29.3 29.2 29.2 29.2 29.2 29.1 29.1 29.1 29.0

90 30.6 30.6 30.4 30.3 30.2 30.0 29.9 29.8 29.7 29.6 29.5 29.5 29.4 29.4 29.4 29.3 29.3 29.3

100 30.9 30.8 30.6 30.6 30.5 30.3 30.2 30.1 30.0 29.8 29.8 29.8 29.7 29.7 29.7 29.6 29.6 29.6

110 31.2 31.2 30.9 30.8 30.8 30.6 30.4 30.3 30.2 30.0 30.0 30.0 30.0 30.0 29.9 29.9 29.8 29.8

120 31.5 31.4 31.2 31.2 31.1 30.8 30.7 30.6 30.5 30.4 30.3 30.3 30.2 30.2 30.2 30.1 30.1 30.1

130 31.8 31.7 31.5 31.4 31.4 31.1 31.0 30.9 30.8 30.7 30.6 30.6 30.5 30.5 30.4 30.4 30.4 30.4

140 32.1 32.0 31.8 31.7 31.6 31.4 31.3 31.2 31.1 31.0 30.9 30.8 30.8 30.8 30.8 30.7 30.7 30.6

150 32.4 32.4 32.1 32.0 31.9 31.7 31.6 31.5 31.4 31.2 31.2 31.2 31.1 31.1 31.0 31.0 30.9 30.9

160 32.7 32.7 32.4 32.4 32.3 32.0 31.9 31.8 31.7 31.5 31.4 31.4 31.4 31.4 31.3 31.3 31.2 31.2

170 33.0 33.0 32.7 32.6 32.6 32.3 32.2 32.1 32.0 31.8 31.7 31.7 31.7 31.6 31.6 31.6 31.5 31.5

180 33.4 33.3 33.0 33.0 32.9 32.6 32.5 32.4 32.3 32.2 32.1 32.0 32.0 32.0 31.9 31.9 31.8 31.8

190 33.8 33.7 33.4 33.3 33.2 32.9 32.8 32.7 32.6 32.5 32.4 32.4 32.3 32.3 32.2 32.2 32.1 32.1

200 34.1 34.0 33.7 33.6 33.5 33.2 33.1 33.0 32.9 32.8 32.7 32.6 32.6 32.6 32.6 32.5 32.4 32.4

212 34.5 34.4 34.2 34.1 33.0 33.6 33.5 33.4 33.3 33.2 33.1 33.0 33.0 33.0 32.9 32.9 32.8 32.8

220 34.8 34.7 34.4 34.3 34.2 33.9 33.8 33.7 33.5 33.4 33.3 33.3 33.2 33.2 33.1 33.1 33.1 33.0

227 35.0 34.9 34.7 34.5 34.4 34.1 34.0 33.9 33.8 33.7 33.6 33.5 33.5 33.4 33.4 33.3 33.3 33.3

230 35.2 35.0 34.8 34.7 34.5 34.2 34.1 34.0 33.9 33.8 33.7 33.6 33.6 33.5 33.5 33.4 33.4 33.4

Industrial Boiler & Mechanical

Potrebbero piacerti anche

- Table - Factor of EvaporationDocumento4 pagineTable - Factor of EvaporationRey FiedacanNessuna valutazione finora

- Ada 634x638xcf Edin DiscontinuedDocumento13 pagineAda 634x638xcf Edin DiscontinuedRaghavendran BalakumarNessuna valutazione finora

- Á Vü Ethê/T: &üø ºsy Kõ - Ø Et Ø S¡ X S¡ÀDocumento1 paginaÁ Vü Ethê/T: &üø ºsy Kõ - Ø Et Ø S¡ X S¡ÀyeshuNessuna valutazione finora

- Kathrein antenna pattern gain and frequency dataDocumento33 pagineKathrein antenna pattern gain and frequency datarubenpatNessuna valutazione finora

- S Wave 09 OD 11 F O1 (Atoll)Documento7 pagineS Wave 09 OD 11 F O1 (Atoll)NOKIAXL CJNessuna valutazione finora

- DirectionalSurveys 020910Documento849 pagineDirectionalSurveys 020910americaNessuna valutazione finora

- Vulnerability Calculation ModuleDocumento288 pagineVulnerability Calculation ModuleKhawar RiazNessuna valutazione finora

- CT-G2973G / CT-G2973LG / CT-G2983G / CT-G3353G / CT-G3353XG circuit board schematicDocumento12 pagineCT-G2973G / CT-G2973LG / CT-G2983G / CT-G3353G / CT-G3353XG circuit board schematicZa RacsoNessuna valutazione finora

- 1B UskDocumento36 pagine1B UskIqbal MaulanaNessuna valutazione finora

- Fares For Myrapid Smart 30 Monthly: Only SahajaDocumento1 paginaFares For Myrapid Smart 30 Monthly: Only SahajaKevin KwokNessuna valutazione finora

- Tabel IHSDocumento3 pagineTabel IHSIsfahdi Kanha SemidangNessuna valutazione finora

- Zachary Davis - FinalDocumento8 pagineZachary Davis - FinalZacNessuna valutazione finora

- VCF Gasoline and Gasoline Ethanol BlendsDocumento5 pagineVCF Gasoline and Gasoline Ethanol BlendsEdgar GuardiaNessuna valutazione finora

- VCF JetADocumento5 pagineVCF JetAAlexNessuna valutazione finora

- Antenna PatternsDocumento317 pagineAntenna PatternsOpeyemi Dada0% (1)

- Taxation Trends in The European Union - 2012 218Documento1 paginaTaxation Trends in The European Union - 2012 218d05registerNessuna valutazione finora

- Design MethodDocumento32 pagineDesign MethodPrateek SinghNessuna valutazione finora

- Visco Measure - Water - 30C-2Documento53 pagineVisco Measure - Water - 30C-2song LiNessuna valutazione finora

- Age-specific mortality rates in Portugal 1970-2009Documento24 pagineAge-specific mortality rates in Portugal 1970-2009MarceloAbiNessuna valutazione finora

- Gabi 1978 To 1984Documento39 pagineGabi 1978 To 1984Rm OtNessuna valutazione finora

- PP No 82 TH 2001Documento106 paginePP No 82 TH 2001Hilih KintilNessuna valutazione finora

- Nmme Precip FCST JUNic 7-9 2015-2015Documento189 pagineNmme Precip FCST JUNic 7-9 2015-2015Romi ApriantoNessuna valutazione finora

- VCF Aviation GasolineDocumento5 pagineVCF Aviation GasolineEdgar GuardiaNessuna valutazione finora

- FilesDocumento15 pagineFilesRm OtNessuna valutazione finora

- VCF JetA PDFDocumento5 pagineVCF JetA PDFJose De GouveiaNessuna valutazione finora

- VCF JetA PDFDocumento5 pagineVCF JetA PDFMuhammad Dicky AmrullahNessuna valutazione finora

- Issued: January 2016Documento5 pagineIssued: January 2016davpaffNessuna valutazione finora

- Tablas EstadísticaDocumento5 pagineTablas EstadísticaJose ColrosNessuna valutazione finora

- P.I Control of Temp of CSTRDocumento9 pagineP.I Control of Temp of CSTRpulkitNessuna valutazione finora

- Increments & Corrections TableDocumento21 pagineIncrements & Corrections Tablemateo100% (1)

- Supercias Estado Cambios PatrimonioDocumento6 pagineSupercias Estado Cambios PatrimonioByron SincheNessuna valutazione finora

- Supercias Estado Cambios PatrimonioDocumento6 pagineSupercias Estado Cambios PatrimonioByron SincheNessuna valutazione finora

- Team4 Assignment11 ISE500-1Documento61 pagineTeam4 Assignment11 ISE500-1Ananth RameshNessuna valutazione finora

- Canara Bank StatementDocumento65 pagineCanara Bank StatementEr Md AamirNessuna valutazione finora

- Pressure Temperature Chart According To ASME B16.34 ASME B PV CodeDocumento5 paginePressure Temperature Chart According To ASME B16.34 ASME B PV CodeDwayne YiiNessuna valutazione finora

- Tabel Korelasi 2012-2017Documento536 pagineTabel Korelasi 2012-2017Muhammad WildanNessuna valutazione finora

- Isolated Footing (M, P) Aci 318-14Documento9 pagineIsolated Footing (M, P) Aci 318-14محمد حاج اسماعيلNessuna valutazione finora

- Resultsinter MCDocumento35 pagineResultsinter MCMelissaNessuna valutazione finora

- Joint Masses and Reactions TableDocumento230 pagineJoint Masses and Reactions TableGian Visnu AdiNessuna valutazione finora

- Pulsating JetDocumento102 paginePulsating JetMohmmed MahmoudNessuna valutazione finora

- ParticipacionesDocumento2.822 pagineParticipacionesqcx2j79m8xNessuna valutazione finora

- Bang TraDocumento4 pagineBang TraVân NhiNessuna valutazione finora

- Diesel fuel volume correction factors tableDocumento5 pagineDiesel fuel volume correction factors tablelasithNessuna valutazione finora

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Documento5 pagineVolume Correction Factors - Diesel Fuel: Issued: July 2018NarendraNessuna valutazione finora

- Diesel fuel volume correction factors tableDocumento5 pagineDiesel fuel volume correction factors tableRajan ChopraNessuna valutazione finora

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Documento5 pagineVolume Correction Factors - Diesel Fuel: Issued: July 2018ساهر رباطهNessuna valutazione finora

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Documento5 pagineVolume Correction Factors - Diesel Fuel: Issued: July 2018Abu Syeed Md. Aurangzeb Al MasumNessuna valutazione finora

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Documento5 pagineVolume Correction Factors - Diesel Fuel: Issued: July 2018Joni MartonoNessuna valutazione finora

- Diesel fuel volume correction factors tableDocumento5 pagineDiesel fuel volume correction factors tabletadilakshmikiranNessuna valutazione finora

- Diesel fuel volume correction factors tableDocumento5 pagineDiesel fuel volume correction factors tableMeet KhuntNessuna valutazione finora

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Documento5 pagineVolume Correction Factors - Diesel Fuel: Issued: July 2018NarendraNessuna valutazione finora

- Diesel fuel volume correction factors tableDocumento5 pagineDiesel fuel volume correction factors tablekhaja valiNessuna valutazione finora

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Documento5 pagineVolume Correction Factors - Diesel Fuel: Issued: July 2018JOERAM PILARCONessuna valutazione finora

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Documento5 pagineVolume Correction Factors - Diesel Fuel: Issued: July 2018JOERAM PILARCONessuna valutazione finora

- Stress Analysis Report 51Documento1 paginaStress Analysis Report 51Morad M SwidNessuna valutazione finora

- Subnet EoDocumento2 pagineSubnet EoGian Pierre CuevaNessuna valutazione finora

- bm1 Block Caving 20x20x20 OriginalDocumento340 paginebm1 Block Caving 20x20x20 OriginaljoibarraNessuna valutazione finora

- Visco Measure - Water - 30CDocumento53 pagineVisco Measure - Water - 30Csong LiNessuna valutazione finora

- Fane 121Documento3 pagineFane 121Johan BonillaNessuna valutazione finora

- Refraction Through Lenses & Optical Instruments5Documento144 pagineRefraction Through Lenses & Optical Instruments5geniusamahNessuna valutazione finora

- Rotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaDocumento3 pagineRotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaKirit IndustriesNessuna valutazione finora

- Chemical reactions and structuresDocumento22 pagineChemical reactions and structuresStormy StudiosNessuna valutazione finora

- Booster Pump Service ManualDocumento11 pagineBooster Pump Service ManualSGI AUTOMOTIVE PVT LTDNessuna valutazione finora

- SHS-Physical Science (Biological Macromolecules) : I-Introductory ContentDocumento13 pagineSHS-Physical Science (Biological Macromolecules) : I-Introductory ContentJane182004Nessuna valutazione finora

- LirikDocumento537 pagineLirikMuhamad Iqbal FahmiNessuna valutazione finora

- Medication - Safety - v4 Last Update 2015Documento81 pagineMedication - Safety - v4 Last Update 2015Retno PalupiNessuna valutazione finora

- Dokumen - Tips - Astm A535 9 Percent NickelDocumento5 pagineDokumen - Tips - Astm A535 9 Percent NickelJeovanne CabralNessuna valutazione finora

- 1 SM PDFDocumento14 pagine1 SM PDFSiti HamsyiahNessuna valutazione finora

- Why Check Valves SlamDocumento2 pagineWhy Check Valves SlamBramJanssen76Nessuna valutazione finora

- 1296169395JH 122310 - WebDocumento12 pagine1296169395JH 122310 - WebCoolerAdsNessuna valutazione finora

- MACRO-ETCHING SOLUTIONS FOR ALUMINIUM ALLOYSDocumento1 paginaMACRO-ETCHING SOLUTIONS FOR ALUMINIUM ALLOYSsensoham03Nessuna valutazione finora

- Borneo SporenburgDocumento2 pagineBorneo SporenburgDorin TecuceanuNessuna valutazione finora

- 3.1-T.C.Dies PDFDocumento6 pagine3.1-T.C.Dies PDFYahyaMoummouNessuna valutazione finora

- Finite Element Simplified Fatigue AnalysisDocumento4 pagineFinite Element Simplified Fatigue AnalysisJin Hwan KimNessuna valutazione finora

- Rapid Communication: Spontaneous Abortions and Policies On COVID-19 mRNA Vaccine Use During PregnancyDocumento14 pagineRapid Communication: Spontaneous Abortions and Policies On COVID-19 mRNA Vaccine Use During PregnancyStéphane BoucherNessuna valutazione finora

- M. Valerio Assignment 6.1Documento1 paginaM. Valerio Assignment 6.1Mark Kristian ValerioNessuna valutazione finora

- Self-Balancing Two-Wheeler Using GyroscopeDocumento33 pagineSelf-Balancing Two-Wheeler Using Gyroscopemilan mottaNessuna valutazione finora

- Operation & Maintenance Manual For Bolted Steel Tanks: Complete InstallationDocumento6 pagineOperation & Maintenance Manual For Bolted Steel Tanks: Complete InstallationIrvansyah RazadinNessuna valutazione finora

- Modeling Vessel Impacts for Lock Wall DesignDocumento15 pagineModeling Vessel Impacts for Lock Wall DesignSalam FaithNessuna valutazione finora

- Operating and Installation Guide For The Digital Instrument: Motoscope Tiny / Speedster / VintageDocumento12 pagineOperating and Installation Guide For The Digital Instrument: Motoscope Tiny / Speedster / Vintagepeter timmermansNessuna valutazione finora

- TICSA - Diesel Uno Petroleos Guatemala (13.01.23)Documento1 paginaTICSA - Diesel Uno Petroleos Guatemala (13.01.23)Luis M LópezNessuna valutazione finora

- Mathematics: Minimum Level Learning MaterialDocumento60 pagineMathematics: Minimum Level Learning MaterialTusar SardarNessuna valutazione finora

- Chapter 3 (CHM 127)Documento105 pagineChapter 3 (CHM 127)FiqajasmeNessuna valutazione finora

- Datasheet De14h (II) HC 1500v May2019 NTDocumento2 pagineDatasheet De14h (II) HC 1500v May2019 NTkrishnakumar paamireddyNessuna valutazione finora

- Chapter 5 Coordinate GeometryDocumento33 pagineChapter 5 Coordinate GeometryKalNessuna valutazione finora

- Site Master FileDocumento51 pagineSite Master FileMilonhg100% (2)

- KTS - Sarao.bakus Temple of Eternal FiireDocumento176 pagineKTS - Sarao.bakus Temple of Eternal FiireK.T.S. SaraoNessuna valutazione finora

- MSC Syllabus AllDocumento13 pagineMSC Syllabus AllOmSilence2651Nessuna valutazione finora