Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

4 - Hazard Work Sheet

Caricato da

Gaganpreet KaurTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

4 - Hazard Work Sheet

Caricato da

Gaganpreet KaurCopyright:

Formati disponibili

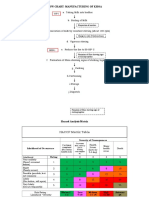

Hazard analysis Report E/HACCP/04/02,Issue No.

01

Page 1 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

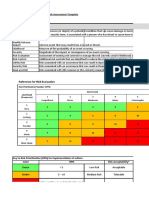

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 2 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Microbiological

c

o

n

t

a

m

in

a

ti

o

n

d

u

ri

n

g

p

r

o

c

e

s

s

a

t

s

o

u

r

c

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 3 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

External

contamination

from Curtains/ cushions fitted to all

endogenous loading bays to prevent

material; external contamination;

Exogenous Prerequisite programmes in

material (dirt), place to control all named

rain water, bird hazards (hygiene and

droppings, cleaning schedules); cleaning

vermin, programmes; glass policy and

rodents and sanitation audits;

flying insects External and internal pest

during control programmes, EFK’s in

Contaminated

Intake raw unloading; place in intake areas;

Nil 2 2 4 product could Y Y N N -- No

materials Glass All light fittings covered;

affect consumer

contamination Selection of supplier and

from internal good hygiene practices at

light source; source (harvest training and

Pests/rodents certification in place) ) to

or flying reduce or eliminate potential

insects due to foreign body or

poor microbiological contamination;

hygiene/debris Quality intake inspection to

build up; identify foreign bodies or

Physical risks source of contamination.

from straps,

foreign bodies

found on

pallox/pallet.

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 4 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Selection of supplier, control

Chemical Contaminated and incoming inspection and

Intake raw EU

Pesticide 1 3 3 product could verification control (MRL Y Y N N -- No

materials

Residue affect consumer analysis report). Records

retained

As per

specifi

Quality

cation Poor quality can

Intake raw As per raw Each lot is checked as per

(EU 1 3 3 affect finished N -- -- -- -- No

materials material quality plan.

trade product.

specification

norms

)

Selection of supplier and

good hygiene practices at

Allergens Contaminated source (harvest training and

Intake raw

Contamination Nil 1 1 1 product could certification in place) to Y Y N N -- No

materials

at source affect consumer reduce or eliminate potential

foreign body or

microbiological contamination.

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 5 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 6 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Microbiological

c

o

n

t

a

m

in

a

ti

o

n

d

u

ri

n

Selection of supplier and

g

Intake good hygiene practices at

p

pre-pack Contaminated source (harvest training and

r

(only at Nil 1 2 2 product could certification in place) to Y Y N N -- No

o

loading affect consumer reduce or eliminate potential

c

docks) foreign body or

e

microbiological contamination.

s

s

a

t

s

o

u

r

c

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 7 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

External

contamination Curtains/ cushions fitted to all

from loading bays to prevent

endogenous external contamination;

material; Prerequisite programmes in

Exogenous place to control all named

material (dirt), hazards (hygiene and

vermin, cleaning schedules); cleaning

rodents and programmes; glass policy and

flying insects sanitation audits;

during External and internal pest

Intake

unloading; control programmes, EFK’s in

pre-pack Contaminated

Glass place in intake areas;

(only at Nil 2 2 4 product could Y Y N N -- No

contamination All light fittings covered;

loading affect consumer

from internal Selection of supplier and

docks)

light source; good hygiene practices at

Pests/rodents source (harvest training and

or flying certification in place) ) to

insects due to reduce or eliminate potential

poor hygiene; foreign body or

debris build microbiological contamination;

up; Physical Quality intake inspection to

risks from identify foreign bodies or

straps, foreign source of contamination.

bodies found

on

pallox/pallet.

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 8 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Intake Selection of supplier, control

pre-pack Chemical Contaminated and incoming inspection and

EU

(only at Pesticide 1 3 3 product could verification control (MRL Y Y N N -- No

loading Residue affect consumer analysis report). Records

docks) retained

As per

Intake specifi

Quality

pre-pack cation Poor quality can

As per raw Each lot is checked as per

(only at (EU 1 3 3 affect finished N -- -- -- -- No

material quality plan.

loading trade product.

specification

docks) norms

)

Selection of supplier and

Intake good hygiene practices at

pre-pack Allergens Contaminated source (harvest training and

(only at Contamination Nil 1 1 1 product could certification in place) to Y Y N N -- No

loading at source affect consumer reduce or eliminate potential

docks) foreign body or

microbiological contamination.

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 9 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Microbiological

c

o

n

t

a

m

in

a

Contamination

ti

during inspection Quality inspector is trained in

o

Intake due to poor food safety / hygiene

n Nil 1 2 2 Y Y N N -- No

control hygienic measures programmes with records of

d

can affect training maintained

u

consumer

ri

n

g

p

r

o

c

e

s

s

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 10 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical Quality inspector is trained in

Physical food safety / hygiene

contamination programmes with records of

from quality training maintained;

inspector; All products are sampled and

foreign bodies Contaminated inspected on intake as per

Intake

found within Nil 2 2 4 product could procedure. Any foreign body Y Y N N -- No

control

product and/or affect consumer contamination is identified

packaging and communicated to

from source of management and grower;

origin or Positive release system in

during place.

transport

As per

specifi

Quality inspector must consult

Quality cation Poor quality can

Intake EU trade norms for fresh

Poor (EU 1 3 3 affect finished N -- -- -- -- No

control apples and pears as guidance

inspection trade product.

tool.

norms

)

Allergens Quality inspector is trained in

Contaminated

Intake Contamination food safety / hygiene

Nil 1 1 1 product could Y Y N N -- No

control from quality programmes with records of

affect consumer

inspector training maintained;

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 11 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Microbiological

c

o

n

t

a

m

in

a

ti

Transfer Contamination

o

raw during transfer due Accept clean bins, make sure

n Nil 2 2 4 Y Y N N -- No

materials / to dirty bins can bins are clean before transfer.

d

pre-pack affect consumer

u

ri

n

g

p

r

o

c

e

s

s

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 12 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

Endogenous

Prerequisite programmes in

material

place to control named

(leaves,

hazards including hygiene

branches);

schedules and cleaning

Exogenous

programmes, glass policy,

material (dirt); Damaging of

pest control programmes

Transfer Physical packaging

(EFK’s) in intake areas

raw contamination materials during

Nil 1 2 2 maintained by external Y Y N N -- No

materials / from Quality transfer;

contractor; Staff

pre-pack inspector; contamination can

awareness/training

Contamination affect consumer

programmes in place with

from insects,

records of training retained;

rodents,…;

Washing of the fruit to remove

Glass

endogenous and exogenous

contamination

materials at grading stage

from internal

light source

As per

Quality

specifi Each lot is checked as per

Transfer Improper Improper handling

cation quality plan; Staff

raw handling of can affect quality

(EU 1 3 3 awareness/training Y Y N N -- No

materials / products (bruising,

trade programmes in place with

pre-pack during damaging)

norms records of training retained

transferring

)

Transfer Allergens

Contaminated Staff awareness/training

raw Contamination

Nil 1 1 1 product could programmes in place with Y Y N N -- No

materials / during

affect consumer records of training retained

pre-pack transferring

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 13 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 14 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Microbiological

g

r

o

w

t

h

/

c

o

n

t

a

m

in

a

ti

o

n

d

u

ri

n

g

p Prerequisites in place to

r control named hazards;

Microbiological

o procedures for maintenance;

contamination from

Pre- c refrigeration breakdown

microbiological

cooling e procedure; temperature

Nil 2 4 8 growth due to Y Y N Y Y CP

raw s checking pre-cooling (Apple

improper pre-

materials s (0° - 1°C)

P = Probability of occurrence 5 Very High 4 cooling

Highcould affect

3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 15 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

Endogenous

material; Use of wooden

Pre-

Exogenous pallox (wood Procedures for maintenance

cooling

material (dirt, Nil 1 2 2 contamination); and hygiene; glass policy and Y Y N N -- No

raw

dust); Glass Broken glass could procedures

materials

contamination affect consumer

from internal

light source

Quality

As per

Deterioration

specifi

Pre- due to high Deterioration of

cation Procedures in place to check

cooling temperature of quality can affect

(EU 2 4 8 quality and temperature after Y Y N Y Y CP

raw fresh apples quality of final

trade pre-cooling (24 hours).

materials (0°C – 1°C) product.

norms

and pears (-

)

0,5°C – 0°C)

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 16 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Microbiological

g

r

o

w

t

h

/

c

o

n

t

a

m

in

a

ti

o

n

d

u

ri

n

g

p

r

o

c

e

s

s

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 17 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

Endogenous Use of wooden

material; pallox (wood

Exogenous contamination);

Storage of

material (dust, Broken glass could Procedures for maintenance

Raw

dirt build up in Nil 1 2 2 affect consumer; and hygiene; glass policy and Y Y N N -- No

materials

cooling unit); Dust build up in procedures

Glass cooling unit can

contamination affect finished

from internal product.

light source

Quality

Deterioration

As per Deterioration of

due to high Procedures in place to check

specifi quality can affect

Storage of temperature of quality and temperature.

cation quality of final

Raw fresh apples Quality assessment raw

(EU 2 4 8 product. Poor Y Y N Y Y CP

materials (0°C – 1°C) materials to avoid CO2

trade quality to CO2

and pears (- breakdown (early picked, hard

norms breakdown

0,5°C – 0°C) and firm apples)

) (apples).

CO2 damage

(apples)

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 18 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Microbiological

g

r

o

w

t

h

/

c

o

n

t

a

m

in

a

ti

o

n

d

u

ri

n

g

p

r

o

c

e

s

s

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 19 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

Endogenous Use of wooden

material; crates (wood

Storage of Exogenous contamination);

Pre-pack / material (dust, Broken glass could Procedures for maintenance

Temporary dirt build up in Nil 1 2 2 affect consumer; and hygiene; glass policy and Y Y N N -- No

storage cooling unit); Dust build up in procedures

Glass cooling unit can

contamination affect finished

from internal product.

light source

Quality As per

Storage of Deterioration specifi

Deterioration of

Pre-pack / due to high cation Procedures in place to check

quality can affect

Temporary temperature of (EU 2 4 8 quality and temperature. Y Y N Y Y CP

quality of final

storage fresh apples trade Quality assessment in place

product.

(>4°C) and norms

pears (>2°C) )

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 20 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

External Curtains/ cushions fitted to all

contamination loading bays to prevent

from foreign external contamination;

material; Prerequisite programmes in

Exogenous place to control all named

material (dirt), hazards (hygiene and

vermin, cleaning schedules); cleaning

rodents and programmes; glass policy and

flying insects sanitation audits;

during External and internal pest

Improper handling

unloading; control programmes, EFK’s in

Intake of at vendor place

Glass place in intake areas;

packaging Nil 1 1 1 can cause an Y Y N N -- No

contamination All light fittings covered;

materials indirect risk for

from internal Selection of supplier and

consumer.

light source; good hygiene practices at

Pests/rodents source eliminate potential

or flying foreign body;

insects due to Intake inspection to identify

poor hygiene; foreign bodies or source of

debris build contamination. Outer

up; Physical packaging materials should

risks from be closed at all times and not

straps, foreign damaged.

bodies found

on pallet.

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 21 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

Endogenous

Prerequisite programmes in

material

place to control named

(leaves,

hazards including hygiene

branches);

schedules and cleaning

Exogenous

programmes, glass policy,

material (dirt); Damaging of

pest control programmes

Physical packaging

Transfer (EFK’s) in intake areas

contamination materials during

packaging Nil 1 2 2 maintained by external Y Y N N -- No

from Quality transfer;

materials contractor; Staff

inspector; contamination can

awareness/training

Contamination affect consumer

programmes in place with

from insects,

records of training retained;

rodents,…;

Washing of the fruit to remove

Glass

endogenous and exogenous

contamination

materials at grading stage

from internal

light source

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 22 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

Endogenous

Use of wooden

material;

pallets (wood

Exogenous

Storage of contamination);

material (dust, Procedures for maintenance

Packaging Broken glass could

dirt build up in Nil 1 2 2 and hygiene; glass policy and Y Y N N -- No

materials affect consumer;

cooling unit); procedures

Dust build up in

Glass

can affect finished

contamination

product.

from internal

light source

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 23 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

If the temperature

Biological

rise to temper the

Microbiological

fresh apples and /

growth /

or pears is to high, Temperature/ quality

Tempering contamination

Nil 1 2 2 the cooling takes to monitoring in function of time Y Y N N -- CP

of the fruit during process

long and can cause during tempering.

due

breakdown and / or

temperature vs

microbiological

time issues

contamination.

Quality If the temperature

To long and to rise to temper the

Temperature/ quality

Tempering high fresh apples and /

Nil 1 2 2 monitoring in function of time Y Y N N -- CP

of the fruit temperature or pears is to high,

during tempering.

rise can cause quality breakdown

quality issues could occur.

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 24 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Improper cleaning

Microbiological

Emptying of contact surfaces; Cleaning schedules and

contamination

bins in contaminated water maintenance plans in place.

during process Nil 1 2 2 Y Y N Y Y CP

transport due to SOP’s to monitor water

due to dirty

water contaminated condition and quality.

contaminated

source

water

Physical

Endogenous

material

(leaves, Rinsing with fresh water in

branches); next step to eliminate possible

Any physical

Emptying Exogenous foreign materials; training of

foreign matter in

bins in material (dirt); personnel to recognize and

Nil 1 2 2 crates, box, … can Y Y N Y Y No

transport Contamination remove contamination

affect the condition

water from insects, (communicated to quality

of the final product.

rodents,…; manager, records retained);

Glass Glass policy in place

contamination

from internal

light source

Careful handling to

Emptying Pre-operational inspections,

Quality avoid

bins in maintenance and proper

Damage due Nil 1 2 2 quality Y Y N N -- No

transport training in handling the

to handling proble

water product (records retained)

ms

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 25 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Microbiological

Contaminated SOP’s to monitor water

Rinsing contamination

water due to condition and quality. In

with fresh during process Nil 1 2 2 Y Y N Y Y CP

contaminated previous step no chlorination

water due to

source is used.

contaminated

water

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 26 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Workers (staged on grader)

Biological need to wash their hands with

Microbiological water and soap / disinfect at

contamination Improper cleaning time of entrance. Procedures

Grading during process of contact surfaces for cleaning and hygiene to

Nil 1 2 2 Y Y N N -- No

on sorter due to dirty and hands of eliminate possible

contaminated workers. contamination of contact

contact surfaces; swab tests

surfaces. performed and records

retained

Physical

Contamination

from insects,

rodents,…;

Glass Any physical matter Proper follow up of SOP’s and

Grading

contamination Nil 1 2 2 in crates, box, bags hygiene practice and follow up Y Y N N -- No

on sorter

from internal or punnet. of production SOP

light source;

Contamination

from dust, dirt

build up

Improper rinsing

Chemical

after cleaning with

Contamination Cleaning procedures in place

Grading cleaning chemicals

due to Nil 1 2 2 with quality and effectiveness Y Y N N -- No

on sorter can cause leftovers

improper checks (dip sticks)

and contamination

cleaning

when grading.

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 27 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Probable defect.

Improp

er

handlin

Quality

g/settin

Damage due Pre-operational inspections,

gs by

Grading to improper maintenance and proper

Nil 1 1 1 machin Y Y N N -- No

on sorter settings of training in handling the

e

grader or product

operato

defects

r/

quality

manag

er

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 28 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Workers need to wash their

Contamination

Improper cleaning hands with water and soap /

due to

of contact disinfect at time of entrance,

improper

surfaces/work training is held and records

cleaning of

Packing Nil 1 2 2 garments and retained; At random Y Y N N -- No

hands, contact

hands of workers inspections of cleaning of

surfaces,

could affect hands (swab tests) and work

contaminated

consumer clothes. Certified packaging

packaging

suppliers.

materials.

Physical

Contamination

from insects,

Workers are trained in food

rodents,…;

safety / hygiene programmes

Glass

with records of training

contamination Any physical matter

maintained;

from internal in crates, box, bags

Any foreign body

Packing light source; Nil 1 2 2 or punnet can Y Y N N -- No

contamination is identified and

Contamination affect final product

communicated to

from dust, dirt and consumer

management. Waste

build up;

management and pest control.

Physical

contamination

from personnel

(Hairs)

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 29 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Chemical

Cleaning

Workers are trained in food

chemicals Chemical

safety / hygiene programmes

used to wash contamination from

with records of training

hands / cleaning agents or

retained; No chemicals are

Packing contact Nil 1 1 1 glove material can Y Y N N -- No

used during packing; Cleaning

material from cause

chemicals are food grade;

gloves can contamination of

Gloves are made of food

cause the product.

grade materials

contamination

of product

Improper handling

can

Quality cause Workers are trained in food

Damage due quality handling and specifications of

Packing Nil 1 2 2 Y Y N N -- No

to improper issue finished product; Quality

handling from monitored by quality manager

finished

product

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 30 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Improper hygienic

conditio

Allergens

ns /

Contamination

handlin

by personnel

g of

due to

allergen

handling Workers are trained in food

s by

allergens safety / hygiene programmes

Packing Nil 1 2 2 person Y Y N N -- No

during with records of training

nel can

breaks/before maintained;

cause

start of work;

contami

Improper

nation

washing of

of

hands

finished

product

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 31 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

Contamination

from insects,

rodents,…; Workers are trained in food

Glass safety / hygiene programmes

contamination Any physical matter with records of training

from internal in crates, box, bags maintained;

Stickering light source; Nil 1 2 2 or punnet can Any foreign body Y Y N N -- No

Contamination affect final product contamination is identified and

from dust, dirt and consumer communicated to

build up; management

Physical

contamination

from personnel

(Hairs)

No food grade glue

Chemical

on stickers can Supplier selection of

Contamination

Stickering Nil 1 1 1 cause packaging materials; migration Y Y N N -- No

from glue from

contamination of testing and analysis reports

stickers

finished product

Improper handling

can

Quality cause Workers are trained in food

Damage due quality handling and specifications of

Stickering Nil 1 2 2 Y Y N N -- No

to improper issue finished product; Quality

handling from monitored by quality manager

finished

product

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 32 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Improper hygienic

conditio

Allergens

ns /

Contamination

handlin

by personnel

g of

due to

allergen

handling Workers are trained in food

s by

allergens safety / hygiene programmes

Stickering Nil 1 2 2 person Y Y N N -- No

during with records of training

nel can

breaks/before maintained;

cause

start of work;

contami

Improper

nation

washing of

of

hands

finished

product

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 33 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Physical

Exogenous

material (dirt);

Physical

Damaging of

contamination

packaging Staff awareness/training

from workers;

materials during programmes in place with

Palletise Contamination Nil 1 2 2 Y Y N N -- No

transfer; records of training retained;

from insects,

contamination can

rodents,…;

affect consumer

Glass

contamination

from internal

light source

As per

Quality

specifi

Improper Improper handling

cation Staff awareness/training

handling of can affect quality

Palletise (EU 1 3 3 programmes in place with Y Y N N -- No

products (bruising,

trade records of training retained

during damaging)

norms

transferring

)

Allergens

Contaminated Staff awareness/training

Contamination

Palletise Nil 1 1 1 product could programmes in place with Y Y N N -- No

during

affect consumer records of training retained

transferring

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Hazard analysis Report E/HACCP/04/02,Issue No.01

Page 34 OF 34

Product Description: Fresh Apples and Pears Date: 22-11-2017 Reviewed By Quality manager

(4)

(9)

(1) (2) (3) Proba (10)

(5) (6) What preventive control Remarks/Is it

Ingredient/ Identify Accept bility (8)

Sever Magnit measure(s) can be applied to Q1 Q2 Q3 Q4 Q5 (Critical)

Processing potential food able of Justify your decision control point?

ity ude of prevent, reduces, or eliminate

step. safety hazards Limited occurr (Yes/No)

impact food safety hazards?

ence

Biological

Inspection of proper cleaning

Micro

Contamination due of lorry; supplier selection of

biological

to poor hygienic transporter; transport

Dispatch / contamination

conditions of lorry; agreements; temperature

load during Nil 1 1 1 Y Y N N -- No

low temperature inspection; Staff

vechile process;

and time control in awareness/training

temperature

dispatch area. programmes in place with

of lorry

records of training retained.

Physical

Nails, or

Closed packaging

sharp object

does not pose a Inspection of proper cleaning

damages the

problem. Open of lorry; supplier selection of

packing

Dispatch / trays or boxes can transporter; transport

material.

load Nil 2 2 4 be subject to agreements; Proper care Y Y N N -- No

Hair, dust,

vechile physical matter and during QC checks and

insect, other

cause transport; Staff

foreign

contamination of awareness/training

particles

finished product programmes in place with

records of training retained

As per

Quality

specifi

Improper Improper handling

Dispatch / cation Staff awareness/training

handling of can affect quality

load (EU 1 1 1 programmes in place with Y Y N N -- No

products (bruising,

vechile trade records of training retained

during damaging)

norms

transferring

)

P = Probability of occurrence 5 Very High 4 High 3 Moderate 2 Low 1 Negligible

S = Severity 5 Very Sever 4 Sever 3 Moderate 2 Low Impact 1 Negligible

Magnitude of impact = P * S , if it is more then 12 then it is significant

Potrebbero piacerti anche

- Kalite Ve Gıda GüvenliğiDocumento3 pagineKalite Ve Gıda GüvenliğiFatma Tuba AltunbaşNessuna valutazione finora

- Name Position Qualifications / Experiance: Haccp TeamDocumento15 pagineName Position Qualifications / Experiance: Haccp TeamAngelyn Cardenas CatalanNessuna valutazione finora

- Risk Assessment On New Sample Collection Area (Revised - Final)Documento4 pagineRisk Assessment On New Sample Collection Area (Revised - Final)Ruel BariaNessuna valutazione finora

- H4 3a HazardAnalysis Soup ProductsDocumento23 pagineH4 3a HazardAnalysis Soup ProductsAelindahNessuna valutazione finora

- Working at Elevated Areas (Scaffolding)Documento4 pagineWorking at Elevated Areas (Scaffolding)Ali Al-GhamghamNessuna valutazione finora

- RA Excessive Noise .Vibration.Documento11 pagineRA Excessive Noise .Vibration.Ndifor Dinho0% (1)

- HIRARC Table Dosh OfficeDocumento4 pagineHIRARC Table Dosh OfficeeimanmunirahNessuna valutazione finora

- Presentation For Partial Fulfillment of The Diploma in Occupational Safety and HealthDocumento16 paginePresentation For Partial Fulfillment of The Diploma in Occupational Safety and HealthmarinaNessuna valutazione finora

- Topic 4 Relevant Notes Part 2 - FireExtinguisherDocumento18 pagineTopic 4 Relevant Notes Part 2 - FireExtinguisherNazrina RinaNessuna valutazione finora

- Hazard Identification and Risk Assessment FormDocumento4 pagineHazard Identification and Risk Assessment FormAli Al-GhamghamNessuna valutazione finora

- H PSAF RAINALDI Process Safety PDFDocumento12 pagineH PSAF RAINALDI Process Safety PDFanton100% (1)

- Disposal of Old Material HIRADocumento3 pagineDisposal of Old Material HIRAAli Al-GhamghamNessuna valutazione finora

- Risk Assessment ProcedureDocumento9 pagineRisk Assessment ProcedureDukhidilNessuna valutazione finora

- Baseline Risk Assessment1 PDFDocumento25 pagineBaseline Risk Assessment1 PDFRico100% (2)

- Bow Tie SafetyDocumento15 pagineBow Tie SafetyAshish MishraNessuna valutazione finora

- Risk Assessment & Control Module 3Documento38 pagineRisk Assessment & Control Module 3Marvin ReggieNessuna valutazione finora

- Generic HACCP: Flow Diagram, Hazard-Analysis and HACCP Plan WorksheetsDocumento7 pagineGeneric HACCP: Flow Diagram, Hazard-Analysis and HACCP Plan WorksheetsLind SayNessuna valutazione finora

- Context - General Risk AssessmentDocumento14 pagineContext - General Risk AssessmentAngeloNessuna valutazione finora

- Haccp WsDocumento11 pagineHaccp WsFreg GregNessuna valutazione finora

- Hazard Identification and Risk Assessment Form: Project ProcessDocumento4 pagineHazard Identification and Risk Assessment Form: Project ProcessAli Al-GhamghamNessuna valutazione finora

- Generic Risk Assessment FormDocumento2 pagineGeneric Risk Assessment Formblackiceman100% (1)

- QMS Risk Planning RegisterDocumento34 pagineQMS Risk Planning RegisterKarthi Thiyagarajan100% (1)

- HIRAC Sample and PresentationDocumento14 pagineHIRAC Sample and PresentationEric Valenzuela100% (2)

- Hazard Risk Assessment ActivityDocumento5 pagineHazard Risk Assessment ActivityMelanie MacatangayNessuna valutazione finora

- Food Safety - Part 2Documento62 pagineFood Safety - Part 2Thẩm NguyễnNessuna valutazione finora

- Template 3-Part HIRACDocumento7 pagineTemplate 3-Part HIRACJoemar TarlitNessuna valutazione finora

- Score: Mayb e Minim Al Clinica L/ Financi Al Fai RDocumento8 pagineScore: Mayb e Minim Al Clinica L/ Financi Al Fai RedwardNessuna valutazione finora

- Hoarding Install and DismantleDocumento5 pagineHoarding Install and Dismantleஅருண்ராஜ் கிருஷ்ணன்சாமி100% (1)

- SOP For Quality Risk Management - Pharmaceutical GuidelinesDocumento3 pagineSOP For Quality Risk Management - Pharmaceutical Guidelinessakib44586% (7)

- METHODOLOGYDocumento3 pagineMETHODOLOGYSyakirin Spears100% (1)

- Facility-Onset Infections(s) Device-Or Care-Related: Clostridioides DifficileDocumento27 pagineFacility-Onset Infections(s) Device-Or Care-Related: Clostridioides DifficileMOHAMEDNessuna valutazione finora

- 8-8 Nail-Risk Management Report PDFDocumento12 pagine8-8 Nail-Risk Management Report PDFDiana Rodriguez ParodiNessuna valutazione finora

- Risk Assessment Mr. BiteDocumento7 pagineRisk Assessment Mr. Biteजितेन्द्र जीतNessuna valutazione finora

- ISK Eduction Rocess: List TasksDocumento13 pagineISK Eduction Rocess: List TasksMichael AlexanderNessuna valutazione finora

- HACCP Methodology - KhoaDocumento7 pagineHACCP Methodology - KhoaPawanNessuna valutazione finora

- Total Risk Management Kingdom DrillingDocumento15 pagineTotal Risk Management Kingdom Drillingbengam100% (3)

- Methodology For Determination of Hazard Controls CCP S and OPRP SDocumento4 pagineMethodology For Determination of Hazard Controls CCP S and OPRP SRosinanteNessuna valutazione finora

- Hazard Identification and Risk Assessment Form: Project ProcessDocumento4 pagineHazard Identification and Risk Assessment Form: Project ProcessAli Al-GhamghamNessuna valutazione finora

- Principle2 CCPDocumento24 paginePrinciple2 CCPNitesh PanchalNessuna valutazione finora

- HACCP Control MeasuresDocumento4 pagineHACCP Control MeasuresAishwary SamarthNessuna valutazione finora

- SF 011 Hazard Risk AseessmentDocumento3 pagineSF 011 Hazard Risk AseessmentShahid RazaNessuna valutazione finora

- HazardsControls Part 3Documento35 pagineHazardsControls Part 3John Mark DulawanNessuna valutazione finora

- Risk Assement UpdatedDocumento10 pagineRisk Assement Updatedashwin0% (1)

- Econpile (M) SDN BHD: Hazard Identification Risk Assessment Risk ControlDocumento3 pagineEconpile (M) SDN BHD: Hazard Identification Risk Assessment Risk Controlalam dooNessuna valutazione finora

- PP. Manajemen Risiko, RCA Dan FMEADocumento52 paginePP. Manajemen Risiko, RCA Dan FMEACaesar Ahmad TidelNessuna valutazione finora

- Biorisk Mitigation Strategies - PASMETH - PhBBA - DTRADocumento66 pagineBiorisk Mitigation Strategies - PASMETH - PhBBA - DTRARyan Marañon PedregosaNessuna valutazione finora

- Risk Assessment - Hand ToolsDocumento2 pagineRisk Assessment - Hand ToolsRoy Chandra Sekar JeyapaulNessuna valutazione finora

- Construction Project Risk Evaluation Based On FMEADocumento16 pagineConstruction Project Risk Evaluation Based On FMEABoopathiNessuna valutazione finora

- Sample Work Activity Ra Template 2021aDocumento8 pagineSample Work Activity Ra Template 2021aAnwar HusseinNessuna valutazione finora

- Envi Sci & Eng'g. Learning Material-Topic 5Documento27 pagineEnvi Sci & Eng'g. Learning Material-Topic 5Janice C. PusposNessuna valutazione finora

- Risk Management For Food and Beverage Industry Usi PDFDocumento12 pagineRisk Management For Food and Beverage Industry Usi PDFMariana VictoriaNessuna valutazione finora

- Master - HIRARC Table (Latest)Documento17 pagineMaster - HIRARC Table (Latest)Nur Alisha AlishaNessuna valutazione finora

- Emsp-24 Aspects IdentificationDocumento4 pagineEmsp-24 Aspects IdentificationrememberNessuna valutazione finora

- Date / Time Student Score Passing Score Result: Hazard Recognition BilalDocumento1 paginaDate / Time Student Score Passing Score Result: Hazard Recognition BilalbillNessuna valutazione finora

- 4 Tools For Safety Excellence RK SinghDocumento27 pagine4 Tools For Safety Excellence RK SinghPT. SAMUDRA INTIM JAYA SHIPPINGNessuna valutazione finora

- Risk - and - Issues - Analysis - QA FinalDocumento10 pagineRisk - and - Issues - Analysis - QA FinalEmba MadrasNessuna valutazione finora

- HIRADocumento14 pagineHIRAGobindaSahu100% (2)

- Effect Measures Revision Lecture - SlidesDocumento48 pagineEffect Measures Revision Lecture - SlidesKatie NolanNessuna valutazione finora

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsDa EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNessuna valutazione finora

- Adventurer's Guide to Risk Management: Fictional Tales about Risk ManagementDa EverandAdventurer's Guide to Risk Management: Fictional Tales about Risk ManagementNessuna valutazione finora

- Bake 5 - Micro - Quality High Risk Bakery Products, NZ 2007Documento46 pagineBake 5 - Micro - Quality High Risk Bakery Products, NZ 2007Gaganpreet KaurNessuna valutazione finora

- Cake Quality and Evaluation BAKERpaperDocumento9 pagineCake Quality and Evaluation BAKERpaperGaganpreet KaurNessuna valutazione finora

- Calcium PropionateDocumento8 pagineCalcium PropionateGaganpreet KaurNessuna valutazione finora

- Canadian Guidelines For Physical HazardsDocumento4 pagineCanadian Guidelines For Physical HazardsGaganpreet KaurNessuna valutazione finora

- Bake 3 - Bakery Products, Microbial Summary, CampdenDocumento2 pagineBake 3 - Bakery Products, Microbial Summary, CampdenGaganpreet KaurNessuna valutazione finora

- CFR 2016 Title9 Vol2 Part430Documento4 pagineCFR 2016 Title9 Vol2 Part430Gaganpreet KaurNessuna valutazione finora

- 5 Guide AnceDocumento4 pagine5 Guide AnceGaganpreet KaurNessuna valutazione finora

- 12 Haccp Baking PDFDocumento32 pagine12 Haccp Baking PDFMuzammal FarooqNessuna valutazione finora

- (Polish Journal of Food and Nutrition Sciences) Implementation of Hazard Analysis Critical Control Points (HACCP) in A SME - Case Study of A BakeryDocumento13 pagine(Polish Journal of Food and Nutrition Sciences) Implementation of Hazard Analysis Critical Control Points (HACCP) in A SME - Case Study of A BakeryDarja SubotičkiNessuna valutazione finora

- Environmental Monitoring Risk Assessment PDFDocumento11 pagineEnvironmental Monitoring Risk Assessment PDFanon_675597701Nessuna valutazione finora

- Mitigation Strategies To Protect Food Against Intentional Adulteration FDA Guidance PDFDocumento159 pagineMitigation Strategies To Protect Food Against Intentional Adulteration FDA Guidance PDFscf9827Nessuna valutazione finora

- REcall Handbok PDFDocumento29 pagineREcall Handbok PDFMark A. ButlerNessuna valutazione finora

- Bakery Ind HygieneDocumento104 pagineBakery Ind Hygienelabie100% (1)

- AuRzSAyoRDe2oYeujs0x Big Dream Worksheet V1Documento2 pagineAuRzSAyoRDe2oYeujs0x Big Dream Worksheet V1Gaganpreet KaurNessuna valutazione finora

- Chlorine ArticlesDocumento7 pagineChlorine ArticlesScherjeal JangdaNessuna valutazione finora

- 817755.food Defence 16 03 2016Documento10 pagine817755.food Defence 16 03 2016Gaganpreet KaurNessuna valutazione finora

- Alchemy Academy Navigating Food InterviewDocumento6 pagineAlchemy Academy Navigating Food InterviewGaganpreet KaurNessuna valutazione finora

- A Guide To ATP Hygiene MonitoringDocumento32 pagineA Guide To ATP Hygiene MonitoringGaganpreet KaurNessuna valutazione finora

- ATP Hygiene Monitoring Do Sanitisers Really Affect MeasurementsDocumento4 pagineATP Hygiene Monitoring Do Sanitisers Really Affect MeasurementsGaganpreet KaurNessuna valutazione finora

- Precision and Accuracy in ATP Hygiene TestingDocumento3 paginePrecision and Accuracy in ATP Hygiene TestingGaganpreet KaurNessuna valutazione finora

- The Optimum Disinfection Treatment According To The Antibacterial Efficacy & Impact On Vegetable QualityDocumento51 pagineThe Optimum Disinfection Treatment According To The Antibacterial Efficacy & Impact On Vegetable QualityGaganpreet KaurNessuna valutazione finora

- Section9.Effective Cleaning and Sanitizing Procedures PDFDocumento8 pagineSection9.Effective Cleaning and Sanitizing Procedures PDFAnalyn GirasolNessuna valutazione finora

- Sanitation & Hygiene in Food ProcessingDocumento17 pagineSanitation & Hygiene in Food ProcessingAdela PopescuNessuna valutazione finora

- Exploding The Myths About ATP Hygiene MonitoringDocumento5 pagineExploding The Myths About ATP Hygiene MonitoringGaganpreet KaurNessuna valutazione finora

- Chlorine FAODocumento289 pagineChlorine FAOTrầnĐứcHùngNessuna valutazione finora

- Pocket Thermometer Calibration InstructionsDocumento3 paginePocket Thermometer Calibration InstructionsGaganpreet KaurNessuna valutazione finora

- Mock Tracebility Exercise ASQDocumento24 pagineMock Tracebility Exercise ASQspp100% (8)

- Supplier Quality & Food Safety Audit: Your LogoDocumento6 pagineSupplier Quality & Food Safety Audit: Your LogokarupukamalNessuna valutazione finora

- Microbial Safety of Minimally Processed FoodsDocumento357 pagineMicrobial Safety of Minimally Processed FoodsGaganpreet KaurNessuna valutazione finora

- Management Review ProcedureDocumento1 paginaManagement Review ProcedureGaganpreet KaurNessuna valutazione finora

- TTLM 01. Manage Safety and Environmental ProtectionDocumento62 pagineTTLM 01. Manage Safety and Environmental ProtectionEyobNessuna valutazione finora

- Igc1 نيبوش انجليزي بترو اسيلDocumento53 pagineIgc1 نيبوش انجليزي بترو اسيلكاتم الاسرارNessuna valutazione finora

- Dow Corning (R) 200 Fluid, 50 Cst.Documento11 pagineDow Corning (R) 200 Fluid, 50 Cst.Sergio Gonzalez GuzmanNessuna valutazione finora

- 4621 NYI Exam BlueprintDocumento4 pagine4621 NYI Exam BlueprintjelenabasaNessuna valutazione finora

- TP48200A-HX09A1 and TBC300A-DCA5 Telecom Power User ManualDocumento95 pagineTP48200A-HX09A1 and TBC300A-DCA5 Telecom Power User ManualALexNessuna valutazione finora

- Safety Data Sheet (SDS) : Section I. Product IdentificationDocumento4 pagineSafety Data Sheet (SDS) : Section I. Product IdentificationNugroho DavidNessuna valutazione finora

- NEBOSHDocumento8 pagineNEBOSHSenthil KumarNessuna valutazione finora

- Sds Copper Sulfate MitsubishiDocumento8 pagineSds Copper Sulfate MitsubishiFonfon JangNessuna valutazione finora

- Ohsas 18001 Manual - NslsDocumento15 pagineOhsas 18001 Manual - Nslspercy00100% (1)

- PRC 2017 Annual Report ENDocumento88 paginePRC 2017 Annual Report ENmuhammad suryadiNessuna valutazione finora

- Sebu9048 09 00 - Manuals Operation MaintenanceDocumento160 pagineSebu9048 09 00 - Manuals Operation MaintenanceArturo ChiaNessuna valutazione finora

- Construction Equipment Operations and Maintenance Pt.2Documento13 pagineConstruction Equipment Operations and Maintenance Pt.2maryNessuna valutazione finora

- Pe 1 Uninterruptible Power SystemsDocumento61 paginePe 1 Uninterruptible Power SystemsSureshKumarNessuna valutazione finora

- Safety in GPR Prospecting: A Rarely-Considered IssueDocumento2 pagineSafety in GPR Prospecting: A Rarely-Considered Issuerahmaan perkasa alamNessuna valutazione finora

- Analisis Gagal Antar Dengan Penerapan Metode Fmea Dan Fta Studi Kasus Di PT Pos Indonesia Jakarta Pusat 10900Documento7 pagineAnalisis Gagal Antar Dengan Penerapan Metode Fmea Dan Fta Studi Kasus Di PT Pos Indonesia Jakarta Pusat 10900Hamda AidilNessuna valutazione finora

- Hospital Admission and DischargeDocumento5 pagineHospital Admission and DischargeRenuga SureshNessuna valutazione finora

- Functional Description TP900 en Side Cylinder Filterpress Veoila 1500 101Documento90 pagineFunctional Description TP900 en Side Cylinder Filterpress Veoila 1500 101anjung darma putraNessuna valutazione finora

- Safety Data Sheet Fescon Thinner enDocumento19 pagineSafety Data Sheet Fescon Thinner enPrimes Alga 'angga' PutraNessuna valutazione finora

- JSA-020 Fence InstallationDocumento4 pagineJSA-020 Fence InstallationMoaatazz Nouisri75% (4)

- RRC Risk Assessment Dec 2010Documento14 pagineRRC Risk Assessment Dec 2010Li ChenNessuna valutazione finora

- Shop Self AssessDocumento3 pagineShop Self AssessVepxvia NadiradzeNessuna valutazione finora

- Legal Register-QatarDocumento62 pagineLegal Register-QatarRamasubramanian Sankaranarayanan80% (5)

- A Guide To Restaurant HKDocumento203 pagineA Guide To Restaurant HKequitybabaNessuna valutazione finora

- Safety Data Sheet: Leybonol Lvo 210Documento9 pagineSafety Data Sheet: Leybonol Lvo 210J. Carlos Alvarez C.Nessuna valutazione finora

- CBC - Epas NC II Updated August 2020Documento93 pagineCBC - Epas NC II Updated August 2020Gie Ko100% (2)

- 6 Appendix C HazMat Group Equipment ListDocumento5 pagine6 Appendix C HazMat Group Equipment ListShiro IshiiNessuna valutazione finora

- Emergency Management PlanDocumento47 pagineEmergency Management PlanemmaNessuna valutazione finora

- Performance-Based Fire and Gas Systems Engineering HandbookDocumento176 paginePerformance-Based Fire and Gas Systems Engineering HandbookMichael Lagundino100% (1)

- School Disaster Risk Reduction ManagementDocumento4 pagineSchool Disaster Risk Reduction Managementjunapoblacio100% (5)

- Fire Protection Hardware and Fire Science - 1st IIEE Socsargen Technical Webinar 2020Documento49 pagineFire Protection Hardware and Fire Science - 1st IIEE Socsargen Technical Webinar 2020Nilagang BaboyNessuna valutazione finora