Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quick Release Valve

Caricato da

agusCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quick Release Valve

Caricato da

agusCopyright:

Formati disponibili

Quick Release Valve Description

Description

The Airflex quick release valve (QRV) is a pneu- Quick release valve sizes 3/8, 1/2 and 3/4 uti- Air flows through the radial holes in the stem to

matic in-line, three-way valve designed to auto- lizes a diaphragm in their design. Air pressure, the cylinder port.

matically close upon pressurization and open to at the inlet, seats the diaphragm on the end cap,

exhaust when a pressure drop occurs in the closing the exhaust port. Pressure on the outer When a sufficient pressure drop occurs on the

supply line. The valve provides an exhaust port unsupported diaphragm area causes it to de- inlet side of the plunger, the spring force shifts

close to the pressurized chamber of the device flect, allowing air to flow to the cylinder port. the plunger, opening the exhaust port and block-

being controlled rather than exhausting through When a pressure drop occurs in the air supply, ing the inlet port. Air is now free to flow from

long supply lines and/or control components. the pressure differential lifts the diaphragm from the cylinder to exhaust. Blockage of the inlet

The end result is a reduction in lag time between the exhaust port and seats it on the inlet port. forces the air in the supply line to exhaust back

the signal to exhaust and response. The benefits Air from the pressurized device can now flow through the control valve.

derived include: freely to atmosphere through the exhaust port.

• Faster cyclic rates The 1 quick release valve utilizes a

plunger in its design. The spring-biased

• Reduction or elimination of overlap plunger is guided during its travel by the

fit between its stem and the house. When

• Reduced wear of drive components sufficient pressure is developed on the

stem’s diametrical area to overcome the

Inlet

Four basic valve sizes are available, identified by spring force, the plunger shifts, seats on

the American National Pipe Thread on the cylin- the seal washer closing the exhaust port.

der port: 3/8, 1/2, 3/4 and 1. Models are avail- The unbalance in the exposed plunger

able with inlet ports suitable for either pipe or pressurized area favors the inlet side; Exhaust

tubing connections. Mufflers are also available thereby, keeping the exhaust port closed.

to reduce exhaust noise.

Cylinder

Spring Plunger Seal Washer

Exhaust Inlet

End Cap Diaphragm

Cylinder

Valve Pressurized Valve Open to Exhaust

Exhaust Inlet

Exhaust Side Inlet Side

Cylinder Cylinder

Valve Pressurized Valve Open to Exhaust Plunger Pressure Unbalance for Closed Valve

J - 19 Copyright Eaton Corporation, 1997, All rights reserved.

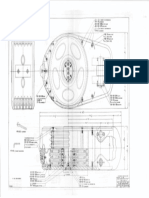

Quick Release Valves

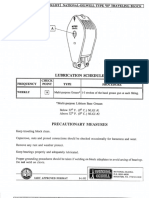

Component Part Descriptions

Diaphragm Type Valve

5 1 2 3 4

Plunger Type Valve

1 8 9 10 12 11 3

Item Description Item Description

1 End Cap 8 Seal

2 Diaphragm 9 Spring

Rubber Sleeve 10 Washer

3

Metal Sleeve 11 Plunger

4 Pipe Adapter 12 Cushion

5 Muffler

Copyright Eaton Corporation, 1997, All rights reserved. J - 20

Quick Release Valves

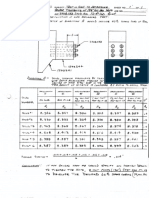

Forms QRV 909 & 910 Technical Data

Technical Data for Diaphragm Type Valve

Maximum operating pressure: 150 psi (10,3 bar) Inlet Port Options Cylinder

Port

American Tubing American

Size Outside National

Minimum sealing pressure: 2 psi (0,14 bar) National

Pipe Thread Diameter Pipe

(in) Thread

Air quality: Clean and dry to avoid contamination of housing and 3/8 3/8-18 0.500 3/8-18

1/2 1/2-14 0.625 1/2-14

diaphragm. Any additive used in air supply must be compatible

3/4 3/4-14 0.750 3/4-14

with valve materials.

1 1-11 1/2 1.000 1-11 1/2

Operating temperature range: -40oF (-40oC) to 120oF (49oC).

Mean life: Over five million cycles at 75 psi (5,2 bar) and 80oF

(27oC).

Diaphragm material: Polyurethane

Flow Capacity Ï

Housing material: Zinc alloy English SI

Standard Cubic Cubic Meter

Size Feet per Minute per Minute

Inlet to Cylinder Inlet to Cylinder

Cylinder to Exhaust Cylinder to Exhaust

3/8 121 206 3,4 5,8

1/2 172 256 4,9 7,2

3/4 287 376 8,1 17,2

ANSI Symbol ISO Symbol

Part Numbers 3/8, 1/2, 3/4 Quick Release Valve Options

The basic quick release valve part numbers Description Designation

are given in the following table. A double w/Metal Sleeve DE

alpha suffix must be added, to the basic w/Rubber Sleeve DF

number to completely identify the valve. For w/Inlet Pipe Thread DG

instance, part number 145407DG identifies w/Metal Sleeve & Muffler DS

a 1/2 QRV having pipe threads on its inlet w/Rubber Sleeve & Muffler DR

port. w/Inlet Pipe Thread & Muffler DT

w/Metal Sleeve & Pipe Adapter DL

w/Metal Sleeve & 1/4 Pipe Adapter DM

Diaphragm & End Cap Kit DP

Diaphragm, Muffler & End Cap Kit DQ

Size Basic Part Number 1 Quick Release Valve Options

3/8 145406 Description Designation

1/2 145407 w/Steel Sleeve BD

3/4 145141 w/Steel Sleeve & Muffler BE

1 145413 w/1-11 1/2 Pipe Threads Both Ports BF

w/Pipe Adapter BR

w/Pipe Adapter & Muffler CA

Replacement Kit Ð BZ

Replacement Kit w/Muffler Ð DX

J - 21 Copyright Eaton Corporation, 1997, All rights reserved.

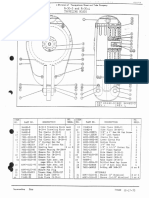

Quick Release Valves

Forms QRV 909 & 910 Dimensional Data

D53 D

W2

L2

O O3

H

P

O4

O1

U1 U5 M

QRV with metal or rubber sleeve QRV with inlet pipe thread

L1 D2

O1

U2

QRV with metal or rubber sleeve and muffler QRV with metal sleeve and pipe adapter

English Dimensions in inches

3/8 2.10 3.52 0.31 1.93 1.42 0.56 0.95 0.500 3/8-18 0.43 3/4-16 1.26 1.17 2.47 2.00 1.36

1/2 2.50 3.92 0.34 2.18 1.42 0.63 1.10 0.625 1/2-14 0.56 7/8-14 1.44 1.33 2.63 2.15 1.49

3/4 2.85 4.27 0.34 2.33 1.42 0.74 1.28 0.750 3/4-14 0.67 1 1/16-16 1.56 1.49 2.80 2.52 1.56

1 3.38 6.04 0.38 2.94 3.09 0.81 1.61 1.000 1-11 1/2 0.94 1 5/16-16 1.94 1.90 4.50 2.75 2.00

Size D D2 D53 Ê H L1 L2 M OË O1 Ì O3 O4Í P U1 Î U2 Î U5 Î W2

3/8 53 89 8 49 36 14 24 12,7 3/8-18 11 3/4-16 32 30 63 51 35

1/2 64 100 9 55 36 16 28 15,9 1/2-14 14 7/8-14 37 34 67 55 38

3/4 72 108 9 59 36 19 33 19,1 3/4-14 17 1 1/16-16 40 38 71 64 40

1 86 153 10 75 78 21 41 25,4 1-11 1/2 24 1 5/16-16 49 48 114 70 51

SI Dimensions in millimeters

Notes:

Ê Depth of tube insertion. Í American National Standard for Unified Screw Ð See component parts page (J-16). Includes

Threads. items 8, 9, 10, 11 and either 1 or 5 as indi-

Ë Outside tube diameter. Î Swing radius. cated.

Ì American Pipe Thread Ï At 100 psi (6,9 bar) inlet pressure with full pres-

sure drop.

Copyright Eaton Corporation, 1997, All rights reserved. J - 22

Typical Applications

Propel Clutch Dual Passage Rotorseal

Swing Clutches

A dual passage rotorseal supplies air to the swing clutches on this power crane shaft

assembly. A single passage rotorseal (not shown) on the opposite shaft end supplies air to

the propel clutch.

Air Receiver Tank

Solenoid Valve

Rotorseal

QRV

Four QRV’s are used to exhaust a pneumatic clutch, which is mounted to the inside

bullgear web, in this punch press drive.

J - 23 Copyright Eaton Corporation, 1997, All rights reserved.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 092 M-002 Mechanical Symbols and LegendsDocumento1 pagina092 M-002 Mechanical Symbols and Legendseuri08Nessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Operator'S Manual: Bop Control System With Air Remote ControlDocumento12 pagineOperator'S Manual: Bop Control System With Air Remote ControlagusNessuna valutazione finora

- 5 - Tank Itp - Inspection & Test Plan For TanksDocumento10 pagine5 - Tank Itp - Inspection & Test Plan For TanksAhmed Hassan100% (2)

- Hysys 2Documento85 pagineHysys 2Erick SaLaNessuna valutazione finora

- Fundamentals of HV Circuit-BreakersDocumento22 pagineFundamentals of HV Circuit-BreakersBastian OspinaNessuna valutazione finora

- Week 5 Waste Management in Singapore Case Study For SSE1201 v6Documento34 pagineWeek 5 Waste Management in Singapore Case Study For SSE1201 v6ZihNessuna valutazione finora

- Drilling Mast and Subtructure CertificatDocumento10 pagineDrilling Mast and Subtructure CertificatAhmed Imtiaz Rao0% (1)

- Pe Final Ex SS 2010-2011Documento8 paginePe Final Ex SS 2010-2011Saif Uddin100% (1)

- LPG Co-MinglingDocumento17 pagineLPG Co-MinglingderhgawenrahulNessuna valutazione finora

- Environmental Impact Assessment by L.W. CanterDocumento38 pagineEnvironmental Impact Assessment by L.W. CanterDewi Hadiwinoto33% (9)

- Investigation of Technical and Economic Aspects For Methanol Production Through CO2 Hydrogenation PDFDocumento13 pagineInvestigation of Technical and Economic Aspects For Methanol Production Through CO2 Hydrogenation PDFCarlosNessuna valutazione finora

- Safety Alert: Block Hanging Line Load PathDocumento1 paginaSafety Alert: Block Hanging Line Load PathagusNessuna valutazione finora

- Rig-36 Cyclone Drilling Inc.Documento2 pagineRig-36 Cyclone Drilling Inc.leoNessuna valutazione finora

- Accumulator Function TestDocumento1 paginaAccumulator Function TestamirakhavansafarNessuna valutazione finora

- 1500 HP SCR Mobile Desert Drilling Rig Example SpecifcationsDocumento48 pagine1500 HP SCR Mobile Desert Drilling Rig Example SpecifcationsMustafa SaidNessuna valutazione finora

- Safety Alert: Block Hanging Line Load PathDocumento1 paginaSafety Alert: Block Hanging Line Load PathagusNessuna valutazione finora

- Maximum Bearing Clearances Service BulletinDocumento1 paginaMaximum Bearing Clearances Service BulletinagusNessuna valutazione finora

- System Requirements For AutoCAD Plant 3D 2019 - AutoCAD Plant 3D 2019Documento3 pagineSystem Requirements For AutoCAD Plant 3D 2019 - AutoCAD Plant 3D 2019agusNessuna valutazione finora

- 2004 Advance Ballast SpecificationsDocumento1 pagina2004 Advance Ballast SpecificationsagusNessuna valutazione finora

- IOM-RH RotorSealDocumento6 pagineIOM-RH RotorSealagusNessuna valutazione finora

- RS9031 PDFDocumento7 pagineRS9031 PDFagusNessuna valutazione finora

- Level III Inspection Vfinal Form Enabled PDFDocumento3 pagineLevel III Inspection Vfinal Form Enabled PDFagusNessuna valutazione finora

- Rotorseal Tech Specs PDFDocumento19 pagineRotorseal Tech Specs PDFFAVIONessuna valutazione finora

- Outline Oilwell 480 BlockDocumento1 paginaOutline Oilwell 480 BlockagusNessuna valutazione finora

- Quick Release ValveDocumento5 pagineQuick Release ValveagusNessuna valutazione finora

- Mud PumpDocumento2 pagineMud PumpagusNessuna valutazione finora

- Emsco L-300 Parts ListDocumento1 paginaEmsco L-300 Parts ListagusNessuna valutazione finora

- Emsco BlockDocumento1 paginaEmsco BlockagusNessuna valutazione finora

- Eaton AirflexDocumento12 pagineEaton AirflexagusNessuna valutazione finora

- National Type G Hook-Block Iadc Check ListDocumento2 pagineNational Type G Hook-Block Iadc Check ListagusNessuna valutazione finora

- Block EmscoDocumento1 paginaBlock EmscoagusNessuna valutazione finora

- Hook Derating ChartsDocumento6 pagineHook Derating ChartsagusNessuna valutazione finora

- Oilwell 350 HD PartslistDocumento4 pagineOilwell 350 HD PartslistagusNessuna valutazione finora

- Set Up Instructions PWMDocumento1 paginaSet Up Instructions PWMagusNessuna valutazione finora

- SSSSSSSSSSSSSSSS: Tb1 & 2 For All PWM Control SystemsDocumento1 paginaSSSSSSSSSSSSSSSS: Tb1 & 2 For All PWM Control SystemsagusNessuna valutazione finora

- National Type H Block Iadc Check ListDocumento2 pagineNational Type H Block Iadc Check ListagusNessuna valutazione finora

- Emsco Nc-36-3 & 36-4 Block PartslistDocumento1 paginaEmsco Nc-36-3 & 36-4 Block PartslistagusNessuna valutazione finora

- Set Up Instructions PWMDocumento1 paginaSet Up Instructions PWMagusNessuna valutazione finora

- Climbing Film EvaporatorDocumento8 pagineClimbing Film Evaporatorsaz140% (1)

- Datasheet Noise FilterDocumento2 pagineDatasheet Noise FilternellyyulitasariiNessuna valutazione finora

- Vapor and Combined Power Cycles: Çengel BolesDocumento20 pagineVapor and Combined Power Cycles: Çengel BolesSalman ShaxShax HeissNessuna valutazione finora

- Conclusion & ReferencesDocumento4 pagineConclusion & ReferencesAlejandro GilNessuna valutazione finora

- UBL3&4 E 0 G0 ES AA0 002P - R3 - Color Schedule For Power PlantDocumento12 pagineUBL3&4 E 0 G0 ES AA0 002P - R3 - Color Schedule For Power PlantAdvent ManurungNessuna valutazione finora

- Plate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumDocumento1 paginaPlate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumCardoso MalacaoNessuna valutazione finora

- Harris - AN-PRC150 HF-VHF Combat Radio - Instruction ManualDocumento49 pagineHarris - AN-PRC150 HF-VHF Combat Radio - Instruction ManualAbhinav Ashok ChandelNessuna valutazione finora

- ENDA-5000 HRE2406B- Gas Analyzer- Thiết Bị Phân Tích KhíDocumento6 pagineENDA-5000 HRE2406B- Gas Analyzer- Thiết Bị Phân Tích KhíminhNessuna valutazione finora

- Fire Warden Monthly ChecklistDocumento3 pagineFire Warden Monthly ChecklistTichaona KwazvichasvikaNessuna valutazione finora

- Teikin Catalog Vol 18-Automotive FiatDocumento6 pagineTeikin Catalog Vol 18-Automotive FiatJuan Esteban Ordoñez BonillaNessuna valutazione finora

- MR-E-A-QW003 MR-E - AG-QW003: General-Purpose AC Servo Ezmotion Mr-E Super General-Purpose InterfaceDocumento326 pagineMR-E-A-QW003 MR-E - AG-QW003: General-Purpose AC Servo Ezmotion Mr-E Super General-Purpose InterfaceKailas PardeshiNessuna valutazione finora

- Magnum OpusDocumento4 pagineMagnum OpusPharaohgodking100% (1)

- Phasor Analysis of Mechanical Systems Rev B PDFDocumento6 paginePhasor Analysis of Mechanical Systems Rev B PDFBjørn-Magnus MoslåttNessuna valutazione finora

- 487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing TransformersDocumento55 pagine487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing Transformersjose eduardo mejia sanchezNessuna valutazione finora

- Hazardous Area Classification: Codes of Practice and StandardsDocumento13 pagineHazardous Area Classification: Codes of Practice and StandardsborrowmanaNessuna valutazione finora

- Survey Questionnaire On Transforming Recycled Cooking Oil Into A Sustainable Butane Alternative For Stove FuelDocumento2 pagineSurvey Questionnaire On Transforming Recycled Cooking Oil Into A Sustainable Butane Alternative For Stove Fueljohnphilipcornelio04Nessuna valutazione finora

- Ductile-Brittle Transition Temperature and Impact Energy Tests - Yena EngineeringDocumento7 pagineDuctile-Brittle Transition Temperature and Impact Energy Tests - Yena EngineeringKASHFI UDDINNessuna valutazione finora

- Synchronous Machines Question BankDocumento10 pagineSynchronous Machines Question BankelecenggNessuna valutazione finora

- Potenciometro Multivuelta 3006p Trimpot 1kDocumento1 paginaPotenciometro Multivuelta 3006p Trimpot 1kdanielinforgraNessuna valutazione finora

- Hphysics5 Roller Coaster Marbles Lab Report Jose GallardoDocumento1 paginaHphysics5 Roller Coaster Marbles Lab Report Jose Gallardoapi-345842338Nessuna valutazione finora

- Peugeot Elystar Diagnostic AidDocumento13 paginePeugeot Elystar Diagnostic Aidpiter4012Nessuna valutazione finora