Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Life Cycle Assessment of Food: International Agricultural Engineering Journal November 2013

Caricato da

cretuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Life Cycle Assessment of Food: International Agricultural Engineering Journal November 2013

Caricato da

cretuCopyright:

Formati disponibili

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/264464181

Life cycle assessment of food

Article in International Agricultural Engineering Journal · November 2013

CITATION READS

1 1,304

1 author:

Mahesh Satpute

Chr. Hansen A/S

6 PUBLICATIONS 8 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

surface modification View project

All content following this page was uploaded by Mahesh Satpute on 05 August 2014.

The user has requested enhancement of the downloaded file.

A REVIEW International Journal of Agricultural Engineering | Volume 6 | Issue 2 | October, 2013 | 558–563

Life cycle assessment of food

M.S. SATPUTE, A.G. LAMDANDE, V.D. KADAM AND S.R. GARUD

Received : 11.04.2013; Accepted : 15.11.2013

See end of the Paper for ABSTRACT : Life cycle assessment is an effective tool in assessing the environmental performance of

authors’ affiliation product or process or service. Life cycle assessment is a “cradle-to-grave” approach for assessing industrial

Correspondence to : systems. It means that assessment starts from the extraction of raw material from the ground and end at a

M.S. SATPUTE point where final waste or used product is returned to the ground; therefore cradle-to-grave approach avoids

Aditya College of Food ‘problem shifting’. Global warming is a serious and far-reaching challenge facing us. Global temperature is

Technology, BEED (M.S.) INDIA increasing and human activities are the primary cause. The food industry is one of the world’s largest industrial

sectors and hence, a large consumer of energy which leads to environmental pollution. It is, thus, essential to

evaluate the environmental impact and the utilization of resources in food production and distribution systems

for sustainable consumption. The review involves the identification of best available practice in establishing a

database for the life cycle inventory phase, and a list of environmental impact categories and accompanying

factors to address these impact categories.

KEY WORDS : Life cycle assessment, Environmental impact, Inventory phase

HOW TO CITE THIS PAPER : Satpute, M.S., Lamdande, A.G., Kadam, V.D. and Garud, S.R. (2013). Life cycle assessment

of food. Internat. J. Agric. Engg., 6(2) : 558-563.

W

e are witnessing a scenario where overexploitation consumer of energy which leads to environmental pollution.

of natural resources and degradation of It is, thus, essential to evaluate the environmental impact

environment in the developmental process has and the utilization of resources in food production and

brought our planet earth at the verge of losing its balance distribution systems for sustainable consumption.

which posing a threat to human survival. Therefore, Consumers in the developed countries demand safe food of

sustainability in the development process has become the high quality that has been produced with minimal adverse

core issue and has assumed a global dimension. impact on the environment.

Scientific opinion also holds that the threat posed will Life cycle assessment had its beginnings in the 1960’s.

become more severe over coming decades In 1969; researchers initiated an internal study for The Coca-

(Intergovernmental Panel on Climate Change 2001) from Cola Company that laid the foundation for the current

both the greenhouse gases we have already emitted and from methods of life cycle inventory analysis in the United States.

those we are continuing to emit. It is vitally important that Life cycle assessment is a “cradle-to-grave” approach for

governments, business and the community act now to reduce assessing industrial systems. It means that assessment starts

greenhouse emissions and adapt to climate change. from the extraction of raw material from the ground and end

Although the environment sustainability aspects of food at a point where final waste or used product is returned to

production have different imperatives in developing and the ground; therefore, cradle-to-grave approach avoids

developed countries, they are facing certain similar ‘problem shifting’. Most important, a cradle-to-grave analysis

challenges like conservation of soil and nutrient status wise involves a ‘holistic’ approach, bringing the environmental

utilization of fertilizers, selection and preservation of impacts into one consistent framework, wherever and

productive gene stock, careful use of agents for controlling whenever these impacts have occurred, or will occur. LCA

diseases, efficient use of resources especially water and enables the estimation of the cumulative environmental

energy, minimization of waste, careful disposal of waste and impacts resulting from all stages in the product life cycle.

productive use of by- products. The food industry is one of In ISO 14040 (see below) LCA is defined as the “compilation

the world’s largest industrial sectors and, hence, a large and evaluation of the inputs, outputs and potential

HIND AGRICULTURAL RESEARCH AND TRAINING INSTITUTE

M.S. SATPUTE, A.G. LAMDANDE, V.D. KADAM AND S.R. GARUD

environmental impacts of a product system throughout its Frame work:

life cycle”. The LCA process is a systematic, phased approach and

The main applications of Life cycle assessment are in: consists of following four components (Fig. 1).

– Analyzing the origins of problems related to a

particular product; 1.Goal and

Direct application

– Comparing improvement variants of a given product; scope definition Product

development and

– Designing new products; 4. Interpretation improvements.

– Choosing between a numbers of comparable of results Strategic planning.

2. Inventory analysis Public policy

products.

making.

Marketing.

International developments: 3. Impact assessment Others

Its history goes back to the early seventies, though in

the past, it went by different names such as resource and Fig. 1 : Phases in life cycle assessment and applications

environmental profile analysis (REPA), energy analysis or

product ecobalance. Goal definition and scoping (ISO 14041):

Define and describe the product, process or activity.

SETAC : Establish the context in which the assessment is to be made and

SETAC (the Society of Environmental Toxicology and identify the boundaries and environmental effects to be reviewed

Chemistry) was the first international body to act as an for the assessment. The goal establishes ‘Function and

umbrella organization for the development of LCA. It is a Functional Unit’. Careful selection of the functional unit to

scientific organization with its roots in academia, industry measure and display the LCA results will improve the accuracy

and government. SETAC’s involvement with LCA dates from of the study and the usefulness of the results. In comparing two

1989, when its first workshop was held in Smugglers Notch, or more product, functional unit selection is useful.

Vermont. The goal must be revisited periodically as the study

progresses to ensure consistency of data collection with end

ISO: use of the results. In this phase following information is

ISO (the International Organization for Standardization) determined: the type of information which adds value to final

is a world-wide private organization, including national decision, how accurate result must be to add the value and

bodies from both industrialized and developing countries, how the result must be interpreted and displayed in order to

which aims to standardize a wide range of products and be meaningful and usable. Goal definition and scoping of

activities. LCA project will determine the time and resources needed

The 14000 series of ISO standards includes the standard and it will also guide the entire process to get the meaningful

14001 on environmental management systems, as well as a results.

series of standards relating to LCA (the 14040 series). These The primary goal is to choose best process, product or

ISO activities began in 1994 and aimed to produce the first service which has least effect on human health and

complete series of LCA standards. environment. Conducting LCA can also help to guide the

The ISO LCA standards concern the technical as well development of new process, product or service. There may

as organizational aspects of an LCA project. The be secondary goals in conducting the LCA which vary

organizational aspects mainly focus on the design of critical depending upon the project. e.g. to support public policy, to

review processes, with special attention to comparative support product certification, to rank the relative contribution

assertions disclosed to the public. of individual steps or process, to identify the data gaps, to

guide the product and process development.

UNEP:

A third international player in the field of LCA is UNEP Inventory analysis (ISO 14041):

(the United Nations Environmental Programme), represented A life cycle inventory is a process of quantifying energy

by its Department of Technology, Industry and Economics and raw material requirements, atmospheric emissions,

in Paris. UNEP’s focus is mainly on the application of LCA, waterborne emissions, solid wastes, and other releases for

particularly in developing countries. The task involves the the entire life cycle of a product, process, or activity.

identification of best available practice in establishing a Following four steps of a life cycle inventory:

database for the life cycle inventory phase, and a list of Develop a flow diagram of the processes being

environmental impact categories and accompanying factors evaluated:

to address these impact categories. A flow diagram is a tool to map the inputs and outputs

Internat. J. agric. Engg., 6(2) Oct., 2013: 558-563

HIND AGRICULTURAL RESEARCH AND TRAINING INSTITUTE

559

LIFE CYCLE ASSESSMENT OF FOOD

to a process or system. The “system” or “system boundary” process and requires reconsideration following the data

varies for every LCA project. The goal definition and scoping collection phase. The items identified in the LCI have

phase establishes initial boundaries that define what are to potential human health and environmental impacts.

be included in a particular LCA; these are used as the system For an LCIA, impacts are defined as the consequences

boundary for the flow diagram. Unit processes inside the that could be caused by the input and output streams of a

system boundary link together to form a complete life cycle system on human health, plants, and animals, or the future

picture of the required inputs and outputs (material and availability of natural resources. Three main categories:

energy) to the system. human health, ecological health, and resource depletion.

Develop a data collection plan : Classification :

Defining data quality goals – No pre-defined list of data The purpose of classification is to organize and possibly

quality goals exists for all LCA projects. The number and combine the LCI results into impact categories. For LCI

nature of data quality goals necessary depends on the level items that contribute to only one impact category, the

of accuracy required to inform the decision-makers involved procedure is a straightforward assignment. For example,

in the process. carbon dioxide emissions can be classified into the global

Identifying data sources and types – It determines if warming category.

data quality requirements have been met. There is no pre-

defined list of data quality indicators for all LCIs. Examples Characterization :

of data quality indicators are precision, completeness, Impact characterization uses science-based conversion

representativeness, consistency, and reproducibility. factors, called characterization factors, to convert and

Identifying data quality indicators – For each life cycle combine the LCI results into representative indicators of

stage, specify the necessary data source and/or type required impacts to human and ecological health. Characterization

to provide sufficient accuracy and quality to meet the study’s provides a way to directly compare the LCI results within

goals. Defining the required data sources and types prior to each impact category. In other words, characterization

data collection helps to reduce costs and the time required factors translate different inventory inputs into directly

to collect the data. comparable impact indicators. For example, characterization

would provide an estimate of the relative terrestrial toxicity

Developing a data collection worksheet and checklist:

between lead, chromium, and zinc.

The next step is to develop a life cycle inventory

spreadsheet that covers most of the decision areas in the

Normalization:

performance of an inventory. A spreadsheet can be prepared

Normalization is an LCIA tool used to express impact

to guide data collection and validation and to enable

indicator data in a way that can be compared among impact

construction of a database to store collected data

categories. This procedure normalizes the indicator results

electronically. The spreadsheet is a valuable tool for ensuring

by dividing by a selected reference value.

completeness, accuracy, and consistency. It is especially

important for large projects when several people collect data

Grouping :

from multiple sources.

Grouping assigns impact categories into one or more

sets to better facilitate the interpretation of the results into

Collect data :

specific areas of concern. Typically, grouping involves

Data collection efforts involve a combination of

sorting or ranking indicators (ISO, 1998).

research, site-visits and direct contact with experts, which

generates large quantities of data. As an alternative, it may

Weighting :

be more cost effective to buy a commercially available LCA

The weighting step (also referred to as valuation) of an

software package.

LCIA assigns weights or relative values to the different

A second method to reduce data collection time and

impact categories based on their perceived importance or

resources is to obtain non-site specific inventory data.

relevance.

Several organizations have developed databases specifically

for LCA that contain some of the basic data commonly

Evaluate and document the LCIA results:

needed in constructing a life cycle inventory.

Now that the impact potential for each selected category

Impact assessment: has been calculated, the accuracy of the results must be

This step should be completed as part of the initial goal verified. The accuracy must be sufficient to support the

and scope definition phase to guide the LCI data collection purposes for performing the LCA as defined in the goal and

Internat. J. agric. Engg., 6(2) Oct., 2013: 558-563

560 HIND AGRICULTURAL RESEARCH AND TRAINING INSTITUTE

M.S. SATPUTE, A.G. LAMDANDE, V.D. KADAM AND S.R. GARUD

scope. When documenting the results of the life cycle impact the most cost effective or works the best. Therefore, the

assessment, thoroughly describe the methodology used in information developed in an LCA study should be used as

the analysis; define the systems analyzed and the boundaries one component of a more comprehensive decision process

that were set, and all assumptions made in performing the assessing the trade-offs with cost and performance, e.g., Life

inventory analysis. cycle management. The life cycle inventory (LCI) analysis

quantifies the resources use, energy use, and environmental

Interpretation (ISO 14043) : releases associated with the system being evaluated. It has

Evaluate the results of the inventory analysis and impact been reported that agricultural LCAs often exclude

assessment to select the preferred product, process or production processes of pesticides, machines, buildings, and

service with a clear understanding of the uncertainty and the roads because of lack of data (Cederberg and Mattsson,

assumptions used to generate the results. 2000). In this study, environmental impact of agricultural

ISO has defined the following two objectives of life chemicals was considered, but that related to the construction

cycle interpretation: of packaging and storage facilities, transport, and other

Analyze results, reach conclusions, explain limitations, machinery used was not, because of lack of data; emissions

and provide recommendations based on the findings of the from tomato waste were not considered either.

preceding phases of the LCA, and to report the results of the As mentioned earlier, an LCA can help identify

life cycle interpretation in a transparent manner. potential environmental tradeoffs. However, converting the

Provide a readily understandable, complete, and impact results to a single score requires the use of value

consistent presentation of the results of an LCA study, in judgments, which must be applied by the commissioner of

accordance with the goal and scope of the study (ISO, 1998b). the study or the modeler. This can be done in different ways

The purpose of conducting an LCA is to better inform such as through the use of an expert panel, but it cannot be

decision-makers by providing a particular type of information done based solely on natural science.

(often unconsidered), with a life cycle perspective of

environmental and human health impacts associated with each Environmental supply chain management:

product or process. However, LCA does not take into account One of the most significant paradigm shifts of modern

technical performance, cost, or political and social business management is that individual no longer compete

acceptance. Therefore, it is recommended that LCA be used as solely autonomous entities, but rather as supply chains

in conjunction with these other parameters. (Christopher, 1998). Executives are becoming aware that the

successful co-ordination, integration and management of key

Conclusions, recommendations and reporting : business processes across members of the supply chain will

The objective of this step is to interpret the results of determine the ultimate success of the single enterprise (Vorst

the life cycle impact assessment (not the LCI) to determine van der, 2000).

which product/process has the overall least impact to human Recently, more attention has been given to

health and the environment, and/or to one or more specific environmental supply chain management (ESCM) defined as

areas of concern as defined by the goal and scope of the “the set of supply chain management policies held, action

study. taken, and relationship formed in response to concerns

If an LCIA stops at the characterization stage, the LCIA related to the natural environment with regard to the design,

interpretation is less clear-cut. The conclusions and acquisition, production, distribution, use, reuse and disposal

recommendations rest on balancing the potential human of the firm’s goods and services” (Zsidisin and Siferd, 2001).

health and environmental impacts in the light of study goals Life cycle assessment (LCA) can be seen as main instrument

and stakeholder concerns. of ESCM. LCA is a context-dependant tool.

Limitations of conducting an LCA: Environmental care strategies, type of LCA and supply

Performing an LCA can be resource and time intensive. chains (Fig. 2):

Depending upon how thorough an LCA the user wishes to Different organizations strive for different goals, which

conduct, gathering the data can be problematic, and the impact the type of LCA that is most suitable in a specific

availability of data can greatly impact the accuracy of the situation. Following care strategies applicable to individual

final results. Therefore, it is important to weigh the companies and supply chains (Vermaak, 1995; Spliethoff and

availability of data, the time necessary to conduct the study, van der Kolk, 1991; van Koppen and Hagelaar, 1998):

and the financial resources required against the projected Process oriented strategy: strive for control of the

benefits of the LCA. environmental burden caused by the production process by

LCA will not determine which product or process is means of production integrated measures that achieve both

Internat. J. agric. Engg., 6(2) Oct., 2013: 558-563

HIND AGRICULTURAL RESEARCH AND TRAINING INSTITUTE

561

LIFE CYCLE ASSESSMENT OF FOOD

compliance with governmental rules and regulation and a

Supply chain better return. Examples are new technologies to save water

environmental care or raw materials.

strategy

– Compliance oriented strategy: Comply with rules

Type of chain Type of

and regulation with the help of end-of-pipe technique. Perfect

structure environmental chain examples are a water clearance installation and filters on

performance chimneys to diminish a particular kind of emission.

LCA based: – Market oriented strategy: Aim for the reduction of

- Information need

environmental burden caused by the design of the product to

achieve competitive advantage. In this stage of environmental

- Execution goals

care the R & D department also incorporates the

environmental aspects in the design process.

Fig. 2 : Research model- environmental supply chain LCA of some foods (Table 1).

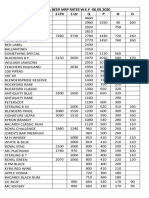

Table 1 : Life cycle assessment of some foods

Sr. Product Impact on environment Reason Suggestion References

No.

1. Bread Photo-oxidant formation, Baking process and nitrogen Organic production of wheat Andersson and

Eutrophication fertilizer used in wheat Ohlsson, 1999;

cultivation Holderbeke et al.,

2003; Braschkat et al.,

2003.

2 Beer Emission of GHG (Global wort production followed by Reusable glass bottles Takamoto et al., 2004

warming) filtration and transportation

3. Tomato ketchup Acidification Geographical location and Prepare less concentrated Andersson et al., 1998;

type of tomato paste tomato paste Andersson and

Ohlsson, 1999

4. Dairy products High consumption of water Pesticide use for feed Reduce nutrient surplus in Williams et al., 2006;

and energy, the discharge of growing, water for cleaning farms, less use of pesticide in Cederberg and

effluent with high organic and drinking imported concentrated feeds, Mattsson, 2000

components and on-farm fodder

(eutrophication) production, a greater use of

concentrated feed,

5. Rice Greenhouse gas (GHG) Cultivation process, Use good variety of rice, large Kasmaprapruets et al.

emissions (global warming) parboiling of rice by local industries for parboiling 2009; Breiling et al.,

small processors, process, sea transporting. 1999; Roy et al. 2005.

transportation

6. Meals (wheat, soy, CO2 emission Cultivation and processing Higher emission for protein- Ozawa and Inaba,

sugar, tomato, oil, rich products followed by 2006.

cooked rice, meat) carbohydrate- rich products.

7. Potato Global warming and Cultivation and shifting from conventional to Williams et al., 2006;

Eutrophication transportation organic production Mattsson and Wallén

2003.

8. Meat Global warming, Feeding length, feed shorter feeding length, organic Ogino et al., 2004;

eutrophication, land use, production and type of feed, farming, Replacing soya meal Williams et al., 2006;

human toxicity animal housing and manure feed by pea and rapeseed- Nemecek, 2006; Roy et

storage cakes, Chicken is most al., 2008

efficient followed by pork and

beef is the least efficient.

9. Sugar beet Eutrophication, resource Pesticides, acidification Genetically modified Haas et al., 2001

depletion herbicide tolerant variety

10. Coffee packaging Resource depletion, global Manufacturing of package Use of polyaminate bags Monte et al., 2005

warming and transportation instead of metallic cans

11. Frozen orange juice Global warming Cultivation and processing Good agricultural practices Coltro et al., 2008

12. Waste management Human and eco toxicity and Processing of food (raw Incineration, incineration after Hirai et al. (2000)

resource depletion material) bio-gasification, bio

gasification followed by

composting and composting

Internat. J. agric. Engg., 6(2) Oct., 2013: 558-563

562 HIND AGRICULTURAL RESEARCH AND TRAINING INSTITUTE

M.S. SATPUTE, A.G. LAMDANDE, V.D. KADAM AND S.R. GARUD

Conclusion : Hirai, Y., Murata, M., Sakai, S. and Takatsuki, H. (2000). Life

Adding life cycle assessment to the decision-making cycle assessment for food waste recycling and management. In:

process provides an understanding of the human health and Proceedings of the Fourth International Conference on EcoBalance,

environmental impacts that traditionally is not considered Tsukuba, Japan.

when selecting a product or process. This valuable Holderbeke, M.V., Sanjuán, N., Geerken, T. and Vooght, D.D.

information provides a way to account for the full impacts ( 2003). The history of bread production: using LCA in the past. In:

of decisions, especially those that occur outside of the site Proceedings of the Fourth International Conference on Life Cycle

that are directly influenced by the selection of a product or Assessment in the Agri-Food Sector, Bygholm, Denmark.

process. ISO 14040 (1997). Environmental management – life cycle assessment

LCA has been done on large variety of food products – goal and scope definition, inventory analysis, Geneva: International

across the world but it is least developed and studied in India. Organization for Standardization (ISO).

As we are bound voluntarily to reduce our carbon emission Kasmaprapruet, S. Paengjuntuek, W., Saikhwan, P. and

in the Copanhegan Summit, there is lot of scope for Phungras-sami, H. (2009). Life cycle assessment of milled rice

implementing the LCA. production : case study in Thailand. Eur. J. Sci. Res., 30 : 195-203.

Remember, LCA is a tool to better inform decision- Mattsson, B. and Wallen, E. (2003). Environmental LCA of organic

makers and should be included with other decision criteria, potatoes. In: Proceedings of the 26 th International Horticultural

such as cost and performance, to make a well-balanced Congress, ISHS, Acta Hort., 691.

decision.

Monte, M.D., Padoano, E. and Pozzetto, D. (2005). Alternative

coffee packaging: an analysis from a life cycle point of view. J. Food

Authors’ affiliations: Engg., 66 (4) : 405– 411.

A.G. LAMDANDE, Aditya College of Food Technology, BEED (M.S.) INDIA

Ogino, A., Kaku, K. and Shimada, K. (2004). Environmental

V.D. KADAM, College of Food Technology, Naigaon, NANDED (M.S.) INDIA impacts of the Japanese beef fattening system with different feeding

S.R. GARUD, K.S.K. alias ‘Kaku’ College of Food Technology, BEED (M.S.) lengths as evaluated by a life cycle assessment method. J. Animal

INDIA Sci., 82 (7) : 2115–2122.

Ozawa, T. and Inaba, A. (2006). Life cycle inventory analysis on

REFERENCES meals: efforts of the food study group, the Institute of Life Cycle

Assessment, Japan. In: Proceedings of the Fifth AIST Workshop on

Andersson, K. and Ohlsson, T. (1999a). Including environmental

LCA for Asia Pacific Region, Tsukuba, Japan.

aspects in production development: A Case Study of tomato ketchup

wtl, 32, 134–141. Roy, P., Orikasa, T., Nei, D., Okadome, H., Nakamura, N. and

Shiina, T. (2008). A comparative study on the life cycle of different

Andersson, K. and Ohlsson, T. (1999b). Life cycle assessment

types of meat. In: Proceedings of the Third LCA Society Research

of bread produced on different scales. Int. J. LCA, 4 : 25–40

Symposium, Nagoya, Japan.

Andersson, K., Ohlsson, T. and Olsson, P. (1998). Screening

Spliethoff, H. and van der Kolk, J. (1991). Bedrijfsmilieuzorg :

life cycle assessment (LCA) of tomato ketchup: a case study. J.

Ontwikkelingen in en samenspel tussen technogic en organisate. In

Cleaner Prod., 6 (3–4) : 277–288.

T. Mol, G. Spaargaren and B. Klapwijk (Eds), Technologie en

Breiling, M., Tatsuo, H. and Matsuhashi, R. (1999). Contribution Milieubeheer (pp. 131-146). Den Haag : SDV (in Dutch).

of rice production to Japanese greenhouse gas emissions applying life

cycle assessment as a methodology. University of Tokyo, Japan. Takamoto, Y., Mitani, Y., Takashio, M., Itoi, K. and Muroyama,

K. (2004). Life cycle inventory analysis of a beer production process.

Cederberg, C. and Mattsson, B. (2000). Life cycle assessment Master Brewers Assoc. America, 41 (4) : 363–365.

of milk production – a comparison of conventional and organic farming.

J. Cleaner Prod., 8 (1) : 49–60. Van Koppen, C.S.A. and Hagelaar, J.L.F. (1998). Milieuzorg als

strategische keuze : van bedrijfsspecifieke situatie naar

Christopher, M.G. (1998). Logistics and Supply Chain milieuzorgraytematiek. Bedrijfskunde, 70 (1) : 45-51 (in Dutch)

Management; strategies for reducing costs and improving services,

Pitman Publishing, London. Vermaak, H. (1995). Strategieen voor groen concurreren. Holland/

Belgim Management Review, 45 : 80-87 (M. Dutch)

Coltro, L., Mourad, A.L., Germer, S.P.M. and Mendonça, T.A.

(2008). Proc. of the 6th Int. Conf. on LCA in the Agri-Food Sector, Vorst, van der Jack G.A.J. (2000). Effective food supply chains;

Zurich. pp. 228-233. generating, modelling and evaluating supply chain scenarios, PhD-

thesis Wageningen University, the Netherlands.

Haas, G., Wetterich, F. and Köpke, U. (2001). Comparing

intensive, extensified and organic grassland farming in southern Zsidisin, G.A. and Siferd, S.P. (2001). Environmental Purchasing:

Germany by process life cycle assessment. Agric., Ecosystems & a framework for theory development. European J. Purchasing &

Supply Mgmt., 7:61-73

6Year

Environ., 83 (2) : 43–53.

th

of Excellence

Internat. J. agric. Engg., 6(2) Oct., 2013: 558-563

HIND AGRICULTURAL RESEARCH AND TRAINING INSTITUTE

563

View publication stats

Potrebbero piacerti anche

- Quantification of Sustainability Indicators in the Food SectorDa EverandQuantification of Sustainability Indicators in the Food SectorNessuna valutazione finora

- DIPAKE Obtaining Sustainable Production From The Product Design Analysis PDFDocumento23 pagineDIPAKE Obtaining Sustainable Production From The Product Design Analysis PDFStericho FerdinanNessuna valutazione finora

- Sustainability Metrics and Indicators of Environmental Impact: Industrial and Agricultural Life Cycle AssessmentDa EverandSustainability Metrics and Indicators of Environmental Impact: Industrial and Agricultural Life Cycle AssessmentNessuna valutazione finora

- Bibin Seminar TopicDocumento6 pagineBibin Seminar TopicNikhil NambiarNessuna valutazione finora

- Life Cycle Assessment ChapterDocumento10 pagineLife Cycle Assessment ChaptertazmaneasNessuna valutazione finora

- Assessment Emerging Approaches, Challenges and Opportunities in Life CycleDocumento6 pagineAssessment Emerging Approaches, Challenges and Opportunities in Life CycleKenan SaatciogluNessuna valutazione finora

- Life Cycle AssessmentDocumento6 pagineLife Cycle Assessmentpartha das sharmaNessuna valutazione finora

- Life Cycle AssessmentDocumento5 pagineLife Cycle Assessmentgabriella nzomoNessuna valutazione finora

- Lca Reference DocumentDocumento9 pagineLca Reference Documentid22m1005Nessuna valutazione finora

- What Is Life Cycle Assessmen1Documento10 pagineWhat Is Life Cycle Assessmen1Laxmi LamichhaneNessuna valutazione finora

- Comparing The Environmental Impacts of Paracetamol Dosage Forms Using Life Cycle AssessmentDocumento21 pagineComparing The Environmental Impacts of Paracetamol Dosage Forms Using Life Cycle Assessmentde22Nessuna valutazione finora

- Int. J. Production Economics: M. Gaussin, G. Hu, S. Abolghasem, S. Basu, M.R. Shankar, B. BidandaDocumento9 pagineInt. J. Production Economics: M. Gaussin, G. Hu, S. Abolghasem, S. Basu, M.R. Shankar, B. BidandaJanak ValakiNessuna valutazione finora

- Thomas 2020Documento14 pagineThomas 2020erika montesNessuna valutazione finora

- LCAof Sodium HydroxideDocumento12 pagineLCAof Sodium HydroxideSrToshiNessuna valutazione finora

- Oen751 Green Building Design Important QuestionDocumento122 pagineOen751 Green Building Design Important QuestionNagarajanNessuna valutazione finora

- ISO14040 Life Cycle Assessment LASasatoolforeffectiveenvironmentallyfriendlywastemanagementinthe Food IndustryDocumento11 pagineISO14040 Life Cycle Assessment LASasatoolforeffectiveenvironmentallyfriendlywastemanagementinthe Food IndustrySanoop PrakasanNessuna valutazione finora

- Life Cycle Assessment (ISO 14040, ISO 14044)Documento11 pagineLife Cycle Assessment (ISO 14040, ISO 14044)Takács ZsuzsannaNessuna valutazione finora

- Life Cycle Assessment and Its ApplicationsDocumento39 pagineLife Cycle Assessment and Its ApplicationsAmol MahajanNessuna valutazione finora

- Higg Index 2-6-9789812871633-c2-GDocumento37 pagineHigg Index 2-6-9789812871633-c2-GRanjit SamalNessuna valutazione finora

- Emerging Approaches, Challenges and Opportunities in Life Cycle AssessmentDocumento6 pagineEmerging Approaches, Challenges and Opportunities in Life Cycle AssessmentJoãoPauloAzevedoNessuna valutazione finora

- Analisis Dan Rekayasa Proses Produksi Untuk Mengendalikan: Environmental Impact Menggunakan Metode LCADocumento10 pagineAnalisis Dan Rekayasa Proses Produksi Untuk Mengendalikan: Environmental Impact Menggunakan Metode LCAHendixieNessuna valutazione finora

- Waste Literature Review FinalDocumento12 pagineWaste Literature Review FinalAdegoke Teniola100% (1)

- GCSM2010final2 SCFDocumento7 pagineGCSM2010final2 SCFNhi LêNessuna valutazione finora

- Sustainability of Bioprocesses and Life Cycle Assessement (LCA)Documento48 pagineSustainability of Bioprocesses and Life Cycle Assessement (LCA)MarinaNessuna valutazione finora

- 1 s2.0 S0959652609002820 MainDocumento11 pagine1 s2.0 S0959652609002820 Mainprem kumarNessuna valutazione finora

- Business Tool For SustainabilityDocumento50 pagineBusiness Tool For SustainabilityMarcelino Putra PerdanaNessuna valutazione finora

- Life Cycle AssesmentDocumento33 pagineLife Cycle AssesmentLakshmi PrabhaNessuna valutazione finora

- Scenarios For Ecodesign in Loudspeakers MotorDocumento12 pagineScenarios For Ecodesign in Loudspeakers MotorHenri DesvalleesNessuna valutazione finora

- LCA Lesson 1Documento17 pagineLCA Lesson 1Ignatius Yan RosarioNessuna valutazione finora

- Sac & HiggsDocumento36 pagineSac & HiggssimaproindiaNessuna valutazione finora

- Foodsource Chapter 2Documento20 pagineFoodsource Chapter 2Venii Putra Ar-RassyidNessuna valutazione finora

- Guide - Product-Related Environmental Performance Indicators - ENDocumento40 pagineGuide - Product-Related Environmental Performance Indicators - ENArmand LiviuNessuna valutazione finora

- Norris2006 Article SocialImpactsInProductLifeCyclDocumento8 pagineNorris2006 Article SocialImpactsInProductLifeCyclCarlos Mauricio Rondon TijaroNessuna valutazione finora

- Assessing Social Impacts in A Life Cycle Perspective-Lessons LearnedDocumento5 pagineAssessing Social Impacts in A Life Cycle Perspective-Lessons LearnedDidi SNessuna valutazione finora

- JETEAS - Biopolymers and Bio-Plastics - PublicationDocumento15 pagineJETEAS - Biopolymers and Bio-Plastics - PublicationDr Vijayan Gurumurthy IyerNessuna valutazione finora

- Manajemen Mutu TerpaduDocumento7 pagineManajemen Mutu TerpaduKim HyemiNessuna valutazione finora

- GM - Module 2 Edited 8th Sem Mechanical Engineering VtuDocumento13 pagineGM - Module 2 Edited 8th Sem Mechanical Engineering VtuPhone Pe100% (4)

- Life Cycle Assessment and Its Application To Process Selection, Design and OptimisationDocumento21 pagineLife Cycle Assessment and Its Application To Process Selection, Design and OptimisationAmir JoonNessuna valutazione finora

- CE CenterDocumento11 pagineCE CenterM PatelNessuna valutazione finora

- Life Cycle Assessment of Fertilizer Manufacturing: Indian Institute of Technology, DelhiDocumento31 pagineLife Cycle Assessment of Fertilizer Manufacturing: Indian Institute of Technology, DelhiVijay SinghNessuna valutazione finora

- Life Cycle AssessmentDocumento10 pagineLife Cycle AssessmentWade Coleman100% (1)

- Sustainability ArticleDocumento9 pagineSustainability ArticlesdfgvbnhjvNessuna valutazione finora

- Assessing The Ability of The Cradle To Cradle Certified™ Products Program To Reliably Determine The Environmental Performance of ProductsDocumento19 pagineAssessing The Ability of The Cradle To Cradle Certified™ Products Program To Reliably Determine The Environmental Performance of Productssb200Nessuna valutazione finora

- Aula 7 Artigo 1Documento11 pagineAula 7 Artigo 1rafaeldesconsiNessuna valutazione finora

- 2013 CIRP MFG & TechDocumento11 pagine2013 CIRP MFG & TechSafwan AltaraziNessuna valutazione finora

- Chapter 1Documento6 pagineChapter 1Crazy MechonsNessuna valutazione finora

- (2014) Sustainable Production, Consumption, and Livelihoods - Global and Regional Research PerspectivesDocumento12 pagine(2014) Sustainable Production, Consumption, and Livelihoods - Global and Regional Research PerspectivesAndré ZidaneNessuna valutazione finora

- Eco LabelDocumento14 pagineEco LabelTrusha HaribhaktiNessuna valutazione finora

- Assignment 2Documento8 pagineAssignment 2anon_926824359Nessuna valutazione finora

- Sustainable Manufacturing DavimDocumento20 pagineSustainable Manufacturing DavimtalhawasimNessuna valutazione finora

- Fpac-Lca White Paper - FinalDocumento24 pagineFpac-Lca White Paper - FinalartupsetNessuna valutazione finora

- LCA in Food ProcessingDocumento13 pagineLCA in Food Processingfernando MurciaNessuna valutazione finora

- GSCP IjreamDocumento5 pagineGSCP IjreamAnil DubeNessuna valutazione finora

- Hosseinijou 2014Documento26 pagineHosseinijou 2014Carlos Mauricio Rondon TijaroNessuna valutazione finora

- 3.0 Sytem Tools For IE-LCADocumento37 pagine3.0 Sytem Tools For IE-LCAIshega AdamNessuna valutazione finora

- Life Cycle Approaches To Sustainable Consumption A Critical ReviewDocumento12 pagineLife Cycle Approaches To Sustainable Consumption A Critical ReviewAmir JoonNessuna valutazione finora

- Sustainable Manufacturing A PrimerDocumento5 pagineSustainable Manufacturing A PrimerEditor IJTSRDNessuna valutazione finora

- Environmental and Social Life Cycle Assessment of Bamboo BicycleDocumento12 pagineEnvironmental and Social Life Cycle Assessment of Bamboo BicycleMariana EneNessuna valutazione finora

- Evalution Tool (1) AmbientalDocumento13 pagineEvalution Tool (1) AmbientalFrancia E. LópezNessuna valutazione finora

- Environmental Impact Evaluation Using GR 76654082Documento7 pagineEnvironmental Impact Evaluation Using GR 76654082YunitaNessuna valutazione finora

- Menu DietDocumento11 pagineMenu DietKrisnaNessuna valutazione finora

- Jurnal DAMPAK PERUBAHAN IKLIM DAN STRATEGI ADAPTASI TANAMAN BUAH DAN SAYURAN DI DAERAH TROPISDocumento12 pagineJurnal DAMPAK PERUBAHAN IKLIM DAN STRATEGI ADAPTASI TANAMAN BUAH DAN SAYURAN DI DAERAH TROPISDefani IhsaNessuna valutazione finora

- Bhojan As Per ScripturesDocumento3 pagineBhojan As Per Scripturesmaverick6912Nessuna valutazione finora

- Project of In-Plant Training On Avalon Cosmetics Pvt. LTDDocumento77 pagineProject of In-Plant Training On Avalon Cosmetics Pvt. LTDRAHUL CHAUDHARYNessuna valutazione finora

- EjerciciosPresentTenses 210907 171536Documento10 pagineEjerciciosPresentTenses 210907 171536Andrea Martinez JiménezNessuna valutazione finora

- Dairy Business PlanDocumento19 pagineDairy Business Planvinay kumar0% (1)

- Eloor Industrial Health Study - Research Adviser-Dr. Rajan R PatilDocumento27 pagineEloor Industrial Health Study - Research Adviser-Dr. Rajan R PatilDr. Rajan R PatilNessuna valutazione finora

- Coc2: Conduct of Competency Assessment Assessors Script: A. PrologueDocumento4 pagineCoc2: Conduct of Competency Assessment Assessors Script: A. PrologueKringmehNessuna valutazione finora

- X12 - Skarda's MirrorDocumento54 pagineX12 - Skarda's Mirrormadcap01100% (3)

- Fleshing Out Curse of Strahd: Barovian Player PrimerDocumento8 pagineFleshing Out Curse of Strahd: Barovian Player PrimerWarwick MarrisonNessuna valutazione finora

- Coca-Cola (Often Referred To Simply As Coke) Is ADocumento10 pagineCoca-Cola (Often Referred To Simply As Coke) Is ATrúc HoàngNessuna valutazione finora

- Liquor & Beer MRP Rates Wef 17.12.2019 (1) - 1Documento2 pagineLiquor & Beer MRP Rates Wef 17.12.2019 (1) - 1Kondu Krishna Vamsi ChowdaryNessuna valutazione finora

- Energy Drink Exploritory PaperDocumento7 pagineEnergy Drink Exploritory PaperJohn GoodmanNessuna valutazione finora

- Recipe For A Healthy Fruit Salad Activity CardDocumento4 pagineRecipe For A Healthy Fruit Salad Activity CardboobooNessuna valutazione finora

- ExcelDocumento1 paginaExcelJosh KempNessuna valutazione finora

- SCM of NirulsDocumento10 pagineSCM of NirulsajaykhoslaNessuna valutazione finora

- Kellogg's All-Bran - IPA Case StudyDocumento11 pagineKellogg's All-Bran - IPA Case Studyallan61Nessuna valutazione finora

- Solowiej2016 - Processed Cheese AnaloguesDocumento9 pagineSolowiej2016 - Processed Cheese AnaloguesDinoNessuna valutazione finora

- Rules of Subject Verb Agreement Are All You NeedDocumento8 pagineRules of Subject Verb Agreement Are All You Needalexandra jacobNessuna valutazione finora

- BBQ Chicken Tenders: IngredientsDocumento18 pagineBBQ Chicken Tenders: IngredientsBawen MuralitharanNessuna valutazione finora

- Kids BookDocumento12 pagineKids Bookthings2learnksNessuna valutazione finora

- World07 08 15Documento31 pagineWorld07 08 15The WorldNessuna valutazione finora

- Jonathan's Last Day: True FalseDocumento2 pagineJonathan's Last Day: True FalseDiego Luis Gonzalez RestrepoNessuna valutazione finora

- Fruit and Vegetable Canning Business PlanDocumento67 pagineFruit and Vegetable Canning Business Plankyaq001100% (1)

- Leafu PDFDocumento362 pagineLeafu PDFWen RollandNessuna valutazione finora

- Resources DistributionDocumento10 pagineResources DistributionDarshan KanganeNessuna valutazione finora

- C4.8 CalculationsChemsheets GCSE 1105 (Titrations 1)Documento2 pagineC4.8 CalculationsChemsheets GCSE 1105 (Titrations 1)Bee AbeilleNessuna valutazione finora

- Class 12th Chemistry Project On Cleaning Action of SoapsDocumento22 pagineClass 12th Chemistry Project On Cleaning Action of SoapsPremlata JoshiNessuna valutazione finora

- Important Drug Nutrient Interactions: Pamela MasonDocumento35 pagineImportant Drug Nutrient Interactions: Pamela MasonRijantono Franciscus MariaNessuna valutazione finora

- DeliveryDocumento12 pagineDeliveryBeto De AlmeidaNessuna valutazione finora