Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

General Specification For Wire Mesh Demisters: Fgeir Fmfgitg

Caricato da

priti kumariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

General Specification For Wire Mesh Demisters: Fgeir Fmfgitg

Caricato da

priti kumariCopyright:

Formati disponibili

STANDARD SPECIFICATION No.

101 ENGINEERS GENERAL SPECIFICATION

fgeir fMfgitg INDIA LIMITED FOR WIRE MESH DEMISTERS 6-14-0017 Rev. 3

>Ten ofemit' im aflOrs0 IA Goot of India Undertaking)

Page 1 of 6

*111-111-ti i cl i 1 kill

GENERAL SPECIFICATION

FOR WIRE MESH DEMISTERS

07.11.2013 REVISED & ISSUED AS STANDARD

3 7t11 Sc

SPECIFICATION

REAFFIRMED & REISSUED AS STANDARD

2 17.09.2008 VDY HCN AKG VC

SPECIFICATION

REVISED & ISSUED AS STANDARD

1 22.08.2003 SK HCN RKA SKG

SPECIFICATION

0 07.05.1997 ISSUED AS STANDARD SPECIFICATION HCN SKK RKA AS

Standards Standards

Rev. Committee Bureau

Prepared Checked

Date Purpose Convenor Chairman

No. by by

Approved by

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 4452 of 7025

STANDARD SPECIFICATION No.

ENGINEERS GENERAL SPECIFICATION

Ogar Oil&

I .TIM ere4g7 .1,R35711

INDIA LIMITED

(A Goof of Ind.) Undertaking)

FOR WIRE MESH DEMISTERS

Rev. 3

Page 2 of 6

Abbreviations:

ASME : American Society of Mechanical Engineers

AISI : American Iron and Steel Institute

AIA : Authorized Inspection Agency

TIG : Tungsten Insert Gas

Heat & Mass Transfer Standards Committee

Convenor: Mr. Amit Prakash

Members: Mr. Inder Kumar

Mr. Mandip Kapoor

Mr. Ratan Lal (Projects)

Mr. GK Iyer ( Construction )

Copyright EIL — All rights reserved

Format No. 8-00-0001-F1 Rev. 0

Page 4453 of 7025

STANDARD SPECIFICATION No.

0 el ENGINEERS GENERAL SPECIFICATION

fa5leg

etront maga,'

INDIA LIMITED

IA Govt of InMa Undeffak,o9) WIRE MESH DEMISTERS

6-14-0017 Rev. 3

Page 3 of 6

CONTENTS

1.0 SCOPE 4

2.0 REFERENCES 4

3.0 MATERIAL 4

4.0 DESIGN & FABRICATION 4

5.0 SPARES 5

6.0 INSPECTION & TESTING 5

7.0 PACKING & FORWARDING 5

8.0 GUARANTEE 6

9.0 DOCUMENTATION 6

10.0 AS BUILT DOCUMENTATION 6

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 4454 of 7025

STANDARD SPECIFICATION No.

t_Silfazie-i ENGINEERS GENERAL SPECIFICATION

ligar taliteg INDIA LIMITED 6-14-0017 Rev. 3

Uif'~f i4 JOCA.if (A GovI of India Undertaking) FOR WIRE MESH DEMISTERS

Page 4 of 6

1.0 SCOPE

This specification covers the general requirements for design, fabrication, inspection and

supply of knitted wiremesh assemblies (Demisters) in duly packed condition.

The demister assembly(ies) shall consist of wiremesh pad, top and bottom holding grids,

major beams (if specified), bolting/clamps/tie rods/J-bolts/spacer pipes and any other

components which are essential to complete the demister assembly to be installed on supports

welded inside the vessel.

2.0 REFERENCES

Following documents/standards/specifications in their latest edition shall form the basis of

design, fabrication, inspection, testing and acceptance of the demister:

Demister data sheet As per Material Requisition

6-14-0009 Packing, Marking and Shipping Specifications for

Trays and Tower Internals

7-12-0036*/Licensor's standards - Details of Wire Mesh Demister Supports (as

applicable)

7-12-0001 Vessel Tolerances

ASME Sec. II Material Specifications

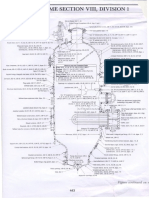

ASME Sec. VIII Div.I Boiler and Pressure Vessel Code

ASME Sec. IX Welding Qualifications

AISI Material Specification for Wires, Spacer Rods etc.

(* Standard 7-12-0036 shall be used for reference only. Final design of demister supports shall

be as per vendor design standards/calculations and shall be submitted to EIL for review prior

to start of fabrication.)

3.0 MATERIAL

All the material used for fabrication & supply of Demister shall be new & of first quality and

shall be duly supported with material test certificates.

4.0 DESIGN & FABRICATION

4.1 Basic details such as demister specification (surface area, voidage, and bulk density), material

of construction, supporting arrangement, manhole size etc. shall be as per drawings/

specification furnished by EIL.

4.2 In the General Arrangement drawing Demister Vendor shall indicate the following outside

dimensions (incase of square / rectangular demister) / diameter:

a) The oversized outside dimensions / diameter to take care of the tolerances/column ovality

defined in applicable Code / EIL Standard 7-12-0001/ drawings for snug fitment. These

dimensions / diameter shall be used for shop inspection of the demister mock up

assembly.

b) The final fit-up dimensions / diameter.

4.3 Demister assembly shall be designed for a net upward thrust of 100 kg/m2 (uniform) due to the

vapour loadings. The assembly should also be able to withstand a concentrated live load of 60

kg at mid point of any of the demister sub-assembly/component.

In addition to the above loading, demister shall be designed to withstand the additional

pressure surges, if specified.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL—All rights reserved

Page 4455 of 7025

STANDARD SPECIFICATION No.

k3111 ENGINEERS GENERAL SPECIFICATION

22- es

5fgai cream „prom, INDIA LIMITED

(A Govt of India Undertaking)

WIRE MESH DEMISTERS

6-14-0017 Rev. 3

Page 5 of 6

4.4 All demister sub-assemblies shall be sized to facilitate installation inside the column/vessel

through the manhole. These shall rest on support ring/cleats welded inside vessel/column by

others.

4.5 Tentative details of the support rings/cleats, mid span beams (wherever required) grid details

& fixing arrangements shall be as given in the referenced documents listed in clause 2.0.

Vendor is advised to follow the same for the design/fabrication in their scope of work. Vendor

may, however, suggest any improvement in the design. Such suggestions will however be

reviewed/ approved by EIL/Client and can be followed by the vendor only on written

acceptance by EIL/Client.

4.6 All internal bolting shall be minimum M10 size and shall be compatible with Demister

material. All bolting shall be provided with locknuts.

4.7 Welding

All welding shall be done by metal arc welding. For welding on thinner gauge sheets TIG

welding is preferred. Welding wherever required, is to be done by qualified and approved

welders using the suitable fillers and fluxes recommended for materials used for the

fabrication.

5.0 SPARES

5.1 Constructional Spares

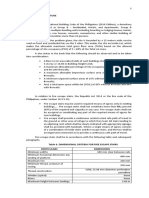

Following constructional spares shall be supplied:

Fasteners - bolts, nuts, clamps, spacer pipes, - 10% (minimum 4 Nos. of each type/size)

J-bolts etc.

5.2 Operational Spares

In addition to Constructional spares as indicated above, vendor shall also supply following

operational spares:

Fasteners - bolts, nuts, clamps, spacer pipes, - 10% (minimum 4 Nos. of each type/size)

J-bolts etc.

6.0 INSPECTION AND TESTING

6.1 The material, fabrication and trial assembly shall be Inspected by the EIL/Client and/or their

AIA.

6.2 Complete demister assemblies (along with grids) and Beams etc. shall be assembled as floor

mock-up & shall be offered for final inspection. Assembly shall be checked for oversized

dimensions as per the approved drawing.

7.0 PACKING & FORWARDING

The individual components shall be marked with proper item/part number as given in the

drawings to facilitate identification at site. Demister shall be wrapped in polythene and

supplied in wooden cases for damage free transportation. For all other requirements refer EIL

Specification No. 6-14-0009.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL—All rights reserved

Page 4456 of 7025

STANDARD SPECIFICATION No.

ENGINEERS GENERAL SPECIFICATION

5'1:

gar tle-e-g w INDIA LIMITED

Wert eiCarre ZINJER/5,

11 IA Govt of India Undettahing)

FOR WIRE MESH DEMISTERS

6-14-0017 Rev. 3

Page 6 of 6

8.0 GUARANTEE

Vendor shall guarantee the design, performance (i.e. separation efficiency, and pressure drop),

material, fabrication and workmanship for the demisters for the period as outlined in General

Purchase Conditions.

9.0 DOCUMENTATION

Documents/drawings shall be furnished as per the 'Vendor Data Requirement' enclosed with

requisition / feed document. All the drawings prepared by the vendor shall be on AUTOCAD.

10.0 AS BUILT DOCUMENTATION

Nos. and type of documents to be supplied as 'As-built' document shall be per 'Vendor Data

Requirement' enclosed with requisition / feed document.

Shop changes made by Vendor after approval of drawings under Code-1 by EIL and

deviations granted in deviation permits, if any, shall be marked in hard copy of drawings

which shall then be stamped 'As-built' by the vendor. These 'As-built' drawings shall be

reviewed and stamped by Authorised Inspector also. Vendor shall prepare scanned image files

of all marked-up 'As-built' drawings. Vendor shall also incorporate the above changes in the

native soft files of the drawings.

Authorised Inspector shall ensure/certify completeness of Vendor's Final/As-built documents

before equipment dispatch.

In addition, vendor shall also incorporate site changes, if any, based on mismatch observed at

site and resubmit the 'As-built' documents.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 4457 of 7025

Potrebbero piacerti anche

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocumento1 paginaElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanNessuna valutazione finora

- Table-1 Scope of Work Supply (MR For ACHE)Documento6 pagineTable-1 Scope of Work Supply (MR For ACHE)Avinash ShuklaNessuna valutazione finora

- Standard Specification For Storage TanksDocumento22 pagineStandard Specification For Storage TanksJITENDER KUMAR75% (4)

- Sex, Law, and Society in Late Imperial China (Law, Society, and Culture in China) by Matthew SommerDocumento444 pagineSex, Law, and Society in Late Imperial China (Law, Society, and Culture in China) by Matthew SommerFer D. MONessuna valutazione finora

- 6-15-0091 STD Spec For Hardness Req of Static EqDocumento5 pagine6-15-0091 STD Spec For Hardness Req of Static EqMurli ramchandranNessuna valutazione finora

- 6-24-0004 Catridge FilterDocumento9 pagine6-24-0004 Catridge FilterMurli ramchandran100% (1)

- A869-6-44-0005 PMS For RevampDocumento950 pagineA869-6-44-0005 PMS For RevampMastram HatheshNessuna valutazione finora

- Astm F436.04 PDFDocumento6 pagineAstm F436.04 PDFWelington Volpatto MoraisNessuna valutazione finora

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocumento25 paginePage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidNessuna valutazione finora

- ASME Formula DerivationDocumento1 paginaASME Formula Derivationvm153748763Nessuna valutazione finora

- Index - Amendment To TBPDocumento4 pagineIndex - Amendment To TBPVineet 01Nessuna valutazione finora

- V754749001XC (241 242) PDFDocumento5 pagineV754749001XC (241 242) PDFErin JohnsonNessuna valutazione finora

- Engineering Group: Kuwait Oil Company (K.S.C.)Documento14 pagineEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNessuna valutazione finora

- 16 B 06 HDocumento20 pagine16 B 06 HVaibhav Bhoir0% (1)

- Calcs 4Documento19 pagineCalcs 4Syariful Maliki NejstaršíNessuna valutazione finora

- Etank Full ReportDocumento108 pagineEtank Full ReportFaizal Sattu100% (1)

- Sphere Design and Thickness Calculation (Div 2)Documento6 pagineSphere Design and Thickness Calculation (Div 2)Asad KhanNessuna valutazione finora

- 6946-6-77-0005 Rev1Documento24 pagine6946-6-77-0005 Rev1Karthick VenkatswamyNessuna valutazione finora

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocumento127 paginePC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresNessuna valutazione finora

- Annexure-2 Tailing Lug DesignDocumento2 pagineAnnexure-2 Tailing Lug DesignRajeshNessuna valutazione finora

- Superheated Steam SeparatorDocumento4 pagineSuperheated Steam SeparatorGanesh BhardwajNessuna valutazione finora

- Procedure For Positive Material Identification at Vendor'S WorksDocumento7 pagineProcedure For Positive Material Identification at Vendor'S WorksAjay BaggaNessuna valutazione finora

- Design of Partition PlateDocumento5 pagineDesign of Partition Platepippo2378793Nessuna valutazione finora

- Spreaer Beam&Lifting Line Beam p3Documento2 pagineSpreaer Beam&Lifting Line Beam p3Sabrang LorNessuna valutazione finora

- Data Sheet For T-8101.RevCDocumento5 pagineData Sheet For T-8101.RevCSuresh SjNessuna valutazione finora

- BS-VI Projects For Panipat Refineriy of IOCL: Column/ Tower Carbon Stee L, CladDocumento301 pagineBS-VI Projects For Panipat Refineriy of IOCL: Column/ Tower Carbon Stee L, CladPradip ShindeNessuna valutazione finora

- Raw Material & Bought Out Items InspectionDocumento3 pagineRaw Material & Bought Out Items InspectionSuraj ShettyNessuna valutazione finora

- Bulk Air Eliminator R1Documento1 paginaBulk Air Eliminator R1hydrothermsNessuna valutazione finora

- ETHANOL (6.0D X 8.825 H), Rev. 0Documento26 pagineETHANOL (6.0D X 8.825 H), Rev. 0Sangramkeshari BejaNessuna valutazione finora

- Floating Roof Design (Liquid Hight)Documento4 pagineFloating Roof Design (Liquid Hight)Hamid MansouriNessuna valutazione finora

- Stress RelievingDocumento1 paginaStress RelievingCruz Gabriel Rosetti100% (1)

- Reinforcement Pad CalculationDocumento5 pagineReinforcement Pad Calculationsada siva100% (1)

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWDocumento5 pagineBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiNessuna valutazione finora

- Cyclic Service - Intergraph CADWorx & AnalysisDocumento2 pagineCyclic Service - Intergraph CADWorx & Analysisisrar khanNessuna valutazione finora

- SP-2069 Specification For Pressure VesselsDocumento68 pagineSP-2069 Specification For Pressure Vesselsarjunprasannan7Nessuna valutazione finora

- Sor BPCL KochiDocumento79 pagineSor BPCL KochiPrafulla PatilNessuna valutazione finora

- Mechanical Tender CNG PDFDocumento161 pagineMechanical Tender CNG PDFAWANI SRIVASTAVANessuna valutazione finora

- Double DeckDocumento4 pagineDouble DeckJose CarlosNessuna valutazione finora

- SPC-0804.02-99.90 Rev D3 BEDDDocumento23 pagineSPC-0804.02-99.90 Rev D3 BEDDTimothy LeonardNessuna valutazione finora

- 7-12-0007 Rev6 (Pipe Leg Support)Documento1 pagina7-12-0007 Rev6 (Pipe Leg Support)sumit kumar100% (1)

- Mechanical Design Calculation: DocumentDocumento146 pagineMechanical Design Calculation: DocumentvikramNessuna valutazione finora

- Insulation Thickness TableDocumento9 pagineInsulation Thickness TableSachin MankameNessuna valutazione finora

- Bleed Rings RTJDocumento1 paginaBleed Rings RTJAlessandro1975Nessuna valutazione finora

- Sa 672Documento7 pagineSa 672lalitaliNessuna valutazione finora

- T12026 SACM 0002 N 0 - ProposalDocumento81 pagineT12026 SACM 0002 N 0 - ProposalSubrata DasNessuna valutazione finora

- A 1 KDocumento5 pagineA 1 KSumantrra ChattopadhyayNessuna valutazione finora

- 12 Chaturvedi EIL PresentationDocumento12 pagine12 Chaturvedi EIL Presentationget2anushNessuna valutazione finora

- Spherical Pressure Vessels PDFDocumento10 pagineSpherical Pressure Vessels PDFck19654840Nessuna valutazione finora

- Mechanical Data SheetDocumento7 pagineMechanical Data SheetktejankarNessuna valutazione finora

- Mechanical Datasheet of Black Product (Fuel Oil) Road Tanker Unloading Pump (P-332, P-336)Documento4 pagineMechanical Datasheet of Black Product (Fuel Oil) Road Tanker Unloading Pump (P-332, P-336)Gop MangukiyaNessuna valutazione finora

- Design of Welded Steel Storage Tanks in Accordance With API650 Job DataDocumento4 pagineDesign of Welded Steel Storage Tanks in Accordance With API650 Job DatamirzacogoNessuna valutazione finora

- Microsoft Word - Material Selection GuidelinesDocumento3 pagineMicrosoft Word - Material Selection Guidelinesarjun SinghNessuna valutazione finora

- PMS Rev 0Documento36 paginePMS Rev 0rami ghorbelNessuna valutazione finora

- Checklist For Separator Cum Storage TankDocumento5 pagineChecklist For Separator Cum Storage TankRamalingam PrabhakaranNessuna valutazione finora

- Exterior Mechanical Utility DistributionDocumento106 pagineExterior Mechanical Utility DistributiongabrielNessuna valutazione finora

- 7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionDocumento2 pagine7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionJitender Kumar GuptaNessuna valutazione finora

- Design and Construction of BMW IncineratorDocumento3 pagineDesign and Construction of BMW IncineratorManish PatelNessuna valutazione finora

- Asme Guide For Sec Viii Div 1Documento1 paginaAsme Guide For Sec Viii Div 1siddharth pawarNessuna valutazione finora

- As Built: Rfso, C/W Dip PipeDocumento18 pagineAs Built: Rfso, C/W Dip Piperomeo112976Nessuna valutazione finora

- Standard Specification For Inspection, Flushing and Testing of Piping SystemsDocumento9 pagineStandard Specification For Inspection, Flushing and Testing of Piping SystemsJITENDER KUMARNessuna valutazione finora

- 04 1 Sec IV STD Specs PipingDocumento152 pagine04 1 Sec IV STD Specs PipingdzungNessuna valutazione finora

- KKNNDocumento15 pagineKKNNpriti kumariNessuna valutazione finora

- Packing Marking and Shipping Specifications For Trays and Tower InternalsDocumento6 paginePacking Marking and Shipping Specifications For Trays and Tower Internalspriti kumariNessuna valutazione finora

- Lec6 Principle of Fusion Welding Processes Gas WeldingDocumento13 pagineLec6 Principle of Fusion Welding Processes Gas Weldingpriti kumariNessuna valutazione finora

- Welded Tube To Tubesheet Joints 6-15-0003Documento9 pagineWelded Tube To Tubesheet Joints 6-15-0003priti kumariNessuna valutazione finora

- Long Seam and Circumference Seam SetupDocumento4 pagineLong Seam and Circumference Seam Setuppriti kumariNessuna valutazione finora

- RT Film ReviewDocumento1 paginaRT Film Reviewpriti kumariNessuna valutazione finora

- Head InspectionDocumento7 pagineHead Inspectionpriti kumariNessuna valutazione finora

- (6!44!0051) Technical Notes For PipesDocumento10 pagine(6!44!0051) Technical Notes For Pipespriti kumariNessuna valutazione finora

- Week 14 Report2Documento27 pagineWeek 14 Report2Melaku DesalegneNessuna valutazione finora

- Chemistry Project Paper ChromatographyDocumento20 pagineChemistry Project Paper ChromatographyAmrita SNessuna valutazione finora

- Heat ExchangerDocumento5 pagineHeat Exchangersara smithNessuna valutazione finora

- Risk LogDocumento1 paginaRisk LogOzu HedwigNessuna valutazione finora

- Chuck Eesley - Recommended ReadingDocumento7 pagineChuck Eesley - Recommended ReadinghaanimasoodNessuna valutazione finora

- Case Analysis, Case 1Documento2 pagineCase Analysis, Case 1Aakarsha MaharjanNessuna valutazione finora

- Sony DVD Player Power Circuit DiagramDocumento40 pagineSony DVD Player Power Circuit DiagramHariyadiNessuna valutazione finora

- Additional Material On CommunicationDocumento15 pagineAdditional Material On CommunicationSasmita NayakNessuna valutazione finora

- Long PassagesDocumento12 pagineLong PassagesAml AmlNessuna valutazione finora

- 1 - Unit 3 MCQDocumento11 pagine1 - Unit 3 MCQRAMESH KUMAR MAURYANessuna valutazione finora

- 01 Gyramatic-Operator Manual V2-4-1Documento30 pagine01 Gyramatic-Operator Manual V2-4-1gytoman100% (2)

- Dossat PrinciplesOfRefrigerationDocumento554 pagineDossat PrinciplesOfRefrigerationHernan CobaNessuna valutazione finora

- Serie 20 Sauer DanfossDocumento18 pagineSerie 20 Sauer DanfossCristian100% (1)

- RH 120eDocumento8 pagineRH 120eSawadogo Gustave NapinguebsonNessuna valutazione finora

- PQA824 ManualDocumento100 paginePQA824 ManualElkin AguasNessuna valutazione finora

- Assignment ProblemsDocumento22 pagineAssignment ProblemsPooja Yadav100% (1)

- Awb 4914934813Documento1 paginaAwb 4914934813Juandondr100% (1)

- Configuration Diagrams: Group 80ADocumento24 pagineConfiguration Diagrams: Group 80ASaHdo AbdelHamid100% (1)

- JMPGuitars 18 Watt Tremolo TMB Reverb LayoutDocumento1 paginaJMPGuitars 18 Watt Tremolo TMB Reverb LayoutRenan Franzon GoettenNessuna valutazione finora

- 10 DLAH-Vessel Movement 28 Nov - 7 Dec 2020Documento3 pagine10 DLAH-Vessel Movement 28 Nov - 7 Dec 2020herlambangNessuna valutazione finora

- A Research Paper On DormitoriesDocumento5 pagineA Research Paper On DormitoriesNicholas Ivy EscaloNessuna valutazione finora

- Rail Inspection Vehicle Using Ir Sensor and Spot Marking SystemDocumento63 pagineRail Inspection Vehicle Using Ir Sensor and Spot Marking SystemNarayananNanuNessuna valutazione finora

- Floor DiaphragmDocumento24 pagineFloor DiaphragmChristian LeobreraNessuna valutazione finora

- Transient Thermal Conduction ExampleDocumento14 pagineTransient Thermal Conduction ExampleDevendra BangarNessuna valutazione finora

- THDP-3 Worm Gear Manual Interchangeable Single Punch Tablet PressDocumento8 pagineTHDP-3 Worm Gear Manual Interchangeable Single Punch Tablet Pressdibimrane13Nessuna valutazione finora

- Wbuhs PG ThesisDocumento7 pagineWbuhs PG Thesisgbx272pg100% (2)

- Embargoed: Embargoed Until April 24, 2019 at 12:01 A.M. (Eastern Time)Documento167 pagineEmbargoed: Embargoed Until April 24, 2019 at 12:01 A.M. (Eastern Time)Las Vegas Review-JournalNessuna valutazione finora

- 107 01 Covers and Side Doors A SideDocumento38 pagine107 01 Covers and Side Doors A Sideben vervuurtNessuna valutazione finora

- Maximus MHX DatasheetDocumento5 pagineMaximus MHX Datasheetjulya julyaNessuna valutazione finora