Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hot in Place Recycling (HIPR)

Caricato da

Alok Singh RajawatCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hot in Place Recycling (HIPR)

Caricato da

Alok Singh RajawatCopyright:

Formati disponibili

HOME ABOUT HCME CORE BUSINESS CORPORATE INFO PROJECTS HIGHLIGHTS INFO

HOT IN PLACE RECYCLING (HIPR)

What is HIPR?

Hot In Place Recycling (HIPR) is a process of heating up the existing asphalt pavement surface, loosening it, mixing it with rejuvenating agent with or without new hot mix

material in an on-board pug-mill mixer and laying it back on the same pavement surface, all in a single pass operation.

The Application

With HIPR, the effective depth of scarified pavement layers is up to 50 mm. The primary purpose of the HIPR technique is to correct surface distresses. HIPR provides

solutions to surface crackings, minor ruttings, ravelling and stripping. HIPR can also be used to recoat stripped aggregates, re-establish crown and drainage and modify

aggregate gradation and asphalt content, and improve surface frictional resistance.

"...an on-site method that

rehabilitates deteriorated

bituminous pavements surface with

minimal use of new material..."

L-R : Completed projects : North-South Expressway (Bkt Kayu Hitam – Jitra); FTT 1251 (Jalan Pulau Indah); FT63 (Bkt Ibam – Leban Condong) and FT02 (Temerloh)

The Operations

1. Pavement surface is softened 2. Remixer scarifies the surface material 3. While still hot, the newly remixed 4. Rolled to final compaction.

with radiant convection heat. and mixes the material with recycling agent material is laid down.

and virgin mix.

The Advantages

HIPR offers a viable cost-effective technique for rehabilitation of pavements by using existing in-place materials. HIPR represents the future of pavement technology and

will replace conventional pavement rehabilitation methods.

Cost effective where operations use less manpower and machineries, and a shorter construction time. Saves on the investment in repair costs.

Versatile where pavements are now easy to construct through one pass operations, production is highly mobile, and causes less traffic disruption.

Ecologically Friendly where existing materials can be reused, causes less air pollution and conserves natural resources (quarry product).

The Machinery

REMIXER 4500 PANEL HEATING MACHINE HM 4500

Max. recyling depth : 0 – 60 mm Heating width : 4,500 mm

Working width : 3,000 – 4,500 mm Heating surface : 44.64 m 2 – Infrared heating

Heating performance : 1,445 kW Max. heating capacity : 2,260 kW

Copyright © HCM Engineering Sdn Bhd

HCM Engineering Sdn. Bhd. No 87, Jalan Kampung Pandan,55100 KUALA LUMPUR, Malaysia

Tel: +603 - 9286 4050 Fax: +603 - 9281 5507

Potrebbero piacerti anche

- Recycling Equipments and MethodsDocumento10 pagineRecycling Equipments and MethodsClint Escabal MosenabreNessuna valutazione finora

- An Ambitious Project Taken Up by Kerala PWD (National Highways) - Cold in Place Recycling of Bituminous PavementDocumento4 pagineAn Ambitious Project Taken Up by Kerala PWD (National Highways) - Cold in Place Recycling of Bituminous Pavementdivyadeenu9390Nessuna valutazione finora

- Recycling of Asphalt Pavement (RAP) - SUDDHASHIL PURKAIT - MTech. Geo Tech Civil - 2022-24Documento17 pagineRecycling of Asphalt Pavement (RAP) - SUDDHASHIL PURKAIT - MTech. Geo Tech Civil - 2022-24suddhashil purkaitNessuna valutazione finora

- Reclaimed Asphalt Pavement PDFDocumento5 pagineReclaimed Asphalt Pavement PDFThulasirajan KrishnanNessuna valutazione finora

- Irc RecyclingDocumento64 pagineIrc Recyclingkranthi13Nessuna valutazione finora

- Bituminous Pavement Recycling - Effective Utilization of Depleting Non-Renewable ResourcesDocumento9 pagineBituminous Pavement Recycling - Effective Utilization of Depleting Non-Renewable ResourcestheijesNessuna valutazione finora

- Recent Developments in Ground Improvement Techniques-A ReviewDocumento12 pagineRecent Developments in Ground Improvement Techniques-A ReviewANJITHA A RNessuna valutazione finora

- Recycling of Asphalt Pavements: An OverviewDocumento12 pagineRecycling of Asphalt Pavements: An OverviewProf. Prithvi Singh Kandhal100% (1)

- Matecconf Iceice2016 01059 PDFDocumento4 pagineMatecconf Iceice2016 01059 PDFCHIDI BETHEL CHIMEZIENessuna valutazione finora

- BFC 31802 Chapter 6 ADocumento34 pagineBFC 31802 Chapter 6 AfathullahaizatNessuna valutazione finora

- Monthly Internship ReportDocumento5 pagineMonthly Internship ReportBernie QuepNessuna valutazione finora

- Maintenance of Highway by Surface RecyclDocumento13 pagineMaintenance of Highway by Surface RecyclCivil Engineering Ak ChannalNessuna valutazione finora

- Pavement Evaluation: Pavement Condition Index (PCI) MethodDocumento11 paginePavement Evaluation: Pavement Condition Index (PCI) MethodFaizal HakimiNessuna valutazione finora

- Application of Cipr - Cold in Place ReyclingDocumento18 pagineApplication of Cipr - Cold in Place ReyclingakmalNessuna valutazione finora

- Dynamic Compaction DCDocumento4 pagineDynamic Compaction DCDewa Gede Wahyu WidiarthaNessuna valutazione finora

- IJETR2012003Documento7 pagineIJETR2012003erpublicationNessuna valutazione finora

- Tech - Paper - Assessing RDC Effectiveness - DFI EventDocumento10 pagineTech - Paper - Assessing RDC Effectiveness - DFI Event_seeNessuna valutazione finora

- Lecture 7 ADocumento30 pagineLecture 7 ASajjad HussainNessuna valutazione finora

- BFC 31802 Chapter 5Documento38 pagineBFC 31802 Chapter 5fathullahaizatNessuna valutazione finora

- Building and Environment: SciencedirectDocumento11 pagineBuilding and Environment: SciencedirectAkku DiljithNessuna valutazione finora

- AddtiX Airport PDF (1) - 1 PDFDocumento7 pagineAddtiX Airport PDF (1) - 1 PDFSyahrul PasaribuNessuna valutazione finora

- In-Situ Recycling of A Cement Treated Base Course UsingDocumento14 pagineIn-Situ Recycling of A Cement Treated Base Course UsingHery BudiantoNessuna valutazione finora

- Ap 5 Bitumen Disposal PitsDocumento3 pagineAp 5 Bitumen Disposal Pitsnischal_babuNessuna valutazione finora

- Materiales Calidad ActualesDocumento101 pagineMateriales Calidad ActualesleviagustinNessuna valutazione finora

- Kroenert Sets New StandardsDocumento4 pagineKroenert Sets New Standardsjuergen.blum2743Nessuna valutazione finora

- 33-Article Text-439-1-10-20220129 PDFDocumento10 pagine33-Article Text-439-1-10-20220129 PDFAdityo Bambang WNessuna valutazione finora

- Government Engineering College Civil Engineering Department: Internship Project 2021-22Documento23 pagineGovernment Engineering College Civil Engineering Department: Internship Project 2021-22PranavRajsinh ZalaNessuna valutazione finora

- Foam Bitumen RecyclingDocumento65 pagineFoam Bitumen Recyclingkemas100% (7)

- Austress Menard Pty LTD: Head Office - Sydney 13-15 Lyonpark Road, Macquarie Park NSW 2113Documento1 paginaAustress Menard Pty LTD: Head Office - Sydney 13-15 Lyonpark Road, Macquarie Park NSW 2113Pn EkanayakaNessuna valutazione finora

- J.conbuildmat.2011.10.026 - Questão 3Documento7 pagineJ.conbuildmat.2011.10.026 - Questão 3Bruna GiovanniniNessuna valutazione finora

- DR Fixit Piditop 444 106 1Documento3 pagineDR Fixit Piditop 444 106 1Mohammed Abdul BaseerNessuna valutazione finora

- Assignment 6 - Somesh Siddharth - A1988520002Documento9 pagineAssignment 6 - Somesh Siddharth - A1988520002Somesh SiddharthNessuna valutazione finora

- Executive SummaryDocumento42 pagineExecutive SummaryCarissa May Maloloy-onNessuna valutazione finora

- Methodology Used in Low Cost Housing: H.R. TewaniDocumento6 pagineMethodology Used in Low Cost Housing: H.R. TewaniBasavaraju SNessuna valutazione finora

- Minnesota Heat-Transfer Method For Recycling Bituminous PavementDocumento9 pagineMinnesota Heat-Transfer Method For Recycling Bituminous PavementsefrifamilyNessuna valutazione finora

- High Impact Energy Dynamic CompactionDocumento10 pagineHigh Impact Energy Dynamic CompactionsezaitanyoluNessuna valutazione finora

- Bituminous Pavement RecyclingDocumento4 pagineBituminous Pavement RecyclingMatei PopaNessuna valutazione finora

- B.O.Q. OF Auditorium FOR Proposed National Law University Orissa at Naraj, CuttackDocumento55 pagineB.O.Q. OF Auditorium FOR Proposed National Law University Orissa at Naraj, CuttackSemamlak AdmasuNessuna valutazione finora

- Rehabilitation of Concrete Tank Using Epoxy and FRP LiningDocumento5 pagineRehabilitation of Concrete Tank Using Epoxy and FRP LiningChaitanya ShahNessuna valutazione finora

- Chapter 2Documento35 pagineChapter 2Gbemisola LawalNessuna valutazione finora

- O106960v77 W Brochure KMA240KMA240i 0121 V2 ENDocumento44 pagineO106960v77 W Brochure KMA240KMA240i 0121 V2 ENpotenzaengenhariaNessuna valutazione finora

- Design and Development of Railway Sleepers Using Recycled Waste Tyre Rubber SAROJ Et Al 2019Documento4 pagineDesign and Development of Railway Sleepers Using Recycled Waste Tyre Rubber SAROJ Et Al 2019Nii DmNessuna valutazione finora

- Management of Land Reclamation Quality For Agricultural Use in Opencast MiningDocumento7 pagineManagement of Land Reclamation Quality For Agricultural Use in Opencast MiningYuriiNessuna valutazione finora

- 10.price Bid 1. Site GradingDocumento1 pagina10.price Bid 1. Site GradingLeilani JohnsonNessuna valutazione finora

- Considerations in Performing Full Depth Reclamation in Cold ClimatesDocumento23 pagineConsiderations in Performing Full Depth Reclamation in Cold Climatesheru nurudinNessuna valutazione finora

- Deep Compaction: Group 04 Members: Macusi, Gerbin Rey Ishaya, Jerry Alconis, Christian Carl Padica, RedenDocumento20 pagineDeep Compaction: Group 04 Members: Macusi, Gerbin Rey Ishaya, Jerry Alconis, Christian Carl Padica, RedenJerry IshayaNessuna valutazione finora

- Cold in Place Recycling A Relevant Process For Road PDFDocumento13 pagineCold in Place Recycling A Relevant Process For Road PDFMatei PopaNessuna valutazione finora

- Review of Superfinishing by The Magnetic AbrasiveDocumento14 pagineReview of Superfinishing by The Magnetic AbrasiveStanislav ArtemenkovNessuna valutazione finora

- 2B. Surface TreatmentsDocumento72 pagine2B. Surface TreatmentsZenna WongNessuna valutazione finora

- CH-InT-RWSR041-CN TMS Shennongjia Airport Rev01Dec16Documento2 pagineCH-InT-RWSR041-CN TMS Shennongjia Airport Rev01Dec16bim07Nessuna valutazione finora

- 1 s2.0 S0950061819328594 MainDocumento13 pagine1 s2.0 S0950061819328594 Main104 GOPAL BANOTHNessuna valutazione finora

- 1 s2.0 S1687404816000031 MainDocumento10 pagine1 s2.0 S1687404816000031 MainShreeya DeosantNessuna valutazione finora

- CH 02.09.04 Pliant MediaDocumento5 pagineCH 02.09.04 Pliant MediaRinush Fedrikdo Bushido OdaNessuna valutazione finora

- Compressed Soil BlocksDocumento2 pagineCompressed Soil Blocksak123456Nessuna valutazione finora

- Dr. Fixit ProductsDocumento8 pagineDr. Fixit ProductsYati ChanNessuna valutazione finora

- Brochure Menard GB 2010Documento9 pagineBrochure Menard GB 2010militia14Nessuna valutazione finora

- Buildings 13 00932 v2Documento22 pagineBuildings 13 00932 v2Yusuf EfendiNessuna valutazione finora

- Elbadry 2016Documento10 pagineElbadry 2016Juan Camilo PinedaNessuna valutazione finora

- Innovative Material 1Documento6 pagineInnovative Material 1Ashish trivediNessuna valutazione finora

- Abhi Shah: Career ObjectiveDocumento2 pagineAbhi Shah: Career ObjectiveAlok Singh RajawatNessuna valutazione finora

- Curriculum Vitae: Applied For Post Of: - QC EngineerDocumento3 pagineCurriculum Vitae: Applied For Post Of: - QC EngineerAlok Singh RajawatNessuna valutazione finora

- Yogesh Mishra PDFDocumento2 pagineYogesh Mishra PDFAlok Singh RajawatNessuna valutazione finora

- Tech Tangent Solutions Pvt. Ltd. Madhya Pradesh Road Development Corporation Limited PNC Infratech Limited 45A, Areva Hills BhopalDocumento1 paginaTech Tangent Solutions Pvt. Ltd. Madhya Pradesh Road Development Corporation Limited PNC Infratech Limited 45A, Areva Hills BhopalAlok Singh RajawatNessuna valutazione finora

- BOT (Annuity) Roads, Rating Methodology, Aug 2018Documento9 pagineBOT (Annuity) Roads, Rating Methodology, Aug 2018Alok Singh RajawatNessuna valutazione finora

- FWHA Fog SealDocumento16 pagineFWHA Fog SealAlok Singh RajawatNessuna valutazione finora

- HCCDocumento272 pagineHCCAlok Singh RajawatNessuna valutazione finora

- District - Hamirpur: Mineral AtlasDocumento1 paginaDistrict - Hamirpur: Mineral AtlasAlok Singh RajawatNessuna valutazione finora

- Prespective View - Type 1Documento1 paginaPrespective View - Type 1Alok Singh RajawatNessuna valutazione finora

- SEBI On Toll ProjectsDocumento733 pagineSEBI On Toll ProjectsAlok Singh RajawatNessuna valutazione finora

- Benkelman Beam: Product ManualDocumento8 pagineBenkelman Beam: Product ManualAlok Singh RajawatNessuna valutazione finora

- Police Ranks and Insignia of India - WikipediaDocumento3 paginePolice Ranks and Insignia of India - WikipediaAlok Singh RajawatNessuna valutazione finora

- NBC NormsDocumento32 pagineNBC NormsArathi KNessuna valutazione finora

- Faq of Module 2Documento4 pagineFaq of Module 2rather chotulNessuna valutazione finora

- Certificado Brida 3Documento1 paginaCertificado Brida 3juan aguilarNessuna valutazione finora

- Designing of High Rise BuildingsDocumento45 pagineDesigning of High Rise BuildingsruksarNessuna valutazione finora

- Cont HSE Alignment Kickoff Meeting F0228Documento2 pagineCont HSE Alignment Kickoff Meeting F0228NAGARJUNA75% (4)

- BSR IctadDocumento88 pagineBSR IctadRavindu Ransara100% (1)

- SIR Homeowners 04-21-11Documento2 pagineSIR Homeowners 04-21-11TimesreviewNessuna valutazione finora

- KR - MV IV - R410A - 5060Hz - HR - EU - MFL67474006 - 0CVY0-01A - July.2013Documento349 pagineKR - MV IV - R410A - 5060Hz - HR - EU - MFL67474006 - 0CVY0-01A - July.2013diegoescalona1985Nessuna valutazione finora

- Chokhi DhaniDocumento3 pagineChokhi DhaniLAksh MAdaanNessuna valutazione finora

- Ultra Deep Water Subsea Pipeline Design and Assessment: Proceeding of Ocean, Mechanical and Aerospace, Vol.2Documento6 pagineUltra Deep Water Subsea Pipeline Design and Assessment: Proceeding of Ocean, Mechanical and Aerospace, Vol.2Riza SaidNessuna valutazione finora

- Specification For Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower - Temperature ServiceDocumento4 pagineSpecification For Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower - Temperature ServiceBowo Edhi Wibowo100% (1)

- NYY J 0 6 1 KVDocumento4 pagineNYY J 0 6 1 KVkaloresibluNessuna valutazione finora

- Engineering GeologyDocumento19 pagineEngineering GeologyNaniNessuna valutazione finora

- SSI AFD270 9in DiscDiff 012210Documento2 pagineSSI AFD270 9in DiscDiff 012210Chris HdezNessuna valutazione finora

- Security Services in Canada Industry ReportDocumento34 pagineSecurity Services in Canada Industry ReportThe Hamilton SpectatorNessuna valutazione finora

- Mansory 1Documento5 pagineMansory 1John Isaac BanaagNessuna valutazione finora

- Cast Steel Cylindrical Body Gate Valves Outside Screw and Yoke, PN 100Documento2 pagineCast Steel Cylindrical Body Gate Valves Outside Screw and Yoke, PN 100Seymur AkbarovNessuna valutazione finora

- PHD ThesisfgITBV in Construction Industry - Dec 2012 HardCover Final-06!06!2013Documento332 paginePHD ThesisfgITBV in Construction Industry - Dec 2012 HardCover Final-06!06!2013gren900Nessuna valutazione finora

- NEOM-NEN-TGD-304 - 01.00 - Wind Design Requirements For Building StructuresDocumento11 pagineNEOM-NEN-TGD-304 - 01.00 - Wind Design Requirements For Building Structuresmahmudulalam konokNessuna valutazione finora

- Study On Noise Control of Building: Civil EngineeringDocumento32 pagineStudy On Noise Control of Building: Civil EngineeringMr KalyanNessuna valutazione finora

- NORSOK C-001, Living Quarters AreaDocumento37 pagineNORSOK C-001, Living Quarters Areageorgekc77100% (4)

- 43 - Drill Head Assembly FinalDocumento1 pagina43 - Drill Head Assembly Finaladmam jonesNessuna valutazione finora

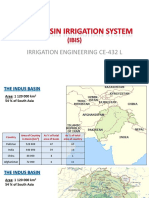

- Irrigation Engineering Ce-432 LDocumento18 pagineIrrigation Engineering Ce-432 LAhmed FiazNessuna valutazione finora

- Da 20Documento43 pagineDa 20Prasath SivaNessuna valutazione finora

- Metitherm Technical BrochureDocumento62 pagineMetitherm Technical BrochureHussain ElarabiNessuna valutazione finora

- API 579 BlueDocumento65 pagineAPI 579 BlueMohamed Alkhiat100% (2)

- Approx Vertical ModifiedDocumento25 pagineApprox Vertical ModifiedShafkat SaminNessuna valutazione finora

- Thermal InsulationDocumento2 pagineThermal InsulationPrabhat DhekaleNessuna valutazione finora

- ISTpure Install Guide SR120V 180VDocumento8 pagineISTpure Install Guide SR120V 180VHamid KharazmiNessuna valutazione finora

- ConPave 01Documento5 pagineConPave 01Dhen UlesNessuna valutazione finora