Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting System

Caricato da

Jay PadamaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting System

Caricato da

Jay PadamaCopyright:

Formati disponibili

Product Data Sheet

Edition No. 03 (October 2015)

Sikadur -42 MP Normal HC

®

Sikadur®-42 MP Normal HC

3-part, multi purpose epoxy grouting system

®

Product Sikadur -42 MP Normal HC is a three-component, multipurpose, moisture tolerant,

Construction

epoxy grouting system. For use at temperatures between +10°C and +30ºC.

Description

Uses High-strength grouting and fixing of:

Starter bars

Anchors

Fasteners

Tie rods

Crash barrier posts

Fence and railing posts

Under-grouting and bedding of:

Base plates

Machine bases, seat base-plates for light and heavy machinery including heavy

impact and vibratory machinery, reciprocating engines, compressors, pumps,

presses, etc.

Bridge bearings

Mechanical joints (i.e. road/bridge/deck types, etc.)

Sleeper-less, direct rail fixing:

Crane tracks

Light rail and permanent way in tunnels

Light rail and permanent way over bridges

Characteristics / High early strength

Advantages Ready-to-mix, pre-batched units

Moisture tolerant

Non-shrink

Corrosion and chemically resistant

Stress and impact resistant

High compressive strength

High vibration resistance

Low coefficient of thermal expansion

Sikadur®-42 MP Normal HC 1/5

Tests

Approval / Standards Testing according to EN 1504-6.

Product Data

Form

Appearance / Colour Concrete Grey

Packaging 12 kg (A+B+C): pre-batched unit

30 kg (A+B+C): pre-batched unit

Storage

Storage Conditions/ 24 months from date of production if stored properly in original and unopened,

Shelf-Life sealed and undamaged packaging, in dry conditions at temperatures between

+15°C and +30°C. Protect from direct sun light.

Technical Data

Chemical Base Epoxy resin.

3

Density 2’130 kg/m (A+B+C)

Layer Thickness Minimum grout depth: 10 mm

Maximum grout depth: 150 mm

Temperature 10°-20°C 20°-30°C

Layer Thickness max. 150mm 100mm*

* no reduction of fillers; apply only with Mixing Ratio A : B : C = 5 : 1 : (30-36)

Change of Volume Creep:

2

4.14 N/mm (600 psi) / 31’500 N (+60°C) 1.10% (According to ASTM C1181)

2

2.76 N/mm (400 psi) / 21’000 N (+60°C) 0.21% (According to ASTM C1181)

2

API requirements: 0.5% with 2.76 N/mm load

Linear Shrinkage: -0.027% (According to ASTM C531)

Linear Shrinkage: -0.03% (According to EN 52450)

-5

Thermal Expansion 2.1 x 10 mm/mm/°C (Temp. range -30°C - +30°C) (According to ASTM C531)

-5

Coefficient 4.4 x 10 mm/mm/°C (Temp. range +24°C - +100°C)

-5

2.7 x 10 mm/mm/°C (Temp. range -20°C - +60°C) (According to EN 1770)

Water Absorption 0.059% (7 days) (According to ASTM C413)

Coefficient W

Thermal Stability Heat Deflection Temperature HDT:

HDT = +55°C (7 days / +23°C) (According to ISO 75)

Effective Bearing Area > 90% (According to ASTM C 1339)

Mechanical / Physical

Properties

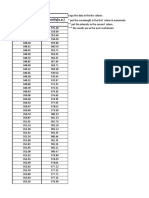

Compressive Strength (According to ASTM C-579)

Curing time +10°C +23°C +30°C

2 2

1 day ~ 25 N/mm ~ 67 N/mm ~ 90 N/mm2

3 days ~ 75 N/mm2 ~ 89 N/mm2 ~ 104 N/mm2

2 2

7 days ~ 85 N/mm ~ 92 N/mm ~ 107 N/mm2

Product cured and tested at temperatures indicated.

Test specimen size: 50 * 50 * 50mm

Sikadur®-42 MP Normal HC 2/5

2

Flexural Strength ~ 32 N/mm (According to ASTM C580)

2

Tensile Strength ~ 15 N/mm (According to ASTM D638)

2

Bond Strength > 47 N/mm (concrete failure) (slant shear) (According to ASTM C882)

(According to According to ISO 4624, EN 1542 and EN 12188)

2

~ 9 N/mm (on steel)

2

> 3.5 N/mm (concrete failure)

2

E-Modulus ~ 13’500 N/mm (Tangent modulus of elasticity in bending) (ASTM C580)

2

~ 18’000 N/mm (Compressive) (According to ASTM D695-96)

2

~ 16’000 N/mm (Flexural) (According to EN 53452)

Elongation ~ 1.3% (ASTM D638)

Elongation at Break 0.1 + 0.05% (7 days at +23°C) (According to ISO 75)

Strength Development Confirm the strength development by producing cubes on site and testing them for

compressive and flexural strength.

Thermal Compatibility No delamination / pass (According to ASTM C884)

Exotherm Peak 44°C (at +23°C) (According to ASTM D 2471)

System

Information

Application Details

Substrate Quality Mortar and concrete must be older than 28 days (dependent on minimum strength

requirements).

Verify the substrate strength (concrete, natural stone etc.).

The substrate surface (all types) must be clean, dry and free from contaminants

such as dirt, oil, grease, existing surface treatments and coatings etc.

Steel substrates must be de-rusted to a standard equivalent to Sa 2.5

The substrate must be sound and all loose particles must be removed.

Substrate must be dry or mat damp and free from any standing water, ice etc.

Substrate Preparation Concrete, mortar, stone:

Substrates must be sound, dry, clean and free from laitance, ice, standing water,

grease, oils, old surface treatments or coatings and all loose or friable particles

must be removed to achieve a laitance and contaminant free, open textured

surface.

Steel:

Must be cleaned and prepared thoroughly to an acceptable quality standard

equivalent to SA 2.5 i.e. by blastcleaning and vacuum. Avoid dew point conditions.

Surface and base plate contact area must be clean and sound. For best results, the

substrate shall be dry. Remove dust, laitance, oils, grease, curing compounds,

impregnations, waxes, foreign particles, coatings, and disintegrated materials by

mechanical means, i.e. chipping with a chisel, blastcleaning etc.

All anchor pockets or sleeves must be free of water. Apply grout immediately to

prevent re-oxidizing / rust formation.

For optimum results:

When grouting areas or equipment that is sensitive to vibration, it is recommended

that the contact surfaces are prepared according to the latest edition of the

American Petroleum Institute’s Recommended Practice 686 “Machinery Installation

and Installation Design”, Chapter 5.

Sikadur®-42 MP Normal HC 3/5

Application

Conditions /

Limitations

Substrate Temperature +15°C min. / +30°C max.

Ambient Temperature +15°C min. / +30°C max.

®

Material Temperature Sikadur -42 MP Normal HC must be applied at temperatures between +15°C and

+30°C.

Condition the material by also storing at this temperature for 48 hours before use.

Substrate Moisture ≤ 4% pbw

Content

Dew Point Substrate temperature during application must be at least 3°C above dew point to

avoid condensation.

Application

Instructions

Mixing Part A : B : C = 5 : 1 : 30 by weight (Standard)

Solid / liquid = 5 : 1 by weight

Mixing Time Pre-batched units:

Mix components A and B in the component A pail for approx.

30-60 seconds with a paddle attached to a low speed drill

(300-450 rpm). Avoid aeration while mixing until the material

becomes uniformly blended in colour and viscosity. Place the

mixed epoxy into an appropriate mixing vessel. Slowly add the

contents of component C (to keep air entrapment at a

minimum) dependent on flow requirements (observe the

correct mixing ratio) and mix until uniform and homogeneous.

(approx. 3 min)

Mix only that quantity which can be used within its potlife.

Never mix Component A and B without adding component C

(as the exothermic reaction between A and B alone generates

excess heat)

®

Leave Sikadur -42 MP Normal HC to stand in the normal

mixing vessel for 2 – 3 minutes until the majority of entrained

air bubbles have dispersed.

Application Method / Forming:

®

Tools The consistency of the Sikadur -42 MP Normal HC epoxy grout system requires the

use of permanent or temporary forms to contain the material around base plates, for

example. In order to prevent leakage or seepage, all of these formers must be

sealed. Apply polyethylene film or wax to all forms to prevent adhesion of the grout.

Prepare the formwork to maintain more than 100 mm liquid head to facilitate

placement. A grout box equipped with an inclined trough attached to the form will

enhance the grout flow and minimize air encapsulation.

Pour the mixed grout into the prepared forms from one or two sides only, to

eliminate air entrapment. Maintain the liquid head to ensure intimate contact to the

base plate. Place sufficient epoxy grout in the forms to rise slightly above the

underside (3 mm) of the base plate. The minimum void depth beneath the base-

plate shall be 12 mm. Where the void beneath the base plate is greater than 150

mm, place the epoxy grout in successive 150 mm lifts or less, once the preceding

lift has cooled.

Once hardened check the adhesion by tapping with a hammer.

Sikadur®-42 MP Normal HC 4/5

Cleaning of Tools Sweep excess grout into appropriate containers for disposal before it has hardened.

Dispose of in accordance with applicable local regulations. Uncured material can be

removed with Sika® Colma Cleaner or Xylene based solvent. Cured material can

only be removed mechanically.

Potlife (200g, adiabatic testing)

+10°C +23°C

5 : 1 : 30

130 minutes 75-80 minutes

The potlife begins when the resin and hardener are mixed. It is shorter at high

temperatures and longer at low temperatures. The greater the quantity mixed, the

shorter the potlife. To obtain longer workability at high temperatures, the mixed

adhesive may be divided into portions. Another method is to condition parts A+B

and C to lower temperature before mixing them (i.e. only when application

temperatures are above +20°C).

Notes on Application / Minimum substrate temperature: +15°C. The material must be conditioned by being

Limitations stored in an area with an ambient temperature between +15°and +30°C for a

minimum of 48 h before using.

Construction

Do not thin with solvents. Solvents will prevent proper curing and change

mechanical properties.

®

Sikadur -42 MP Normal HC is a vapour barrier when cured. Minimum grout depth:

10 mm. Maximum grout depth: 150 mm per lift. The last lift must be kept at 50 mm.

Component C must be kept dry. For specific bolt grouting applications please refer

to Sika® Technical Services. For proper seating, allow the grout to rise above the

bottom (3 mm) of the base plate.

Avoid splitting prebatched units to mix. Mix complete units only. Cold ambient,

substrate or material temperatures will influence the curing and flow characteristics

®

of Sikadur -42 MP Normal HC. Do not subject cured epoxy grout to sudden

temperature changes especially during early curing stages. Contact Sika®

Technical Services for control joint spacing on large base plate grouting projects.

®

Sikadur resins are formulated to have low creep under permanent loading.

However due to the creep behaviour of all polymer materials under load, the long

term structural design load must account for creep. Generally the long term

structural design load must be lower than 20-25% of the failure load. Please consult

a structural engineer for load calculations for your specific application.

Value Base All technical data stated in this Product Data Sheet are based on laboratory tests.

Actual measured data may vary due to circumstances beyond our control.

Local Restrictions Please note that as a result of specific local regulations the performance of this

product may vary from country to country. Please consult the local Product Data

Sheet for the exact description of the application fields.

Health and Safety For information and advice on the safe handling, storage and disposal of chemical

products, users shall refer to the most recent Material Safety Data Sheet containing

Information physical, ecological, toxicological and other safety-related data.

Legal Notes The information, and, in particular, the recommendations relating to the application and

end-use of Sika® products, are given in good faith based on Sika's current knowledge

and experience of the products when properly stored, handled and applied under normal

conditions in accordance with Sika’s recommendations. In practice, the differences in

materials, substrates and actual site conditions are such that no warranty in respect of

merchantability or of fitness for a particular purpose, nor any liability arising out of any

legal relationship whatsoever, can be inferred either from this information, or from any

written recommendations, or from any other advice offered. The user of the product must

test the product’s suitability for the intended application and purpose. Sika reserves the

right to change the properties of its products. The proprietary rights of third parties must

be observed. All orders are accepted subject to our current terms of sale and delivery.

Users must always refer to the most recent issue of the local Product Data Sheet for the

product concerned, copies of which will be supplied on request.

Sika Philippines, Inc.

888 Unit A & B,

Marcos Alvarez Ave., Talon V, Tel. No.: +(632) 806-2875

Las Piñas City 1747 Fax No.: +(632) 806-2883

Philippines Website: phl.sika.com

Sikadur®-42 MP Normal HC 5/5

Potrebbero piacerti anche

- Is 13849 PDFDocumento517 pagineIs 13849 PDFsauravNessuna valutazione finora

- Analysis & Design of Combined Footing: Condition:1Documento3 pagineAnalysis & Design of Combined Footing: Condition:1Nikhil PoriyaNessuna valutazione finora

- Sand Asphalt Base Course 2260Documento4 pagineSand Asphalt Base Course 2260Tinh HuynhNessuna valutazione finora

- Kerala State Pollution Control BoardDocumento34 pagineKerala State Pollution Control Boardprofessionalservices_infoNessuna valutazione finora

- Design of RC Pad With Single Column Footing: Dead Imposed WindDocumento22 pagineDesign of RC Pad With Single Column Footing: Dead Imposed Windsvrao4u100% (2)

- Gb 50934-2013 石油化工工程防渗技术规范Documento61 pagineGb 50934-2013 石油化工工程防渗技术规范ccq0707Nessuna valutazione finora

- Check Detailing For 160 Mva Fire WallDocumento12 pagineCheck Detailing For 160 Mva Fire WallAnindit MajumderNessuna valutazione finora

- Slab Foundation Design 1Documento6 pagineSlab Foundation Design 1Renato ZanescoNessuna valutazione finora

- Design Doc. - Rt. WallDocumento16 pagineDesign Doc. - Rt. WallAnindit MajumderNessuna valutazione finora

- Beam DesignDocumento8 pagineBeam DesignGeorge GeorgianNessuna valutazione finora

- Abstract of Cost ProjectDocumento3 pagineAbstract of Cost ProjectamritNessuna valutazione finora

- Mxy Abs MX MX Mxy Abs My My Mxy Abs MX MX: Sample CalculationDocumento3 pagineMxy Abs MX MX Mxy Abs My My Mxy Abs MX MX: Sample CalculationUttam Kumar GhoshNessuna valutazione finora

- Ctural: CLVLBL Structural. Design CalculationDocumento70 pagineCtural: CLVLBL Structural. Design CalculationthakrarhitsNessuna valutazione finora

- Canopy StructureDocumento22 pagineCanopy StructuresravanNessuna valutazione finora

- Specification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeDocumento5 pagineSpecification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeSOMNATH JANANessuna valutazione finora

- Civil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFDocumento6 pagineCivil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFArjun S SanakanNessuna valutazione finora

- Analysis and Design of Steel Dome Using Software: Anuj ChandiwalaDocumento5 pagineAnalysis and Design of Steel Dome Using Software: Anuj ChandiwalaSaqlain Awan100% (1)

- MJPN PGAS 3514 CV CA 009 - Calculation For Guard HouseDocumento735 pagineMJPN PGAS 3514 CV CA 009 - Calculation For Guard Houseabduh81Nessuna valutazione finora

- CE8501 Notes PDFDocumento53 pagineCE8501 Notes PDFprem rajanNessuna valutazione finora

- CAESAR II Input Echo and OutputDocumento264 pagineCAESAR II Input Echo and OutputSanjayNessuna valutazione finora

- Master Foods 12 MDocumento16 pagineMaster Foods 12 MSarfarazNessuna valutazione finora

- A Solar Chimney Power Plant TULJAPURDocumento16 pagineA Solar Chimney Power Plant TULJAPURDIPAK VINAYAK SHIRBHATE100% (3)

- Rectangular Steel Bar DesignDocumento2 pagineRectangular Steel Bar DesignAmit Kumar PaulNessuna valutazione finora

- Check For Punching Shear:: Pile Cap Design (PC3a)Documento6 pagineCheck For Punching Shear:: Pile Cap Design (PC3a)Sheikh Mizanur RahmanNessuna valutazione finora

- Post-Tensioned Concrete Column Supported Slab Design (Flat Plate System)Documento6 paginePost-Tensioned Concrete Column Supported Slab Design (Flat Plate System)Educadd AMEERPET HyderabadNessuna valutazione finora

- Pa5 MC SH 01 c14 003 - 00 - Calculation For Platform Beam of ChimneyDocumento33 paginePa5 MC SH 01 c14 003 - 00 - Calculation For Platform Beam of ChimneyHmilkNessuna valutazione finora

- Paper For Bearing Capacity PDFDocumento4 paginePaper For Bearing Capacity PDFernestnsabimana74Nessuna valutazione finora

- Steel Beam DesignDocumento36 pagineSteel Beam DesignTan Choon LengNessuna valutazione finora

- Snow Load As Weight Per MM Calculation 330Documento1 paginaSnow Load As Weight Per MM Calculation 330Anonymous Iev5ggSRNessuna valutazione finora

- Design and Analysis ofDocumento17 pagineDesign and Analysis ofSomnath BhuniaNessuna valutazione finora

- RC Raft Foundation (Bs8110) : Project Job RefDocumento5 pagineRC Raft Foundation (Bs8110) : Project Job RefsitheeqNessuna valutazione finora

- List of Materials ConstructionDocumento1 paginaList of Materials ConstructionMaan GalangNessuna valutazione finora

- Jee Mains Previous YearsDocumento6 pagineJee Mains Previous YearsPoodari VenkateshNessuna valutazione finora

- Design Basis Report - Cold StoreDocumento8 pagineDesign Basis Report - Cold Storekvsj2001Nessuna valutazione finora

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocumento8 pagineHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNessuna valutazione finora

- Boq For Road WorksDocumento6 pagineBoq For Road WorksFaisal KhanNessuna valutazione finora

- Pinned Base Plate - 03SF01Documento15 paginePinned Base Plate - 03SF01vivekNessuna valutazione finora

- DmTank Ring Wall Foundation+&+Annular+RaftDocumento5 pagineDmTank Ring Wall Foundation+&+Annular+RaftRM PaduaNessuna valutazione finora

- Circular Footing Design Based On ACI 318-14: Input Data & Design SummaryDocumento3 pagineCircular Footing Design Based On ACI 318-14: Input Data & Design SummaryinnovativekarthiNessuna valutazione finora

- Concrete Ring Wall FoundationDocumento16 pagineConcrete Ring Wall Foundationchenfs27531Nessuna valutazione finora

- Worked Example Header PlateDocumento8 pagineWorked Example Header PlateNikola PejatovicNessuna valutazione finora

- Annexure Wind LoadDocumento36 pagineAnnexure Wind LoadVijeswara RaoNessuna valutazione finora

- Designing BeamDocumento10 pagineDesigning BeamSyahmie DaudNessuna valutazione finora

- M3D - SampleProblemSet ACI PDFDocumento6 pagineM3D - SampleProblemSet ACI PDFasaisenthilNessuna valutazione finora

- Is 6533 Part-2 Design of Construction of Steel Chimney-CodDocumento23 pagineIs 6533 Part-2 Design of Construction of Steel Chimney-CodRiaz M IbrahimNessuna valutazione finora

- Mechanical Calculation TANK 53 KL (T-05)Documento4 pagineMechanical Calculation TANK 53 KL (T-05)Priyo Jati WahyonoNessuna valutazione finora

- Bill of Quantities - Civil Engineering Civil EngineeringDocumento10 pagineBill of Quantities - Civil Engineering Civil EngineeringNazar ShafiqNessuna valutazione finora

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocumento13 pagineSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNessuna valutazione finora

- Architectural Drawings For G+1 Residential Building: Name of Owner Plot No. LocationDocumento36 pagineArchitectural Drawings For G+1 Residential Building: Name of Owner Plot No. LocationTokio87Nessuna valutazione finora

- RCC41 Continuous Beams (A & D)Documento17 pagineRCC41 Continuous Beams (A & D)Zayyan RomjonNessuna valutazione finora

- IES MASTER Digital Online ClassesDocumento5 pagineIES MASTER Digital Online ClassesSumanNessuna valutazione finora

- Isolated Footing (4 Sides Wind)Documento4 pagineIsolated Footing (4 Sides Wind)saiNessuna valutazione finora

- Sikadur-42 MP Normal HCDocumento6 pagineSikadur-42 MP Normal HCDidiet PuteraNessuna valutazione finora

- Sikadur®-42 MP Slow - PDSDocumento7 pagineSikadur®-42 MP Slow - PDSkamran abbasiNessuna valutazione finora

- Sika Nigeria - Sikadur 42 MP Slow v1Documento7 pagineSika Nigeria - Sikadur 42 MP Slow v1willy iremNessuna valutazione finora

- Sikadur - 42: 3-Part, High Performance, Pourable Epoxy Grouting SystemDocumento4 pagineSikadur - 42: 3-Part, High Performance, Pourable Epoxy Grouting SystemSunny RohillaNessuna valutazione finora

- Sikadur - 42: 3-Part, High Performance, Pourable Epoxy Grouting SystemDocumento4 pagineSikadur - 42: 3-Part, High Performance, Pourable Epoxy Grouting SystemAnonymous XVEucVMsENessuna valutazione finora

- Sikadur®-42 MP Slow HC: Product Data SheetDocumento4 pagineSikadur®-42 MP Slow HC: Product Data SheetCbeztNessuna valutazione finora

- Sikadur - 42 HES (IN) : 3-Part, High Performance, Pourable Epoxy Grouting SystemDocumento4 pagineSikadur - 42 HES (IN) : 3-Part, High Performance, Pourable Epoxy Grouting SystemAnonymous XVEucVMsENessuna valutazione finora

- Murugesan-reddiar-Thesis - Kent and Park ModelDocumento2 pagineMurugesan-reddiar-Thesis - Kent and Park ModelJay PadamaNessuna valutazione finora

- Aci 374.1-05Documento9 pagineAci 374.1-05Arshadahc100% (2)

- Eur Ocode Design Factor S and Limits: Horizontal DeflectionsDocumento1 paginaEur Ocode Design Factor S and Limits: Horizontal DeflectionsJay PadamaNessuna valutazione finora

- Course SyllabusDocumento2 pagineCourse SyllabusJay PadamaNessuna valutazione finora

- Dong 2003 Thesis (1) - TheSISDocumento380 pagineDong 2003 Thesis (1) - TheSISJay PadamaNessuna valutazione finora

- Masters CostDocumento1 paginaMasters CostJay PadamaNessuna valutazione finora

- Course SyllabusDocumento2 pagineCourse SyllabusJay PadamaNessuna valutazione finora

- Reinforced-Concrete-Tilt-Up-Wall-Panel-Analysis-Design-ACI551 - Structure Point PDFDocumento18 pagineReinforced-Concrete-Tilt-Up-Wall-Panel-Analysis-Design-ACI551 - Structure Point PDFDivy JainNessuna valutazione finora

- 2014 OlmatiTrasborgNaitoBontempiIJCritInf DraftDocumento17 pagine2014 OlmatiTrasborgNaitoBontempiIJCritInf DraftJay PadamaNessuna valutazione finora

- Sustainability 11 00867 v2 PDFDocumento22 pagineSustainability 11 00867 v2 PDFMatías Pino YáñezNessuna valutazione finora

- BLASRDocumento10 pagineBLASRJay PadamaNessuna valutazione finora

- Cyclic Behavior of Steel Shear Links Used in Replaceable Coupling BeamsDocumento11 pagineCyclic Behavior of Steel Shear Links Used in Replaceable Coupling BeamsJay PadamaNessuna valutazione finora

- New Replaceable Coupling Beams For Shear Wall Structures: Yun ChenDocumento10 pagineNew Replaceable Coupling Beams For Shear Wall Structures: Yun ChenFrancisco GarridoNessuna valutazione finora

- Precast ConnectionDocumento108 paginePrecast ConnectionFreddie Koo100% (2)

- (MSC) A Finite Element Approach To Reinforced Concrete Slab DesignDocumento170 pagine(MSC) A Finite Element Approach To Reinforced Concrete Slab DesignAbera MamoNessuna valutazione finora

- Analytical Investigation Between, Precast and In-Situ Concrete Under Seismic ConditionDocumento16 pagineAnalytical Investigation Between, Precast and In-Situ Concrete Under Seismic ConditionJay PadamaNessuna valutazione finora

- Behaviour of A Precast Concrete Beam-Column Connection: Sergio M Alcocer, Rene Carranza and David Perez-NavarreteDocumento8 pagineBehaviour of A Precast Concrete Beam-Column Connection: Sergio M Alcocer, Rene Carranza and David Perez-NavarreteAbdul HafeezNessuna valutazione finora

- Behaviour of A Precast Concrete Beam-Column Connection: Sergio M Alcocer, Rene Carranza and David Perez-NavarreteDocumento8 pagineBehaviour of A Precast Concrete Beam-Column Connection: Sergio M Alcocer, Rene Carranza and David Perez-NavarreteAbdul HafeezNessuna valutazione finora

- 2014 OlmatiTrasborgNaitoBontempiIJCritInf DraftDocumento17 pagine2014 OlmatiTrasborgNaitoBontempiIJCritInf DraftJay PadamaNessuna valutazione finora

- Numerical FE Modelling of Occupant Injury in Soil Vehicle Blast InteractionDocumento14 pagineNumerical FE Modelling of Occupant Injury in Soil Vehicle Blast InteractionJay PadamaNessuna valutazione finora

- Analytical Investigation Between, Precast and In-Situ Concrete Under Seismic ConditionDocumento16 pagineAnalytical Investigation Between, Precast and In-Situ Concrete Under Seismic ConditionJay PadamaNessuna valutazione finora

- Precast ConnectionDocumento108 paginePrecast ConnectionFreddie Koo100% (2)

- Evaluation and Prediction of Common Stock Prices - A StatisticalDocumento66 pagineEvaluation and Prediction of Common Stock Prices - A StatisticalJay PadamaNessuna valutazione finora

- Blast Resistant DesignDocumento6 pagineBlast Resistant DesignKumaraavel ViswanathanNessuna valutazione finora

- Gs Recommendation-Manila PDFDocumento2 pagineGs Recommendation-Manila PDFJay PadamaNessuna valutazione finora

- Seismic Design of Reinforced Concrete Special Moment FramesDocumento31 pagineSeismic Design of Reinforced Concrete Special Moment FrameswilfredNessuna valutazione finora

- SSI and Influence Factors in An Underground Electrical SubstationDocumento23 pagineSSI and Influence Factors in An Underground Electrical SubstationYorman LPNessuna valutazione finora

- Ch3 Bearing Capacity of Shallow FoundationsDocumento53 pagineCh3 Bearing Capacity of Shallow FoundationsBilal MzhrNessuna valutazione finora

- Lec17 Bearing CapacityDocumento57 pagineLec17 Bearing CapacityMuhammad EhtshamNessuna valutazione finora

- Gs Recommendation-Manila PDFDocumento2 pagineGs Recommendation-Manila PDFJay PadamaNessuna valutazione finora

- Varut Marius - Excel CCT Calculator From VIS Spectrum - LED 1 MaDocumento441 pagineVarut Marius - Excel CCT Calculator From VIS Spectrum - LED 1 MaVarut MariusNessuna valutazione finora

- Cfa EqrsDocumento2 pagineCfa EqrsarunachelamNessuna valutazione finora

- A Comparative Research On Corrosion Behavior of A Standard, Crack-Free and Duplex Hard Chromium CoatingsDocumento6 pagineA Comparative Research On Corrosion Behavior of A Standard, Crack-Free and Duplex Hard Chromium CoatingsKarthi SundarNessuna valutazione finora

- Math 121A: Homework 4 Solutions: N N N RDocumento6 pagineMath 121A: Homework 4 Solutions: N N N RcfisicasterNessuna valutazione finora

- Bearing Basics For Gas-Industry Screw CompressorsDocumento5 pagineBearing Basics For Gas-Industry Screw CompressorsDayo IdowuNessuna valutazione finora

- Phy1 11 - 12 Q1 0102 FDDocumento31 paginePhy1 11 - 12 Q1 0102 FDKaye AquinoNessuna valutazione finora

- 19 Epe CMWSSB RSPH RSS&PH SDC 01Documento73 pagine19 Epe CMWSSB RSPH RSS&PH SDC 01juliyet strucNessuna valutazione finora

- K-Flex English-Catalog-2019 (Ic Clad)Documento4 pagineK-Flex English-Catalog-2019 (Ic Clad)ashishvaidNessuna valutazione finora

- Permutations and CombinationsDocumento69 paginePermutations and CombinationsNikhil0% (2)

- PI Section Line - Blocks (SimPowerSystems™)Documento3 paginePI Section Line - Blocks (SimPowerSystems™)Dhondiram Maruthi KakreNessuna valutazione finora

- F80 Press ReleaseDocumento2 pagineF80 Press Releasespscribd1Nessuna valutazione finora

- Laine Tall 2013Documento11 pagineLaine Tall 2013Fadel Muhammad Arraiza FarhanNessuna valutazione finora

- Example Design of A Cold-Formed Steel Lipped Channel Wall Stud in Compression PDFDocumento4 pagineExample Design of A Cold-Formed Steel Lipped Channel Wall Stud in Compression PDFOprisor Costin100% (1)

- Yanmar Brochure 02Documento2 pagineYanmar Brochure 02Fabiano OnaibafNessuna valutazione finora

- Topographical Surveys - Direct LevellingDocumento1 paginaTopographical Surveys - Direct LevellingTsegab DereseNessuna valutazione finora

- Laboratory Report - EvaporationDocumento14 pagineLaboratory Report - EvaporationWayne Tandingan0% (1)

- Workshop 3-3: Rectangular Patch Antenna: Introduction To ANSYS Electronics DesktopDocumento21 pagineWorkshop 3-3: Rectangular Patch Antenna: Introduction To ANSYS Electronics DesktopRodrigoNessuna valutazione finora

- RosemountDocumento24 pagineRosemountVirgilio VillonNessuna valutazione finora

- Yoga in Daily LifeDocumento9 pagineYoga in Daily LifeLaerteNessuna valutazione finora

- Zoomlion Truck Mounted Concrete PumpDocumento14 pagineZoomlion Truck Mounted Concrete PumpAsad Aijaz100% (7)

- Applied III, Worksheet 1Documento4 pagineApplied III, Worksheet 1mintuwondeNessuna valutazione finora

- DC 53 CatalogDocumento4 pagineDC 53 CatalogHonza MičkaNessuna valutazione finora

- Visible Emission of Hydrogen FlamesDocumento8 pagineVisible Emission of Hydrogen FlamesgajodharlauduNessuna valutazione finora

- Case Studies in Engineering Failure Analysis: K. Gurumoorthy, Bradley D. Faye, Arindam GhoshDocumento8 pagineCase Studies in Engineering Failure Analysis: K. Gurumoorthy, Bradley D. Faye, Arindam GhoshRif SenyoNessuna valutazione finora

- Pave RuttingDocumento440 paginePave RuttingbloomdidoNessuna valutazione finora

- A Field Method For Measurement of Infiltration PDFDocumento31 pagineA Field Method For Measurement of Infiltration PDFHamza MamiNessuna valutazione finora

- Chemistry Form 4 A NotesDocumento67 pagineChemistry Form 4 A NotesJia En TanNessuna valutazione finora

- Nikuradse's ExperimentDocumento50 pagineNikuradse's ExperimentAli BahuNessuna valutazione finora

- Rieber Sealing in AmericaDocumento10 pagineRieber Sealing in Americaulloap*100% (1)

- Sko0061283 R2Documento52 pagineSko0061283 R2ciwidop390Nessuna valutazione finora