Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Beam Column Joint

Caricato da

Anonymous KyLhn6Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Beam Column Joint

Caricato da

Anonymous KyLhn6Copyright:

Formati disponibili

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X.

PP 32-37

www.iosrjournals.org

Strengthening Of Exterior Beam Column Joint With Modified

Reinforcement Technique

Aditya Kumar Tiwary1, Mani Mohan2

1

(PG Student, Dept. of Civil Engineering, Jaypee University of Information Technology, Waknaghat, Solan

(HP), India

2

(Assistant Professor, Dept. of Civil Engineering, Jaypee University of Information Technology, Waknaghat,

Solan (HP), India

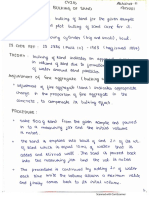

ABSTRACT : Modified reinforcement technique using crossed inclined bar at beam column junction is a

feasible solution for increasing the shear capacity. The presence of crossed inclined bars introduces an

additional mechanism for shear transfer. Exterior beam-column joints with crossed inclined bar modeled in

ANSYS workbench showed high strength. From experimental data the analytical result done via ansys

workbench concludes that the specimen with diagonal cross bar at joint shows better performance under the

static loading and it is a feasible solution for increasing the shear capacity of exterior and interior beam-

column joints. Behavior of beam column joint is less efficient when subject to large lateral loads, such as strong

wind. One of existing solution is inclusion of high percentages of transverse hoops in the core of joints in order

to meet the requirement of strength, stiffness and ductility under static loading. From the analytical study it is

observed that the provision of cross diagonal reinforcement increased the ultimate load carrying capacity,

stiffness and ductility of joints in the both upward and downward loading conditions. The present study is

confined to static load only.

Keywords - Comparison of Results, Exterior Joints, Finite-Element Modeling, RC Frame, Static load.

I. INTRODUCTION

The shear strength and confinement pressure provided by joint panel stirrups are crucial to preserve

joint panels from premature brittle failures; a suitable amount of transverse reinforcement allows the action

between the beams and columns to be appropriately transferred. However, the lack of joint panel transverse

reinforcement is very common in structural systems designed for gravity load or according to obsolete seismic

codes, especially in the Mediterranean area. For this reason, several surveys carried out in the aftermath of

major recent earthquakes have shown that beam column joints represent one of the main sources of vulnerability

in existing reinforced concrete (RC) constructions. In most of earthquake prone countries, preseismic code

designed reinforced concrete (RC) buildings do not comply with the current seismic codes requirements. In

Recent earthquakes failure/collapse of moment resisting RC frame buildings in the existing beam column joints,

especially exterior ones with inadequate shear strength and ductility is the prime reason. The present study is to

study the behavior of beam column joint under static load only with modified reinforcement technique at the

beam column junction. Further investigation can be carried out for seismic behavior of beam column joint with

modified reinforcement scheme as done for static load.

1.1 Literature Review

Number of works has been reported on experimental studies of composite up gradation for

strengthening beam column joint. The literature has been reviewed to get the experimental data for making

comparison with analytical model of present study.

S. H. Alsayed, Y. A. Al-Salloum, T. H. Almusallam, and N.A. Siddiqui, in 2010,epoxy-bonded CFRP

sheets have been used with different scheme such as control, strengthened, repaired specimens at the joints for

the upgrading the shear strength and ductility of exterior beam-column joints. The author compared the results

of different scheme through hysteretic loops, load-displacement envelopes, joint shear distortion, ductility, and

stiffness degradation and found that CFRP sheets are very effective in improving shear resistance and

deformation capacity of the exterior beam-column joints and delaying their stiffness degradation.

K.R.Bindhu and K.P. Jaya studied the seismic performance of exterior beam column joint with non-

conventional reinforcement detailing. The specimens were sorted into two groups based on the joint

reinforcement detailing. The first group (Group A) comprises of two joint assemblages having joint detailing as

per construction code of practice in India (IS 456:2000) with two axial load cases. The second group (Group B)

comprises of two specimens having additional cross bracing reinforcements for the joints detailed as per IS

456:2000 with similar axial load cases that in first group. The experimental investigations are validated with the

National Conference on Advances in Engineering, Technology & Management 32 | Page

(AETM’15)”

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X.

PP 00-00

www.iosrjournals.org

analytical studies carried out by finite element models using ANSYS. The experimental results and analytical

study indicated that additional cross bracing Reinforcements improve the seismic performance.

Suhasini M Kulkarni, Yogesh D Patil concluded that, the important factors affecting the shear capacity of

exterior RC beam-column joints are the compressive strength of concrete, aspect ratio of the joints and number

of transverse hoops in the core of the joint.

Modified reinforcement technique using crossed inclined bar at beam column junction showed

increased shear capacity of the statically loaded exterior beam-column joints. The cross inclined bars is intended

for creating an additional mechanism for shear transfer. Exterior beam-column joint modelled in ANSYS

Workbench showed high strength for crossed inclined bar arrangement at joint.

II. EXTERIOR JOINTS

An exterior beam-column joint is vulnerable for shear failure for beam-column joints designed without

transverse reinforcement and hence is identified as the principal cause of collapse of many moment-resisting

frame buildings during recent earthquakes. Effective techniques to increase joint shear resistance and ductility is

needed in these zones.

Table 2.1: Geometric Properties of Exterior Joint considered for FEM modeling

Parameter Value (mm) Parameter Value (mm)

Beam dimension and details Column dimension

and details

Width 160 Width 160

Depth 350 Depth 300

Span 2000 Clear height 1450

Concrete cover 15 Floor to floor height 1800

Top steel 4-12 Concrete cover 15

Bottom steel 4-12 Longitudinal steel 10-10

Transverse steel diameter 6 Transverse steel 6

diameter

Transverse steel spacing 225 Transverse steel 140

spacing

Bearing plate dimension Cross inclined bars at 10

joint Diameter

Width 160 Depth 10

2.2 Finite-Element Modeling

The finite-element analysis of bare and strengthened beam-column joints first require modeling of the

joints with the dimensions and properties corresponding to beam-column joints tested in the experiment. In this

section, modeling, including meshing, details of beam-column joints, is presented. The finite-element program

ANSYS Workbench Version 12 is used for this purpose. The element details of each material are presented

subsequently.

Concrete: To model the concrete an eight-node solid element, Solid65, is used. This solid element has eight

nodes with three degrees of freedom at each node with translations in the nodal x, y, and z directions. Plastic

deformation, cracking in three orthogonal directions and crushing capability can be utilized by the element.

Reinforcing Steel: Discrete modeling is used for reinforcement steel by defining the element between the nodes

in the performed meshes. Steel reinforcement in the experimental beam-column joint is constructed with typical

Grade 60 (fy-500 MPa) steel reinforcing bars. The steel for the finite-element model was assumed to be an

elastic–perfectly plastic material with identical properties in tension and compression. A Link8 element is used

to model the steel reinforcement. Two nodes are required for this element. Each node has three degrees of

freedom, which are translations in the nodal x, y, and z directions.

2.3 Creation of Geometry

Using the geometry tools of ANSYS software, beam column joint specimens is modeled as a 3D

model. The created geometry and typical steel reinforcement locations for the half-scale beam-column joint

National Conference on Advances in Engineering, Technology & Management 33 | Page

(AETM’15)”

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X.

PP 00-00

www.iosrjournals.org

shown in fig 2 and meshing of sizing 40 mm shown in fig 4. In the finite-element models, 3D spar elements,

Link8, were employed to represent the steel reinforcement. Ideally, the actual bond strength between the

concrete and steel reinforcement should be considered. However, in this study, a perfect bond between the two

materials is assumed. To provide the perfect bond, the link element, representing the steel reinforcing bars, is

connected between the nodes of each adjacent concrete solid element; thus, the two materials shared the same

nodes.

2.4 Loading Condition

Displacement boundary conditions were needed to constrain the model to get a unique solution. To

ensure that the model acts in the same way as the experimental beam-column joint, boundary Conditions are

applied at the supports and where loadings exist. To simulate the lateral load conditions, at the top of the

column, a 30-mm displacement and an axial constant load of magnitude 4240 N is applied.

Fig. 2.1: ANSYS Workbench Model for Loading

2.5 Reinforcement Detailing

The reinforcement detailing is done by using ANSYS Workbench v12. The properties are listed in

Table 1.

Fig. 2.2: Reinforcement Detailing (ANSYS v12) Fig. 2.3Reinforcement Detailing (ANSYS v11)

2.6 Meshing

To obtain good results from the Solid65 element, a square mesh is used. Therefore, the mesh is setup

such that square or rectangular elements are created (Fig. 4&5). The volume sweep command of ANSYS v12 is

used to mesh the support. This properly sets the width and length of elements in the concrete support and makes

it consistent with the elements and nodes in the concrete portions of the model. In the analysis, the specimen

was modeled with 4,141 square concrete elements by using a 40 mm mesh configuration.

National Conference on Advances in Engineering, Technology & Management 34 | Page

(AETM’15)”

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X.

PP 00-00

www.iosrjournals.org

Fig. 2.4 Mesh v12 Fig. 2.5: Mesh v11

The following material properties were used for the present FE analysis:-

CONCRETE:

Elastic Modulus, Ec= 4700√fc, Ultimate uniaxial compressive strength, fc = 30 Mpa, Ultimate tensile compressive

strength, fr = 0.62√fc, Poisson ratio for concrete = 0.2

STEEL:

Elastic Modulus, Es =200000 Mpa, Yield stress of longitudinal steel bars, fy = 500 Mpa, Yield stress of

transverse steel bars, fy = 380 Mpa, Poisson ratio for steel = 0.3

III. RESULT

3.1 Control Specimen

The result of FE analysis of control specimen using ANSYS Workbench under the static loading of

4240 N. Figure 6 and 7 shows the result of total deformation, maximum principal stress and maximum principal

elastic strain respectively.

TABLE 3.1

RESULT MAXIMUM VALUE

Total deformation 14.173 mm

Maximum principal stress 72.327 Mpa

Maximum principal strain 0.00725 mm/mm

Fig. 3.1: ANSYS Workbench Model for Total Deformation and Maximum Principal Stress

National Conference on Advances in Engineering, Technology & Management 35 | Page

(AETM’15)”

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X.

PP 00-00

www.iosrjournals.org

Fig. 3.2 ANSYS Workbench Model for Maximum Principal Elastic Strain

3.2 Strengthen Specimen

Figure 8 shows the reinforcement detailing of strengthen specimen. In this model Modified

reinforcement technique using crossed inclined bar10 mm diameter in beam-Column joint is used. Figure 9

shows the deformation of strengthen specimen under the static loading of 4240 N and from the result it is clear

that, the deflection in strengthen specimen as compare to control specimen is minimum.

Fig. 3.3 Reinforcement detailing of Exterior joint Fig. 3.4 ANSYS Workbench Model

As per IS: 456-2000 Deformation of strengthening Joint

3.3Comparison of FE Results with Test Result

The goal of the comparison of FE analysis results with the experimental test results is to ensure that the

present finite-element model and analysis are capable of predicting the response of the beam-column joints. The

results were compared through load-displacement behavior.

TABLE 3.2: Comparison of Experimental Test Result with Strengthening Exterior Beam Column Joint

Load (N) Test result FE result Percent difference

4240 16.88 mm 14.172 mm 11

The Exterior joint comprises of specimen having additional cross bracing reinforcements for the joints

detailed as per IS 456:2000 with similar axial load cases that in experimental setup. The experimental

investigations are validated with the analytical studies carried out by finite element models using ANSYS. The

experimental results and analytical study indicate that additional cross bracing reinforcements improves the

seismic performance.

Load-Displacement

TABLE 3.3

Load(N) Test result Strengthening specimen Percent difference

4240 16.88 mm 11.314 mm 22

National Conference on Advances in Engineering, Technology & Management 36 | Page

(AETM’15)”

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684, p-ISSN: 2320-334X.

PP 00-00

www.iosrjournals.org

IV. CONCLUSION

Modified reinforcement technique using crossed inclined bars at beam column junction is a feasible

solution for increasing the shear capacity of the cyclically loaded exterior beam-column joints. The cross

inclined bars aids in creating an additional mechanism for shear transfer. External beam-column joint

reinforcement modified with crossed inclined bars modeled in ANSYS Workbench showed high strength under

static applied load. From experimental data the analytical result done via ANSYS concludes that the specimen

with diagonal cross bar at joint shows better performance under the static loading and it is a feasible solution for

increasing the shear capacity of exterior and interior beam-column joints.The reinforcement details of such

structures though conform to the general construction code of practice may not adhere to the modern seismic

provisions. A beam column joint becomes structurally less efficient when subject to large lateral loads, such as

strong wind. One of the solutions to meet the requirement of strength, stiffness and ductility is by providing high

percentages of transverse hoops in the core of joints. Another which can be proposed is the modified

reinforcement technique as studied in present study in which the provision of cross diagonal reinforcement

increased the ultimate load carrying capacity, stiffness and ductility of joints in the both upward and downward

loading conditions.

V. RESEARCH SCOPE

Investigate behavior of other beam column joint i.e. interior and corner joint.

Study the behavior of beam column joint under dynamic loading.

Study the variation of stresses in reinforcing bars of column and beam.

REFERENCES

JOURNAL PAPERS:

[1] S.H.ALSAYED, Y.A.AL-SALLOUM, N.A. SIDDIQUI AND T.H.ALMUSALLAM, 2010, “SEISMIC RESPONSE OF FRP-

UPGRADED EXTERIOR RC BEAM COLUMN JOINTS”, JOURNAL OF COMPOSITES FOR CONSTRUCTION

ASCE/MARCH/APRIL, 2010, PAGE NO.195-208.

[2] S. H. Alsayed, Y. A. Al-Salloum, T. H. Almusallam, and N.A. Siddiqui, 2010, “Seismic Rehabilitation of

Corner RC Beam-Column Joints Using CFRP Composites” journal of composites for construction

ASCE/NOVEMBER/DECEMBER , 2010, page no.681-692.

[3] C.D.Vecchio, M.D.Ludovico, Albeeto Balsamo, Andrea Prota, Gaetano Manfredi, and Mauro Dolce,2014,

“Experimental Investigation of Exterior RC Beam-Column Joints Retrofitted With FRP system” journal of

composites for construction ASCE/JANUARY/, 2014, page no.01-13.

[4] Tarek H. Almusallam, Yousef A. Al-salloum, and M.sc student, dept. of civil engineering, king saud

university, Riyadh, Saudi Arabia, 2007, “seismic response of interior RC beam-column joints upgraded with

FRP sheets. II: Analysis and Parametric Study” journal of composites for construction

ASCE/NOVEMBER/DECEMBER, 2007, page no.590-600.

[5] Tarek H. Almusallam, Yousef A. Al-salloum, and M.sc student, dept. of civil engineering, king saud

university, Riyadh, Saudi Arabia,2007, “Numerical Investigations on the seismic Behavior of FRP and TRM

Upgraded RC Exterior Beam-column Joints I” journal of composites for construction ASCE/MAY/JUNE,

2012, page no.308-321.

[6] K.R.Bindhu Department of Civil Engineering, College of Engineering, Thiruvananthapuram, India, and K.P.

Jaya Structural Engineering Division, Anna University, Chennai, India,2010. “Strength and Behavior of

Exterior Beam Column Joints with Diagonal Cross Bracing Bars” ASIAN JOURNAL OF CIVIL

ENGINEERING ( BUILDING AND HOUSING) VOL. 11, NO. 3(2010) page no. 397-410.

[7] Suhasini M Kulkarni (Civil Engineering Department, Parul Institute of Engineering & Technology, India),

Yogesh D Patil (Applied Mechanics Department, Sardar Vallabhbhai Patel National Institute of Technology,

India). “Cyclic Behavior of Exterior Reinforced Beam-Column Joint with Cross-Inclined Column Bars” IOSR-

JMCE VOL. 11, Issue 4, JUL-AUG, 2014, page no. 09-17.

[8] Jack Moehle University of California, Berkeley, ppt on Beam Column Connection.

[9] Martin Alberto Masuelli, “Introduction of Fibre-Reinforced Polymers – Polymers and Composites: Concepts,

Properties and Processes”, 2014.

[10] E. Rakesh Reddy,“Strengthening Of RC Beam Using FRP Sheet”International OPEN ACCESS Journal Of

Modern Engineering Research (IJMER)

BOOK:

[1] Park and paulay, “Design of concrete structure” Page no. 716-751.

National Conference on Advances in Engineering, Technology & Management 37 | Page

(AETM’15)”

Potrebbero piacerti anche

- Ijciet 08 01 018 PDFDocumento19 pagineIjciet 08 01 018 PDFIAEME PublicationNessuna valutazione finora

- Exterior Beam-Column Joint Study With Non-ConventionalDocumento16 pagineExterior Beam-Column Joint Study With Non-ConventionalAtano RoyNessuna valutazione finora

- Nimiya Rose JoshuvaDocumento9 pagineNimiya Rose JoshuvaVishnu P SudhakaranNessuna valutazione finora

- Cyclic Behaviour of Beam Column Joint Retrofitted With Simcon LaminatesDocumento20 pagineCyclic Behaviour of Beam Column Joint Retrofitted With Simcon LaminatesJay PatelNessuna valutazione finora

- Investigation of Seismic Behavior of Steel Coupling Beams in Hybrid Coupled StructuresDocumento9 pagineInvestigation of Seismic Behavior of Steel Coupling Beams in Hybrid Coupled StructuresSinem Kocabaş ŞirikçiNessuna valutazione finora

- Jurnal ASTMDocumento11 pagineJurnal ASTMIpink OctavianaNessuna valutazione finora

- Improvement in Properties of Circular Columns Using Welded Wire Mesh WWM An Experimental StudyDocumento7 pagineImprovement in Properties of Circular Columns Using Welded Wire Mesh WWM An Experimental StudyEditor IJTSRDNessuna valutazione finora

- Experimental Stress Analysis of Trapezoidal Corrugated Steel Web Beam - A ReviewDocumento4 pagineExperimental Stress Analysis of Trapezoidal Corrugated Steel Web Beam - A ReviewAsr FlowerNessuna valutazione finora

- Seismic Performance of Concentric BracedDocumento7 pagineSeismic Performance of Concentric BracedChirag JainNessuna valutazione finora

- Numerical Study of R.C. Beams Strengthening by External Steel PlateDocumento9 pagineNumerical Study of R.C. Beams Strengthening by External Steel PlateAJER JOURNALNessuna valutazione finora

- 2 CompositeDocumento9 pagine2 CompositeSurumi Rasia SalimNessuna valutazione finora

- Behaviour of Castellated Beams With andDocumento6 pagineBehaviour of Castellated Beams With andvijaykrishna kotapatiNessuna valutazione finora

- Experimental Performance of R.C.C Beam with Rectangular Trough ReinforcementDocumento11 pagineExperimental Performance of R.C.C Beam with Rectangular Trough ReinforcementSwapnil BelsareNessuna valutazione finora

- Cyclic Tests On Bolted Steel Double-Sided Beam-To-Column JointsDocumento11 pagineCyclic Tests On Bolted Steel Double-Sided Beam-To-Column JointsAli KhalafNessuna valutazione finora

- Performance of RC Beams With Embedded Steel TrusseDocumento9 paginePerformance of RC Beams With Embedded Steel TrussevignamNessuna valutazione finora

- Engineering Structures: Aydin Demir, Naci Caglar, Hakan Ozturk, Yusuf SumerDocumento3 pagineEngineering Structures: Aydin Demir, Naci Caglar, Hakan Ozturk, Yusuf SumerAbel MulugetaNessuna valutazione finora

- 1 s2.0 S0141029620342395 MainDocumento14 pagine1 s2.0 S0141029620342395 MainKim HyeonJinNessuna valutazione finora

- Seismic Design Basis For Internally-Braced RC Frames: M.R. Maheri and H. GhaffarzadehDocumento8 pagineSeismic Design Basis For Internally-Braced RC Frames: M.R. Maheri and H. Ghaffarzadehhlong123123Nessuna valutazione finora

- 1 s2.0 S0141029621015686 MainDocumento17 pagine1 s2.0 S0141029621015686 MainKim HyeonJinNessuna valutazione finora

- 672 2451 1 PBDocumento3 pagine672 2451 1 PBSMEETHANessuna valutazione finora

- Sand 4Documento17 pagineSand 4Pavan MNessuna valutazione finora

- Bond Characteristics High-Strength Steel ReinforcementDocumento6 pagineBond Characteristics High-Strength Steel ReinforcementUmair BaigNessuna valutazione finora

- Paper With y MX 2)Documento25 paginePaper With y MX 2)Shreyas AlagundiNessuna valutazione finora

- Engineering Structures: Cheng-Cheng Chen, Chien-Chung Chen, Jia-Hau ShenDocumento10 pagineEngineering Structures: Cheng-Cheng Chen, Chien-Chung Chen, Jia-Hau ShenvardhangargNessuna valutazione finora

- Engineering Structures: Jingchen Liu, Yuanlong Yang, Jiepeng Liu, Xuhong ZhouDocumento17 pagineEngineering Structures: Jingchen Liu, Yuanlong Yang, Jiepeng Liu, Xuhong ZhouSachintha WijekoonNessuna valutazione finora

- Seismic Performance of Post-Tensioned Precast ConcDocumento9 pagineSeismic Performance of Post-Tensioned Precast ConcAbderrahmane SaidNessuna valutazione finora

- Finite Element Modeling and Theoretical Analysis of SFRSCC Composite Beams Strengthened by Bottom Tensioned Steel PlatesDocumento18 pagineFinite Element Modeling and Theoretical Analysis of SFRSCC Composite Beams Strengthened by Bottom Tensioned Steel PlatesbroodyNessuna valutazione finora

- Jurnal Teknologi: S C E R C B: F E SDocumento8 pagineJurnal Teknologi: S C E R C B: F E SYulista ApriliaNessuna valutazione finora

- Innovative Technique For Seismic Upgrade of RC Square ColumnsDocumento15 pagineInnovative Technique For Seismic Upgrade of RC Square Columns오상진Nessuna valutazione finora

- 122 AviramDocumento12 pagine122 AviramKY PengNessuna valutazione finora

- Development and Seismic Performance Evaluation of New High Strength Reinforced Concrete Column and Steel Beam (New-RCS) Joint - 2023Documento14 pagineDevelopment and Seismic Performance Evaluation of New High Strength Reinforced Concrete Column and Steel Beam (New-RCS) Joint - 2023KRISHNA MURARINessuna valutazione finora

- Push Over Analysis of Unstiffened Steel Plate Shear Wall: Abhishek Verma, P. R. MaitiDocumento9 paginePush Over Analysis of Unstiffened Steel Plate Shear Wall: Abhishek Verma, P. R. MaitiIJERDNessuna valutazione finora

- Seismic Performance of A 3D Full-Scale High-Ductility Steel-Concrete Composite Moment-Resisting Structure-Part I: Design and Testing ProcedureDocumento26 pagineSeismic Performance of A 3D Full-Scale High-Ductility Steel-Concrete Composite Moment-Resisting Structure-Part I: Design and Testing ProcedureKrishna MurariNessuna valutazione finora

- (2-4) (ES) Structural Performance of Detachable Precast Composite Column Joints With Mechanical Metal PlatesDocumento17 pagine(2-4) (ES) Structural Performance of Detachable Precast Composite Column Joints With Mechanical Metal PlatesPhạm Tiến ĐạtNessuna valutazione finora

- Experimental Study On Behaviour of Composite Column CFTDocumento7 pagineExperimental Study On Behaviour of Composite Column CFTnilkanthNessuna valutazione finora

- I-Beam To Box Column Connection by A VerDocumento15 pagineI-Beam To Box Column Connection by A VerHenry CzenczekNessuna valutazione finora

- Short ColumnsDocumento15 pagineShort ColumnssrividyaNessuna valutazione finora

- Planted ColumnDocumento7 paginePlanted Columnabdul khaderNessuna valutazione finora

- Stress-Strain Relationship of High-Strength Steel (HSS) Reinforcing BarsDocumento9 pagineStress-Strain Relationship of High-Strength Steel (HSS) Reinforcing BarsAISWARYA K VIJAY M.Tech CASE 2021-2023Nessuna valutazione finora

- Comparative Study On Concentric Steel Braced Frame Structure Due To Effect of Aspect Ratio Using Pushover AnalysisDocumento6 pagineComparative Study On Concentric Steel Braced Frame Structure Due To Effect of Aspect Ratio Using Pushover AnalysisijsretNessuna valutazione finora

- Is I Journal PaperDocumento20 pagineIs I Journal PaperYonny Pacompìa YucraNessuna valutazione finora

- Comparison of Experimental Values With EC 4, ACI-318, AISC-LRFD of Concrete Filled Steel Fluted Columns For Concentric LoadDocumento10 pagineComparison of Experimental Values With EC 4, ACI-318, AISC-LRFD of Concrete Filled Steel Fluted Columns For Concentric Loadmohamed alyozbakiNessuna valutazione finora

- Ijesit201301 55Documento10 pagineIjesit201301 55mfhfhfNessuna valutazione finora

- Journal of Thi-Qar University Vol.13 No.4 Dec 2018: WWW - Jutq.utq - Edu.iqDocumento21 pagineJournal of Thi-Qar University Vol.13 No.4 Dec 2018: WWW - Jutq.utq - Edu.iqnagham tariqNessuna valutazione finora

- An Analytical Model Computing The Flexural StrengthDocumento24 pagineAn Analytical Model Computing The Flexural StrengthDandi AgindaNessuna valutazione finora

- F 97 S 65Documento12 pagineF 97 S 65Tavio TavioTavioNessuna valutazione finora

- 10 1016@j Engstruct 2018 09 051Documento13 pagine10 1016@j Engstruct 2018 09 051Reza JamalpourNessuna valutazione finora

- Elastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004Documento16 pagineElastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004EliyaHeninNessuna valutazione finora

- Retrofitting PANKAJ PDFDocumento15 pagineRetrofitting PANKAJ PDFraihanNessuna valutazione finora

- Shear Strength Prediction of Reinforced Concrete Transfer BeamsDocumento21 pagineShear Strength Prediction of Reinforced Concrete Transfer Beamsmohammed_fathelbabNessuna valutazione finora

- Initial Imperfection Analysis and Design of Concrete-Filled Stiffened Thin-Walled Steel TubularDocumento13 pagineInitial Imperfection Analysis and Design of Concrete-Filled Stiffened Thin-Walled Steel TubularAbdul BariNessuna valutazione finora

- Behavior and Strength of RC Column-To-Steel Beam Connections Subjected To Seismic LoadingDocumento8 pagineBehavior and Strength of RC Column-To-Steel Beam Connections Subjected To Seismic Loadingbravo deltafoxNessuna valutazione finora

- Ain Shams Engineering Journal: Suzan A.A. Mustafa, Osama M. Elhussieny, Ehab B. Matar, Ahmed G. AlaaserDocumento11 pagineAin Shams Engineering Journal: Suzan A.A. Mustafa, Osama M. Elhussieny, Ehab B. Matar, Ahmed G. Alaasermortada JasimNessuna valutazione finora

- Investigation On Buckling Behaviour of RC Rectangular Long Column Confined With Aluminium MeshDocumento10 pagineInvestigation On Buckling Behaviour of RC Rectangular Long Column Confined With Aluminium MeshIJRASETPublicationsNessuna valutazione finora

- Analytical Investigation of The Cyclic Behavior and Plastic Hinge Formation in Deep Wide-Flange Steel Beam-ColumnsDocumento22 pagineAnalytical Investigation of The Cyclic Behavior and Plastic Hinge Formation in Deep Wide-Flange Steel Beam-ColumnsJuan BravoNessuna valutazione finora

- J BRR Col Sc1& 2 R Short Comm - Add Compressive Strain Data 21-12-10Documento12 pagineJ BRR Col Sc1& 2 R Short Comm - Add Compressive Strain Data 21-12-10mizanaNessuna valutazione finora

- RRL1Documento3 pagineRRL1Jenz TeppangNessuna valutazione finora

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDa EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNessuna valutazione finora

- Design of Steel Structures: Materials, Connections, and ComponentsDa EverandDesign of Steel Structures: Materials, Connections, and ComponentsNessuna valutazione finora

- Invitation FinalDocumento2 pagineInvitation FinalAnonymous KyLhn6Nessuna valutazione finora

- AssignsubmissionDocumento10 pagineAssignsubmissionAnonymous KyLhn6Nessuna valutazione finora

- Seismic Behavior Comparison of Reinforced Concrete Interior 2018 EngineeringDocumento15 pagineSeismic Behavior Comparison of Reinforced Concrete Interior 2018 EngineeringAnonymous KyLhn6Nessuna valutazione finora

- Circular of Expert Lecture Under CoE DRRDocumento2 pagineCircular of Expert Lecture Under CoE DRRAnonymous KyLhn6Nessuna valutazione finora

- Assignsubmission - File - Assignment 2Documento10 pagineAssignsubmission - File - Assignment 2Anonymous KyLhn6Nessuna valutazione finora

- Invitation On Guest LectureDocumento1 paginaInvitation On Guest LectureAnonymous KyLhn6Nessuna valutazione finora

- End Block Design of PSCDocumento33 pagineEnd Block Design of PSCAnonymous KyLhn6100% (1)

- AssignmentDocumento9 pagineAssignmentAnonymous KyLhn6Nessuna valutazione finora

- Assignsubmission FileDocumento11 pagineAssignsubmission FileAnonymous KyLhn6Nessuna valutazione finora

- Faculty Development Program on Fiber Reinforced ConcreteDocumento2 pagineFaculty Development Program on Fiber Reinforced ConcreteAnonymous KyLhn6Nessuna valutazione finora

- Expert TalkDocumento3 pagineExpert TalkAnonymous KyLhn6Nessuna valutazione finora

- Analysis and Design of Reinforced Concrete ElementsDocumento4 pagineAnalysis and Design of Reinforced Concrete ElementsAnonymous KyLhn6Nessuna valutazione finora

- Dr. Shu-Qing Yang - Profile2Documento1 paginaDr. Shu-Qing Yang - Profile2Anonymous KyLhn6Nessuna valutazione finora

- Expert Lecture on Coastal Reservoir InfrastructureDocumento1 paginaExpert Lecture on Coastal Reservoir InfrastructureAnonymous KyLhn6Nessuna valutazione finora

- Sa 3 PDFDocumento16 pagineSa 3 PDFAnonymous KyLhn6Nessuna valutazione finora

- Tele-Cobalt Facility (Bhabhatron-II) For Gamma IrradiationDocumento2 pagineTele-Cobalt Facility (Bhabhatron-II) For Gamma IrradiationAnonymous KyLhn6Nessuna valutazione finora

- Sa 3 PDFDocumento16 pagineSa 3 PDFAnonymous KyLhn6Nessuna valutazione finora

- Coastal Reservoir Expert LectureDocumento1 paginaCoastal Reservoir Expert LectureAnonymous KyLhn6Nessuna valutazione finora

- Faculty Development Program on Fiber Reinforced ConcreteDocumento2 pagineFaculty Development Program on Fiber Reinforced ConcreteAnonymous KyLhn6Nessuna valutazione finora

- ICEVCEDocumento2 pagineICEVCEAnonymous KyLhn6Nessuna valutazione finora

- Hands on FUSION 360 training by BIMITDocumento1 paginaHands on FUSION 360 training by BIMITAnonymous KyLhn6Nessuna valutazione finora

- ICEVCEDocumento2 pagineICEVCEAnonymous KyLhn6Nessuna valutazione finora

- S1 Result 27-04-17Documento39 pagineS1 Result 27-04-17Anonymous KyLhn6Nessuna valutazione finora

- Annual Hours Total Teaching and Related Duties: SubtotalDocumento6 pagineAnnual Hours Total Teaching and Related Duties: SubtotalRavi SharmaNessuna valutazione finora

- Apj Abdul Kalam Technological University Thiruvananthapuram, Kerala, INDIADocumento35 pagineApj Abdul Kalam Technological University Thiruvananthapuram, Kerala, INDIAAnonymous KyLhn6Nessuna valutazione finora

- TPC Questions MCQDocumento12 pagineTPC Questions MCQAnonymous KyLhn6Nessuna valutazione finora

- Watertank GS PDFDocumento24 pagineWatertank GS PDFManoj RautNessuna valutazione finora

- s1 Revaluation Result 11-09-17Documento12 pagines1 Revaluation Result 11-09-17Anonymous KyLhn6Nessuna valutazione finora

- Quick HealDocumento1 paginaQuick Healsamarth_bajpai2322Nessuna valutazione finora

- Tutorial 1 Discussion Document - Batch 03Documento4 pagineTutorial 1 Discussion Document - Batch 03Anindya CostaNessuna valutazione finora

- The Dominant Regime Method - Hinloopen and Nijkamp PDFDocumento20 pagineThe Dominant Regime Method - Hinloopen and Nijkamp PDFLuiz Felipe GuaycuruNessuna valutazione finora

- Endangered EcosystemDocumento11 pagineEndangered EcosystemNur SyahirahNessuna valutazione finora

- Rubric 5th GradeDocumento2 pagineRubric 5th GradeAlbert SantosNessuna valutazione finora

- Indian Standard: Pla Ing and Design of Drainage IN Irrigation Projects - GuidelinesDocumento7 pagineIndian Standard: Pla Ing and Design of Drainage IN Irrigation Projects - GuidelinesGolak PattanaikNessuna valutazione finora

- White Box Testing Techniques: Ratna SanyalDocumento23 pagineWhite Box Testing Techniques: Ratna SanyalYogesh MundhraNessuna valutazione finora

- CDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Documento152 pagineCDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Gilles DellaccioNessuna valutazione finora

- Copula and Multivariate Dependencies: Eric MarsdenDocumento48 pagineCopula and Multivariate Dependencies: Eric MarsdenJeampierr Jiménez CheroNessuna valutazione finora

- Masteringphys 14Documento20 pagineMasteringphys 14CarlosGomez0% (3)

- Technical Manual - C&C08 Digital Switching System Chapter 2 OverviewDocumento19 pagineTechnical Manual - C&C08 Digital Switching System Chapter 2 OverviewSamuel100% (2)

- Product Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966Documento1 paginaProduct Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966shama093Nessuna valutazione finora

- Wheeled Loader L953F Specifications and DimensionsDocumento1 paginaWheeled Loader L953F Specifications and Dimensionssds khanhNessuna valutazione finora

- AD Chemicals - Freeze-Flash PointDocumento4 pagineAD Chemicals - Freeze-Flash Pointyb3yonnayNessuna valutazione finora

- Kate Elizabeth Bokan-Smith ThesisDocumento262 pagineKate Elizabeth Bokan-Smith ThesisOlyaGumenNessuna valutazione finora

- Indian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewDocumento8 pagineIndian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewPRINCIPAL BHILWARANessuna valutazione finora

- Special Power of Attorney: Benedict Joseph M. CruzDocumento1 paginaSpecial Power of Attorney: Benedict Joseph M. CruzJson GalvezNessuna valutazione finora

- Speed Reducer GearboxDocumento14 pagineSpeed Reducer Gearboxعبد للهNessuna valutazione finora

- Alternate Tuning Guide: Bill SetharesDocumento96 pagineAlternate Tuning Guide: Bill SetharesPedro de CarvalhoNessuna valutazione finora

- Google Earth Learning Activity Cuban Missile CrisisDocumento2 pagineGoogle Earth Learning Activity Cuban Missile CrisisseankassNessuna valutazione finora

- Test Bank For Fundamental Financial Accounting Concepts 10th by EdmondsDocumento18 pagineTest Bank For Fundamental Financial Accounting Concepts 10th by Edmondsooezoapunitory.xkgyo4100% (47)

- Prac Res Q2 Module 1Documento14 paginePrac Res Q2 Module 1oea aoueoNessuna valutazione finora

- Statistical Quality Control, 7th Edition by Douglas C. Montgomery. 1Documento76 pagineStatistical Quality Control, 7th Edition by Douglas C. Montgomery. 1omerfaruk200141Nessuna valutazione finora

- ITP Exam SuggetionDocumento252 pagineITP Exam SuggetionNurul AminNessuna valutazione finora

- EC GATE 2017 Set I Key SolutionDocumento21 pagineEC GATE 2017 Set I Key SolutionJeevan Sai MaddiNessuna valutazione finora

- Mobile ApplicationDocumento2 pagineMobile Applicationdarebusi1Nessuna valutazione finora

- TJUSAMO 2013-2014 Modular ArithmeticDocumento4 pagineTJUSAMO 2013-2014 Modular ArithmeticChanthana ChongchareonNessuna valutazione finora

- Srimanta Sankaradeva Universityof Health SciencesDocumento3 pagineSrimanta Sankaradeva Universityof Health SciencesTemple RunNessuna valutazione finora

- Pasadena Nursery Roses Inventory ReportDocumento2 paginePasadena Nursery Roses Inventory ReportHeng SrunNessuna valutazione finora

- STS Prelim ExamDocumento2 pagineSTS Prelim ExamMychie Lynne MayugaNessuna valutazione finora

- Kaydon Dry Gas SealDocumento12 pagineKaydon Dry Gas Sealxsi666Nessuna valutazione finora