Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pages From 2. GE-Power Break 2 ICCB

Caricato da

shrikanth5singhCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pages From 2. GE-Power Break 2 ICCB

Caricato da

shrikanth5singhCopyright:

Formati disponibili

Application

V. Individual Pole Short-Circuit Test Sequence (Isu) Breakers with 100% rating are so marked on the front of

the devices. This marking includes minimum enclosure size,

1. Individual Pole Short-Circuit Breaking Capacity: minimum ventilation (if any) , minimum cable sizes and tem-

Power Break® II Circuit breakers are tested to complete a perature ratings to be used. Current versions of the National

series of short-circuit interruptions with a 3-minute rest Electric Code permit such use in the exceptions to Articles

period between interruptions. The breakers must com- 210-22(c) and 220-10 (b).

plete an “open” operation followed by a “close-open”

operation on each pole individually. The circuit breakers Factors Affecting the Current Ratings

are tested with an open circuit voltage sufficient to en- of Installed Devices

able a recovery voltage of the rated voltage plus 5%. The There are six application factors to consider in selecting cur-

800-2000 amp Power Break II circuit breakers are tested rent rating on installed Power Break II insulated case circuit

using two phases of a three-phase 25,000 amp rms breakers. These are: 1) the size of the cable or bus used in

symmetrical, 50 Hz, 25% power factor short circuit. the line and load connections, 2) the actual installed ambient

2. Verification of Dielectric Withstand: temperature, 3) the system operating frequency, 4) the alti-

Following the short-circuit interruptions, the breakers tude of the installation, 5) the type of loading of the protected

main circuit is verified to withstand a voltage equal to circuit, and 6) the design safety factor.

twice its rated insulation voltage; however, not less than

1000 V for 1 minute. The following simple relationship combines these six applica-

3. Verification of Overload Release: tion factors into a single equation:

Following the dielectric verification, the circuit breaker

overload protection is verified by applying 250% of rated ICB = IA x A x B x C x D x E x F

current through each pole individually. The breaker must

trip within the trip time curve. ICB = Installed circuit breaker current rating, amps

IA = Actual load current, amps

Table 52.1 A = Cable of bus sizing factor

Test Tolerance: Unless Otherwise Specified B = Ambient temperature rating factor

All Tests No Load, Normal Short Circuit C = Frequency rating factor

Load or Over Load D = Altitude rating factor

Current +5%-0% — 3500 E = Load class rating factor

Voltage +5%-0% — 2500 F = Safety factor

Frequency — ±5%(47.5-52.5 Hz) ±5%(47.5-52.5 Hz)

Cable or Bus Size

Power Factor — ±0.05 +0 -0.05

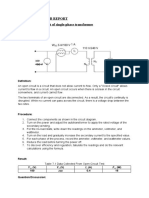

The thermal design of a circuit breaker takes into account

the ability of the line and load cables or buses to act as heat

Power Break® II – sinks. Standard UL 489 has assigned specific cable or bus

100 % Rated Circuit Breakers sizes for each current rating. Generally, these assignments

Power Breaker II circuit breakers are UL Listed to carry 100% are coordinated with specific conductor temperature ratings.

of rating-plug nameplate current, continuously, when Increasing a conductor’s temperature rating decreases both

installed in accordance with guideline printed on the breaker, the cross-sectional area and its ability to conduct heat from

and as detailed in the following Current Rating Factors por- the circuit breaker. The chart below illustrates the effect of

tion of this section. changing cable areas on the current-carrying ability of the

circuit breaker.

Standard Rated Devices

A “Standard rated” device is rated to carry 100% of its name-

plate current for short periods of time (up to 3 hours maxi-

mum) when enclosed in equipment, such as a switchboard.

The enclosed device has a continuous rating of 80% of rating

according to current versions of the National Electric Code

(Article 220-10).

100% Rated Devices Effects of changing load and line conductor sizes

100% rated devices are designed to carry 100% of their

nameplate current rating when enclosed and tested in distri-

bution equipment.

4000 A stationary 80 %

52

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Technical Data Sheet For DG Sets Contract No:Icb Bid No - Wrmsp/Icb-02 Furkat-1 Pumping Station DG SetDocumento4 pagineTechnical Data Sheet For DG Sets Contract No:Icb Bid No - Wrmsp/Icb-02 Furkat-1 Pumping Station DG Setshrikanth5singhNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 48V DC System - AuxDocumento3 pagine48V DC System - Auxshrikanth5singh100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Battery SizingDocumento2 pagineBattery Sizingshrikanth5singhNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- 24042020Documento2 pagine24042020shrikanth5singhNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Cable TrayDocumento10 pagineCable Trayshrikanth5singhNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Washer 09.03.2020Documento1 paginaWasher 09.03.2020shrikanth5singhNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- ACB Plug Socket DetailsDocumento2 pagineACB Plug Socket Detailsshrikanth5singhNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Teflon Washer RequirementDocumento3 pagineTeflon Washer Requirementshrikanth5singhNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Zamil HVACDocumento6 pagineZamil HVACshrikanth5singhNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Control CheckDocumento1 paginaControl Checkshrikanth5singhNessuna valutazione finora

- Control Philosophy - Master Gas 2 Addn PDFDocumento11 pagineControl Philosophy - Master Gas 2 Addn PDFshrikanth5singhNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Farabi SpecsDocumento1 paginaFarabi Specsshrikanth5singhNessuna valutazione finora

- Control Study BGCS#1Documento8 pagineControl Study BGCS#1shrikanth5singhNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- PLC VS DDC ComparisonDocumento1 paginaPLC VS DDC Comparisonshrikanth5singhNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Cable GlandDocumento1 paginaCable Glandshrikanth5singhNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Surge ArresterDocumento1 paginaSurge Arrestershrikanth5singhNessuna valutazione finora

- Option:1 - 48V Derived From AC-DC Converter Fed From Main AC UPSDocumento4 pagineOption:1 - 48V Derived From AC-DC Converter Fed From Main AC UPSshrikanth5singhNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Option:1 - 48V Derived From AC-DC Converter Fed From Main AC UPSDocumento4 pagineOption:1 - 48V Derived From AC-DC Converter Fed From Main AC UPSshrikanth5singhNessuna valutazione finora

- 26042020Documento1 pagina26042020shrikanth5singhNessuna valutazione finora

- Battery Charger Sizing SS 1, Rev 03Documento15 pagineBattery Charger Sizing SS 1, Rev 03Pramod B.Wankhade100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 48V DC System - AuxDocumento3 pagine48V DC System - Auxshrikanth5singh100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 1Documento1 pagina1shrikanth5singhNessuna valutazione finora

- 48V DC OptionsDocumento4 pagine48V DC Optionsshrikanth5singhNessuna valutazione finora

- 24042020Documento2 pagine24042020shrikanth5singhNessuna valutazione finora

- 48V DC System - AuxDocumento3 pagine48V DC System - Auxshrikanth5singh100% (1)

- Power PanelsDocumento1 paginaPower Panelsshrikanth5singhNessuna valutazione finora

- Geethanjali/ Arun, Please Note, Below Are The Cable Sizes W.r.to 3.7% of Voltage DropDocumento2 pagineGeethanjali/ Arun, Please Note, Below Are The Cable Sizes W.r.to 3.7% of Voltage Dropshrikanth5singhNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- 1.25 MultiplierDocumento1 pagina1.25 Multipliershrikanth5singhNessuna valutazione finora

- Data TravelDocumento3 pagineData Travelshrikanth5singhNessuna valutazione finora

- MOV POWER PANEL LIST (Version 1)Documento22 pagineMOV POWER PANEL LIST (Version 1)shrikanth5singhNessuna valutazione finora

- Adv of XLPE Over PVC in DetailDocumento1 paginaAdv of XLPE Over PVC in Detailaravin9786Nessuna valutazione finora

- Guide For Application of IEC 62271-100 AND IEC 62271-1: Making and Breaking TestsDocumento186 pagineGuide For Application of IEC 62271-100 AND IEC 62271-1: Making and Breaking TestsJosé Alejandro RangelNessuna valutazione finora

- Manual p8Documento190 pagineManual p8Thanos HontzakisNessuna valutazione finora

- 8 Acd 1 DDocumento9 pagine8 Acd 1 DcommorilNessuna valutazione finora

- Fupact: Catalog 2020Documento170 pagineFupact: Catalog 2020Ionescu Silvian IonutNessuna valutazione finora

- Sinamics V20 Invertersinamics V20 InverterDocumento412 pagineSinamics V20 Invertersinamics V20 Invertervikki chowdaryNessuna valutazione finora

- PC200-8 SM - 013 Troubleshooting by Failure Code Part-3Documento50 paginePC200-8 SM - 013 Troubleshooting by Failure Code Part-3t5442071100% (2)

- 05 - Short Circuit Strength of Power TransformersDocumento10 pagine05 - Short Circuit Strength of Power Transformersjm.mankavil6230Nessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Electrical Design Basis - Offshore PlatformDocumento48 pagineElectrical Design Basis - Offshore Platformvamcodong100% (6)

- Arc Fault Detection DevicesDocumento9 pagineArc Fault Detection Devicesluhusapa-1Nessuna valutazione finora

- 5 - Balanced and Unbalanced FaultsDocumento117 pagine5 - Balanced and Unbalanced FaultsJuan Manuel VegaNessuna valutazione finora

- Acti 9 Catalogue 2012 KSADocumento298 pagineActi 9 Catalogue 2012 KSAJabir QuadriNessuna valutazione finora

- Test HVDocumento110 pagineTest HVChandru BadachiNessuna valutazione finora

- FASTflo WHC56 Service ManualDocumento40 pagineFASTflo WHC56 Service Manualn67250Nessuna valutazione finora

- T2500Documento2 pagineT2500kylegazeNessuna valutazione finora

- D-70 PillerDocumento10 pagineD-70 PillerAhmed JaNessuna valutazione finora

- E-Line DLDocumento21 pagineE-Line DLiulian17dNessuna valutazione finora

- ETP48200-C5D1 V500R001 User Manual 01Documento83 pagineETP48200-C5D1 V500R001 User Manual 01Emre KayaNessuna valutazione finora

- Yanmar TNV Troubleshooting Electronic Control 0DTNV-G00600 Troubleshooting ManualDocumento234 pagineYanmar TNV Troubleshooting Electronic Control 0DTNV-G00600 Troubleshooting Manualjads301179100% (18)

- FusesDocumento34 pagineFusesOrlando RomaniNessuna valutazione finora

- C40 Trace Manual EnglishDocumento24 pagineC40 Trace Manual EnglishBertNessuna valutazione finora

- Direct Current Detailed Specification For Caneco BT - 2012-01-30Documento13 pagineDirect Current Detailed Specification For Caneco BT - 2012-01-30Mohammed BouzianeNessuna valutazione finora

- Siemens MCB Betagard 5SX45SJ4 ET 01 014 053Documento12 pagineSiemens MCB Betagard 5SX45SJ4 ET 01 014 053Rahul BhujbalNessuna valutazione finora

- L&T ACBsDocumento38 pagineL&T ACBsPavan KumarNessuna valutazione finora

- Manual XGR (2009.12.24) (Eng)Documento204 pagineManual XGR (2009.12.24) (Eng)ViswanathanNessuna valutazione finora

- Fault AnalysisDocumento37 pagineFault Analysisavinash_sinha20100% (2)

- New MR 3 PDFDocumento22 pagineNew MR 3 PDFHossam Mohi EldinNessuna valutazione finora

- Catalogo Circuit BreakersDocumento184 pagineCatalogo Circuit BreakersSebastián FernándezNessuna valutazione finora

- Generator TestingDocumento50 pagineGenerator TestingZamani Mahdi93% (15)

- Ele 291 Lab Report Exp7Documento7 pagineEle 291 Lab Report Exp7Hamzah أسَدُ أللَّهNessuna valutazione finora

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDa EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesValutazione: 5 su 5 stelle5/5 (1)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDa EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialValutazione: 3.5 su 5 stelle3.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDa EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeValutazione: 4.5 su 5 stelle4.5/5 (9)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosDa EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosValutazione: 5 su 5 stelle5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDa EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNessuna valutazione finora