Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3 Piece Ball Valves PDF

Caricato da

Shaik Mudassar NazarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3 Piece Ball Valves PDF

Caricato da

Shaik Mudassar NazarCopyright:

Formati disponibili

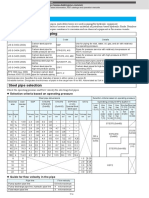

METRIC

THREE PIECE BALL VALVES

47 SERIES

THREE PIECE BALL VALVES

The 47 Series is the main lines of Technical Summary

HABONIM 3-piece ball valves for

Size Range: ¼"- 8" (DN6 - DN200)

industrial applications. The valves Application: General Service, Chemical, Petrochemical, Oil and Gas, Refinery,

are suitable for applications requiring Energy, Pharmaceutical, Food & Beverage, Cosmetics, Semiconductor

high flow capacity and tight shutoff, Service: Water, Gas, Steam, Chemicals, Solvents, Thermal Fluid

where reliability, functionality and Pressure Range: Vacuum 10-6 torr to 155 bar (2250 psig)

interchangeability are essential for Temperature Range: -60°C to 260°C (-76°F to 500°F)

the product quality. HABONIM has Materials: Carbon Steel, Stainless Steel, Hasteloy-C, Hasteloy-C22, Alloy-20,

various valve solutions and designs Monel, Duplex, SMO 254

that give the end user the freedom End Connection: Screwed, Socket & Butt weld, Flanged, Clamp, Compression Fitting

of choice for the toughest Operation: Hand or Gear operated, Pneumatic or Electric Actuated

requirements imposed by the industry

and by international standards.

NAMUR interface

enables mounting of

Visual Indication of compatible solenoid

valve position

Spring Return or

Double Acting

Threaded holes actuators

for additional

instrumentation

Quarter Turn operation

suitable for pneumatic,

Valve and actuator electric or hydraulic

packages for on/off actuation

or control

applications

Floating Ball

concept

for positive shutoff

Spring loaded stem

seal with locking clip

Rigid handles

indicating flow

direction with optional

Locking Devices

Bi-directional shutoff

from vacuum

to high pressures

Interchangeable

seats, balls, stems

Rugged construction and seals for various

with ISO top applications

mounting flange for

actuation

Blowout proof stem

with optional firesafe

and Antistatic device

A large range of end

connections for Full

or Reduce bore

valves

Various type of seat designs

and materials including

characterized metal seats

High flow capacity for control applications

with low pressure

drop at full opening

Easy in-line serviceable

with swing-out body

2 THREE PIECE BALL VALVES 47 SERIES

47 Series

Valve Construction Body and Trim Materials

The rigid valve body construction is designed in accordance Standard HABONIM body and end materials are Carbon Steel

with ANSI B16.34. The 47 series valve bodies have a top or Stainless Steel. Carbon Steel bodies and ends are forgings

mounting flange conforming to ISO 5211 with centering ring to ASTM A105 or castings to ASTM A216 WCB. Stainless Steel

for direct mounting of actuators, limit switches, fugitive emission bodies are casting to ASTM A351 CF8M. The ends are castings

bonnets or extended handles. to ASTM A351 CF3M, which have a lower carbon content and

The 46 series valve bodies do not have an ISO top mounting are therefore more suitable for welding.

flange and they carry a different wrench (see page 10).

The standard ball and stem material is stainless steel 316.

CLOCKWISE All high torque valve stems are made out of high tensile

TO CLOSE

17-4PH stainless steel. Balls made out of 17-4PH stainless

steel are also available. Other valve and trim materials such as

Alloy-20, Hastelloy-C22, Duplex or Monel for specified

applications are available on request.

All valve pressure containing parts such as bodies and ends

47 top mounting flange for 47 top mounting flange are heat numbered and can be traced by their work number

Actuation & Accesories for Manual Operation

which is stamped on the valve tag. Documentation will be

The 3-piece body construction enables valve in-line maintenance supplied on request.

and replacement of internal parts. Standard 47 valve bodies Stainless steel valves have stainless steel bolts and nuts.

have through body bolts. Firesafe valves have threaded body Carbon steel valves have plated carbon steel bolts and nuts.

screws. With the ISO mounting flange there is no need to loosen Special alloy valves carry stainless steel bolts and nuts unless

body bolts when fitting actuators. otherwise specified.

The 47 series ball, seats and seals are interchangeable with

HABONIM flanged 31/32 series reduced bore valves and with

HABONIM flanged 73/74/77/78 series full bore valves up to

and including 2. Stem assemblies are interchangeable

through out.

End Connections

Many types of end connections are made to suit most customer Other Ends

requirements. The standard types are screwed, welded or Other available ends are Clamp ends for the Biopharm and

flanged connections. Food industry, Compression Fitting ends for Instrumentation

and the Semiconductor industry, Extended Pipe ends for the

Screwed Ends Chemical industry. Other ends are available on request. Please

Screwed ends are identified by a marking on the end face: refer to Bulletin C-515 for dimensions.

BSPT - no identification

NPT - concentric groove

BSPP DIN 2999 - external chamfer

DIN 3852 - external step

Other screwed ends identification will be advised on request.

Pipe weld Ends

Welded ends are available according to the pipe type and

schedule in buttweld or socket weld. The standard pipe schedule

is 40. Buttweld ends are available from Sch 5 to Sch 160 .

Tube weld ends Screwed Buttweld Socket weld Flange

Tube ends are available in imperial or metric sizes. The ends

are short stubs or one piece extended stubs suitable for AOW

(automatic orbital welding). Weld end valves can be installed

in-line without dismantling the valve or changing internal parts,

as long as the proper welding procedures are kept. Please refer

to Habonim Welding Instructions for more information.

Flanged Ends

Flanged ends complying to class 150 ANSI B16.5 and DIN Extended Tube Clamp Compression

3202 F1 face-to-face dimensions are available in reduce or full Fitting

bore. In some cases ANSI flange end valves will comply to

class 300 face-to-face dimensions only.

HABONIM THREE PIECE BALL VALVES 47 SERIES 3

THREE PIECE BALL VALVES

Floating Ball Principle Body Seals

The floating ball design is based on the concept that both the

seat preload and the line pressure contribute to a compressive

force between the ball and seat to create a bubble tight shut-

off at low and high pressure drops. The line pressure forces the

ball to the downstream seat, the seat flexes and creates the

seal. The upstream seat is forced forward, allowing the pressure

to penetrate from behind through the grooves and into the body

cavity, relieving the load and reducing its wear. Other designs

such as diverter and double block and bleed seats, incorporate

a seat/seal or seat with a backup O-ring to seal from the

upstream side of the valve.

Standard Body Seal

The body seal in a standard valve

is constructed with three closed

sides and one side open into the

valve cavity. Pressure in the valve

cavity forces the seal to the corners,

thus creating a tight seal. All seal

Floating ball Double block & bleed materials are flexible and will

Downstream seal Upstream seal

compress according to the groove

shape. Each time the valve is

opened for repair, the seals must

be replaced with new ones.

Metal Ring

The Metal Ring Encapsulated

Groove design uses a thinner body

seal supported by a metal ring and

is used in the standard body. It

provides tighter compression of the

Ball Material body seal for higher pressure and

A highly polished solid ball ensures tight shutoff and long temperature fluctuations. It also

service life. All balls are solid and have specially rounded leading serves a barrier for all flexible

edges to eliminate excessive seat wear during rotation. The graphite body seals from penetrating

balls have a hole in the stem slot to equalize pressure behind into the valve body.

the ball in the valve cavity (see illustration below). Standard

ball materials are 316 Stainless Steel, Hasteloy-C, Monel, Alloy-

20, Duplex and Inconel. All materials (except 316 SS) are marked Encapsulated Groove

in the slot for identification. The fully Encapsulated Groove body

Other ball designs such as diverter balls, cavity pressure relief serves the same purpose as the

balls with a vent hole to the upstream side, characterized port Metal Ring design, only the groove

balls for control applications, balls for flushing body cavity and is machined in the valve body.

more are available on request (see illustrations below). This body construction utilizes the

same seals without the metal ring.

Equalizing Upstream Characterised T-Port Tongue & Groove

pressure pressure port for for

hole in slot relief hole control flushing The Tongue & Groove design is used

in all firesafe valves and is intended

to allow full compression of the

flexible graphite body seal and the

alignment of the body and ends.

This is implemented by having the

body seal groove in the end

connector and not in the body.

Firesafe bodies and end connectors

are not interchangeable with the

standard bodies and ends.

4 THREE PIECE BALL VALVES 47 SERIES

47 Series

Reduced Bore and Full Bore Stem

HABONIMs 47 series valves are Reduced Bore, (Nominal A precision machined blowout-proof stem is inserted into the

Bore) where the ball port ID is reduced from the nominal pipe valve body from within. Available as standard, antistatic or

ID. This reduction creates a pressure drop across the valve and firesafe. The firesafe stem has a special contour for metal to

must be considered when doing flow calculations. metal contact in the event of fire. Stems ½ to 2½ output shaft

are double D. Stems 3 and above have square shaft as

HABONIMs B47 series valves are full bore, where the ball standard and double D can be provided upon request by

port ID matches the nominal pipe ID. The full bore valve has mentioning WR Stem

one-size-up body and trim with a full bore end connection.

Full bore valves are used when maximum flow at minimum Standard Stem Firesafe Stem

pressure drop is required.

All the types of end connections are available in both reduce

bore or full bore.

For any fixed nominal pipe size you can have a reduced bore

valve with regular ends, or a full bore valve with full bore ends

and one-size-up body and ball. This is illustrated below:

Antistatic Device

Antistatic stem device to discharge static electricity buildup on

the ball are optional. This conforms to BS 5351 for continual

electrical contact between ball/stem and stem/body. Contact

is made by a spring loaded stainless steel element inserted in

the stem or a conductive

PTFE stem seal. Valve

sizes up to 2 require

a stem/body contact,

while larger size

valves also need a

ball/stem contact.

Full Bore Reduce Bore

Stem Assemblies

All valves have blowout-proof stems. The stem assembly

incorporates live loaded springs to compensate for pressure

and temperature surges and wear. A tab washer ensures that

the stem nut will not loosen during cyclic operations. The stem O-Ring Stem Assembly

is machined with a high surface finish for better sealing capability.

Optional stem seal materials and shapes are available. Special O-ring stem assemblies for

High Cycle stem arrangements are available for specific searching gas, high vacuum and

applications. other special applications such as

ammonia or high cycle applications

Standard Stem Assembly are standard options. The O-ring,

followed by backup rings, is secured

Sizes ½ to 2½ in place by a metal washer and

A blowout-proof stem and thrust bearing.

washer are inserted in the valve

body from its cavity. A set of one or

two stem packings followed by a

stem-centering gland are spring

V-Ring Stem Assembly

loaded and fastened by a nut and V-ring or sandwich style stem seals

tab washer from the outside. A rigid are some times more efficient for

handle is fastened above it by a applications such as high cycle or

second nut and serrated washer. where it is essential to have low

emissions. These seals can be fitted

Standard Stem Assembly into the standard valve body.

Sizes 3 to 8

A blowout-proof stem and thrust

washer are inserted in the valve

High Cycle Stem Assembly

body from its cavity. A set of three In high cycle applications where the valves may pass through

stem packings followed by a stem- many operational cycles per year, an upgrade to the stem

centering gland and stop plate are assembly is done according to the working conditions. Thrust

fastened by a slotted gland nut from seal with better wear resistant material, hardened polished

the outside. A pipe wrench is stems and special stem seals are suggested. A unique gland

inserted into a TEE head and with an O-ring groove securred by a live-loading spring-pack

fastened by a screw to the stem. give the valve long service life.

HABONIM THREE PIECE BALL VALVES 47 SERIES 5

THREE PIECE BALL VALVES

Seats Type and material

A flexible seat design provides tight shutoff at high and low

pressures, reduces wear and valve torque. The seat perimeter H Glass & Metal Oxide Filled PTFE

has equalizing pressure slots to allow penetration of pressure This seat withstands higher temperatures and pressures than

to the body cavity for better sealing capability. glass filled PTFE, has good resistance under load, not

Other available seat designs are Cavity Filler seats for reducing recommended for foodstuff

dead volume in the ball cavity, One-piece Seat/Seal for diverter Identification: Color blue.

valves or Double-Block and Bleed seats with O-ring.

U UHMWPE (Ultra High Molecular Weight Polyethylene)

UHMWPE is mainly used where PTFE is not acceptable. It has

high radioactive resistance of 2 x 10 rads. Other typical

applications are the tobacco industry, H2SO4 and the handling

of highly abrasive media.

Identification: Color pale white with green stripe.

Standard Diverter Cavity Filler Characterized

seat with slots seat/seal seat metal seat

Y Delrin®(Acetal Resin)

Delrin® is used for high pressure applications where resistance

Habonim has a line of metal seated valves for severe service to wear and deformation under load is essential. It is mainly

applications where high temperature, abrasion and/or corrosion used in the Petroleum industry. Its maximum temperature is

restrict the use of soft seats. Please refer to Habonim limited to 80°C (176°F) under full load.

Bulletin T-624 for additional information on seat materials and Delrin® must not be used in presence of OXYGEN.

pressure temperature limits. Identification: Color creamy white with black stripe.

K Carbon Filled PEEK®

PEEK® (Polyetheretherketone) is a tough, high temperature,

T PTFE semicrystalline thermoplastic offering excellent characteristics

such as high tensile strength and elongation properties, excellent

PTFE is the material of choice where the characteristics of low shear strength and creep resistance, outstanding fatigue and

friction, high durability, excellent thermal resistance or chemical chemical resistance, no susceptibility to hydrolysis (Steam/Hot

inertness are required. Recommended for use with water, Water).

foodstuff or corrosive chemicals.

Identification: Color black with yellow stripe.

Identification: Color white.

A TFM (Modified PTFE) L Virgin PEEK®

TFM is a chemically modified PTFE that offers enhanced Virgin PEEK® has no fillers and comprises similar physical

properties while retaining all the proven advantages of characteristics as filled PEEK®. It has higher radiation resistance

conventional PTFE. and is suitable for food, tabacco and pharmaceutical

applications.

Identification: Color white with brown stripe.

Identification: Color beige.

J R Glass Filled PTFE

Glass filled PTFE has virtually the same chemical compatibility S Vespel®

as virgin PTFE but extends the pressure/temperature rating of

the valve. Its superior compression and heat resistance provide Vespel® is a polyimide material that has high temperature

the seat good wear resistance at high loads and is particularly capabilities under load and is mainly used for heat transfer

good for steam application. applications, hot gases and oils.

Vespel must not be used in with STEAM or media containing

Available with glass fibre content of 15% (R) or 25% (J). WATER or WATER VAPOR.

Identification 15% GF: Color off-white with blue stripe. Identification: Color brown.

Identification 25% GF: Color off-white with red stripe.

P Carbon Filled PTFE (NRG) C PCTFE (Kel-F®)

NRG seats are suitable for elevated temperatures, resistance PCTFE material, better known as Kel-F® (Chloro Tri Floro

under high pressure loads, low coefficient of friction and are Ethylene) is used extensively for cryogenic services for

suitable for many corrosive applications. They are available in temperatures down to -196°C (-320F°) to 121°C (250°F). Its

two different profiles to suit both steam or thermal fluid at high main applications are for gas production, transportation and

temperature and cryogenic applications. storage.

Identification: Color charcoal black with white stripe. Identification: Color see through white.

6 THREE PIECE BALL VALVES 47 SERIES

47 Series

Pressure / Temperature Rating (Seat Material)

The solid lines in the Pressure/Temperature (PT) graphs are the of #300 for all seat material. The PT lines are based on differential

maximum seat rating for each material*, and are not the valve pressure with the valve in the closed position. Data is given

body rating. Valves above 2 have a limiting body rating from field applications and laboratory tests.

T PTFE A TFM R Glass Filled PTFE P NRG

2 2

lb/in bar 45o

lb/in bar

2000 140 138 2000 140 138

130 130

1800 A 1800

120 120 R P

½- 2

1600 110 1600 110

½- 2

100 100

Pressure

Pressure

1400 1400

90 90

1200 1200

80 80

*T R P

1000 70 1000 70

2½- 8 * T - Sizes 1/2 to 8 2½- 8

60 60

800 800

50 50

600 40 600 40

30 30

400 400

20 20

200 200

10 10

2 0 2 0

lb/in 0 bar 230 260 320 lb/in 0 bar 230 260 320

C° -40 0 50 100 150 200 250 300 350 C° -40 0 50 100 150 200 250 300 350

Temperature Temperature

F° -40 0 50 100 150 200 250 300 350 400 450 500 550 600 650 662 F° -40 0 50 100 150 200 250 300 350 400 450 500 550 600 650 662

K L PEEK S VESPEL Y DELRIN U UHMWPE

2 2

lb/in bar lb/in bar

2600 180 2600 180

170 170

2400 2400

160 KL S 160 Y

2200 150 ½- 2 2200 150 ½- 2

2000 140 2000 140

130 130

1800 1800

120 120

1600 110 1600 110

Pressure

Pressure

100 100

1400 1400

90 90

1200 1200

80 80

KL S *U Y * U - Sizes 1/2 to 8

1000 70 1000 70

2½- 8 2½- 8

60 60

800 800

50 50

600 40 600 40

400 30 400 30

20 20

200 200

10 10

2 2

lb/in 0 0bar 260 350

lb/in 0 0bar 60 80

C° -40 0 50 100 150 200 250 300 350 C° -40 0 50 100 150 200 250 300 350

Temperature Temperature

F° -40 0 50 100 150 200 250 300 350 400 450 500 550 600 650 662 F° -40 0 50 100 150 200 250 300 350 400 450 500 550 600 650 662

HABONIM THREE PIECE BALL VALVES 47 SERIES 7

THREE PIECE BALL VALVES

Main Valve Applications

Firesafe Valves Cryogenic Valves

The AF series Fire Safe valves are designed and The C series valves for cryogenic service

tested to the requirements of API 607 and to BS applications are used for speciality gas production,

6755 Part 2 specifications. The valves contain soft food industry, metallurgy, transportation and other.

seat rings. In the event of fire, a secondary metalic With a precision welded body and extended bonnet,

machined ring comes in contact with the ball and prevents one piece high tensile stem, PCTFE or NRG seat material and

leakage through the valve port. The stem incorporates a V-shape stem packing, the valves can operate at temperatures

machined ring shaped surface which will prevent leakage, once down to -196°C (-320°F) and pressures up to 100 bar (1500

the thrust seal has been burned off. All firesafe valves are fitted psi). All cryogenic valve balls have an upstream pressure relief

with flexible graphite body seals and graphite stem seals. hole to prevent buildup of pressure in the body cavity.

Bulletin: P - 119

Bulletin: P - 115

Control Valves Clean Valves

The N series V-port control valves are used in many The Habonim line of Clean Valve applications include

industrial processes such as steam, pH, pressure, the Semiconductor, Pharmaceutical, Biotechnology,

temperature and other control applications. The Food and Beverage and Cosmetic industries. Special

specially mate-lapped hard coated ball and body and trim material selection, machining

characterised metal seats, matched ball and stem, direct ISO procedures, assembly and testing in a class 1000 cleanroom

mounting pad and fastened adaptor mounting kit provide are some of the valve specifications. The I series High Purity

reduced hysteresis, precise control and tight shuttoff. A wide valves for the Semiconductor industry including the FDS (Fluid

range of end connectors are available together with various Distribution Systems) lateral valves are well proved worldwide.

types of seat and seat materials.

Bulletin: P - 411 (characterized & round port)

Diverter Valves Vacuum and Searching Gas Valves

The D and S series diverting valves reduce the The V series valves for high vacuum and searching

number of valves in a system, thereby saving cost gas applications. The valves are suitable for vacuum

and giving the user easier control by using a single down to 10-6 torr and lower. All valves are assembled,

valve in place of multiple valves. The diverter valve tested and packaged in a cleanroom area.

can be used with all the standard end connections and has Bulletin: D-502

various types of ball porting. Bulletin: P - 108

Instrumentation Valves Special Application Valves

The L series valves for instrumentation applications Valves for Oxygen, Chlorine or Ammonia service

are assembled with the Let-Lok compression are specified Special Application Valves and each

fitting ends. The ends are one-piece casting, is manufactured under strict quality conditions. The

machined to fit Imperial or Metric tubing from 1/4 O series valves for Oxygen service require very

to 1 or 6 mm to 25 mm. Pressure rating up to 2250 psi selective body and trim materials with special cleaning

(155 bar) and temperatures up to 250°C (not combined). procedures. The K series valves for Dry Chlorine service are

Bulletin: P - 116 in accordance with the guidelines of the Chlorine Institute

Pamphlet 6. Ammonia service valves have special Hermetix

assemblies. All valves are assembled, tested and packaged in

a cleanroom area.

Oxygen Service: D - 503 Chlorine Service: D - 501

Steam and Thermal Fluid Valves

The W series valves for Saurated Steam service

up to 35 bar and Heat Transfer Fluids for temperatures

up to 260°C have NRG seats, encapsulated graphite

body seal and graphite stem packing. The valve has

a red sleeved handle for identification and is available with stem

extension for actuation.

Bulletin: P - 113

* VESPEL must NOT be used with steam.

8 THREE PIECE BALL VALVES 47 SERIES

47 Series

Fugitive Emissions Locking Device

In applications where it is essential to eliminate LLP (Locked in Last Position)

escape of volatile organic compounds (VOC) into The Habonim spring loaded locking device (LD) is ideal for

the atmosphere, a Fugitive Emission kit can applications where it is critical to keep the valve position without

be mounted directly onto the top ISO the risk of accidental operation. The locking device fits easily to

platform of the valves. The kits are the valve stem by simply removing the stem nut and threading

available for all sizes and can be operated the lock stem above the handle. The LD can lock the valve in

manually or with an actuator. Each closed or open position. The LD can be fitted to the valve in-line.

housing has two threaded ports for

connecting tubing or instrumentation for

registering potential leaks.

series ISO platform make the valves

ideal for add-to such as extended 3 2

1

handles, spring return handles and

other attachments.

for more info please refer to Fugitive

Emission Solutions Catalogue.

Cavity Filler Valves Valve in OPEN position Valve in CLOSED position

All the 47 series valves are available with cavity filler

seats that eliminate all crevices, gaps and pockets

While lifting the lock housing above the stop pin (1) turn the

between the ball and valve body and reduce the

wrench (2) to its new position. When the handle is in its new

risk of contaminants being trapped or the

position release the housing to fit on the stop pin (3).

solidification of product. The valve body

is specially machined to fit the

seat/seal dimensions. Cavity filler

valve bodies cannot be replaced

with standard bodies as they

have larger bore dimensions.

Bulletin: P - 117 Flush Bottom Tank

Valves with special flush tank ends that are welded or bolted

flush to the bottom of reactors or vessels allow complete

drainage and stirring of product leaving no pockets above the

ball. The tank end contour and radius provide effective gravity

drainage, removing any traces of

Diverter Valves liquids. Special or custom

designed tank ends are

Habonims line of diverting valves are available in D47, S47. optional. Additional options

The valves have ball types for any flow pattern. These flow such as special C-Balls for

combinations reduce the number of valves in a system, thereby full drainability of body cavity,

saving costs and giving the user easier control by using a single or purge ports for flushing the

valve in place of multiple valves. They have the advantage of valve or the tank are available

incoporating the same body dimensions that will allow any on request. The valves can be

standard end connection to be fitted to the valve. The valves fitted to the piping system with

incoporate all the additional options of the two way valves any type of end connector.

including cavity seats (in D47, S47 series only).

Bulletin: P - 108 Bulletin: P - 120 Bulletin: P - 118.

Steam Jacketed Valves

The 47 series valves are available with steam jackets for thermal

fluids, hot water or steam. The valves are available with any

number or type of inlet and outlet ports. The steam jacket is

welded to the center body to minimize heat loss.

S47 Side Entry D47 Diverter Bulletin: C - 511

HABONIM THREE PIECE BALL VALVES 47 SERIES 9

THREE PIECE BALL VALVES

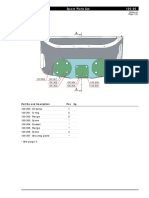

Material Specifications ½- 2½

16

16

15 17

13

16

12 14 17

24 15

16 23

15 13 14

13 22 12

12

11

21

10

9

8

Stem arrangement for actuated valves.

19

Release the handle nut 16 and serrated

washer 15 remove the handle 14 and 2

refasten the nut 16 on the locking clip 13 .

Valves ½ to ¾ reduce bore (½ full bore) 6

3

do not require the handle nut 16 . 5 5

6

1

20

7

18

4

1

2

Full Bore End

Item Description Material Specifications Qty. Item Description Material Specifications Qty.

1 Body Stainless St. ASTM A351 CF8M, Carbon 1 10 Follower Stainless St. ASTM B783 316L 1-2**

St. A105, WCB, Hasteloy C, Hasteloy C22, 11 Disc spring Stainless St. ASTM A693 17-7PH 2

Alloy 20, Monel, Duplex, Super Duplex 12 Stem nut Stainless St. ASTM A194 316 1

2 End connector Stainless St. ASTM A351 CF3M, Carbon St. 2 13 Locking clip Stainless St. ASTM A164 304 1

A105, WCB, Hasteloy C, Hasteloy C22, Alloy 14 Handle Stainless St. ASTM A240 430 1

20, Monel, Duplex, Super Duplex Carbon St. ST37 ZINC PLATED

3 Ball Stainless St. ASTM A351 CF8M Hasteloy C, 1 15 Serrated washer Stainless St. AISI 410 1

Hasteloy C22, Alloy 20, Monel, Duplex, 16 Handle nut Stainless St. ASTM A194 316 1

Super Duplex 17 Sleeve Vinil Plastisol 1

4 Stem Stainless St. ASTM A276 316 / 316L Hasteloy 1 18 Body bolt Stainless St. ISO 4014 A2-70 4

C, Hasteloy C22, Alloy 20, Monel, Duplex, Carbon St. ISO 4014 GR 8.8 zinc plated

Super Duplex 19 Body nut Stainless St. ISO 4032 A2-70 4

*5 Seat PTFE, RPTFE, NRG, PEEK, TFM, UHMWPE, 2 Carbon St. ISO 4032 GR 8.8 zinc plated

VESPEL, DELRIN 20 Tag (not shown) Stainless St. ASTM A167 304 1

*6 Body seal PTFE, RPTFE, TFM, UHMWPE, Graphite, 2 21 LD housing Stainless St. ASTM A351 CF8 1

Metal O -Ring 22 LD stem Stainless St. ASTM A351 CF8 1

*7 Stem thrust seal RPTFE, NRG, PEEK, TFM, UHMWPE, 1 23 LD spring Stainless Steel, Music Wire 1

VESPEL, NYLATRON 24 LD circlip Spring Steel 1

8 Stop pin Stainless St. ASTM A582 303 1 ** 2 Followers are used on ½"& ¾"

*9 Stem packing PTFE, RPTFE, NRG, TFM, UHMWPE 2

Graphite 1

* Standard items for repair kits

10 THREE PIECE BALL VALVES 47 SERIES

47 Series

Valves Dimensions ½- 2½

S

(47 SERIES)

47 Series ½- 2 (½- 1½ FB)

with ISO top

F PCD TxL THREAD

H

STEM (47)

D HEIGHT

C

BALL

BORE

CLOCKWISE

TO CLOSE

B

W A

S

(46 SERIES)

46 Series ½- 2 (½- 1½ FB)

without ISO top

STEM

HEIGHT

H

D (46)

BALL

BORE

CLOCKWISE

TO CLOSE

B

W A

STEM DIMENSIONS PREPARATION FOR ACTUATION

2½ (2 FB) 47 top

(ISO 5211 F07)

ACROSS FLATS P

Stem flats

CLOCKWISE M show valve P

TO CLOSE ball position

2½ (2 FB) 46 top

(ISO 5211 F05)

N THREAD

CLOCKWISE

TO CLOSE ½, ¾ & 2½ 1- 2

without nut 16 with nut 16

RB FB Unit Bore A B C D H(47P) H(46) S(47) S (46) W M N P TxL F(ISO) Weight

mm 11.15 66.0 20.6 29.0 38.7 61.5 44.5 150.0 114.0 47.0 5.5 7.2 F03 0.6 Kg

½ ¼, 8 8 UNF M5x10

inch 0.44 2.598 0.811 1.142 1.524 2.421 1.752 5.906 4.49 1.850 0.217 0.283 36.0 1.33 lb

mm 14.3 70.6 24.5 31.4 40.3 63.9 46.7 150.0 114.0 53.7 5.5 7.2 F03 0.8 Kg

¾ ½ 8 UNF M5x10

inch 0.56 2.779 0.965 1.236 1.587 2.516 1.838 5.906 4.49 2.114 0.217 0.283 36.0 1.77 lb

mm 20.6 93.7 31.7 38.2 55.6 79.4 60.0 187.0 146.0 63.7 7.54 7.2 F04 1.6 Kg

1 ¾ 7 16 UNF M5x10

inch 0.81 3.689 1.248 1.504 2.189 3.126 2.362 7.362 5.75 2.507 0.297 0.283 42.0 3.54 lb

mm 25.4 108.0 41.3 42.7 60.2 84.1 64.8 187.0 146.0 71.7 7.54 7.2 F04 2.5 Kg

1¼ 1 7 16 UNF M5x10

inch 1.00 4.252 1.624 1.679 2.370 3.311 2.551 7.362 5.75 2.822 0.297 0.283 42.0 5.53 lb

mm 31.8 115.5 48.4 43.6 73.0 97.0 76.5 237.0 178.0 86.7 8.71 8.0 F05 3.6 Kg

1½ 1¼ 9 16 UNF M6x12

inch 1.25 4.547 1.906 1.717 2.874 3.819 3.011 9.331 7.00 3.413 0.343 0.315 50.0 7.96 lb

mm 38.1 128.0 56.3 48.3 77.8 101.8 81.2 237.0 178.0 96.9 8.71 8.5 F05 4.5 Kg

2 1½ 9 16 UNF M6x12

inch 1.50 5.039 2.217 1.902 3.063 4.008 3.197 9.331 7.00 3.815 0.343 0.334 50.0 9.95 lb

mm 50.8 158.0 72.6 70.0 88.1 115.1 112.1 237.0 287.0 108.0 8.71 13.5 F07 9.5 Kg

2½ 2 9 16 UNF M8x12

inch 2.0 6.220 2.858 2.756 3.469 4.531 4.413 9.331 11.3 4.252 0.343 0.531 70.0 21.0 lb

HABONIM THREE PIECE BALL VALVES 47 SERIES 11

THREE PIECE BALL VALVES

Material Specifications 3- 8

13

22

9

16

21

11 14

15

13

22

13

9

22

21

12

11

Stem arrangement for actuated valves. 8

10

Release the wrench bolt 16 and remove the

wrench handle 14 the wrench head 15 , the 1 19

stem nut 13 and stop plate 12 . Assemble the

two disc springs 21 , stem location ring 9

tab washer 22 and refasten the non-slotted 2

stem nut 13 .

3 6

5 5

17 20

6

Stainless steel 1

2

7 18

18

4

Carbon steel

Item Description Material Specifications Qty. Item Description Material Specifications Qty.

1 Body Stainless St. ASTM A351 CF8M, 1 12 Stop plate Stainless St. ASTM A240 430 1

Carbon St. ASTM A216 WCB Carbon St. ST37 ZINC PLATED

2 End connector Stainless St. ASTM A351 CF3M, 2 13 Stem nut Carbon St. Zinc Plated 1

Carbon St. ASTM A216 WCB 14 Wrench handle Stainless St. 304

3 Ball Stainless St. ASTM A351 CF8M 1 Carbon St. Zinc Plated 1

4 Stem Stainless St. ASTM A276 316 / 316L 1 15 Wrench head ASTM A47 Maleable Iron 1

*5 Seat PTFE, RPTFE, NRG, PEEK, TFM, UHMWPE, 2 16 Wrench bolt Stainless St. ISO 4014 A2-70 1

VESPEL, DELRIN 17 Seat retaining ring Stainless St. ASTM A351 CF8M 1

*6 Body seal PTFE, RPTFE, TFM, UHMWPE, Graphite, 2 Carbon St., WCB

Metal O -Ring 18 Body bolt Stainless St. ISO 4014 A2-70 8

*7 Stem thrust seal RPTFE, NRG, PEEK, TFM, UHMWPE, 1 Carbon St. ISO 4014 GR 8.8 zinc plated 16

VESPEL, NYLATRON 19 Body nut Stainless St. ISO 4032 A4-70 8

8 Stop pin Stainless St. ASTM A582 303 1 20 Tag Stainless St. ASTM A167 304 1

*9 Stem locking ring Stainless St. ASTM A240 316 1 21 Disc spring Stainless St. ASTM A693 17-7PH 2

*10 Stem packing PTFE, RPTFE, NRG, TFM, UHMWPE 3 22 Tab washer Stainless St. ASTM A240 304 1

Graphite 1

11 Follower Stainless St. ASTM B783 316L 1

* Standard items for repair kits

12 THREE PIECE BALL VALVES 47 SERIES

47 Series

Valves Dimensions 3- 8

S

Stainless Steel

TxL THREAD

F PCD

D H

STEM

HEIGHT

C

BALL

BORE

CLOCKWISE

TO CLOSE

B

W A

Carbon Steel

TxL THREAD

F PCD

H

D

STEM

C HEIGHT

BALL

BORE

CLOCKWISE

TO CLOSE

B

W A

STEM DIMENSIONS PREPARATION

FOR ACTUATION

DD SQUARE

Q STEM GROOVE M P

M

SHOW VALVE

BALL POSITION

M

N THREAD N THREAD ACROSS

FLATS

Stainless Steel Valves Carbon Steel Valves

have thru bolts & nuts have threaded bolts

RB FB Bore A A B C D H S W M M-DD N P Q TxL F (ISO) Weight

R/B F/B

63.5 169.0 169.0 83.3 98.3 144.9 185.0 400.0 140.0 18.9 15.9 1-14 16.7 22.7 M10x20 F10 13.7 Kg

3 2½

2.50 6.653 6.653 3.280 3.870 5.705 7.287 15.75 5.500 0.744 0.626 UNS -2A 0.657 0.894 - 102.0 30.3 lb

82.6 214.0 214.0 108.8 114.1 160.7 200.0 600.0 177.0 18.9 15.9 1-14 16.7 22.7 M10x20 F10 23.7 Kg

4 3

3.25 8.425 8.425 4.283 4.492 6.327 7.894 23.62 6.969 0.744 0.626 UNS -2A 0.657 0.894 - 102.0 52.4 lb

100.0 - 239.0 123.0 124.0 170.5 211.0 600.0 217.0 18.9 15.9 1-14 16.7 22.7 M10x20 F10 30.0 Kg

4

3.94 - 9.409 4.843 4.882 6.713 8.299 23.62 8.543 0.744 0.626 UNS -2A 0.657 0.894 - 102.0 66.3 lb

111.1 283.0 - 146.0 157.0 226.0 286.0 916.0 266.0 28.45 23.75 1½-12 26.2 35.2 M12x20 F12 63.0 Kg

6

4.374 11.142 - 5.748 6.181 8.898 11.260 36.063 10.472 1.118 0.935 UNF -1A 1.031 1.368 - 125.0 138.9 lb

8 Valve dimensions will be given on request

HABONIM THREE PIECE BALL VALVES 47 SERIES 13

THREE PIECE BALL VALVES

ISO 9001:2008 Certified Assembly, Marking and Packaging

As an ISO 9001:2008 certified company, Habonim operates All valves are 100% leak tested before packaging. Each valve

according to internal manufacturing specifications written for is tagged for traceability and material certification will be

each application and for specific customers. From material provided on request. Habonim valves are delivered in the open

procurement to final inspection of assembled valves, Habonim position and with capped ends. Keep the valve in the open

controls its procedures for the integrity of the parts, their position and remove end caps only prior to installation. Actuated

manufacturing process, storing and preservation and final valves are kept in their Fail-Safe position. Use the bolt torque

assembly, to keep the highest standards of perfection of the figures according to the tightening patterns shown below for

product. safe operation. It is recommended to flush the pipe line before

operating the valve, to prevent seat damage.

Standards of Compliance Valve

Size

Bolt Tightening

Size Torque 1 3

1 5

Design: ANSI B16.34 Nm in-lb 7 3

Threaded End Connections: NPT ANSI B1.20.1 ½"-¾" M6 10 89

BSPT ISO R/7, BS 21 1-1¼" M8 22 195

BSPP ISO R/7, BS 2779 1½"-3" M10 45 400 4 8

DIN 2999, DIN 3852 4 M12 75 655 4 2

Socket Weld End Connections: BS 1600. API 5L. 6 M16 161 1425 6 2

ANSI B16.11, DIN 3239/Pt 2

Buttweld End Connections: API 5L. BS 1600

(Schedules 5, 10, 40, 80) ANSI B16.25, DIN 3239/Pt 1

Pressure Testing: EN 12266-1 Cv Values Limiting Stem Input Torque*

Valve

Fire Testing: API 607 Size Flow Coefficients 316 S/S 17-4PH

Stem material Stem material

ISO 10497

RB FB Cv Kv Nm in-lb Nm in-lb

NACE (must be specified): MR-0175

¼ 3 2.6 13.2 117 91 800

Quality Assurance: ISO 9001

8 5 4.3 13.2 117 91 800

Certification: PED 97/23/EC Module H

½ 8 6.9 13.2 117 91 800

¾ ½ 12 10.4 13.2 117 91 800

1" ¾ 32 28.1 24.4 216 165 1,460

1¼ 1" 57 49.3 24.4 216 165 1,460

1½ 1¼ 80 69.2 48.6 430 268 2,370

2 1½ 104 90 48.6 430 268 2,370

2½ 2 240 208 - - 268 2,370

In-Line Maintenance 3

4

2½

3

320

580

277

501

385

385

3400

3400

1920

1920

17,000

17,000

The 47 series 3-piece ball valves are in-line repairable, thus 4 2400 2070 - - 1920 17,000

6 820 707 1570 13900 7500 66,300

reducing on maintenance time and cost when servicing the

valves. This also allows quick and easy replacement of the Cv - Flow in US GPM at 1 psi pressure drop.

valve trim or upgrading for new applications without loss of Kv - Flow in m3/hr at 1 bar pressure drop.

Valve flow rates are determined in full open position with water at 15 C° (60 F°).

downtime. * Limiting Stem torque figures are based on random laboratory tests.

Prior to servicing the valve, bring it to the open position making These are not to be confused with valve operating torque.

sure to release line pressure and drain all trapped media from

the valve cavity. Keep the valve in the open position and remove

all but one body bolt, so the valve body can swing away from Actuated Valves

its installed position and be brought out of the pipe line. In this Where automation is required, the 47 series ball valves are

position it is easy to replace all internal parts and then swing available with Habonims unique 4-Piston pneumatic Compact

the body back to its original position. actuator. The Compact actuator is available in 8 sizes, spring

If it is required to completely remove the body, remove the last return or double acting. All sizes have NAMUR air connections

bolt and bring out the body center section. for attaching solenoids. Limit switches and positioners can be

mounted on the actuator top face according to or VDI/VDE

3845. Please refer to Bulletin B-360.

Valve Actuator Sizing

Valve Sizing Tables of the Compact actuators on Habonim

Valves are available on request. The sizing table is based on

the line pressure, valve seats, working temperature and other

factors.

The valve torque figures are calculated from tests using water

at room temperature at different pressure drops for each seat

material and actuator air pressure.

Please contact HABONIM for more details.

14 THREE PIECE BALL VALVES 47 SERIES

47 Series

47 Series Automated Valves Dimensions

½- 2½ 47 series 3- 4 47 series

SR

DA

D

H E

D

B

H E

B

A

C

Actuator 47 Series Compact Actuator

Valve Size size A B C E H D DA SR

C15 40 69.0 138.0 158.0 69.0 86.0 110.0

½

C20 29.0 40 69.0 149.7 169.7 80.7 102.0 131.0

F03

C25 40 69.0 166.2 186.2 97.2 132.0 161.0

C15 40 71.4 140.4 160.4 69.0 86.0 110.0

¾

C20 31.4 40 71.4 152.1 172.1 80.7 102.0 131.0

F03

C25 40 71.4 168.6 188.6 97.2 132.0 161.0

C15 50 88.2 157.2 177.2 69.0 86.0 110.0

1 C20 50 88.2 168.9 188.9 80.7 102.0 131.0

38.2

F04 C25 50 88.2 185.4 205.4 97.2 132.0 161.0

C30 50 88.2 204.8 224.8 116.6 151.0 186.0

C15 50 92.6 161.6 181.6 69.0 86.0 110.0

1¼ C20 50 92.6 173.3 193.3 80.7 102.0 131.0

42.6

F04 C25 50 92.6 189.8 209.8 97.2 132.0 161.0

C30 50 92.6 209.2 229.2 116.6 151.0 186.0

C20 60 103.6 184.3 204.3 80.7 102.0 131.0

1½ C25 60 103.6 200.8 220.8 97.2 132.0 161.0

43.6

F05 C30 60 103.6 220.2 240.2 116.6 151.0 186.0

C35 60 103.6 239.1 259.1 135.5 182.0 222.0

C20 60 108.3 189.0 209.0 80.7 102.0 131.0

2 C25 60 108.3 205.5 225.5 97.2 132.0 161.0

48.3

F05 C30 60 108.3 224.9 244.9 116.6 151.0 186.0

C35 60 108.3 243.8 263.8 135.5 182.0 222.0

C25 60 130.0 227.2 247.2 97.2 132.0 161.0

2½ C30 60 130.0 246.6 266.6 116.6 151.0 186.0

70.0

F07 C35 60 130.0 265.5 285.5 135.5 182.0 222.0

C45 60 130.0 294.0 314.0 164.0 221.0 269.0

C30 80 178.3 294.9 314.9 116.6 151.0 186.0

C35 80 178.3 313.8 333.8 135.5 182.0 222.0

3

C45 98.3 80 178.3 342.3 362.3 164.0 221.0 269.0

F10

C60 80 178.3 395.8 425.8 217.5 285.0 360.0

C75 80 178.3 448.3 478.3 270.0 342.0 437.0

C35 80 194.1 329.6 349.6 135.5 182.0 222.0

4 C45 80 194.1 358.1 378.1 164.0 221.0 269.0

C60 114.1 80 194.1 411.6 441.6 217.5 285.0 360.0

F10

C75 80 194.1 464.1 494.1 270.0 342.0 437.0

C35 80 203.3 338.8 358.8 135.5 182.0 222.0

4 FB C45 123.3 80 203.3 367.3 387.3 164.0 221.0 269.0

F10 C60 80 203.3 420.8 450.8 217.5 285.0 360.0

C75 80 203.3 473.3 503.3 270.0 342.0 437.0

All dimensions are for reduce bore valve sizes. For full bore valve size dimension up to 3, use a one size-up valve.

HABONIM THREE PIECE BALL VALVES 47 SERIES 15

THREE PIECE BALL VALVES 47 Series

How to order The HABONIM 47 Ball Valve Identification Code

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 . . . 30

1 0 A F B 4 7 P - 6 6 6 6 T G / B S P T - P 0 4 3

Size Service Series Body End Ball Stem Seat Seal End Connection Special Application

Size Body / End

Service Seat Seal End Connection

Code inch mm Ball / Stem

02 ¼ 8 A Antistatic 1 Bronze A TFM B Buna "N" BSPT BS 21

03 8 10 B Full bore 4 Carbon Steel C PCTFE Shore 90 DIN DIN 2999 (BSPP)

05 ½ 15 C Cryogenic 5 Brass F PFA E EPDM (EPR) NPT B1.20.1

07 ¾ 20 D Diverter 6 S. St. 316 (L) H VX1 G Expanded BW Buttweld

10 1 25 bottom entry 7 Monel J 25% Glass Graphite Sch 5,10, 40, 80

12 1¼ 32 F Firesafe 8 S. St. 304 filled PTFE I Impregnated XBW Extended Buttweld

15 1½ 40 I High purity 9 C. Steel LCB K Carbon filled Graphite SW Socketweld

20 2 50 K Dry Chlorine A Alloy-20 PEEK J 25% Glass XSW Extended Socket Weld

25 2½ 65 N Control C Hasteloy-C L Virgin PEEK filled PTFE BWO OD tube

30 3 80 O Oxygen D Duplex P CF PTFE K Kalrez® ETO Extended OD tube

40 4 100 Q Cavity filler E S. St. 317L R 15% Glass M PTFE coated SWO Socketweld OD tube

60 6 150 R Bottom tank F C. Steel LF2 filled PTFE S. St O-Ring TC Tri-Clamp

80 8 200 S Diverter I Inconel 625 S VESPEL N Neoprene KLM Copper tube brazing

side entry L AL6XN T PTFE R 15% Glass ETB Extended Copper tube

V Vacuum K Super Duplex U UHMWPE filled PTFE LL Let Lok (Inch)

W Steam & M 17-4PH Y Acetal Resin T PTFE LM Let Lok (Metric)

Thermal Fluid S SMO254 Derlin® U UHMWPE PN40 Flanged DIN PN40

M Ammonia T Titanium Gr.2 V Devlon® V Viton® Other end connections are

W Hasteloy-C22 available on request.

Z Inconel 718

Special Application

How to order

When placing an order for HABONIM valves, please provide as many

P250 Ball with Pressure relief hole

details possible on the application such as: Media, Temperature, Pressure,

J2N05 Jacketed valve, No. of Outlets, Type, Size

FE Fugitive Emission Pipe line size and type of connection.

V60 Control valve seat

Example A: 10 AFB47P - 4466TG / BW

VB30 Control V Ball

LD Locking device Size 1" (10), Antistatic (A), Firesafe (F), Fullbore (B), 3-piece (47P), C. St

EP Electro Polish Body & Ends (4), S. St 316 Trim (6), PTFE Seats (T), Graphite Body Seals

G18 Grit 180 Internal finish (G), Buttweld ends (BW)

G24 Grit 240 Internal finish Example B: 20 R47P - 666MKV / PN40-FT

G32 Grit 320 Internal finish Size 2" (20), Tank Bottom (R), 3-piece ISO (47P), S. St 316 Body, End

HC High Cycle stem arrangement

SRS Self Relieving Seat

& Ball (6), S.St. 17-4PH Stem (M), PEEK Seats (K), Viton Body Seals (V),

DHN DHN coating DIN Flanged end (PN40),

WR DD Stem Flush Tank end (FT)

DELRIN® is a registered trademark of DuPont, VESPEL® is a registered trademark of DuPont, KEL-F® is a registered trademark of 3M Company

NYLATRON® is a registered trademark of Quadrant DSM Engineering Plastic Products, TFM is a trademark of Dyneon, PEEK® is a trademark of VICTREX

In accordance with our policy to strive for continuous improvement of the product, we reserve the right to alter the dimensions, technical data and information

included in this catalogue when required.

Copyright © 2012 HABONIM Ltd. All rights reserved

ISRAEL U.K.

Habonim Headquarter Habonim UK

Tel: +972-4-6914911 / 6914903 Tel: +44-1633-484554

Fax: +972-4-6914935 Fax: +44-1633-482252

www.habonim.com sales_international@habonim.com sales_uk@habonim.com

CAT47PP-111M 01/14

USA China

Habonim USA Habonim China

Toll Free Phone: 1-866-261-8400 Tel: + 86 21 64453190 *146

Toll Free Fax: 1-866-243-9959 Fax: + 86 21 64453191

sales_usa@habonim.com sales_china@habonim.com.cn

Potrebbero piacerti anche

- 40MF Series End Suction Fire Pump & Package System BrochureDocumento4 pagine40MF Series End Suction Fire Pump & Package System BrochurearsushanNessuna valutazione finora

- Universal Accumulator Charging Kit - Instruction Manual PDFDocumento12 pagineUniversal Accumulator Charging Kit - Instruction Manual PDFmusafirNessuna valutazione finora

- IP Pump DataSheet CNLBDocumento2 pagineIP Pump DataSheet CNLBVikk Suriya100% (1)

- Re92076 2005-03Documento32 pagineRe92076 2005-03Şenol MemişNessuna valutazione finora

- Bro ShureDocumento6 pagineBro ShureoskarzNessuna valutazione finora

- Hydraulic PipingDocumento1 paginaHydraulic Pipingpandunugraha04Nessuna valutazione finora

- Staffa Fixed Displacement Hydraulic Motor: Kawasaki Motors Corp., U.S.ADocumento12 pagineStaffa Fixed Displacement Hydraulic Motor: Kawasaki Motors Corp., U.S.AyelmustafaaliNessuna valutazione finora

- Horizontal & Vertical end suction & in-line centrifugal pumps guideDocumento19 pagineHorizontal & Vertical end suction & in-line centrifugal pumps guideRizal Falevy100% (2)

- Recent Development in Marine EnginesDocumento81 pagineRecent Development in Marine EnginesShashidhar ChandraiahNessuna valutazione finora

- FISHER Rotary Valve Selection GuideDocumento16 pagineFISHER Rotary Valve Selection GuidemablangNessuna valutazione finora

- w50df DsDocumento4 paginew50df DssestoubosNessuna valutazione finora

- 2016Q020 02gbDocumento3 pagine2016Q020 02gbDenim102Nessuna valutazione finora

- 1051 and 1052 Style F and G Instruction ManualDocumento36 pagine1051 and 1052 Style F and G Instruction Manualtxlucky80Nessuna valutazione finora

- Injector - Wikipedia, The Free EncyclopediaDocumento7 pagineInjector - Wikipedia, The Free EncyclopediaEbby OnyekweNessuna valutazione finora

- Tdi T50Y Service PDFDocumento18 pagineTdi T50Y Service PDFJosé BelisarioNessuna valutazione finora

- Upa 150c Ing.Documento7 pagineUpa 150c Ing.Alfredo HerreraNessuna valutazione finora

- Component ServiceDocumento7 pagineComponent ServiceFahmi AliNessuna valutazione finora

- Exhaust Valve MaterialsDocumento2 pagineExhaust Valve MaterialsRannier CazagrandeNessuna valutazione finora

- Reduction Gearbox 1500 AGSC KPDocumento1 paginaReduction Gearbox 1500 AGSC KPΣπύρος ΛελούδαςNessuna valutazione finora

- Suppl.B HPK-L - 1136 - 00 - 03 S2-EN - FinalDocumento34 pagineSuppl.B HPK-L - 1136 - 00 - 03 S2-EN - FinalJorge VillalobosNessuna valutazione finora

- Product Overview - LeuschDocumento32 pagineProduct Overview - Leuschprihartono_diasNessuna valutazione finora

- Tech. Info M 25Documento34 pagineTech. Info M 25abuzer1981Nessuna valutazione finora

- ZOLLERN-Broschuere ZAT Drewerksgetriebe ENGDocumento20 pagineZOLLERN-Broschuere ZAT Drewerksgetriebe ENGMomin G.S.100% (1)

- Reduced operational costs with anti-polishing ringsDocumento2 pagineReduced operational costs with anti-polishing ringsVictor NoschangNessuna valutazione finora

- D628 Maintenance ScheduleDocumento3 pagineD628 Maintenance ScheduleDPNessuna valutazione finora

- PCT 211635jDocumento36 paginePCT 211635jjosueNessuna valutazione finora

- Lowara Cat GeralDocumento288 pagineLowara Cat GeralVitor Padrão100% (1)

- Slide Type Fuel Valves PDFDocumento5 pagineSlide Type Fuel Valves PDFThusith AlexanderNessuna valutazione finora

- Wartsila PDFDocumento8 pagineWartsila PDFherysyam1980Nessuna valutazione finora

- Imo Screw Pumps ACG-UCG 7Documento12 pagineImo Screw Pumps ACG-UCG 7Chhoan NhunNessuna valutazione finora

- HOUTTUIN Catalog GeneralDocumento12 pagineHOUTTUIN Catalog GeneralRelu123Nessuna valutazione finora

- SN757 2005-05 eDocumento4 pagineSN757 2005-05 ehasan_676489616Nessuna valutazione finora

- SMX Clamp BrochureDocumento36 pagineSMX Clamp BrochureCjvele81Nessuna valutazione finora

- MANDocumento141 pagineMANFirman Maulana Erawan HakamNessuna valutazione finora

- NEW BUILD 270FT LCT FOR SALEDocumento13 pagineNEW BUILD 270FT LCT FOR SALErafetguzelsoy100% (1)

- Woodward UG ActuatorDocumento4 pagineWoodward UG ActuatorИгорь100% (2)

- MAN B&W Diesel A/S Service Letter on Nimonic Exhaust ValvesDocumento14 pagineMAN B&W Diesel A/S Service Letter on Nimonic Exhaust ValvesKamlakarPatwariNessuna valutazione finora

- VSD Pump Solution Catalog E-PUIO-CC002-E LRDocumento63 pagineVSD Pump Solution Catalog E-PUIO-CC002-E LRharisNessuna valutazione finora

- Techno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVADocumento6 pagineTechno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVASrivatsanNessuna valutazione finora

- Updated accumulator maintenance instructionsDocumento25 pagineUpdated accumulator maintenance instructionsAnakin SkywalkerNessuna valutazione finora

- 5650 TechDocumento7 pagine5650 Techamjath584Nessuna valutazione finora

- Sélecteur Des Articles 880608284 30368910Documento414 pagineSélecteur Des Articles 880608284 30368910TallaNiangNessuna valutazione finora

- Impact of Increased Back Pressure by Exhaust Gas Treatment SystemsDocumento4 pagineImpact of Increased Back Pressure by Exhaust Gas Treatment SystemsLifeatsea100% (1)

- WS A25 Connecting Rod Types Guidelines For Assessment at Bottom End TB00-3301-16Documento4 pagineWS A25 Connecting Rod Types Guidelines For Assessment at Bottom End TB00-3301-16DPNessuna valutazione finora

- Instruction Manual HVI-156A PART 2Documento8 pagineInstruction Manual HVI-156A PART 2Phan Cao An Truong100% (1)

- Crankshaft Damage and Overheating Leads To Replacing A Crankshaft On A Wartsila 32 PDFDocumento4 pagineCrankshaft Damage and Overheating Leads To Replacing A Crankshaft On A Wartsila 32 PDFKurupath SidharthanNessuna valutazione finora

- Valve SpringDocumento36 pagineValve SpringBsd FareedNessuna valutazione finora

- DESMI MARINE PUMPS GUIDEDocumento35 pagineDESMI MARINE PUMPS GUIDEEnrique Fuentes100% (1)

- V&R - Spare Parts Catalogue - 2009Documento264 pagineV&R - Spare Parts Catalogue - 2009Mahmut GüdülNessuna valutazione finora

- Service Bulletin A - 14: Technical Information To All The Owners of Sulzer AS25 and AT25 Type Diesel Engines 18.10.96Documento3 pagineService Bulletin A - 14: Technical Information To All The Owners of Sulzer AS25 and AT25 Type Diesel Engines 18.10.96Gaetano MuccioNessuna valutazione finora

- RTX Piston Running GuideDocumento32 pagineRTX Piston Running GuideDaniel TsvetilovNessuna valutazione finora

- Hitachi Man-B&w Diesel Engine Service DataDocumento4 pagineHitachi Man-B&w Diesel Engine Service Datar100% (2)

- Horizontal MultiStage Pump Data SheetDocumento6 pagineHorizontal MultiStage Pump Data Sheetسمير البسيونىNessuna valutazione finora

- Diagnostics of Marine Propeller Shafts: Piotr BielawskiDocumento10 pagineDiagnostics of Marine Propeller Shafts: Piotr BielawskiAyman SaadNessuna valutazione finora

- M25C MDO Maintenance Intervals PDFDocumento4 pagineM25C MDO Maintenance Intervals PDFMYO WINNessuna valutazione finora

- Instruction Book Part 1Documento244 pagineInstruction Book Part 1George Arimana100% (1)

- Huba Control 604 - Pressure - SwitchDocumento4 pagineHuba Control 604 - Pressure - SwitchNORODDINENessuna valutazione finora

- Durco Big Max BX2001 Valve: Product CatalogDocumento28 pagineDurco Big Max BX2001 Valve: Product Catalogkagasaw023Nessuna valutazione finora

- CT WKM Powrseal GateDocumento28 pagineCT WKM Powrseal GatemoonanbuNessuna valutazione finora

- SchuF Y-Globe Valve Controls Flow in Chemical PlantsDocumento4 pagineSchuF Y-Globe Valve Controls Flow in Chemical PlantsRamazan YaşarNessuna valutazione finora

- Offshore Oil & Gas PipelinesDocumento20 pagineOffshore Oil & Gas PipelinesShaik Mudassar NazarNessuna valutazione finora

- We Are Pleased To Annouce The Launch of Our New Website Design!Documento5 pagineWe Are Pleased To Annouce The Launch of Our New Website Design!Shaik Mudassar NazarNessuna valutazione finora

- Lets PDFDocumento20 pagineLets PDFAugusto Manuel Inga SánchezNessuna valutazione finora

- Saes A 004Documento22 pagineSaes A 004Branko_62100% (1)

- SAEP-140 - Project Training Impact Assessment PDFDocumento28 pagineSAEP-140 - Project Training Impact Assessment PDFQA QCNessuna valutazione finora

- MSS SP 97 PDFDocumento15 pagineMSS SP 97 PDFgowtham_venkat_4100% (1)

- MTC SampleDocumento1 paginaMTC SampleShaik Mudassar NazarNessuna valutazione finora

- Saep 22 PDFDocumento15 pagineSaep 22 PDFShaik Mudassar NazarNessuna valutazione finora

- Alert 01 001 PDFDocumento7 pagineAlert 01 001 PDFShaik Mudassar NazarNessuna valutazione finora

- Core AnalysisDocumento7 pagineCore AnalysisShaik Mudassar NazarNessuna valutazione finora

- Electrical Properties of ClayDocumento75 pagineElectrical Properties of ClayShaik Mudassar NazarNessuna valutazione finora

- 1 HoistingSystemDocumento42 pagine1 HoistingSystemAoun MuhammadNessuna valutazione finora

- PEW-406.03 Pressure TestingDocumento95 paginePEW-406.03 Pressure TestingRaymond de WeeverNessuna valutazione finora

- Drilling MethodsDocumento50 pagineDrilling MethodsKhairul AshrafNessuna valutazione finora

- Misfire, Hangfire, and StoppageDocumento3 pagineMisfire, Hangfire, and StoppageShaik Mudassar Nazar100% (1)

- PEW-406.03 Pressure TestingDocumento95 paginePEW-406.03 Pressure TestingRaymond de WeeverNessuna valutazione finora

- Integrated Gasification Combined Cycle - WikipediaDocumento8 pagineIntegrated Gasification Combined Cycle - WikipediaShaik Mudassar NazarNessuna valutazione finora

- A. RSQM (DQ-029)Documento350 pagineA. RSQM (DQ-029)deso tblNessuna valutazione finora

- The Strategy of IB: International Business - Chapter 13Documento20 pagineThe Strategy of IB: International Business - Chapter 13Yến Ngô HoàngNessuna valutazione finora

- Practice Ch3Documento108 paginePractice Ch3Agang Nicole BakwenaNessuna valutazione finora

- Kribhco Summer Trainning ReportDocumento106 pagineKribhco Summer Trainning ReportMihir Patel0% (1)

- VR Headset QR CodesDocumento35 pagineVR Headset QR CodesAbdelsabour Ahmed100% (1)

- Lab 8 Introduction To XML: Exercise 1Documento4 pagineLab 8 Introduction To XML: Exercise 1HasanNessuna valutazione finora

- FM Approval Standard - 2000 - Automatic Sprinkler PDFDocumento130 pagineFM Approval Standard - 2000 - Automatic Sprinkler PDF이상우Nessuna valutazione finora

- House Bill 470Documento9 pagineHouse Bill 470Steven DoyleNessuna valutazione finora

- DesertationDocumento145 pagineDesertationhishamromi760% (1)

- Philippine Constitutional Commissions Powers and FunctionsDocumento36 paginePhilippine Constitutional Commissions Powers and Functionssharlica1990Nessuna valutazione finora

- Sample Demand LetterDocumento3 pagineSample Demand LetterShaniemielle Torres-BairanNessuna valutazione finora

- Mining Operational ExcellenceDocumento12 pagineMining Operational ExcellencegarozoNessuna valutazione finora

- Introducing Global PoliticsDocumento8 pagineIntroducing Global PoliticsMeann Joy BaclayonNessuna valutazione finora

- Valve Position Monitors: APL 5 Series CSA Approved Type 4X/6Documento12 pagineValve Position Monitors: APL 5 Series CSA Approved Type 4X/6Torres Toledo JttNessuna valutazione finora

- NCP Ineffective Breathing PatternDocumento1 paginaNCP Ineffective Breathing PatternMarc Johnuel HumangitNessuna valutazione finora

- Dokumen - Tips Md110-ForumDocumento317 pagineDokumen - Tips Md110-ForumMiguel Ángel CoriaNessuna valutazione finora

- The Bedford Clanger May 2013 (The Beer Issue)Documento12 pagineThe Bedford Clanger May 2013 (The Beer Issue)Erica RoffeNessuna valutazione finora

- En 12485Documento184 pagineEn 12485vishalmisalNessuna valutazione finora

- AeroCRS 5.95-Premier AirlinesDocumento1 paginaAeroCRS 5.95-Premier AirlinesmohamedNessuna valutazione finora

- Components in Action Script 2.0 UNIT 3Documento4 pagineComponents in Action Script 2.0 UNIT 3k.nagendraNessuna valutazione finora

- Logiq 180 UsuarioDocumento414 pagineLogiq 180 UsuariolaboratorioelectroNessuna valutazione finora

- Postal-BSNL Meeting MinutesDocumento5 paginePostal-BSNL Meeting MinutesP Karan JainNessuna valutazione finora

- Carino v. Insular Govt 212 U.S. 449 (1909)Documento3 pagineCarino v. Insular Govt 212 U.S. 449 (1909)Wendy PeñafielNessuna valutazione finora

- Power BI 101@ ScaleDocumento46 paginePower BI 101@ ScalePRANAV INDINessuna valutazione finora

- This Study Resource Was: Artur Vartanyan Supply Chain and Operations Management MGMT25000D Tesla Motors, IncDocumento9 pagineThis Study Resource Was: Artur Vartanyan Supply Chain and Operations Management MGMT25000D Tesla Motors, IncNguyễn Như QuỳnhNessuna valutazione finora

- (Lecture 10 & 11) - Gearing & Capital StructureDocumento18 pagine(Lecture 10 & 11) - Gearing & Capital StructureAjay Kumar TakiarNessuna valutazione finora

- Lala Lajpat Rai College: Public Relations Project Rough Draft Topic: Nike V/S AdidasDocumento34 pagineLala Lajpat Rai College: Public Relations Project Rough Draft Topic: Nike V/S AdidasNikitha Dsouza75% (4)

- Advance NewsletterDocumento14 pagineAdvance Newsletterapi-206881299Nessuna valutazione finora

- Urban Altoids EDC Kit v2.2.1Documento2 pagineUrban Altoids EDC Kit v2.2.1richard philpNessuna valutazione finora

- Volkswagen Group - Wikipedia PDFDocumento115 pagineVolkswagen Group - Wikipedia PDFFayad A ANessuna valutazione finora