Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Calibration Procedure For BFP-T Turbine Rotor Expansion Sensor

Caricato da

naresh977977Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Calibration Procedure For BFP-T Turbine Rotor Expansion Sensor

Caricato da

naresh977977Copyright:

Formati disponibili

STEAG O&M COMPANY LIMITED

2X520 HINDUJA NATIONAL POWER CORPORATION LTD.

VISAKHAPATNAM, A.P.

Standard Doc. No. :

SOMC/C&I/60A/19/xxx

Maintenance Title: Calibration of BFP Turbine

Procedure rotor expansion sensors

REV.NO. 00 VERSION NO. 00 DOC. NO : PAGE 1 OF 9

STEAG O&M COMPANY LIMITED

2X520 HINDUJA NATIONAL POWER CORPORATION LTD.

VISAKHAPATNAM, A.P.

Revision

Revision Date Prepared By Checked By Approved By

No.

00 21/01/2015 Ashutosh Mayank M. Raghuram

REV.NO. 00 VERSION NO. 00 DOC. NO : PAGE 2 OF 9

STEAG O&M COMPANY LIMITED

2X520 HINDUJA NATIONAL POWER CORPORATION LTD.

VISAKHAPATNAM, A.P.

Table of Contents

1. Purpose.................................................................................................................................. 4

2. Scope ..................................................................................................................................... 4

3. Reference Documents ......................................................................................................... 4

4. General Description ............................................................................................................. 4

5. Procedure .............................................................................................................................. 4

5.1) Pre-Checks before maintenance and calibration ............................................................ 4

5.2) Procedure for mounting of BFP turbine rotor expansion sensor:.................................. 4

5.3) Procedure for calibration BFP turbine rotor expansion sensor ..................................... 5

5.4) Procedure for Zero gap voltage setting (No calibration) ................................................ 6

5.5) Procedure for cable lay after GAP adjustment or Calibration ....................................... 6

6. Special Tools/Equipment .................................................................................................... 7

7. General Precautions ............................................................................................................ 7

8. Frequency.............................................................................................................................. 7

9. Responsibility ........................................................................................................................ 7

10. Record/Checklist .................................................................................................................. 7

11. Annexure-I ............................................................................................................................. 7

REV.NO. 00 VERSION NO. 00 DOC. NO : PAGE 3 OF 9

STEAG O&M COMPANY LIMITED

2X520 HINDUJA NATIONAL POWER CORPORATION LTD.

VISAKHAPATNAM, A.P.

1. Purpose

The purpose of this document is to make understand the standard calibration procedure of

the BFP turbine rotor expansion Sensors.

2. Scope

This document is applicable for Calibration of following in Turbine supervisory Instrument.

a) BFP turbine rotor expansion Sensors (SHINKAWA VL - 143P25A-9012)

There are a total Two No’s of expansion Sensors, one for each turbine.

3. Reference Documents

a) TSI STANDARD INST. DATA SHEET DRG FOR BFPDT 500 MW

b) TSI SCHEME HY-TC-MPA1013-0106-R00

4. General Description

For the measurement of the BFP turbine rotor expansion 1 no of Eddy Current Sensors is

provided at Turbine Exhaust side. Sensor is mounted on BFP side of the measuring collar

facing towards collar. The Measurement range of sensor is 10 mm. expansion of shaft

towards BFP side is taken as negative from rotor zero position while the measurement

towards BP side is taken as positive. The measurement of the sensor is taken through driver

unit to the monitoring channel of Vibration monitoring panel

5. Procedure

5.1) Pre-Checks before maintenance and calibration

Before starting the standard GAP adjustment confirm following:

a) The ZERO position of rotor for the turbine maintenance dept. .

b) Bearing cleared from the turbine maintenance dept. .

5.2) Procedure for mounting of BFP turbine rotor expansion sensor:

a) Mount the sensor in matching hole on bearing pedestal.

b) Tighten the lock washer

a) Tighten the Connect Extension Cable at Sensor and Junction Box end.

REV.NO. 00 VERSION NO. 00 DOC. NO : PAGE 4 OF 9

STEAG O&M COMPANY LIMITED

2X520 HINDUJA NATIONAL POWER CORPORATION LTD.

VISAKHAPATNAM, A.P.

Sensor 1004-527L-012

Driver VW-143PL-3

Extension Cable VK-143-P1

Monitor VM – 5D / 11012

5.3) Procedure for calibration BFP turbine rotor expansion sensor

a) Place the calibration kit VZ-30A-3 near the driver unit of HP rotor expansion sensor.

b) Mount the sensor in front of target plate.

c) Adjust the Sensors for Set gap of 3 mm for the zero position by adjusting the

micrometer.

d) Ensure the drivers are connected and communicating to application software.

e) Ensure - 24V DC supply healthiness at Driver Unit.

f) Ensure Sensor is placed at zero position (8 mm from the collar/target plate).

g) Ensure the upper and lower range is set in application software as per annexure –I

for BFP turbine including the safety gap of 3mm.

h) Check for Zero reading in Monitor/DCS and record the voltage reading.

i) if monitor is showing ZERO fix the position and if current reading after adjusting gap

is not ZERO use Zero Shift parameter to Set current position of ‘Rotor Zero’

j) Slide the sensor away from the target plate up to the gap of maximum range in

positive side and check the reading in DCS and the application software in measured

column. If the reading in measured in application software and DCS not matching

adjust the gain and keep the reading to maximum range.

k) Again move the sensor to zero position using the micrometer and matching the

recorded gap voltage for zero position.

l) Slide the sensor away from the target plate at the gap of 1 mm up to +5 mm and

record the reading of gap voltage at driver, DCS reading, and Vibration monitor

system PC reading.

m) Again move the sensor to zero position.

n) Slide the sensor towards the target plate at the gap of 1 mm up to -5 mm and record

the reading of gap voltage at driver, DCS reading, and Vibration monitor system PC

reading..

o) Compare the DCS and field reading.

p) Ensure the gap voltage from deviation from initial calibration report (Annexure-I) is

not very high.

q) Bring the sensors to Zero position

r) Remove the sensor from calibration kit and place safely.

s) Remove the calibration kit from the site.

REV.NO. 00 VERSION NO. 00 DOC. NO : PAGE 5 OF 9

STEAG O&M COMPANY LIMITED

2X520 HINDUJA NATIONAL POWER CORPORATION LTD.

VISAKHAPATNAM, A.P.

5.4) Procedure for Zero gap voltage setting (No calibration)

a) Adjust the Sensors to set gap voltage as mentioned for zero position as per latest

calibration record.

b) Ensure the driver is connected to the sensor and

c) check for Zero reading in Monitor/DCS

d) if monitor is showing ZERO fix the position

e) Lock the sensor position by locking the sliding plate with screw nuts.

f) Tighten the sensor screw with the mounting bracket.

g) Give clearance to mechanical maintenance dept. for placing the bearing pedestal

covers.

5.5) Procedure for cable lay after GAP adjustment or Calibration

a) Detach the Sensor cable from Extension Cable.

b) Guide the Sensor Cable through Bearing pedestal Junction Box.

c) Route cable in pedestal Junction Box through Cable Seal (fixed inside Junction Box)

and tighten it sufficiently. Cable Seals are used to prevent oil leakage from pedestal.

d) Insert the Insulation Sleeve supplied with sensor, over the Extension Cable

Connector.

e) Connect the Extension Cable & Sensor Cable connectors inside the Junction Box.

f) Cover gold plated Connector joint with Teflon Tape & finally slip the Insulation Sleeve

to entirely cover it.

g) Check Gap Voltage at the Driver. Make sure reading is same as noted above.

h) Check & tie properly, loose cable loops of sensor & extension cables, which are

open & close to rotating parts.

i) This ensures protection against damage to sensor + extension cables due to

touching rotor parts.

REV.NO. 00 VERSION NO. 00 DOC. NO : PAGE 6 OF 9

STEAG O&M COMPANY LIMITED

2X520 HINDUJA NATIONAL POWER CORPORATION LTD.

VISAKHAPATNAM, A.P.

6. Special Tools/Equipment

6.1. Digital Multi meter with range microvolt measurement range

6.2. Calibration kit no. VZ-30A

6.3. 3 no of walkie-talkie

7. General Precautions

Ensure healthiness & safety of the entire activities with respect to electrical and

Mechanical system.

Ensure the safety gap of minimum 3mm sensor while rotor is at zero position.

8. Frequency

Calibration to be done yearly once at the time of turbine overhauling or after replacement

of bearing Parts

9. Responsibility

C&I Engineers are responsible for monitoring and reviewing the effectiveness of the system.

The Authorized persons shall ensure that all instruments and instrumentation are regularly

checked and maintained in serviceable condition.

10. Record/Checklist

Calibration Checklist shall be prepared as per Doc. No. SOMC/C&I/60A/06/XXX

11. Annexure-I

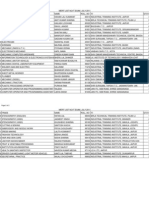

Reference Calibration Sheet for TDBFP-1A turbine Rotor expansion

DT Rotor Expansion (Range - 5 to 5 mm)

KKS No: XAD11CY011 Date: 09.12.14

Probe Model No: 1004-52YL-012 Sr.No: MACS0015

Driver Model No: VK143P1 Sr.No: N2410019

Extension Cable Model No: VW143PL-3 Sr.No: N27C0012

Direct Position

S.No (mm) Actual Gap Voltage Kit Reading (mm) Card display DCS display

Reading (VDC) (mm) (mm)

1 -5 -12.98 22.6 -5.1 -5.07

2 -4 -12.19 21.6 -4.1 -4.09

3 -3 -11.38 20.6 -3.1 -3.05

REV.NO. 00 VERSION NO. 00 DOC. NO : PAGE 7 OF 9

STEAG O&M COMPANY LIMITED

2X520 HINDUJA NATIONAL POWER CORPORATION LTD.

VISAKHAPATNAM, A.P.

4 -2 -10.55 19.6 -2 -2.04

5 -1 -9.72 18.6 -1 -0.99

6 0 -8.91 17.6 0 0.015

7 1 -8.1 16.6 1 1.01

8 2 -7.31 15.6 2 2.01

9 3 -6.52 14.6 3 3

10 4 -5.7 13.6 4 4.02

11 5 -4.89 12.6 5.1 5.05

Reference Calibration Sheet for TDBFP-1B turbine Rotor expansion

DT Rotor Expansion (Range - 5 to 5 mm)

KKS No: XAD21CY011 Date: 28.03.15

Probe Model No: ID04-527L-012 Sr.No: MACS0014

Driver Model No: VK143P1 Sr.No: N2410017

Extension Cable Model No: VW143PL-3 Sr.No: N27C0013

Direct Position Card

S.No (mm) Actual Gap Voltage Kit Reading (mm) display

Reading (VDC) (mm) DCS display (mm)

1 -5 -10.32 19 -5.3 -5

2 -4 -9.37 18 -4.1 -4.14

3 -3 -8.47 17 -3 -3.21

4 -2 -7.59 16 -2.1 -2.14

5 -1 -6.73 15 -1 -1.05

6 0 -5.87 14 0 -0.06

7 1 -5.02 13 1 -0.97

8 2 -4.17 12 2.1 2.02

9 3 -3.34 11 3.1 3.03

10 4 -2.53 10 4 4.01

11 5 -1.78 9 5 4.92

Reference Calibration Sheet for TDBFP-2A turbine Rotor expansion

Name Model No. Location Sr No Range

Sensor 1D04-527L-012 MACS0016

Ex. Cable VW-143PL-3 N27C0010

Driver VK 143 N27C0010 -5 TO 5 mm

Monitor VM5D R2/S7/CH-1 N2670006

CAL. KIT VZ – 30A MA840007

Sr. No Input Card Display DCS Gap vtg.

(mm) (mm) Vdc

1 5 4.8 4.77 -5.04

2 4 3.8 3.77 -5.82

3 3 2.9 2.83 -6.60

4 2 1.9 1.85 -7.36

REV.NO. 00 VERSION NO. 00 DOC. NO : PAGE 8 OF 9

STEAG O&M COMPANY LIMITED

2X520 HINDUJA NATIONAL POWER CORPORATION LTD.

VISAKHAPATNAM, A.P.

5 -1 0.9 0.9 -8.13

6 0 0.0 -0.06 -8.90

7 -1 -1.0 -1.02 -9.67

8 -2 -2.0 -2.01 -10.46

9 -3 -3.0 -2.99 -11.24

10 -4 -3.9 -3.94 -12.00

11 -5 -4.8 -4.85 -12.73

Reference Calibration Sheet for TDBFP-2B turbine Rotor expansion

Name Model No. Location Sr No Range

Sensor 1D04-527L-012 MACS0018

Ex. Cable VW-143PL-3 N27C0011

Driver VK 143 N27C0018 -5 TO 5 mm

Monitor VM5D R2/S7/CH-1 N2670005

CAL. KIT VZ – 30A MA830008

Sr. No Input Card Display (mm) DCS Gap vtg.

(mm) Vdc

1 5 4.9 4.95 -4.92

2 4 3.9 3.94 -5.73

3 3 2.9 2.95 -6.52

4 2 2.0 1.96 -7.31

5 -1 1.0 0.98 -8.09

6 0 0.0 0.00 -8.89

7 -1 -1.0 -1.00 -9.70

8 -2 -2.0 -2.04 -10.53

9 -3 -3.1 -3.09 -11.36

10 -4 -4.1 -4.09 -12.17

11 -5 -5.0 -5.00 -12.94

REV.NO. 00 VERSION NO. 00 DOC. NO : PAGE 9 OF 9

Potrebbero piacerti anche

- Axial Shift Sensors (Thurst Bearing) : Model No. Axial Shift - 1 Sr. No. Axial Shift - 2 Sr. No. Axial Shift - 3 Sr. NoDocumento3 pagineAxial Shift Sensors (Thurst Bearing) : Model No. Axial Shift - 1 Sr. No. Axial Shift - 2 Sr. No. Axial Shift - 3 Sr. NoShiva KotamrajuNessuna valutazione finora

- Códigos SKF Fecha Fabricación PDFDocumento1 paginaCódigos SKF Fecha Fabricación PDFCharqNessuna valutazione finora

- P90 P91 P92 P510 P515 P520: Manual of - Installation - Operating - Maintenance Gas Burners TypeDocumento34 pagineP90 P91 P92 P510 P515 P520: Manual of - Installation - Operating - Maintenance Gas Burners TypeLucian CiudinNessuna valutazione finora

- DCEM 2100 TUV Installalation & Commisioning ManualDocumento37 pagineDCEM 2100 TUV Installalation & Commisioning ManualQuan Nguyen VanNessuna valutazione finora

- Plant Familiarisation: Unit 1 & 2Documento6 paginePlant Familiarisation: Unit 1 & 2Herbert H.Nessuna valutazione finora

- Controls & Instrumentation FOR 660 MW Supercritical Unit at TirodaDocumento23 pagineControls & Instrumentation FOR 660 MW Supercritical Unit at TirodaAakash kumar ShrivastavaNessuna valutazione finora

- Dead Weight TestersDocumento5 pagineDead Weight TestersShrikant EkboteNessuna valutazione finora

- TX2/RX2 Remote Controller With Five Functions: FeaturesDocumento8 pagineTX2/RX2 Remote Controller With Five Functions: FeaturesRambo333Nessuna valutazione finora

- Technical Feedback EhtcDocumento9 pagineTechnical Feedback EhtcPrashant Kumar ChoudharyNessuna valutazione finora

- Clarifications To NTPC CommentsDocumento224 pagineClarifications To NTPC CommentsnishantNessuna valutazione finora

- Esm ManualDocumento4 pagineEsm ManualAkhil BhadouriaNessuna valutazione finora

- Dual Plate: Installation and MaintenanceDocumento28 pagineDual Plate: Installation and MaintenanceAllen AnyayahanNessuna valutazione finora

- TND 063191 135912Documento180 pagineTND 063191 135912Kanupriya AgarwalNessuna valutazione finora

- GJX 3 ManualDocumento13 pagineGJX 3 Manualعبدالحميد عبدالغفار الدرديريNessuna valutazione finora

- General Specification For Electric Actuators - Integral Motor ControlDocumento4 pagineGeneral Specification For Electric Actuators - Integral Motor ControlschgirlNessuna valutazione finora

- Experion PKS Boiler Control For Fossil Fired Boilers Solution NotesDocumento6 pagineExperion PKS Boiler Control For Fossil Fired Boilers Solution NotesAnonymous u0wETydFNessuna valutazione finora

- 2VAA001623 en S Control SPDSO14 Digital Output ModuleDocumento51 pagine2VAA001623 en S Control SPDSO14 Digital Output ModuleanbarasanNessuna valutazione finora

- Atv31 (E)Documento220 pagineAtv31 (E)Santos Zosimo Ocas GoicocheaNessuna valutazione finora

- DHRC Catalog - F164LR.Documento28 pagineDHRC Catalog - F164LR.mdalt9180Nessuna valutazione finora

- Jordan Hussein Power Station GT Operation Manual Revision-01 (20170803)Documento335 pagineJordan Hussein Power Station GT Operation Manual Revision-01 (20170803)Malik HatemNessuna valutazione finora

- U.V. Flame Detectors HoneywellDocumento12 pagineU.V. Flame Detectors HoneywellgabNessuna valutazione finora

- 57-606.9 Eclipse Model 706 Hart Io 1 PDFDocumento108 pagine57-606.9 Eclipse Model 706 Hart Io 1 PDFAbdul Shaharlal ENessuna valutazione finora

- Max DnaDocumento17 pagineMax DnaAdil ButtNessuna valutazione finora

- MaxDNA 4.2.1 Installation Instructions Rev.01Documento10 pagineMaxDNA 4.2.1 Installation Instructions Rev.01Deepak GuptaNessuna valutazione finora

- How To Know About Shaft DisplacementDocumento7 pagineHow To Know About Shaft DisplacementYudha SimbolonNessuna valutazione finora

- Anexo 2. D103605X012 DVC6200 Instruction Manual PDFDocumento104 pagineAnexo 2. D103605X012 DVC6200 Instruction Manual PDFJairo andres Guarnizo SuarezNessuna valutazione finora

- Device Summary EnglishDocumento14 pagineDevice Summary Englishكاظم محمدNessuna valutazione finora

- Main Steam Turbine Controls Retrofit ISA FinalDocumento13 pagineMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- Procon LDS Maintenance Manual-R5Documento18 pagineProcon LDS Maintenance Manual-R5Watchara ThepjanNessuna valutazione finora

- Pressure & Temperature Switch RT SeriesDocumento4 paginePressure & Temperature Switch RT SeriesVivek Vous AimeNessuna valutazione finora

- 06 StemLeakDetectionSystemDocumento32 pagine06 StemLeakDetectionSystemSACHIN PETKAR100% (1)

- Balancing of LP Rotor at Site PDFDocumento5 pagineBalancing of LP Rotor at Site PDFsanjeevchhabra0% (1)

- Emergency Procedures For Operation of Gas Turbine.Documento2 pagineEmergency Procedures For Operation of Gas Turbine.MARISSA DINLASANNessuna valutazione finora

- Hollias Macs v6.5.2 Functon BlockDocumento1.079 pagineHollias Macs v6.5.2 Functon BlockMovieGame Nime99Nessuna valutazione finora

- Fftmu 2ch@aDocumento3 pagineFftmu 2ch@asteam100deg8229Nessuna valutazione finora

- Cooling and Sealing AirDocumento3 pagineCooling and Sealing AirKrishna VachaNessuna valutazione finora

- Itc Limited Paperboards & Speciality Papers Division: Unit: Bhadrachalam, ApDocumento7 pagineItc Limited Paperboards & Speciality Papers Division: Unit: Bhadrachalam, ApMohan RajNessuna valutazione finora

- Nireco Servojet Sj2: GeneralDocumento8 pagineNireco Servojet Sj2: GeneralKen JunNessuna valutazione finora

- Fisher l2 Liquid Level Controllers en 135074Documento16 pagineFisher l2 Liquid Level Controllers en 135074GOKUL PRASADNessuna valutazione finora

- Air-Operated Valve Maintenance Guide PDFDocumento301 pagineAir-Operated Valve Maintenance Guide PDFSuprapto Desmosedici100% (1)

- Field BusDocumento108 pagineField Busvenukumare100% (1)

- 158ADocumento113 pagine158AashokNessuna valutazione finora

- Technical Manual ZETA REVDocumento66 pagineTechnical Manual ZETA REVAnonymous lB6SsHu5KNessuna valutazione finora

- Improved Level Control of A Feed Water ValveDocumento7 pagineImproved Level Control of A Feed Water ValveAli Bari100% (1)

- Vortex FMDocumento14 pagineVortex FMtirutkkNessuna valutazione finora

- GPS DCS Time SyhchronisationDocumento6 pagineGPS DCS Time Syhchronisationkoushik42000Nessuna valutazione finora

- Pacsystems Rx3I Controller: Intelligent PlatformsDocumento4 paginePacsystems Rx3I Controller: Intelligent PlatformsZouhair IguerhzifenNessuna valutazione finora

- Creating and Using Virtual DPUsDocumento20 pagineCreating and Using Virtual DPUsDeepak Gupta100% (1)

- Baa1 PDFDocumento149 pagineBaa1 PDFfebyNessuna valutazione finora

- Satyendra ' S ReportDocumento24 pagineSatyendra ' S ReportSatyendra Singh100% (1)

- DC Motor ControllerDocumento7 pagineDC Motor ControllerJan MicahNessuna valutazione finora

- Flame Scanner PDFDocumento72 pagineFlame Scanner PDFParthiban KarunaNessuna valutazione finora

- Bhel Internship ReportDocumento32 pagineBhel Internship ReportShubham SinghNessuna valutazione finora

- Electrohydraulic Servovalves - Past, Present, and FutureDocumento20 pagineElectrohydraulic Servovalves - Past, Present, and Future1sympatyaga100% (1)

- Burner ManualDocumento36 pagineBurner ManualWajih AnsariNessuna valutazione finora

- ABB Navigator 600Documento96 pagineABB Navigator 600lequydueu100% (1)

- Torsional Vibration Monitoring System - AWM M30-B2, DWG 1142957-2.0Documento21 pagineTorsional Vibration Monitoring System - AWM M30-B2, DWG 1142957-2.0cengiz kutukcu100% (1)

- Calibrator Check: Application NoteDocumento7 pagineCalibrator Check: Application NoteInsan AzizNessuna valutazione finora

- Furuno GP7000F Installation ManualDocumento52 pagineFuruno GP7000F Installation ManualcristianocalheirosNessuna valutazione finora

- Service Manual: Color MonitorDocumento44 pagineService Manual: Color MonitorAntonio AscanioNessuna valutazione finora

- Acc Inter 3 AtsiriDocumento9 pagineAcc Inter 3 AtsiriZania Putri100% (1)

- Software Testing and Quality AssuranceDocumento26 pagineSoftware Testing and Quality Assurancemanoj hNessuna valutazione finora

- Aitkensmethod 170829115234Documento17 pagineAitkensmethod 170829115234Yumi koshaNessuna valutazione finora

- Examples and Non-ExamplesDocumento5 pagineExamples and Non-ExamplesslidegaeNessuna valutazione finora

- Centennial Tower Promotion 1Documento10 pagineCentennial Tower Promotion 1madeNessuna valutazione finora

- Michael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972Documento13 pagineMichael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972earthcrosserNessuna valutazione finora

- Education and Learning: Good Study HabitsDocumento3 pagineEducation and Learning: Good Study Habitsزهرة ZaraNessuna valutazione finora

- Procedure: Pressure Equipment Safety: PurposeDocumento9 pagineProcedure: Pressure Equipment Safety: PurposeChegwe CorneliusNessuna valutazione finora

- Thesis StoryboardDocumento5 pagineThesis StoryboardJill Brown100% (2)

- Appendix-Design CalculationsDocumento3 pagineAppendix-Design CalculationsVanessa M. MartinezNessuna valutazione finora

- Upload Infotype 2006 (Absence Quotas) - Code Gallery - SCN WikiDocumento3 pagineUpload Infotype 2006 (Absence Quotas) - Code Gallery - SCN WikiArun Varshney (MULAYAM)Nessuna valutazione finora

- UT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)Documento7 pagineUT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)UT Dallas Provost's Technology GroupNessuna valutazione finora

- Microprocessor Lab ManualDocumento36 pagineMicroprocessor Lab ManualsivagamasundhariNessuna valutazione finora

- 1 Conformity Asch StudyDocumento31 pagine1 Conformity Asch StudyjasbruNessuna valutazione finora

- An Automated Test and Measurement System For Calibration of Industrial FlowmetersDocumento2 pagineAn Automated Test and Measurement System For Calibration of Industrial FlowmetersfredpintoNessuna valutazione finora

- Worksheet - StatisticsDocumento3 pagineWorksheet - StatisticsGabriel Ch MendezNessuna valutazione finora

- GE 8 ETHICS Week2 9Documento54 pagineGE 8 ETHICS Week2 9Jay Ar OmbleroNessuna valutazione finora

- Lab Manual 10: Z-Transform and Inverse Z-Transform Analysis ObjectiveDocumento7 pagineLab Manual 10: Z-Transform and Inverse Z-Transform Analysis ObjectiveSyed Waqas ShahNessuna valutazione finora

- Lab 5 (... )Documento10 pagineLab 5 (... )Zeeshan JuttNessuna valutazione finora

- SSPC Monitoreo y Control de Condiciones AmbientalesDocumento4 pagineSSPC Monitoreo y Control de Condiciones AmbientalesRony Ruiz100% (1)

- Measuring PovertyDocumento47 pagineMeasuring PovertyPranabes DuttaNessuna valutazione finora

- ABB - Composite Station Post InsulatorsDocumento6 pagineABB - Composite Station Post InsulatorsDominic SantiagoNessuna valutazione finora

- Future Christchurch: Solutions. Housing: Biran HeDocumento108 pagineFuture Christchurch: Solutions. Housing: Biran HecamiayoungNessuna valutazione finora

- Eurotuner February 2010 PDFDocumento1 paginaEurotuner February 2010 PDFJenniferNessuna valutazione finora

- Pertemuan 1 - Verb, Noun, Adjective and AdverbDocumento6 paginePertemuan 1 - Verb, Noun, Adjective and AdverbHaris PambudiNessuna valutazione finora

- Iron Man Helmet Papercraft Template PDFDocumento4 pagineIron Man Helmet Papercraft Template PDFNishant Khandekar25% (8)

- Ass AsDocumento2 pagineAss AsMukesh BishtNessuna valutazione finora

- When A Transformer Has Stomach Pain and Wants ToDocumento4 pagineWhen A Transformer Has Stomach Pain and Wants ToRobert GalarzaNessuna valutazione finora

- Grade 4 SYLLABUS Check Point 1Documento2 pagineGrade 4 SYLLABUS Check Point 1Muhammad HassaanNessuna valutazione finora

- Education During The Ancient Period Primitive EducationDocumento5 pagineEducation During The Ancient Period Primitive EducationEn CyNessuna valutazione finora