Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Schedule Scope: CAIR7892: Weld Repair To C6604 E4 Nozzle (TA)

Caricato da

dewTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Schedule Scope: CAIR7892: Weld Repair To C6604 E4 Nozzle (TA)

Caricato da

dewCopyright:

Formati disponibili

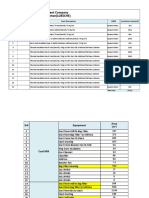

SCHEDULE SCOPE

14/10/2016 10:27:34AM

UNIT: A102-SOUTH-U6600 UNIT NAME: MOGAS ALKYLATION

FLOC: A102-C6604 FLOC NAME: HF STRIPPER COLUMN

EQUIP ID: C6604 EQUIP NAME: HF STRIPPER COLUMN

LEGAL REG: REG AGENCY:

INSP SCHD ID: CAIR00007892 SHELL REG NO: 20020631

CAIR7892: Weld Repair to C6604 E4 Nozzle [TA]

DETAILS OFFLINE? YES

LAST INSP DATE: SCHD CAT: CATEGORY 1 INTRUSIVE? NO

NEXT INSP DATE: 31/10/2016 RESP DISC: ME AND EI RECURRING? NO

USR NEXT INSP DT: 31/10/2016 SCHD DRV: RECOMMENDATION STATUS: FINAL APPROVAL

TM INTRVL INSP DT: TIME INTRVL: SAP RELEASE DATE: 13/10/2016

COMP ID: GENERAL MECH: MECH TYPE:

ACTIONS

DETAIL CTGRY DETAIL NAME QUALIFIER DETAIL VALUE UOM

NARRATIVE

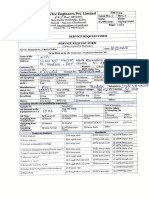

Condition as Found:

2 x transverse linear indication found at 6 o'clock position on WNF to nozzle neck weld on DN350 E4 nozzle on C6604, 20mm and 12mm length respectively. 2 x

transverse linear crack found on internal side of nozzle with MPI. Linear indication extends on internal side through weld metal into parent metal.

Nominal thickness of nozzle neck is 12.7mm. Linear indication was ground to a depth of 5.4mm internally and still existed in both weld metal and parent metal.

The region where linear indication existed had a very fine brown scale on external side of nozzle. Paint was removed at location and area was MPI on external side

of nozzle weld and linear indication was found, approximately 10mm long in weld only. This indication has propagated through the full thickness of the weld from ID

to OD. No leak was detected OTR.

Recommendation:

CAIR7892: Weld Repair to C6604 E4 Nozzle [T/A]

RAM:3/E People

Target End Date: 31/10/2016

Specifications:

A job-specific Inspection and Test Plan (ITP) including all weld procedures and supporting qualification records shall be submitted to Viva Inspection and approved

prior to the commencement of any fabrication works.

A Manufacturers Data Report shall be submitted upon completion .

Reference Viva drawing T995901 for materials of construction and other fabrication details pertaining to C6604.

1. As of 13/10/2016, E4 nozzle has been ground with J-groove configuration internally to a depth of 5.4mm at location of transverse linear indication at 6 o'clock.

Continue grinding to a depth of 6.0mm with a 10.0mm flat landing centred over original weld (figure 2 in attachment). Edges of weld preparation shall be bevelled at

70deg.

2. MPI. Contact inspection. Intent is to see if ground area has removed linear indication in parent metal, and confirm linear indication only exists in original weld

metal and to define length. This must be noted prior to welding.

3. At acceptance of MPI, hydrogen evacuation, 150degC minimum for 30minutes.

4. Weld out internal in accordance with WPS . Low hydrogen electrode shall be used.

5. Grind out on external side of weld. Grind to width of existing external weld cap, minimum depth 6.0mm. Bevel angle shall be dictated by the known width of linear

indication which was welded over from the inside. It may be necessary to increase ground out width/open up bevel angle.

6. MPI area externally ground. If indication exists, contact inspection.

7. Upon acceptance of MPI, hydrogen evacuation, 150degC minimum for 30minutes.

8. Weld out external in accordance with WPS . Low hydrogen electrode shall be only used.

9. MPI internal/external side cap. RT region where new weld metal has been deposited .

10. Upon acceptance of NDT, carry out local PWHT 650 DegC minimum for 1 hour hold time. Temperature shall be controlled from 300degC. Maximum

heating/cooling rate 200degC/hr.

11. Carry out hardness test, the hardness shall not exceed 248Hv10 in any area of weld.

12. MPI pad welded area after completion of PWHT and acceptance of hardness test .

13. PMI pad welded area and surrounding HAZ, minimum 4 areas.

14. Restore shell outside coating to GRAP 3.12.30 System M8.

15. Clock gasket face at completion of work to check for deformation.

Attachments:

L:\Engineering\Inspection\IDMS Documents\6600-C6604-CAIR7892-Oct2016.pdf

Signed Action Completed: Date:

REPORT ID:R407-2.4.2-31JAN2013 PAGE 1 OF 1

Potrebbero piacerti anche

- Free Online GMAT Practice Test - London Business SchoolDocumento2 pagineFree Online GMAT Practice Test - London Business SchooldewNessuna valutazione finora

- Design Guidelines for Surface Mount TechnologyDa EverandDesign Guidelines for Surface Mount TechnologyValutazione: 5 su 5 stelle5/5 (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Documento3 paginePhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Near Bit GammaDocumento2 pagineNear Bit GammaQiang ZhangNessuna valutazione finora

- A-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportDocumento4 pagineA-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportHari KarthickNessuna valutazione finora

- Enlightened Polymer Clay BLAD WebDocumento8 pagineEnlightened Polymer Clay BLAD WebMonika Timári85% (13)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocumento2 pagineUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- SOP For Refrigeration PlantDocumento37 pagineSOP For Refrigeration PlantGaurav Swarup67% (3)

- Equipment Calibration Record ChartDocumento3 pagineEquipment Calibration Record ChartNatarajan MurugesanNessuna valutazione finora

- Insulation BOQ Area Wise (Square MTR.)Documento11 pagineInsulation BOQ Area Wise (Square MTR.)Atiq Ur RehmanNessuna valutazione finora

- QUOTATIONDocumento3 pagineQUOTATIONMaynard SurioNessuna valutazione finora

- FAR D6R LH Final Drive FailureDocumento9 pagineFAR D6R LH Final Drive Failurealisa alainaNessuna valutazione finora

- Visual Inspection ReportDocumento5 pagineVisual Inspection ReportHanuman RaoNessuna valutazione finora

- 322-17483L C0Documento11 pagine322-17483L C0HashemAliHashemNessuna valutazione finora

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocumento11 pagineDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Article Surge Control Analysis For Centrifugal CompressorsDocumento3 pagineArticle Surge Control Analysis For Centrifugal CompressorsHatem Ali100% (1)

- Ut Report-1 PDFDocumento1 paginaUt Report-1 PDFsureshrathod2Nessuna valutazione finora

- Loss Coeff KL On Valves & FittingsDocumento5 pagineLoss Coeff KL On Valves & FittingsJoren HuernoNessuna valutazione finora

- D62 - 691 - 5 - C4-Specification Sheets PDFDocumento26 pagineD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaNessuna valutazione finora

- Kamlesh Kumar Singh Engineers Pvt. LTDDocumento24 pagineKamlesh Kumar Singh Engineers Pvt. LTDAADARSHNessuna valutazione finora

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Documento1 pagina75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNessuna valutazione finora

- International Limited International Limited: JC JCDocumento5 pagineInternational Limited International Limited: JC JCMichael OkwuwaNessuna valutazione finora

- Nonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceDa EverandNonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceNessuna valutazione finora

- Final Insepection Reports and WPS PQRDocumento14 pagineFinal Insepection Reports and WPS PQRVikas Verma100% (1)

- Amca 211Documento62 pagineAmca 211Raji PanickerNessuna valutazione finora

- Pressure Vessel High Pressure Stripper R0 Final Report R1Documento5 paginePressure Vessel High Pressure Stripper R0 Final Report R1AJ NugrohoNessuna valutazione finora

- Viva Energy Prospectus (AU) PDFDocumento310 pagineViva Energy Prospectus (AU) PDFdewNessuna valutazione finora

- Oil Test-1Documento2 pagineOil Test-1ForenTec Engineers RanchiNessuna valutazione finora

- Utm - 1Documento2 pagineUtm - 1Kaushal GandhiNessuna valutazione finora

- 01 Warm GearDocumento21 pagine01 Warm GearAndri SaputraNessuna valutazione finora

- YKEPL MPI Procedure For A668 RMDocumento4 pagineYKEPL MPI Procedure For A668 RMDeepak HoleNessuna valutazione finora

- Gpti Qicl J931 Mut 041Documento3 pagineGpti Qicl J931 Mut 041uselessinstaid52Nessuna valutazione finora

- 4845 PDFDocumento1 pagina4845 PDFRavi patelNessuna valutazione finora

- 23-01-24. Comp MTA 6 Plant SignDocumento4 pagine23-01-24. Comp MTA 6 Plant Signwahyudi140417Nessuna valutazione finora

- Int'L NDT Services: Magnetic Particle Examination ReportDocumento3 pagineInt'L NDT Services: Magnetic Particle Examination Reportsarsan nedumkuzhiNessuna valutazione finora

- Penetrant Test Report: PT DegremontDocumento14 paginePenetrant Test Report: PT DegremontMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Gpti Qicl J931 Mut 019Documento3 pagineGpti Qicl J931 Mut 019uselessinstaid52Nessuna valutazione finora

- CCR JN 5646488-Sis-C9 Engine en Mbd09063-High BlowbyDocumento15 pagineCCR JN 5646488-Sis-C9 Engine en Mbd09063-High Blowbyahmat ramadaniNessuna valutazione finora

- Ut PQRDocumento10 pagineUt PQRArvind Sahani100% (1)

- Uttm ReportDocumento2 pagineUttm ReportVajid Madathil100% (1)

- Chandra Honda: Estimate For Accident RepairDocumento1 paginaChandra Honda: Estimate For Accident RepairLKG Saipranesh SNessuna valutazione finora

- Failure Analysis Report: Information - 01Documento4 pagineFailure Analysis Report: Information - 01Budi ArtantoNessuna valutazione finora

- S Op Surface Peratio e Hydra (OD Nal Phi Aulic Co DIN Valv Ilosoph Ontrol S Ve) Hy System MDocumento28 pagineS Op Surface Peratio e Hydra (OD Nal Phi Aulic Co DIN Valv Ilosoph Ontrol S Ve) Hy System Mwqs_19Nessuna valutazione finora

- MIghty Machine RejectDocumento1 paginaMIghty Machine RejectMohammad Shanawaz MNessuna valutazione finora

- Gpti Qicl J931 Mut 004Documento3 pagineGpti Qicl J931 Mut 004uselessinstaid52Nessuna valutazione finora

- RouteA COC KEC1064591Documento2 pagineRouteA COC KEC1064591asghar khanNessuna valutazione finora

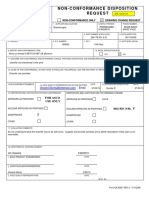

- Non-Conformance Disposition Request: For Asco Use OnlyDocumento1 paginaNon-Conformance Disposition Request: For Asco Use OnlyRavichandran DNessuna valutazione finora

- WI For Inclusion Rating - TkapDocumento10 pagineWI For Inclusion Rating - Tkapamit gajbhiyeNessuna valutazione finora

- Pump QuotationsDocumento3 paginePump Quotationsdibyendu65Nessuna valutazione finora

- Dinshaw Filtration Systems PVT LTDDocumento15 pagineDinshaw Filtration Systems PVT LTDAsif AliNessuna valutazione finora

- Tmu-1105 Job Card Ta-2019Documento20 pagineTmu-1105 Job Card Ta-2019Anonymous YRyGcKPNessuna valutazione finora

- Parts Manual: Automatic ScrubberDocumento147 pagineParts Manual: Automatic ScrubberMarco TailleferNessuna valutazione finora

- VTR 20 KP+FollowersDocumento20 pagineVTR 20 KP+FollowersANDRES LLAGUARIMAY CHIPANANessuna valutazione finora

- Gate WCB 900 RF Size 4 BR2023084Documento1 paginaGate WCB 900 RF Size 4 BR2023084Natthapong ApirattanapanNessuna valutazione finora

- Gpti Qicl 032Documento2 pagineGpti Qicl 032uselessinstaid52Nessuna valutazione finora

- MFG Certificate 79Documento2 pagineMFG Certificate 79Hoshiar BaghelNessuna valutazione finora

- NGP-000-TEL-15.04-0002!03!00 Telecom MTO For Existing Process Unit AreaDocumento3 pagineNGP-000-TEL-15.04-0002!03!00 Telecom MTO For Existing Process Unit Areawqs_19Nessuna valutazione finora

- Final Inspection Release Note: Rawae Al Amal Industrial ServicesDocumento1 paginaFinal Inspection Release Note: Rawae Al Amal Industrial ServicesJamal Mohamed RahamathullahNessuna valutazione finora

- CommissioningDocumento2 pagineCommissioningBug me notNessuna valutazione finora

- FAT Protocol PDFDocumento2 pagineFAT Protocol PDFvinodNessuna valutazione finora

- DPT ReportDocumento3 pagineDPT ReportMANIMARAN QCNessuna valutazione finora

- Example CVDocumento7 pagineExample CVkarthi keyanNessuna valutazione finora

- H-6DEL - Report - DOF - 2017.07.21 Coriendo TR de 20Documento9 pagineH-6DEL - Report - DOF - 2017.07.21 Coriendo TR de 20PAZCOSL3 MEJIANessuna valutazione finora

- Saline Water Conversion Corporation: QA/QC ProcedureDocumento3 pagineSaline Water Conversion Corporation: QA/QC ProcedureBurak BaşNessuna valutazione finora

- Long Term Test Report-9578-001-132-Pvm-W-030-00Documento35 pagineLong Term Test Report-9578-001-132-Pvm-W-030-00Anonymous gr5Pr9AVNessuna valutazione finora

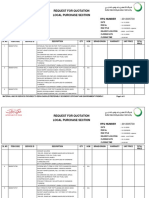

- Request For Quotation Local Purchase Section: RFQ NumberDocumento6 pagineRequest For Quotation Local Purchase Section: RFQ NumberSKS MMGTNessuna valutazione finora

- Ii (Specti I ( (LLTS) A L-Eading NDT: Tndustrial Ser//Ices CornpanyDocumento1 paginaIi (Specti I ( (LLTS) A L-Eading NDT: Tndustrial Ser//Ices Cornpanyআশার আলোNessuna valutazione finora

- Dtic Ada267163Documento74 pagineDtic Ada267163nitharsunNessuna valutazione finora

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceDa EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNessuna valutazione finora

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyDa EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNessuna valutazione finora

- UDJ Cheat Sheet - MergedDocumento2 pagineUDJ Cheat Sheet - MergeddewNessuna valutazione finora

- Constance Tavernier Accomodation: CedepDocumento1 paginaConstance Tavernier Accomodation: CedepdewNessuna valutazione finora

- Individual Assignment - Daniel Hew: Humans Are Irrational BeingsDocumento3 pagineIndividual Assignment - Daniel Hew: Humans Are Irrational BeingsdewNessuna valutazione finora

- Skytrans Charter Flight Schedule: Brisbane To Chinchilla & Taroom Return FlightsDocumento1 paginaSkytrans Charter Flight Schedule: Brisbane To Chinchilla & Taroom Return FlightsdewNessuna valutazione finora

- Volunteer Application Western Downs LibrariesDocumento2 pagineVolunteer Application Western Downs LibrariesdewNessuna valutazione finora

- Petroskills Learning CatalogueDocumento89 paginePetroskills Learning CataloguedewNessuna valutazione finora

- Catalog - Small FUEL & OIL DRAIN VALVESDocumento5 pagineCatalog - Small FUEL & OIL DRAIN VALVESJessie O.Bechayda100% (1)

- Philips - FBH056 057 058 059 PDFDocumento5 paginePhilips - FBH056 057 058 059 PDFVu Duc DuyNessuna valutazione finora

- Production Testing Solutions Three-Phase Test Separator: Features/BenefitsDocumento1 paginaProduction Testing Solutions Three-Phase Test Separator: Features/BenefitsdonyaNessuna valutazione finora

- Wood Anatomy and Topochemistry of Bombax CeibaDocumento14 pagineWood Anatomy and Topochemistry of Bombax CeibaVerapenk Leostarastra RamadhaniNessuna valutazione finora

- Wemco Depurator 2003Documento2 pagineWemco Depurator 20031mmahoneyNessuna valutazione finora

- Dismantling of e Waste and Handling ProcessDocumento4 pagineDismantling of e Waste and Handling ProcessPriyanshu ChaubeyNessuna valutazione finora

- Tk08 Report Revision MidtermDocumento84 pagineTk08 Report Revision MidtermJessille silvNessuna valutazione finora

- Mechanically Induced Chemical ChangesDocumento44 pagineMechanically Induced Chemical ChangesHenokAbayNessuna valutazione finora

- Reebol Emulsion ConcentrateDocumento2 pagineReebol Emulsion ConcentrateJA WPKNessuna valutazione finora

- Design of Machine Members-II QB PDFDocumento24 pagineDesign of Machine Members-II QB PDFAnonymous hUN4K5fZkeNessuna valutazione finora

- Lambda Sensor LSU 4.9: Application Mechanical DataDocumento2 pagineLambda Sensor LSU 4.9: Application Mechanical DataDamirNessuna valutazione finora

- Rev 8Documento2 pagineRev 8api-273257329Nessuna valutazione finora

- Advanced Process Design in High Volume Kneader Reactors Using Multiple Feed Ports To Avoid Crust Forming Foaming and Low Heat TransferDocumento10 pagineAdvanced Process Design in High Volume Kneader Reactors Using Multiple Feed Ports To Avoid Crust Forming Foaming and Low Heat TransferRaja WajahatNessuna valutazione finora

- Ferrous Carbon Austenite, Equivalent Carbon ContentDocumento2 pagineFerrous Carbon Austenite, Equivalent Carbon ContentAmirul NorshahNessuna valutazione finora

- Supporting Information For Thin, Lightweight, Foldable Thermochromic Displays On PaperDocumento6 pagineSupporting Information For Thin, Lightweight, Foldable Thermochromic Displays On PaperDanesh AzNessuna valutazione finora

- PanelGrip - Glass Railing SystemDocumento4 paginePanelGrip - Glass Railing SystemSarinNessuna valutazione finora

- G1909HSDocumento2 pagineG1909HSeisenbarger5607Nessuna valutazione finora

- Lateral Support of Wood Beams in Residential Structures PDFDocumento4 pagineLateral Support of Wood Beams in Residential Structures PDFBrian-Marti BoatrightNessuna valutazione finora

- Ecture 3.1: Low Stiffness in Polymers: Two Types of PolymersDocumento4 pagineEcture 3.1: Low Stiffness in Polymers: Two Types of PolymersThomas Van KuikNessuna valutazione finora

- TECH - Wyntk - Truss Facts For Eng and ArcDocumento24 pagineTECH - Wyntk - Truss Facts For Eng and Arcshaikh85Nessuna valutazione finora

- Chapter 4Documento23 pagineChapter 4syedmuhammadtariqueNessuna valutazione finora

- RB - Specifications Piping MaterialsDocumento21 pagineRB - Specifications Piping MaterialsFalcon PeregrinusNessuna valutazione finora