Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FOR CHEIUICAL, MICROBIOLOGICAL E CIVIL ENGG

Caricato da

Ankush PatialTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FOR CHEIUICAL, MICROBIOLOGICAL E CIVIL ENGG

Caricato da

Ankush PatialCopyright:

Formati disponibili

FOR CHEIUICAL, MICROBIOLOGICAL E CIVIL ENGG,

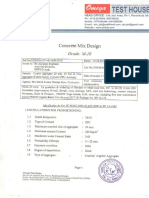

HEAD OFFICE : 134, lnd. Area, Ph-1, Panchkula (Hr.)

Ph : 0172-257 6904, 5057358(O)

Mobile :9779224444 | 9815000244

E-mail : oth_pkl@rediffmail.com, oth.pkl@gmail.com

Website : www.othbio.com

Approvedby:N.A.B.L.,PG.C.|.L.,Hr.PWD(B&R&PH),Pb.PWD(B&R&PH),H.PPWD(B&R&PH),CPWD,M.E.S.,T.B.R.L.,

H.U.D.A., GMADA, HSllDC, Hr. Police Hsg. Corp, NR, Pb. Mandi Board I Approved by: FDA, Haryana (24-LAB-HR, DTD 09-07-2013)

Report of Concrete Mix Desisn Grade M-15

Ref No. OTH,A{M-07 I AEI IOLEl?l | 6 Dated : l2.l1.2016

Issued to: The Assistant Engineer,

Jole Sub Division, Lab No.OTH/M-27 00 12016

HPPWD Jole.

Sample: Coarse aggregate 20 mm, 10 mm & Fine

aggregate (Coarse Sand), Cement [PPC-Ambuja] & Date of receipt : 02.11.2016

Admixture (BSF).

Your reference: Sample delivered by your

Agency: Ws Satish Kumar Sharma Go\,1. Contractor.

representative.

Name of Work: Up-gradation of Baruhi Dumkhar Road under PMGSY-I Batch- I for the year 2016-

2017 Package No. HP l2-l 14 (SH: Formation cutting, C/o Retaining walls, C.D Works, C.C,

pavement, C/O Drain, M/T, P/F PMGSY logo board and KM. stone etc. including maintenance for

five years in KM. 0/00 to 271270.)

Mix Desisn As Per IS:10262-2009,15:456 & SP:23-1982&MORD Specification

1.0 STIPULATIONS FOR PROPORTIONONG:

l.t Grade designation M-15

1.2 Type ofCement PPC [S: 1489 (Part- I)].

1.3 Maximum nominal size of aggregate 20 mm

1.4 Minimum cement Content 250 Kgims as per MORD

1.5 Maximum water Cement Ratio 0.50 as per MORD

1.6 Workability (Slump) 25-50 mm

1.7 Exposure condition Normal

1.8 Degree of supervision Good

1.9 Type of aggregate Crushed

Page- I

Omega Test House,

Plot no-134, Industrial area, Phase-l, Panchkula.(Haryana).

E-mail: oth pklAfediffnail.com, oth-pklaemail.com phone:o172-5057358, 2576904,

Mobile: +919417005387, +9 1977 9Z"OOOO, +919815000244.

2.0 TEST DATA FOR MATERIALS:

2.1 Cement used PPC

2.2 Specific gravity of cement 3.00

2.3 Specific gravities of :-

a.) Coarse aggregate 2.67

b.) Fine aggregate 2.65

c.) Admixture 1.14

2.4 Water absorption

a.) Coarse aggregate 0.70%

b.) Fine aggregate r.00%

2.5 Free (Surface) moisture

a.) Coarse aggregate Nil (Absorbed moisture also nil)

b.) Fine aggregate 2.20%

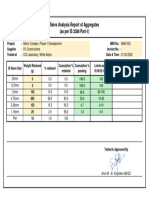

Sieve Analysis:- Coarse aggregate:

Coarse aggregate fraction Toage Different fraction Remarlis

IS: Sieve Analysis of F-I F-II Combined Confoming

designation, Coarse 20 mm 10 mm to table 2 of

mm aggregate IS:383-1970

Fraction Reaf: 2007

F'-I F-II 50 Vo 50 V" 100 %

40 100 100 50.0 50.0 100 100

20 95.18 100 47.6 50.0 97.6 95-100

10 0.60 63.3 0.3 3 1.6 3r.9 25-55

0.30 l0.r 0.15 5.0 5.15 0-10

2.7 Sieve analysis Fine aggregate:-

IS: Sieve designation, mm 7o age Passing Limit for Grading Zone-II

10 100 100

4.75 98.1 90-100

2.36 92.8 75-100

1.18 69.4 55-90

0.60 55.8 35-59

0.30 27.5 8-30 rea

,,.

0.15 8.3 o_to

l[i/ \s]

Omega Test House,

E-mail otl

Page-2

Plot oo-134, Industrial area, Phase-I, Panchkula.(Haryana).

pki@rediftlail.com, oth.pkl@mail.com Ptrone:0172-5057354,2576904,

Mobile: +919417005387, +919779224444, +919815000244.

wp

, 3.0 TARGET STRENGTH FOR MIX PROPORTIONING:

l'ck = /ck+ 1.65 r

Where

/'.1 = target average compressive strength at 28 days.

/ = characteristic compressive strengtl at 28 days, and

S: standard deviation

From table 1, standard deviation, s = 3,J N/mm2

: l5+1.65 x 3.5

: 20,?7 N/mm2 o r 207.7 kgftm2.

4.0 SELECTION OF WATER - CEMENT RATIO

From MORD Table No. 800.1, maximum water - cement ratio : 0.50

Based on experience, adopt water-cement ratio as 0.50

0.50 = 0.50, Hence OK

5.0 SELECTIOM OF WATER CONTENT

From table 2, maximum water content = 186 Liter (for 25 to 50 mm slump range).

(for 20 mm ag$egate).

Estimated water content for 10 to 25 mm slump = 186 Liter

As super plasticizer is used, the water content can be reduced up 15 percent and above.

Based on trials with super plasticizer water content reduction of l0 o/o

has been achieved.

Hence, the arrived water content = 186 x 0.90 : 167 .4 Liter.

6.0 CALCULATION OF CEMENT CONTENT:

Water-cement ratio : 0.50

Cement Content = 167.4/0.50= 335 ks/cmr.

Note : Cement quantity is very high, so we have taken cement content 270

From MORD Table No, 800.1, minimum cement content for Normal

250 kg/m3. So 270 > 250 kg/cm3, Hence OK.

ffi#.rS

So required water content for 270 kg cement = 135 Liter. ir,"#

Page-3

Omega Test House,

Plot no-134, lndustrial area, Phasel, Panchkula.(Haryaia).

E-rnail: 9lb_eE@ed!&gi!.qg$, oth.pkLQ)email.com phone:o172-5057358, 2576904,

Mobile: +9194170053a7, +9 19779224444, +919815OOO244.

7.0 PROPORTION OF VOLIJME COARSE AGGREGATE Ah{D FINE AGGREGATD

CONTENT:

From Table 3, Volume of coarse ag$egate conesponding to 20 mm size aggregate and fine

aggregate (Zone-II) for waler -cement ratio 0.50 = 0.62.

In the present case water - cement ratio is 0.50; therefore, No conection is required in volume

of coarse aggregate to the fine aggregate content. Therefore, conected proportion of volume

ofcoarse aggegate for the water-cement ratio of0.50 :0.62.

Note: In case the coarse aggregate is not angular one, then also volume ofcoarse aggregate

may be required to be increased suitability, based on experience.

8.0 Mix calculations:

The mix calculations per unit volume ofconcrete shall be as follows:

a.) Volume ofconcrete 1m'

b.) Volume of cement 270 1

I

----- x ----- = u.uyu m-

3.00 1000

c.) Volume of water 135 I

------- x ------- = 0.135 m3

1.00 1000

d.) Volume of admixture [@ 1.15

percent by mass of cementitious 3. 105/1. 14x 1/1000 : 0.0027 m3

materiall

e.) Volume of all in aggregate ll- (0.090+ 0.1350+0.0027)l = 0.772m'

f\ Mass of coarse aggregate 0.772x0.62x2.67 x 1000 :1278kp

Mass offine aggregate 0.772x0.i8 x 2.65 x =777 kp -

1000

uft-\.

,,

,s_u/" ',.")

*\,,. j,ti

\ ,-:. r i;: :'* t

Page-4

\:i;;::ij;z

'\)...'il.)?'

Omega Test House,

Plot no- 134, Industrial aiea, PhaseJ, Panchkula.(Haryana).

E'mail: oth pklaredifmail.com, oth.pkl^Aqmail.com Phone:O172-5o5735A,2576904,

Mobile: +9 19417005347, +9 19779224444, +919815000244.

9.0 Mix proportions Calculations for Trial No 1:-

Trial-I

Admixture, Water, Lt/m' Cement, kg/m' Fine Aggregate, kg/m' Coarse Aggregate, kg/m'

Ltlm3

lJ) 270 777 1278

3.105 0.50 I 2.87 .+. /JJ

Similarly Trial II and Trial III carried out:-

Trial-II

Admixture, Water, Ltlm' Cement, kg/mr Fine dgregate, kg/m' Coarse Aggregate, kg/mr

Lt/m3

140 280 769 1265

3.22 0.50 I 2.75 4.518

Trial-I[

Admixture, Water, Ltlm' Cement, kg/m' Fine Aggregate, kg/m' Coarse Aggregate, kg/m'

Ltlm3

t45 290 760 1249

J.JJ) 0.50 1 2.62 4.307

10.0 Compressive strength: Verified compressive strengh in respect of the designs

mentioned in this report is given below for ready reference:-

Compressive strength, Kg/cmz:-

Trial No - I Trial No - II Trial No - III

At 7 days 146.6 t64.4 182.2

At 28 days Under Testing Under Testing Under Testing

Note: The result is based on 75 Yo of Target mean Strength.

The 28 days compressive strength will be conveyed after the

tss

&fthetest. i6

:tI.."',",/ii

Page-5 (:) ,,'Ju)

nmPoa TFct ll^rrcc

PIot no-134, Industrial area, Phase-I, Panchkqla.(Haryana).

E-mail: qb-9E@gdi@AiL!9!q, oth.pkLaemail.com Phone:0172-5057358, 2576904,

Mobile: +919417005387 , +9 19779224444, +919815000244.

11.0 Recommendation: In our opinion Trial No- tr of the essential particulars are given

below, is the most appropriate and economical one and is, therefore recommended to be

adopted for M-15 Grade.

Proportion of constituents:

Trial-II

Admixture, Water. LUmr Cement, kg/mr Fine Aggregate, kg/m3 Coarse Aggregate, kg/mr

Ltlm3

140 280 769 1265

20mm:632.5

10 mm:632.5

3.22 0.50 1 2.75 4.518

Acfual quantities required for the Mix per bag of cement:-

Admixture, Water, LUm' Cement, kg/mr Fine Aggregate, kg/mr Coarse Aggregate, kg/mr

Ltlm3

25 50 13t.) 225.9

20 mm: 112.95

10 mm = 112.95

0.575 0.50 I 2.75 4.518

1. For water cement ratio (dc) for 0.50 = 25.0 Liters

2. Extra quantity of water to be added for absorption in case of = (+) 1.s813

coarse aggregate, at 0.70 % by mass

3. Quantity of water to be deduct for free moisture present in : (-) 3.02s

sand. at 2.20 % bv mass

A

Actual quantity ofwater to be added (25.0+ 1.5813 - 3.025) = 23.56 Liters

5. Actual quantity of lme aggregate required( 137.5+3.025) = 140.52 Kg

6. Actual quaatity of coarse aggregate required (225.9-1.5813) :r7re\

Page-6

\Qiry

Omega Test House,

Plot !0-134, Indusfi:ial ar:ea, Phase-I, Pancbkula.(Haryana).

E-mait otlr pklarediffmail.com, oth.pldla@ail.com Phone:0172-5057354,2576904,

Mobile: +919417005387. +919779224444. +9198150002,14.

Actual quantities required for the Mix:

Adnixfure, Water, kg/mr Cement, kg/mr Fine Aggregate, Coarse Aggregate, kg/m3

Ltlm3 kg/m3

131.9 280 787 r2s6.2

20 mm = 628.1

10mm= 628.1

3.22 0.471 I 2.810 4.486

For 50 kg bag of cement the quantity of naterials are worked as below:

Admixture, Water, kg/m" Cement, kg/mr Fine Aggregate, kg/m' Coarse Aggregate, kglm3

Ltlm3

23.56 50 r40.52

20 mm = 112.15

10 mrn = 112.15

0.575 0.471 I 2.810 4.486

Note: Aggregate should be used in saturated surface dry condition. If otherwise, when

computing the requirement of mixing water, allowance shall be made for the free (surface)

moisture contributed by the fine aggregate and coarse aggregates. On the other hand, if the

aggegates are dry, the amount of mixing water should be increased by an amount equal to

the moisture likely to be absorbed by the aggregates. Necessary adjustments are also

required to be made in mass of aggregates. The surface water aad percent water absorption

of aggregates shall be determined according to IS: 2386.

NOte: l. The results relate to the sanple tested.

2. Sample consumed in testing.

3, This report is not to be reproduced wholly or in part and cannot be used as evidence in the court of

Law & should not be used in any advedising media without special permission in writing.

Page-7

Omega Test House,

Plot no-134, Industrial area, Phase-I, Panchkrla.(Haryana).

E-mail: oth pkl@redituail.com, otll.pkl@@ail.coE Phone:o172-505735a,2576904,

Mobile: +9194170053a7, +919779224444, +9L9a15O0O244 -

FOR CHEMICAL, MICROAIOLOGICAL & CIVILENGG.

APPTOVEdbY:N.A'B'L',PG.C.I.L.,Hr,PWD(B&R&PH),Pb.PWD(B&R&PH),H.PPWD(B&R&PH),CPWD,M.E.S.,T'B,R.L.,

HUD A, GMADA, HSllDc, Hr. Police Hsg. corp, NR, Pb. fi/andi Board

I Approved by: FDA, Haryana (24-LAB-HR, DTD 09-07-2013)

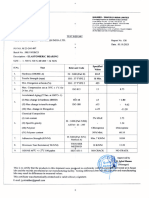

Ref No. OTI-LIJM-07 /AE/JOLE/2Ot6 Dated :03.12.2016

Issued to: The Assistant Engineer,

Jole Sub Division,

Lab No.OTH/M-27 00 /20 | 6

HPPWD Jole.

Sample: Coarse aggregate 20 mm, l0 mrn a fine

aggegate (Coarse Sand), Cement [ppC-Ambuja] & Date of receipt : 02.11.2016

Admixture (BSF).

Agency: M/s Satish Kumar Sharma Govt. Contractor. Your reference: Sample delivere6 by your

Name of Work: Up-gradation of Baruh

2017 Package No. HP 12-l 14 (SH: Formation cutting, C/o Retaining walls, C.D Wirt.,-i.C,

pavement, c/o Drain, NI/T, p/F pMGSy logo board and KM. stone eti. including

maintenance for

five years in KM. 0100 to 271270.)

l. DesignStipulations:

a.) Characteristic Compressive Strength required in the field at 2g days: l5 N/mm2.

3.0 Target Mean Strength: 207.7 N/mm2 or 207.0 K{cm2

13. compressive Strength: verified compressive strength in respect ofthe mix designs mentioned

in

this report is given below for ready reference:

Comoressive Streneth. Ke/cmz

MlX No. - l MIX No. - II MIX No. .lll

At 28 days 186.6 213.3 222.2

14. Recommendations: our recommendation is same which is recommended in our earliest test

reporr of

even lab. No.2700 Dispatched vide Ref No, orH,NM-O7 /,\ElJoLEl2016 Datedz

12.11.2016 for Mix. No. II

Omega Test House,

Plot no-134, Industrial aiea, Phase-I, panchkula.(Haryana).

E maii: oth rklA ediffmail.com, oth.pklAsnail.com phone:0172-505735g,2576904,

Mobile: +919417005387, +9 1977 9224444, +919815000244.

Potrebbero piacerti anche

- RDSO Drawing ListDocumento42 pagineRDSO Drawing Listkaushik96040% (5)

- ASTM E92-17 Standard Test Methods For Vickers Hardness and Knoop Hardness of Metallic MaterialsDocumento27 pagineASTM E92-17 Standard Test Methods For Vickers Hardness and Knoop Hardness of Metallic MaterialsCarlos Pinto Pradilla88% (8)

- Vienna ModernDocumento85 pagineVienna ModernZain ZulfiqarNessuna valutazione finora

- Environmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96Documento22 pagineEnvironmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96scribdledeeNessuna valutazione finora

- M-10 Nandpur MairiDocumento8 pagineM-10 Nandpur MairiAnkush PatialNessuna valutazione finora

- L: ('T' K/ATIO) AL Concordta: QualityDocumento3 pagineL: ('T' K/ATIO) AL Concordta: QualityAung Naing Latt AungNessuna valutazione finora

- Concortta Tyrl:R/A: QualityDocumento3 pagineConcortta Tyrl:R/A: QualityAung Naing Latt AungNessuna valutazione finora

- Sieve Analysis For Fine Aggregate - Kico ProjectDocumento1 paginaSieve Analysis For Fine Aggregate - Kico ProjectMitendra ChauhanNessuna valutazione finora

- Laboratory Test Report: Faculty of Engineering & TechnologyDocumento6 pagineLaboratory Test Report: Faculty of Engineering & TechnologySourav SahaNessuna valutazione finora

- Chancho - SummaryDocumento1 paginaChancho - SummaryALEX BNessuna valutazione finora

- Geotechnical Test Results for Ethiopian Electric Utility ProjectDocumento1 paginaGeotechnical Test Results for Ethiopian Electric Utility ProjectALEX BNessuna valutazione finora

- Nabll Mix DesignDocumento29 pagineNabll Mix DesignPIDCL WITH SUBUDHINessuna valutazione finora

- Report 3523 M40 08 12 2019Documento20 pagineReport 3523 M40 08 12 2019Imran KhanNessuna valutazione finora

- Kampli MVS Material Test 11.12.2021Documento18 pagineKampli MVS Material Test 11.12.2021I'm AJNessuna valutazione finora

- Korugud MVS Material Test 11.12.2021Documento18 pagineKorugud MVS Material Test 11.12.2021I'm AJNessuna valutazione finora

- M25 Concrete Mix Design for Bottom PlugDocumento10 pagineM25 Concrete Mix Design for Bottom PlugBscpl Repalle to EeppurpalemNessuna valutazione finora

- M35 Bhole ConstructionDocumento6 pagineM35 Bhole ConstructionBIPL REPORT100% (1)

- Sieve Analysis-08.08Documento4 pagineSieve Analysis-08.08ASHOKKUMARNessuna valutazione finora

- Mix Design M-25 GradeDocumento9 pagineMix Design M-25 Gradeenjoy begening lifeNessuna valutazione finora

- Mix Design M-35 MCDocumento15 pagineMix Design M-35 MCRana MahatoNessuna valutazione finora

- Draft Letter Regarding Source Approval For Bituminous Concrete Grade-1 With BPCL - VG - 30 BitumenDocumento3 pagineDraft Letter Regarding Source Approval For Bituminous Concrete Grade-1 With BPCL - VG - 30 BitumenAmol Jadhav67% (3)

- Mix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Documento7 pagineMix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Snehashish BasuNessuna valutazione finora

- Sieve Analysis-28-03-19Documento2 pagineSieve Analysis-28-03-19ASHOKKUMARNessuna valutazione finora

- Concrete Mix DesignDocumento12 pagineConcrete Mix DesignAnand.5Nessuna valutazione finora

- Design Mix m40Documento4 pagineDesign Mix m40SOIGNE ENGINEERING CONSULTANTSNessuna valutazione finora

- Design Mix M 30Documento4 pagineDesign Mix M 30SOIGNE ENGINEERING CONSULTANTSNessuna valutazione finora

- Sieve Analysis-05.07.2018 Coarse & FineDocumento3 pagineSieve Analysis-05.07.2018 Coarse & FineASHOKKUMARNessuna valutazione finora

- RCC M-25, Ultratech, OPC43Documento5 pagineRCC M-25, Ultratech, OPC43Sanjoy RoyNessuna valutazione finora

- GRC Sieve Analysis ReportsDocumento2 pagineGRC Sieve Analysis ReportsASHOKKUMARNessuna valutazione finora

- Sieve Analysis of Fine Aggregate IS: 383 - 1970Documento1 paginaSieve Analysis of Fine Aggregate IS: 383 - 1970Chandra Nath DasNessuna valutazione finora

- Nandpur Mairi Road M-15 Mix Design of ConcreteDocumento8 pagineNandpur Mairi Road M-15 Mix Design of ConcreteAnkush PatialNessuna valutazione finora

- KSR Job Mix DBM II - pdf-1Documento6 pagineKSR Job Mix DBM II - pdf-1Ankur BarsainyaNessuna valutazione finora

- SD 221Documento2 pagineSD 221peter njugunaNessuna valutazione finora

- Mix Design Bosowa PDFDocumento11 pagineMix Design Bosowa PDFEriPrawitoNessuna valutazione finora

- Concrete Moisture Correction SheetDocumento7 pagineConcrete Moisture Correction SheetAmit MaityNessuna valutazione finora

- Value Part-4 Elongation Part-1 Absorption Part-3 Aggregate Part-1 LL, Pl&Pi 5 OMC lS2720Part8Documento2 pagineValue Part-4 Elongation Part-1 Absorption Part-3 Aggregate Part-1 LL, Pl&Pi 5 OMC lS2720Part8vishal gupta0% (1)

- Sieve Analysis-03.11Documento2 pagineSieve Analysis-03.11ASHOKKUMARNessuna valutazione finora

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocumento5 pagineDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNessuna valutazione finora

- Thebault Dop01 Teboply Ext GBDocumento2 pagineThebault Dop01 Teboply Ext GBDumitrache IulianNessuna valutazione finora

- Laboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)Documento8 pagineLaboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)SubhadipNessuna valutazione finora

- Offshore Testing Services Lab ReportDocumento3 pagineOffshore Testing Services Lab ReportKandula RajuNessuna valutazione finora

- Central Materials Laboratory - Results Template-1Documento3 pagineCentral Materials Laboratory - Results Template-1Micheal KenethNessuna valutazione finora

- Mir 001Documento1 paginaMir 001MCCIN L&WNessuna valutazione finora

- Report on Concrete Mix DesignDocumento7 pagineReport on Concrete Mix DesignSnehashish BasuNessuna valutazione finora

- Ample Nformation Sample No: RL-01: Ement Ests EportDocumento3 pagineAmple Nformation Sample No: RL-01: Ement Ests EportweamNessuna valutazione finora

- GSB (SOURCE - BATHU UNA QUARRY) Grade - IIIDocumento27 pagineGSB (SOURCE - BATHU UNA QUARRY) Grade - IIIjitendra100% (1)

- Adobe Scan Oct 13, 2023Documento3 pagineAdobe Scan Oct 13, 2023Lokesh BadgujarNessuna valutazione finora

- Sieve Analysis Coarse - 30.06.18Documento2 pagineSieve Analysis Coarse - 30.06.18ASHOKKUMARNessuna valutazione finora

- BC Job MixDocumento3 pagineBC Job MixSOIGNE ENGINEERING CONSULTANTSNessuna valutazione finora

- Eutectic Canada Inc. Product Certification for 13496-5K AlloyDocumento1 paginaEutectic Canada Inc. Product Certification for 13496-5K AlloyJulio CarbonettiNessuna valutazione finora

- Draft Letter Regarding Source Approval For Bituminous Mecadam grade-II With BPCL - VG - 30 BitumenDocumento3 pagineDraft Letter Regarding Source Approval For Bituminous Mecadam grade-II With BPCL - VG - 30 BitumenAmol Jadhav100% (1)

- CONSTRUCTION OF PATENGA CONTAINER TERMINAL (PCT) SIEVE ANALYSISDocumento4 pagineCONSTRUCTION OF PATENGA CONTAINER TERMINAL (PCT) SIEVE ANALYSISEngr.Estiaq AhmedNessuna valutazione finora

- MO & MO Aggregates With BlendingDocumento8 pagineMO & MO Aggregates With BlendingAbu FalasiNessuna valutazione finora

- 00207050Documento6 pagine00207050Maruda8382Nessuna valutazione finora

- Sieve AnalysisDocumento1 paginaSieve AnalysisNational Survey OrganisationNessuna valutazione finora

- 3-Microtome Calibration CartificateDocumento1 pagina3-Microtome Calibration Cartificatemba213Nessuna valutazione finora

- Ultratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Documento24 pagineUltratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Mamata BhangaleNessuna valutazione finora

- 3285-SNS M-25 M-30 InterimDocumento9 pagine3285-SNS M-25 M-30 InterimErHarshGandhiNessuna valutazione finora

- Mir 001Documento1 paginaMir 001MCCIN L&WNessuna valutazione finora

- DLC Design Mix Stipulation1Documento8 pagineDLC Design Mix Stipulation1abhishek negiNessuna valutazione finora

- Rehabilitation and Up-gradation of Repalle to Eeppurpalem Section NH-214ADocumento1 paginaRehabilitation and Up-gradation of Repalle to Eeppurpalem Section NH-214ABscpl Repalle to EeppurpalemNessuna valutazione finora

- Test Report of BricksDocumento1 paginaTest Report of BricksKumar Abhishek67% (3)

- VaibhavDocumento23 pagineVaibhavnajuka ghodvindeNessuna valutazione finora

- Himachal Pradesh Road Project BidsDocumento202 pagineHimachal Pradesh Road Project BidsAnkush PatialNessuna valutazione finora

- Item Rate Boq: Validate Print HelpDocumento34 pagineItem Rate Boq: Validate Print HelpAnkush PatialNessuna valutazione finora

- Item Rate Boq: Validate Print HelpDocumento22 pagineItem Rate Boq: Validate Print HelpAnkush PatialNessuna valutazione finora

- No 3Documento3 pagineNo 3Ankush PatialNessuna valutazione finora

- Project Life Cycle (PLC)Documento15 pagineProject Life Cycle (PLC)Ankush PatialNessuna valutazione finora

- Cantilever Retaining Walls ModelDocumento1 paginaCantilever Retaining Walls ModelAnkush PatialNessuna valutazione finora

- 125 Useful English PhrasesDocumento11 pagine125 Useful English PhrasesMohan PereraNessuna valutazione finora

- The Project in The Organizational StructureDocumento35 pagineThe Project in The Organizational StructureAnkush PatialNessuna valutazione finora

- Cantilever Retaining Walls ModelDocumento1 paginaCantilever Retaining Walls ModelAnkush PatialNessuna valutazione finora

- Project Management Framework: Key Concepts & Best PracticesDocumento19 pagineProject Management Framework: Key Concepts & Best PracticesAnkush Patial100% (1)

- 125 Useful English PhrasesDocumento11 pagine125 Useful English PhrasesMohan PereraNessuna valutazione finora

- National Highways Authority of India Request For ProposalDocumento5 pagineNational Highways Authority of India Request For ProposalAnkush PatialNessuna valutazione finora

- Dhussara Flour Mill Design Elements - 5 PDFDocumento3 pagineDhussara Flour Mill Design Elements - 5 PDFAnkush PatialNessuna valutazione finora

- Lect. 11 - Job SatisfactionDocumento11 pagineLect. 11 - Job SatisfactionAnkush PatialNessuna valutazione finora

- 125 Useful English PhrasesDocumento11 pagine125 Useful English PhrasesMohan PereraNessuna valutazione finora

- Indian StandardDocumento20 pagineIndian Standardamoudi101100% (1)

- Corrected Kathiarito Katour Kalan NabardDocumento92 pagineCorrected Kathiarito Katour Kalan NabardAnkush PatialNessuna valutazione finora

- Topics Covered in This Lesson7Documento5 pagineTopics Covered in This Lesson7Ankush PatialNessuna valutazione finora

- Dhussara Flour Mill Design Elements - 6 PDFDocumento16 pagineDhussara Flour Mill Design Elements - 6 PDFAnkush PatialNessuna valutazione finora

- Dhussara Flour Mill Design Elements - 4 PDFDocumento4 pagineDhussara Flour Mill Design Elements - 4 PDFAnkush PatialNessuna valutazione finora

- IS 875 1987 Part-3 PDFDocumento63 pagineIS 875 1987 Part-3 PDFPrabesh Kc100% (2)

- Indian Standard875Documento10 pagineIndian Standard875Mohammad Tawfiq WaraNessuna valutazione finora

- 300 Basic English SentencesDocumento19 pagine300 Basic English SentencesFaizullahMagsi100% (1)

- Introduction to Modifying Commands and Object Snaps in AutoCADDocumento5 pagineIntroduction to Modifying Commands and Object Snaps in AutoCADAnkush PatialNessuna valutazione finora

- Opics Covered in This Lesson 6Documento3 pagineOpics Covered in This Lesson 6Ankush PatialNessuna valutazione finora

- Adding Text, Dimensions and LayersDocumento7 pagineAdding Text, Dimensions and LayersAnkush PatialNessuna valutazione finora

- Is: 875 (Part 2)Documento20 pagineIs: 875 (Part 2)amoudi101100% (7)

- Tutorial-Valuation of Bond and SharesDocumento1 paginaTutorial-Valuation of Bond and SharesAnkush PatialNessuna valutazione finora

- IS-875-Part1 - Dead Loads For DesignDocumento39 pagineIS-875-Part1 - Dead Loads For Designlokesh2325100% (7)

- Pressure Regulators (DRV Valve) Suitable ForDocumento4 paginePressure Regulators (DRV Valve) Suitable ForNOUREDDINE BERCHAOUANessuna valutazione finora

- Husky Air Assignment 5 and 6Documento15 pagineHusky Air Assignment 5 and 6varunkalra6Nessuna valutazione finora

- Linthwaite: Conservatio N AreaDocumento26 pagineLinthwaite: Conservatio N Areabill baileyNessuna valutazione finora

- SLTRT Service Level Testing Reporting ToolDocumento110 pagineSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- Android Tutorial - Broadcast ReceiversDocumento15 pagineAndroid Tutorial - Broadcast ReceiversTrieu Ngo HuyNessuna valutazione finora

- A Practical Introductory Guide On Using Satellite Technology For CommunicationsDocumento15 pagineA Practical Introductory Guide On Using Satellite Technology For CommunicationsJohan PrinslooNessuna valutazione finora

- PRJCTDocumento10 paginePRJCTrpkn541Nessuna valutazione finora

- Electrical Measurements and InstrumentationDocumento17 pagineElectrical Measurements and InstrumentationRinita Datta100% (1)

- E380b PDFDocumento12 pagineE380b PDFanaNessuna valutazione finora

- CPU Vs vCPUDocumento14 pagineCPU Vs vCPUainseanNessuna valutazione finora

- Float Trap PennantDocumento2 pagineFloat Trap PennantJinalkumarNessuna valutazione finora

- Oral and Practical Tests: MechanicDocumento19 pagineOral and Practical Tests: MechanicHugo AlmeidaNessuna valutazione finora

- Pure Chem p2 - 26pgDocumento26 paginePure Chem p2 - 26pgJhomer CrespoNessuna valutazione finora

- Nitobond EP 0608Documento2 pagineNitobond EP 0608James PittsNessuna valutazione finora

- Multi-disciplinary profile of IS/IT outsourcing researchDocumento47 pagineMulti-disciplinary profile of IS/IT outsourcing researchIsabel MirandaNessuna valutazione finora

- ESD 18-91-067 - Instruction Manual and Parts List - Ed. 305Documento208 pagineESD 18-91-067 - Instruction Manual and Parts List - Ed. 305Centrifugal SeparatorNessuna valutazione finora

- Supplier Deviation Request FormDocumento2 pagineSupplier Deviation Request Formjainik shahNessuna valutazione finora

- MET312 Non Destructive Testing SyllabusDocumento8 pagineMET312 Non Destructive Testing SyllabusHARI KRISHNANNessuna valutazione finora

- Thermostats and Dial Thermometers PDFDocumento252 pagineThermostats and Dial Thermometers PDFAsep MustopaNessuna valutazione finora

- Especificaciones LuminariasDocumento3 pagineEspecificaciones LuminariasRoni DominguezNessuna valutazione finora

- P1125P1/P1250E1: Output RatingsDocumento6 pagineP1125P1/P1250E1: Output Ratingsmohsen_cumminsNessuna valutazione finora

- American English File Starter Ichecker - File 3Documento3 pagineAmerican English File Starter Ichecker - File 3Daniel AugustoNessuna valutazione finora

- Online Quiz System DocumentationDocumento92 pagineOnline Quiz System DocumentationSultan Aiman100% (1)

- Specification - EstimationDocumento4 pagineSpecification - EstimationVenkatesan VenkatNessuna valutazione finora

- Trade Skills Assessment GuideDocumento25 pagineTrade Skills Assessment GuideRandz Lampa0% (1)

- Us01cphy02 Unit 1 2014 THPDocumento18 pagineUs01cphy02 Unit 1 2014 THPapi-264723824Nessuna valutazione finora

- What Is A Gantt Chart - Gantt Chart Information, History and SoftwareDocumento3 pagineWhat Is A Gantt Chart - Gantt Chart Information, History and SoftwareShaikh Saeed AlamNessuna valutazione finora