Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Carboguard 890 PDS

Caricato da

Achraf BoudayaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Carboguard 890 PDS

Caricato da

Achraf BoudayaCopyright:

Formati disponibili

®

Carboguard 890

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generic Type Cycloaliphatic Amine Epoxy

Highly chemical resistant epoxy mastic coating with exceptionally versatile uses in all industrial

markets. Self-priming and suitable for application over most existing coatings, and tightly adherent

rust. Serves as stand-alone system for a variety of chemical environments and is also designed

Description for various immersion conditions. An optional micaceous iron oxide additive (MIO Filler) can

be purchased separately and may be used per the Product Data Sheet to enhance corrosion

protection and film strength for more aggressive service such as severe marine or heavy industrial

uses.

• Excellent chemical resistance

• Surface tolerant characteristics

• Conventional and low-temperature versions

Features • Self-priming and primer/finish capabilities

• Very good abrasion resistance

• VOC compliant to current AIM regulations

• Suitable for use in USDA inspected facilities

Refer to Carboline Color Guide. Certain colors may require multiple coats for hiding.

Color

Note: The low temperature formulation will cause most colors to yellow or discolor more than

normal in a short period of time.

Finish Gloss

Primer Self-priming.

4 - 6 mils (102 - 152 microns) per coat

Dry Film Thickness 6.0-8.0 mils (150-200 microns) over light rust and for uniform gloss over inorganic zincs. Don't

exceed 10 mils (250 microns) in a single coat. Excessive film thickness over inorganic zincs may

increase damage during shipping or erection.

Solids Content By Volume 75% +/- 2%

1203 ft²/gal at 1.0 mils (29.5 m²/l at 25 microns)

Theoretical Coverage 301 ft²/gal at 4.0 mils (7.4 m²/l at 100 microns)

Rate 200 ft²/gal at 6.0 mils (4.9 m²/l at 150 microns)

Allow for loss in mixing and application.

As Supplied : 1.81 lbs/gal (217 g/l)

Thinner 2 : 13 oz/gal (106.8 mg/ml) = 2.30 lbs/gal (276 g/l)

Thinner 2 : 7 oz/gal (57.5 mg/ml) = 2.08 lbs/gal (250 g/l)

Thinner 33 : 16 oz/gal (131.5 mg/ml) = 2.43 lbs/gal (291 g/l)

VOC Values Thinner 33 : 7 oz/gal (57.5 mg/ml) = 2.08 lbs/gal (250 g/l)

Use Thinner 76 up to 8 oz/gal for 890 and 16 oz/gal for 890 LT where non-photochemically reactive

solvents are required.

These are nominal values and may vary with color.

Continuous: 300°F (149°C)

Non-Continuous: 350°F (177°C)

Dry Temp. Resistance

Discoloration and loss of gloss occurs above 200°F (93°C) but does not affect performance.

March 2019 0986 Page 1 of 5

®

Carboguard 890

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Continuous: 300°F (149°C)

Under Insulation

Resistance

Discoloration and loss of gloss occurs above 200 F (93 °C) but does not affect performance.

Do not apply over latex coatings. For immersion projects use only factory made material in special

Limitations

colors. Consult Technical Service for specifics.

• Acrylics

Topcoats • Epoxies

• Polyurethanes

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

General Surfaces must be clean and dry. Remove all dirt, dust, oil and all other contaminant.

Immersion: SSPC-SP10

Non-immersion: SSPC-SP6

Steel

1.5-3.0 mils (38-75 microns) SSPC-SP2 or SP3 are suitable cleaning methods for mild

environments.

Galvanized Steel SSPC-SP 16: for immersion service create 1.5 to 3 mils, (37.5-75 microns), anchor profile.

Concrete shall be designed, placed, cured, and prepared per NACE No. 6/SSPC-SP 13, latest

edition. This includes abrading to remove all laitance, loose concrete, etc. and to create the

Concrete or CMU

surface profile required for the coating system to be used. The concrete shall be considered cured

sufficiently for coating when it passes the moisture tests.

Drywall & Plaster Joint compound and plaster should be fully cured prior to coating application.

Previously Painted Lightly sand or abrade to roughen surface and degloss the surface. Existing paint must attain a

Surfaces minimum 3A rating in accordance with ASTM D3359 “X-Cut” adhesion test.

Stainless Steel SSPC-SP 16: for immersion service create 1.5 to 3 mils, (37.5 to 75) microns, anchor profile.

P E R F O R M A N C E D ATA

Test Method System Results

No effect on plane, rust in scribe.

ASTM B 117 Salt Fog Blasted Steel 2 cts. 890 1/16" (0.16 cm) undercutting

at scribe after 2000 hours

No effect on plane, no rust in scribe

ASTM B117 Salt Fog Blasted Steel 1 ct. IOZ 1 ct 890

and no undercutting after 4000 hours

85 mg. loss after 1000 cycles,

ASTM D 4060 Abrasion Blasted Steel 1 ct Epoxy Pr. 1 ct 890

CS17 wheel 1000 gm. load

No blistering, rusting or

ASTM D1735 Water Fog Blasted Steel 1 ct. Epoxy Pr. 1 ct. 890

delamination after 2800 hours

93% gloss retained after 10,000

ASTM D2486 Scrub Resistance Blasted Steel 1 ct. 890

cycles w/liquid scrub medium

ASTM D3359 Adhesion Blasted Steel 1 ct 890 5A

ASTM D3363 Pencil Hardness Blasted Steel 2 cts 890 Greater than 8H

ASTM E84 Flame and Smoke 2 ct 890 5 Flame 5 Smoke Class A

Test reports and additional data available upon written request.

March 2019 0986 Page 2 of 5

®

Carboguard 890

PRODUCT DATA SHEET

MIXING & THINNING

Mixing Power mix separately, then combine and power mix. DO NOT MIX PARTIAL KITS.

Spray: Up to 13 oz/gal (10%) w/ #2

Brush: Up to 16 oz/gal (12%) w/ #33

Roller: Up to 16 oz/gal (12%) w/ #33

Thinning Thinner #33 can be used for spray in hot/windy conditions. Use of thinners other than those

supplied or recommended by Carboline may adversely affect product performance and void product

warranty, whether expressed or implied.

*See VOC values for thinning limits.

Ratio 1:1 Ratio (A to B)

3 Hours at 75°F (24°C)

Pot Life

Pot life ends when coating loses body and begins to sag. Pot life times will be less at higher

temperatures.

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

This is a high solids coating and may require adjustments in spray techniques. Wet film thickness

Spray Application

is easily and quickly achieved. The following spray equipment has been found suitable and is

(General)

available from manufacturers such as Binks, DeVilbiss and Graco.

Pressure pot equipped with dual regulators, 3/8” (0.95 cm) I.D. minimum material hose,

Conventional Spray

0.070” (0.18 cm) I.D. fluid tip and appropriate air cap.

Pump Ratio: 30:1 (min.)*

GPM Output: 3.0 (min.)

Material Hose: 3/8” I.D. (0.95 cm)(min.)

Airless Spray

Tip Size: 0.017-0.021” (0.04-0.05 cm)

Output PSI: 2100-2300 Filter Size: 60 mesh

*PTFE packings are recommended and available from the pump manufacturer.

Multiple coats may be required to obtain desired appearance, recommended dry film thickness and

Brush & Roller

adequate hiding. Avoid excessive re-brushing or rerolling. For best results, tie-in within 10 minutes

(General)

at 75°F (24°C).

Brush Use a medium bristle brush.

Roller Use a short-nap solvent resistant roller cover.

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 50°F (10°C) 50°F (10°C) 50°F (10°C) 0%

Maximum 90°F (32°C) 125°F (52°C) 110°F (43°C) 90%

This product simply requires the substrate temperature to be above the dew point. Condensation due to substrate temperatures

below the dew point can cause flash rusting on prepared steel and interfere with proper adhesion to the substrate. Special

application techniques may be required above or below normal application conditions.

March 2019 0986 Page 3 of 5

®

Carboguard 890

PRODUCT DATA SHEET

CURING SCHEDULE

Dry to Topcoat w/

Surface Temp. Dry to Recoat Final Cure General Final Cure Immersion

Other Finishes

50°F (10°C) 12 Hours 24 Hours 3 Days NR

60°F (16°C) 8 Hours 16 Hours 2 Days 10 Days

75°F (24°C) 4 Hours 8 Hours 1 Day 5 Days

90°F (32°C) 2 Hours 4 Hours 16 Hours 3 Days

Higher film thickness, insufficient ventilation or cooler temperatures will require longer cure times and could result in solvent

entrapment and premature failure. Excessive humidity or condensation on the surface during curing can interfere with the cure,

can cause discoloration and may result in a surface haze. Any haze or blush must be removed by water washing before recoating.

During high humidity conditions, it is recommended that the application be done while temperatures are increasing. Maximum

recoat/topcoat times are 30 days for epoxies and 90 days for polyurethanes at 75°F (24°C). If the maximum recoat times

have been exceeded, the surface must be abraded by sweep blasting or sanding prior to the application of additional coats.

CLEANUP & SAFETY

Use Thinner 2 or Acetone. In case of spillage, absorb and dispose of in accordance with local

Cleanup

applicable regulations.

Read and follow all caution statements on this product data sheet and on the SDS. Employ normal

Safety

workmanlike safety precautions. Keep container closed when not in use.

When used as a tank lining or in enclosed areas, thorough air circulation must be used during and

Ventilation after application until the coating is cured. User should test and monitor exposure levels to insure all

personnel are below guidelines.

PA C K A G I N G , H A N D L I N G & S T O R A G E

Part A: 36 months at 75°F (24°C)

Part B: 15 months at 75°F (24°C)

Shelf Life

*When kept at recommended storage conditions and in original unopened containers.

40-120 °F (4-49 °C) Store indoors

Storage Temperature &

Can be stored down to 20 °F (-7 °C) for no longer than 30 days

Humidity

0-100% Relative Humidity

Storage Store Indoors

Shipping Weight 2 Gallon Kit - 29 lbs (13 kg)

(Approximate) 10 Gallon Kit - 145 lbs (66 kg)

89 °F (32 °C) for Part A

Flash Point (Setaflash)

73 °F (23 °C) for Part B

March 2019 0986 Page 4 of 5

®

Carboguard 890

PRODUCT DATA SHEET

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject

to change without prior notice. User must contact Carboline Company to verify correctness before specifying or ordering. No

guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no

responsibility for coverage, performance, injuries or damages resulting from use. Carbolines sole obligation, if any, is to replace

or refund the purchase price of the Carboline product(s) proven to be defective, at Carbolines option. Carboline shall not be liable

for any loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

March 2019 0986 Page 5 of 5

Potrebbero piacerti anche

- Carboguard 890 PDSDocumento5 pagineCarboguard 890 PDScrisNessuna valutazione finora

- Carboguard 890: Selection & Specification DataDocumento5 pagineCarboguard 890: Selection & Specification DataMuthazhagan SaravananNessuna valutazione finora

- Carboguard 893: Selection & Specification DataDocumento5 pagineCarboguard 893: Selection & Specification DataQuy RomNessuna valutazione finora

- Carboguard 893 PDSDocumento5 pagineCarboguard 893 PDSUtomoNessuna valutazione finora

- Carboguard 893 PDSDocumento5 pagineCarboguard 893 PDSTrịnh Minh KhoaNessuna valutazione finora

- Carbomastic 15 PDSDocumento4 pagineCarbomastic 15 PDSRiyaz Basheer100% (1)

- Carbothane 133 HB PDS PDFDocumento5 pagineCarbothane 133 HB PDS PDFskNessuna valutazione finora

- Carboguard 893 SG MIO PDSDocumento4 pagineCarboguard 893 SG MIO PDSMuthuKumarNessuna valutazione finora

- Carboline Carbothane 133 HBDocumento5 pagineCarboline Carbothane 133 HBArturo SalinasNessuna valutazione finora

- Carboguard 893 SG PDSDocumento4 pagineCarboguard 893 SG PDSTrịnh Minh KhoaNessuna valutazione finora

- Carbothane 133 HB: Selection & Specification DataDocumento5 pagineCarbothane 133 HB: Selection & Specification DatalavekushNessuna valutazione finora

- Carboguard 1209: Selection & Specification DataDocumento4 pagineCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Carboguard 890 GFDocumento4 pagineCarboguard 890 GFDuongthithuydungNessuna valutazione finora

- Carboguard 893 SG: Selection & Specification DataDocumento5 pagineCarboguard 893 SG: Selection & Specification DataPraveen Sreekumaran NairNessuna valutazione finora

- Sanitile 120 PDSDocumento4 pagineSanitile 120 PDSDuongthithuydungNessuna valutazione finora

- Phenoline 187 Finish PDSDocumento5 paginePhenoline 187 Finish PDSQuy RomNessuna valutazione finora

- Carbozinc 11 PDSDocumento5 pagineCarbozinc 11 PDSSUBODHNessuna valutazione finora

- Carbozinc 11: Selection & Specification DataDocumento5 pagineCarbozinc 11: Selection & Specification DataQuy RomNessuna valutazione finora

- Carboguard 890N PDSDocumento5 pagineCarboguard 890N PDScorey jacobsNessuna valutazione finora

- Protective & Marine Coatings: Polysiloxane 1KDocumento4 pagineProtective & Marine Coatings: Polysiloxane 1KAna CabreraNessuna valutazione finora

- Carbozinc 11: Selection & Specification DataDocumento5 pagineCarbozinc 11: Selection & Specification DatajoehodohNessuna valutazione finora

- Carboguard 60: Selection & Specification DataDocumento5 pagineCarboguard 60: Selection & Specification DataDuongthithuydungNessuna valutazione finora

- Carboguard 893 PDSDocumento2 pagineCarboguard 893 PDSNguyễn Thị Châu TâyNessuna valutazione finora

- Bitumastic 300M: Selection & Specification DataDocumento4 pagineBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNessuna valutazione finora

- Acrolon 218 FTDocumento4 pagineAcrolon 218 FTEdwin VSNessuna valutazione finora

- DTM Acrylic Coating: Protective & Marine CoatingsDocumento4 pagineDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNessuna valutazione finora

- Carbozinc 11 HS PDSDocumento5 pagineCarbozinc 11 HS PDSEsakki muthuNessuna valutazione finora

- Carbozinc 11Documento4 pagineCarbozinc 11DuongthithuydungNessuna valutazione finora

- Carboguard 635: Selection & Specification DataDocumento5 pagineCarboguard 635: Selection & Specification DataPrakashNessuna valutazione finora

- Carboguard 880 MIO PDSDocumento4 pagineCarboguard 880 MIO PDSHerman EngelbrechtNessuna valutazione finora

- Acrolon 218 HS Acrylic PolyurethaneDocumento4 pagineAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNessuna valutazione finora

- Carbozinc 859: Selection & Specification DataDocumento5 pagineCarbozinc 859: Selection & Specification DataFrancis BautistaNessuna valutazione finora

- Acrolon 218 HsDocumento4 pagineAcrolon 218 HsKARENNessuna valutazione finora

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Documento4 pagineCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2Nessuna valutazione finora

- Carboxane 2000 PDSDocumento4 pagineCarboxane 2000 PDSBERSE MAJU INDONESIANessuna valutazione finora

- Carbozinc - 859 - PDS JapanDocumento4 pagineCarbozinc - 859 - PDS JapanFreddyNessuna valutazione finora

- Carbothane 134 HG PDSDocumento5 pagineCarbothane 134 HG PDSsanthoshkumarplNessuna valutazione finora

- Protective & Marine Coatings: Acrolon™ 218 HsDocumento4 pagineProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNessuna valutazione finora

- Fast Clad HB Acrylic: Protective & Marine CoatingsDocumento4 pagineFast Clad HB Acrylic: Protective & Marine CoatingsAna CabreraNessuna valutazione finora

- Phenoline 187 FinishDocumento5 paginePhenoline 187 FinishDuongthithuydungNessuna valutazione finora

- Carbozinc Data SheetDocumento2 pagineCarbozinc Data SheetIra Purnama SariNessuna valutazione finora

- Corothane® I Galvapac 1K Zinc Primer PDFDocumento4 pagineCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Phenoline 187 Chemical Resistant Tank LiningDocumento5 paginePhenoline 187 Chemical Resistant Tank LiningQuy RomNessuna valutazione finora

- Carboline Carboguard 890 PDSDocumento2 pagineCarboline Carboguard 890 PDSSamNessuna valutazione finora

- Carboguard 635 Thinned 50% - Sealer PDSDocumento5 pagineCarboguard 635 Thinned 50% - Sealer PDSjakeNessuna valutazione finora

- Hoja Tecnica Amerlock 400 PDFDocumento3 pagineHoja Tecnica Amerlock 400 PDFJesy M. Maldonado SalinasNessuna valutazione finora

- TDS - Masterseal SP 120 PFDocumento3 pagineTDS - Masterseal SP 120 PFAlexi ALfred H. TagoNessuna valutazione finora

- Carboguard 891 Product Data SheetDocumento4 pagineCarboguard 891 Product Data SheetPrakashNessuna valutazione finora

- Envirolastic 980 PADocumento4 pagineEnvirolastic 980 PAdneradNessuna valutazione finora

- Carboguard 636 XT PDSDocumento4 pagineCarboguard 636 XT PDSCarlos Rojas HandalNessuna valutazione finora

- Protective & Marine Coatings: Acrolon™ 218 HsDocumento4 pagineProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNessuna valutazione finora

- Carbotherm 3300 PDSDocumento4 pagineCarbotherm 3300 PDS이선엽Nessuna valutazione finora

- Carboguard 890 GF PDSDocumento2 pagineCarboguard 890 GF PDSfazeel mohammedNessuna valutazione finora

- Carbozinc 859Documento2 pagineCarbozinc 859Khemaraj PathNessuna valutazione finora

- Carboguard 60 LH PDSDocumento4 pagineCarboguard 60 LH PDSRicardo SantosNessuna valutazione finora

- Phenoline 187 Primer and FinishDocumento2 paginePhenoline 187 Primer and Finish이선엽Nessuna valutazione finora

- Interpon D1036 LSA Cool CoatingsDocumento3 pagineInterpon D1036 LSA Cool Coatings120120120120Nessuna valutazione finora

- 3M Scotchkote Epoxy Primer GP220 - Rev2Documento2 pagine3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanNessuna valutazione finora

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- Series LFII Residential Flush Pendent Sprinklers 4.2 K-FactorDocumento8 pagineSeries LFII Residential Flush Pendent Sprinklers 4.2 K-FactorAchraf BoudayaNessuna valutazione finora

- Series LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorDocumento4 pagineSeries LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorAchraf BoudayaNessuna valutazione finora

- Series LFII Residential SprinklersDocumento6 pagineSeries LFII Residential SprinklersAchraf BoudayaNessuna valutazione finora

- Installer Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersDocumento4 pagineInstaller Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersAchraf BoudayaNessuna valutazione finora

- Majestic Optima: Technical Data SheetDocumento3 pagineMajestic Optima: Technical Data Sheetaditarian .pNessuna valutazione finora

- Series LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorDocumento8 pagineSeries LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorAchraf BoudayaNessuna valutazione finora

- Series LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Documento8 pagineSeries LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Achraf BoudayaNessuna valutazione finora

- Protect Sprinklers from DamageDocumento4 pagineProtect Sprinklers from DamageAchraf BoudayaNessuna valutazione finora

- Sprinkler Spray PatternsDocumento38 pagineSprinkler Spray PatternsAchraf BoudayaNessuna valutazione finora

- Model G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersDocumento4 pagineModel G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersAchraf BoudayaNessuna valutazione finora

- Recessed Escutcheon Installation GuideDocumento4 pagineRecessed Escutcheon Installation GuideAchraf BoudayaNessuna valutazione finora

- Rociador Ty LDocumento8 pagineRociador Ty LOscar Fernandez SanchezNessuna valutazione finora

- Esab Pipeweld 6010R: Classifications: ApprovalsDocumento1 paginaEsab Pipeweld 6010R: Classifications: ApprovalsAchraf BoudayaNessuna valutazione finora

- Jotaplast (ID) : Technical Data SheetDocumento3 pagineJotaplast (ID) : Technical Data SheetBilher SihombingNessuna valutazione finora

- Flyer TycoDocumento8 pagineFlyer TycoAchraf BoudayaNessuna valutazione finora

- Energy Absorber Type 32Documento1 paginaEnergy Absorber Type 32Achraf BoudayaNessuna valutazione finora

- Jotashield Flex: Technical Data SheetDocumento3 pagineJotashield Flex: Technical Data SheetAchraf BoudayaNessuna valutazione finora

- Jotashield Extreme: Technical Data SheetDocumento3 pagineJotashield Extreme: Technical Data SheetAchraf BoudayaNessuna valutazione finora

- Weld-On Brackets Type 35Documento1 paginaWeld-On Brackets Type 35Achraf BoudayaNessuna valutazione finora

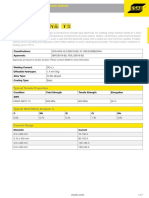

- Classifications: Approvals:: Typical Tensile PropertiesDocumento1 paginaClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNessuna valutazione finora

- Classifications: Approvals:: Typical Tensile PropertiesDocumento1 paginaClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNessuna valutazione finora

- Jotun Essence Easy Clean Matt: Technical Data SheetDocumento3 pagineJotun Essence Easy Clean Matt: Technical Data SheetAchraf BoudayaNessuna valutazione finora

- Classifications: Approvals:: Typical Tensile PropertiesDocumento1 paginaClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNessuna valutazione finora

- Snubbers Type 30Documento1 paginaSnubbers Type 30Achraf BoudayaNessuna valutazione finora

- Typical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeDocumento1 paginaTypical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeAchraf BoudayaNessuna valutazione finora

- Rigid Struts Type 39Documento1 paginaRigid Struts Type 39Achraf BoudayaNessuna valutazione finora

- Snubbers type 31 absorb heavy loads in nuclear installationsDocumento1 paginaSnubbers type 31 absorb heavy loads in nuclear installationsAchraf BoudayaNessuna valutazione finora

- Telescopic Spring Supports Type 29Documento1 paginaTelescopic Spring Supports Type 29Achraf BoudayaNessuna valutazione finora

- Installation Extensions Type 33Documento1 paginaInstallation Extensions Type 33Achraf BoudayaNessuna valutazione finora

- Sway Braces Type 27Documento1 paginaSway Braces Type 27Achraf BoudayaNessuna valutazione finora

- Consumables Accessories DMA 80 PDFDocumento4 pagineConsumables Accessories DMA 80 PDFwillwNessuna valutazione finora

- Air Carbon Arc GougingDocumento3 pagineAir Carbon Arc GougingMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Bio Energiser Hair Boost Caffeine Power Tonic MSDS October 2016Documento3 pagineBio Energiser Hair Boost Caffeine Power Tonic MSDS October 2016Alexander JefferyNessuna valutazione finora

- Jacketed Weld Strength CheckDocumento10 pagineJacketed Weld Strength CheckKshitiz SikkaNessuna valutazione finora

- 13 Chapter 2Documento36 pagine13 Chapter 2Ibtisam SaidNessuna valutazione finora

- DurstDocumento7 pagineDurstRahul KatreNessuna valutazione finora

- Transom cw03Documento2 pagineTransom cw03Pamps MangampoNessuna valutazione finora

- A Project of Mechanics of MaterialsDocumento13 pagineA Project of Mechanics of MaterialsShahZaib AnwarNessuna valutazione finora

- Lecture 10: Nucleic Acids (DNA & RNA)Documento13 pagineLecture 10: Nucleic Acids (DNA & RNA)Binoni Laja EndongNessuna valutazione finora

- Rishab IntroDocumento4 pagineRishab IntroDeborsha DekaNessuna valutazione finora

- 管径计算表Documento11 pagine管径计算表Ascend032Nessuna valutazione finora

- Dielectric Constants Chart: How To Use This GuideDocumento10 pagineDielectric Constants Chart: How To Use This GuideDewet VirmondNessuna valutazione finora

- How Cells Release Stored EnergyDocumento57 pagineHow Cells Release Stored EnergykylevNessuna valutazione finora

- Schaeffler and Delong DiagramsDocumento2 pagineSchaeffler and Delong DiagramsKarna2504100% (1)

- Thermodynamics - Theory T-V Diagram: Phase Change Process Under Constant Pressure (112 KB)Documento3 pagineThermodynamics - Theory T-V Diagram: Phase Change Process Under Constant Pressure (112 KB)rajaraghuramvarmaNessuna valutazione finora

- Beza Air Mineral RO & Alkali Coway Coway OfficialDocumento1 paginaBeza Air Mineral RO & Alkali Coway Coway OfficialNurhajarah KhamisahNessuna valutazione finora

- Pyrocrete 241Documento2 paginePyrocrete 241Carboline2013Nessuna valutazione finora

- EcoFlame B-971 MSDSDocumento8 pagineEcoFlame B-971 MSDSZirve PolimerNessuna valutazione finora

- N ch3 07Documento2 pagineN ch3 07yashNessuna valutazione finora

- Ewald Summation Method for Calculating Ionic Crystal Configuration EnergiesDocumento19 pagineEwald Summation Method for Calculating Ionic Crystal Configuration Energieservina dwiNessuna valutazione finora

- Marine Science Semester 1 ReviewDocumento18 pagineMarine Science Semester 1 ReviewJoe Xavier ReidyNessuna valutazione finora

- Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionDocumento11 pagineHydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionSebastian Chaverra100% (1)

- CH 7 ObjDocumento4 pagineCH 7 ObjchongpeisiNessuna valutazione finora

- Book of AbstractsDocumento56 pagineBook of AbstractsCojocaru Bogdan EugenNessuna valutazione finora

- Science Class 9 Notes SoundDocumento1 paginaScience Class 9 Notes SoundPriyaprasad PandaNessuna valutazione finora

- Fluid Mechanics Tutorial on Fluid Properties and CalculationsDocumento2 pagineFluid Mechanics Tutorial on Fluid Properties and CalculationsGabrielNessuna valutazione finora

- Board Exam Review - Set 3ADocumento4 pagineBoard Exam Review - Set 3AJey-r VenturaNessuna valutazione finora

- Water Quality Index Test ResultsDocumento11 pagineWater Quality Index Test ResultsSunil BhavsarNessuna valutazione finora

- Redox ExerciseDocumento4 pagineRedox ExerciseHau Hei, Matthew LinNessuna valutazione finora

- Essay 2Documento3 pagineEssay 2Norhaida NdNessuna valutazione finora