Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Financial Performance and Evaluation

Caricato da

Arjun sureshCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Financial Performance and Evaluation

Caricato da

Arjun sureshCopyright:

Formati disponibili

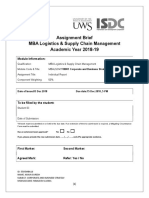

Assignment Brief

MBA Supply Chain Management & Logistics

Academic Year 2018-19

Module Information:

Qualification: MBA Supply Chain Management & Logistics

Module Code & Title: MBASCML 110007 Financial Performance Evaluation in SCML

Assignment Title: Individual Report

Component Weighting: 50%

Date of Issue: 27th June 2019 Due date: 6th July 2019, 5 PM

To be filled by the student:

Student ID: 5505MBA18

Date of Submission: 6th July 2019

*All work must be submitted on or before the due date. If an extension of time to submit work is required, a Mitigating Circumstance

Form must be submitted.

Has an extension been approved? Yes No

If yes, please provide the new submission date ….…/.…./……., and affix appropriate evidence.

First Marker: Second Marker:

Agreed Mark: Refer: Yes / No

5505MBA18 Financial Performance Evaluation in SCML

ARJUN SURESH [1] MBASCML 110007

Statement of Originality and Student Declaration

I hereby, declare that I know what plagiarism entails, namely to use another’s work and to present it as my

own without attributing the sources in the correct way. I further understand what it means to copy another’s

work.

1. I know that plagiarism is a punishable offence because it constitutes theft.

2. I understand the plagiarism and copying policy of the University of the West of Scotland.

3. I know what the consequences will be if I plagiaries or copy another’s work in any of the

assignments for this program.

4. I declare therefore that all work presented by me for every aspect of my program, will be my own,

and where I have made use of another’s work, I will attribute the source in the correct way.

5. I acknowledge that the attachment of this document signed or not, constitutes my agreement on it.

6. I understand that my assignment will not be considered as submitted if this document is not

attached to the attached.

Student’s Signature: Date: 6th July 2019

5505MBA18 Financial Performance Evaluation in SCML

ARJUN SURESH [2] MBASCML 110007

TASK

You are requested to prepare an assignment on “Select a company of your choice with global

operations using various sources (Newspaper, Magazines and Internet).Find out the location

of supply sources, the manufacturing facilities and the market where it sells the products.

Evaluate whether there is any need for the company to change its logistic network in the

future, considering the change in the supply and market environment”

5505MBA18 Financial Performance Evaluation in SCML

ARJUN SURESH [3] MBASCML 110007

INTRODUCTION

The logistics network design is one of the most comprehensive strategic decision problems that

need to be optimized for long-term efficient operation of whole supply chain. It determines the

number, location, capacity and type of plants, warehouses and distribution centers (DCs) to be

used. It also establishes distribution channels, and the amount of materials and items to consume,

produce and ship from suppliers to customers. An important component in logistics network

design and analysis is the establishment of appropriate performance measures. A performance

measure, or a set of performance measures, is used to determine efficiency and or effectiveness

of an existing system, to compare alternative systems, and to design proposed systems.

LOGISTICS NETWORK

Network Design determines the physical configuration and infrastructure of the supply chain.

Key decisions are made on the number, locations, and size of manufacturing plants and

warehouses, the assignment of retail outlets to warehouses, etc. At this stage, major sourcing

decisions are also made. Long-term location, capacity, technology, and supplier selection

decisions have to be made under considerable uncertainty with respect to market development

and changing economic and legal conditions.

Network design is a strategic subject for businesses. It calls for in-depth study to orientate crucial

decisions such as:

•Siting, sizing the right number of factories, platforms and warehouses

•Defining the physical flows between the various links in the supply chain and distribution flows

specializing (or otherwise) factory production lines

•Stocking items in the right place for the best customer delivery terms

•Outsourcing certain activities such as distribution.

Developing a powerful logistics network is a competitive advantage in the current economic

context where competitive pressure is rife, the market volatile and globalized and raw materials

costs are rising. An optimized logistics network makes for lower costs, a grip on logistics flows

and providing excellent customers service.

5505MBA18 Financial Performance Evaluation in SCML

ARJUN SURESH [4] MBASCML 110007

TOYOTA

Introduction

Toyota Motor Corporation is a Japanese-owned company engaged in the manufacture and sale of

motor vehicle. It is a global company with numerous manufacturing plants located not only in its

home country but world-wide. It started operations in 1937 and as of March 2009, it employed

almost 321,000 women and men from around the world. It is a highly acclaimed company, with

excellent products manufactured and distributed globally. Its corporate headquarters is located in

Tokyo, Japan, with regional offices in North America, Europe, Latin America, Australia, and

Southeast Asia.

Global Strategy

Toyota is ranked among five best companies of automobile industry with total 500 companies.

Toyota has made success in global strategies. It has a clear agenda to distribute the channels,

production, marketing and supply chain aspects. Toyota’s best production system and continuous

improvements are the essential pieces of its global strategy. Concept of Kaizen (continuous

improvement) has empowered the company to think about the new strategies and methods no

matter in any area of the company. TPS (Toyota Production System) makes a link between the

global automaker to manage the supply chain system, inventory management, production

capabilities and planning methods. This TPS has empowered the Toyota to dominate the global

automobile industry. Actually the Toyota is based in Japan but it has established itself

throughout the world. No doubt the Toyota is most well known automobile brand of the world.

Toyota’s market is based upon the mission: Stable long-term growth, while striving for harmony

with people, society and the environment” (Toyota Motor Corporation Home Page). Toyota is

providing thousands of jobs in America. Cultural, economic and social issues have allowed the

Toyota to move beyond the brand equity and shaped an international marketing place for Toyota

and achieved the success as a global corporation.

Relations with suppliers

Toyota has established good relations with its suppliers to build a harmonious and mutual

society. As the business of Toyota has been expanded on a global scale the Toyota is stressing

more on close relationships to achieve the customer’s satisfaction. Toyota does respect of its

5505MBA18 Financial Performance Evaluation in SCML

ARJUN SURESH [5] MBASCML 110007

suppliers throughout the world to promote the development and mutual growth. Toyota believes

in CSR activities and issued a guideline for the suppliers in 2009. Toyota is focusing to make

joint manufacturing activities with suppliers to improve the working practices. To promote the

sale of cars in next five years on the basic principle of “Customer first, dealer second, third

manufacture” Toyota is acting on the policy to benefit their dealers. Toyota has more than 170

distributers and 8000 dealers located in overseas countries. In this way Toyota engages its

partners in many ways.

SUPPLIERS

Toyota organized its suppliers into functional tiers. The first tier suppliers worked together in a

product development team and the second tier suppliers made individual parts. The first tier

suppliers were highly co-operative. There is a high degree of co-operation and information

exchange between them. This greatly reduces the lead time in new product development as it

avoids “Re-inventing the wheel”. Toyota also believes in having an overall technological

development throughout their suppliers as well. It sends personnel to suppliers to compensate for

greater working load. Besides that it also transfers senior working managers for top positions at

their suppliers. This not only gives the suppliers greater insights to Toyotas management

practices but is also a move to make the suppliers master “Lean production practices” initiated

by Toyota.

Related to flexibility, the following can be said. Since Toyota strives for a long-term relationship

with its suppliers and also pursues a single-sourcing strategy for their strategic components, it

does leave the OEM vulnerable for disruptions. But, the single-sourcing strategy is also a means

to establish a long-term and flexible relationship with a supplier. Since each supplier shares its

destiny with other suppliers and Toyota, the level of collaboration horizontally and vertically is

higher. Therefore, a singly sourcing strategy itself is considered to be as hazardous, the

relationship itself is far more flexible then a more economic-oriented relationship between a

buyer-and-supplier.

The concept of minimal production cost is so well practice that the vendor pricing is also done

on “Market Price Minus” concept rather than “Supplier Cost Plus” This is basically a value

5505MBA18 Financial Performance Evaluation in SCML

ARJUN SURESH [6] MBASCML 110007

analysis to the end user. By this particular move they try to provide the necessary value to the

end product at minimal manufacturing cost. Besides that the “production smoothening” concept

enables the suppliers to maintain a constant business volumes. Overall the intention of the

company is to maintain long term relationships with co-operation and team work.

PROCUREMENT

Toyota does not partner with its suppliers just functionally but in operation terms as well.

Suppliers are integral elements of Toyota. They are geographically located within 56 miles

radius. A security of guaranteed order is given which enables them to produce the best quality

raw materials at cheapest cost achieving economies of scale. Toyota does not believe in choosing

supplier as a lowest bidder. But it believes in gradual mutual improvement. It believes in “vendor

creation and development”. As an initiative in this direction it trains its suppliers as per required.

Packaging is also given a great importance with respect to transportation efficiency. Packaging is

done in medium box size and small pallets. There is a dedicated transport service. Consistent

daily route and periodic route revision is provided so as to cater to even smaller requirements.

MANUFACTURING

Toyota believes in continuous development by adopting lean production process and is a

pioneered in TPS known as (Toyota Production System). The system is designed on “Pull

strategy” and customer is at the prime focus in the entire production facility. It implements lean

production facility which has features like Cellular layouts and could be set up in small time. It

has pull scheduling emphasizing decreased wastes. Loss aversion is one of the basic feature of

lean. Besides that Toyota also assures six sigma qualities. The overall result of this policy being

excellent quality at low costs combined with fast response abilities. Exhibit 3 shows some key

principles of Lean manufacturing by Toyota.

5505MBA18 Financial Performance Evaluation in SCML

ARJUN SURESH [7] MBASCML 110007

PESTEL ANALYSIS

Being one of the most used frameworks for environmental analysis of companies, PESTEL gives

an in-depth view of the most important factors, which can affect Toyota both externally and

internally, from the outside to the inside of the company.

Political: The supply chain is highly important for Toyota, because it has plants all over the

world, manufacturing and delivering globally. When having this pricing strategy (for example,

Toyota manufactures most of the cars in Japan because of the low costs involved), there are

political factors which must be taken into account. Political instabilities may affect the supply

process, especially the distribution. Also, political decisions such as increasing taxes, inflation,

regulations affect the company and its chain of distribution worldwide.

Economic: According to Hirotaka et. Al (2008), Toyota has an ‘unorthodox’ manufacturing

system. Namely, low cost production in Japanese plants enables the company to develop and

grow new technologies quickly.

Socio-cultural: This factor has a significant influence over the company and its marketing

strategy. Specifically, all Toyota’s marketing campaigns focus on the brand’s commitment to

quality and it uses soft selling in order to create a strong connection between the brand and the

audience watching the adverts.

Technological: Research and investment on innovation – as seen on their website (Toyota 2010),

they rely on the innovative aspect and use it for marketing purposes as well. Also, according to

Jim Lentz, president and chief operating officer of Toyota Motor Sales, U.S.A., the company’s

main headquarter is in Japan because it gives its researchers the chance to review all

technologies (Taylor 2010).

Environmental: According to Toyota,the company is an environmental leader and produces

innovative products, with low fuel consumption, which fulfil the current environmental trends.

An example of a product launched by the company that fulfils this fashion is the hybrid car

5505MBA18 Financial Performance Evaluation in SCML

ARJUN SURESH [8] MBASCML 110007

Toyota Prius. The company also develops other products according to this trend, such as Camry

Hybrid and Highlander Hybrid.

Legal: Headquartered in Japan but expanded worldwide, Toyota needs to take into account laws

and regulations for each country. The company and its success can be affected by legal aspects,

such as government taxes, vehicle safety and emission levels regulations. Also, other regulations

such as employment policies or health and safety are highly important. In order to create a

positive image, the legal factors must be closely analysed. By not accomplishing this, the

company risks to create a negative image among the customers, fact which is likely to decrease

its sales.

CONCLUSION

Analysis of logistical operations and distributions policies of Toyota concludes that the

company, being an independent entity, follows the Arm’s length carrier relationship

management. The Toyota company follows this management for the all the branches worldwide.

The ways of improving the Toyota Company with its carrier servicers has been discussed and

also the ways of communicating has been discussed. The carrier of the goods requires a lot much

information regarding the goods from the company for the accurate delivery of the goods. This

information is to be given to the goods carrier companies by Toyota. Toyota employs several

logistical service patterns in several locations and even though the automobile manufacturer has

succeeded in providing high end and environmentally friendly products to its end users, it

requires several changes to be made in terms of international carrier policies. The responsibility

parameters require being changed in terms of economic variables and accessibility factor. Also,

the distribution facilities is robust in certain markets like the US, India, and Canada, while it’s

marketed in the Middle East and Central Africa, are underdeveloped compared to industry

benchmarks. While Toyota has been able to sustain robust deliverance in top markets, it has

failed inadequate carrier selection in markets requiring compact cars and low-end vehicles.

5505MBA18 Financial Performance Evaluation in SCML

ARJUN SURESH [9] MBASCML 110007

Potrebbero piacerti anche

- Project On Freight ForwardingDocumento72 pagineProject On Freight ForwardingSam Ade88% (84)

- Introduction CoastallineDocumento4 pagineIntroduction CoastallineArjun sureshNessuna valutazione finora

- Incremental and TransformationDocumento31 pagineIncremental and TransformationArjun sureshNessuna valutazione finora

- PerformanceDocumento27 paginePerformanceArjun sureshNessuna valutazione finora

- Financial Performance and EvaluationDocumento9 pagineFinancial Performance and EvaluationArjun sureshNessuna valutazione finora

- Jaguar Cars Company Uk LTD OnlineinterviewDocumento4 pagineJaguar Cars Company Uk LTD OnlineinterviewArjun suresh100% (1)

- Assignment Brief MBA Supply Chain Management & Logistics Academic Year 2018-19Documento10 pagineAssignment Brief MBA Supply Chain Management & Logistics Academic Year 2018-19Arjun sureshNessuna valutazione finora

- Assignment Brief MBA Supply Chain Management & Logistics Academic Year 2018-19Documento10 pagineAssignment Brief MBA Supply Chain Management & Logistics Academic Year 2018-19Arjun sureshNessuna valutazione finora

- Assignment Brief MBA Logistics & Supply Chain Management Academic Year 2018-19Documento11 pagineAssignment Brief MBA Logistics & Supply Chain Management Academic Year 2018-19Arjun sureshNessuna valutazione finora

- Assignment Brief MBA Logistics & Supply Chain Management Academic Year 2018-19Documento11 pagineAssignment Brief MBA Logistics & Supply Chain Management Academic Year 2018-19Arjun sureshNessuna valutazione finora

- Incremental and TransformationDocumento31 pagineIncremental and TransformationArjun sureshNessuna valutazione finora

- Incremental and TransformationDocumento31 pagineIncremental and TransformationArjun sureshNessuna valutazione finora

- Financial Performance and EvaluationDocumento9 pagineFinancial Performance and EvaluationArjun sureshNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Section 3 Solutions PDFDocumento5 pagineSection 3 Solutions PDFSam javaNessuna valutazione finora

- 4067 XLS EngDocumento11 pagine4067 XLS EngMILIND SHEKHARNessuna valutazione finora

- BM AssignmentDocumento7 pagineBM AssignmentAntony LawrenceNessuna valutazione finora

- Boast 1 - Fragility Hip Fractures PDFDocumento1 paginaBoast 1 - Fragility Hip Fractures PDFSam BarnesNessuna valutazione finora

- RizalDocumento6 pagineRizalKin BarklyNessuna valutazione finora

- Take It Easy American IdiomsDocumento226 pagineTake It Easy American Idiomsmrsbellie100% (4)

- To Build A Tower As High As Possible Using There Are Many Ways of Building Towers Using MaterialsDocumento27 pagineTo Build A Tower As High As Possible Using There Are Many Ways of Building Towers Using MaterialsJhunior Huaman YaccaNessuna valutazione finora

- Choral Speaking - Our School LifeDocumento4 pagineChoral Speaking - Our School LifeAINA AZMINA BINTI ANUAR KPM-GuruNessuna valutazione finora

- Saham LQ 20Documento21 pagineSaham LQ 20ALDI.S. TUBENessuna valutazione finora

- Don Mariano Marcos Memorial State University Mid La Union CampusDocumento5 pagineDon Mariano Marcos Memorial State University Mid La Union CampusSam Bernardo100% (2)

- Telephone Triage For Oncology Nurses Print Replica Ebook PDFDocumento57 pagineTelephone Triage For Oncology Nurses Print Replica Ebook PDFdaniel.salazar678100% (37)

- Behavioral Pattern - FinalDocumento6 pagineBehavioral Pattern - FinalSaileneGuemoDellosaNessuna valutazione finora

- 2018 - 14 Sept - Matlit Hymns - Exaltation Holy CrossDocumento16 pagine2018 - 14 Sept - Matlit Hymns - Exaltation Holy CrossMarguerite PaizisNessuna valutazione finora

- A Project Report OnDocumento27 pagineA Project Report OnSAITEJA ANUGULANessuna valutazione finora

- Lec 2 Ideology of PakDocumento49 pagineLec 2 Ideology of PakIshfa Umar0% (1)

- Appointment Letter 17may2022Documento6 pagineAppointment Letter 17may2022Gaurav ChoudharyNessuna valutazione finora

- Jurnal Analisis Stabilitas Lidokain HCLDocumento11 pagineJurnal Analisis Stabilitas Lidokain HCLMusfira Dewy SuardiNessuna valutazione finora

- Enterprise Security Script: Splunk Security Solutions Marketing October 2019Documento26 pagineEnterprise Security Script: Splunk Security Solutions Marketing October 2019RainyNessuna valutazione finora

- Use of English 01Documento2 pagineUse of English 01Doylce TrầnNessuna valutazione finora

- Civil Law - Persons FamilyDocumento59 pagineCivil Law - Persons FamilyCharmaine MejiaNessuna valutazione finora

- Scanner Hardware Stopped Scan - Replace Collimator CAM (A - B) Motor and Coupling AssemblyDocumento5 pagineScanner Hardware Stopped Scan - Replace Collimator CAM (A - B) Motor and Coupling AssemblyLuis BattaNessuna valutazione finora

- Visual Development Milestones and Visual Acuity Assessment in ChildrenDocumento2 pagineVisual Development Milestones and Visual Acuity Assessment in ChildrenNikhil Maha DevanNessuna valutazione finora

- Pain Assessment AND Management: Mr. Swapnil Wanjari Clinical InstructorDocumento27 paginePain Assessment AND Management: Mr. Swapnil Wanjari Clinical InstructorSWAPNIL WANJARINessuna valutazione finora

- EconomicsDocumento19 pagineEconomicsTooba NoushadNessuna valutazione finora

- Edward Taylor S PoemsDocumento6 pagineEdward Taylor S PoemsGodofwarNessuna valutazione finora

- NEO PI R InterpretationDocumento16 pagineNEO PI R InterpretationG. S.100% (5)

- 2006 Consensus Agreement On The Design and Conduct of Clinical Studies With Low-Level Laser Therapy and Light Therapy For Musculoskeletal Pain and DisordersDocumento2 pagine2006 Consensus Agreement On The Design and Conduct of Clinical Studies With Low-Level Laser Therapy and Light Therapy For Musculoskeletal Pain and DisordersDetian WangNessuna valutazione finora

- Computer Coursework ProjectDocumento7 pagineComputer Coursework Projectf675ztsf100% (2)

- Mosaic TRD4 Tests EOY 1Documento4 pagineMosaic TRD4 Tests EOY 1MarcoCesNessuna valutazione finora

- Compare and Contrast: Costa Rica and PanamaDocumento1 paginaCompare and Contrast: Costa Rica and PanamaHong NguyenNessuna valutazione finora