Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

An Equipment FMEA

Caricato da

Dimas Sasongko0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni2 pagineasoygeboyy

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoasoygeboyy

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni2 pagineAn Equipment FMEA

Caricato da

Dimas Sasongkoasoygeboyy

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

An equipment FMEA (EFMEA) is a systematic

approach that applies the generic form of an

FMEA to aid the thought process used by engineers

to identify the equipment’s potential failure

modes and their effects. The focus, however,

is on the operator’s safety.

Purpose

The basic purposes of any EFMEA are to:

1. Identify potential failure modes and rate

the severity of their effects

2. Rank-order potential design and process

deficiencies

3. Help engineers focus on eliminating

equipment design and process concerns

and help prevent problems from occurring

Use

Fundamentally, there are three reasons for using

EFMEA. They are to:

1. Identify potential failure modes that may

adversely affect environment safety

102 Chapter Eight

2. Identify potential failure modes that may

adversely affect operator safety

3. Identify potential design deficiencies

before releasing machinery to production

Benefit

There are at least five basic benefits in completing

an EFMEA. They are:

1. Improve the quality, reliability, and safety

of the customer’s equipment

2. Improve the company’s image and

competitiveness

3. Help to increase customer satisfaction

4. Reduce equipment development time

and cost

5. Document and track actions taken to

reduce risk

Model UP5 11-10

Frequency (Hz) 50

Rated Pressure (barg / psig) 10 / 145

Nominal Power (kW / hp) 11 / 15

Flow (m3min / cfm) 1.54 / 54

Length (cm / in) 128 / 51

Width (cm / in) 92 / 36

Height (cm / in) 105 / 41

Weight (kg / lbs) 509 / 1122

Pengadaan critical spare part untuk stock.

Pemeliharaan overhaul setiap 2000 jam operasi (running hours) untuk periode

6000, 8000, 10000, 12000, 14000 & 16000 jam operasi.

Perbaikan kerusakan berdasarkan on call basis dengan spare part di re-

imburse.

Investigasi penyebab kerusakan yang terjadi.

Membuat laporan tertulis yang terdiri atas:

a. Suku cadang dan alat kerja yang harus disediakan untuk overhaul atau

kunjungan berikutnya.

b. Rekomendasi (jika perlu) pada setiap periode untuk:

- Perubahan prosedur operasi atau perawatan.

- Daftar suku cadang yang harus diganti.

- Daftar suku cadang & alat kerja yang harus dimiliki oleh Perusahaan (NR)

- Daftar pekerjaan dan jadwal preventive maintenance.

c. Time sheet per jam (hourly) untuk setiap jenis pekerjaan.

e. Berita Acara Pemeriksaan (BAP) terkait hasil laporan perbaikan &

pemeriksaan.

Dyadem Press – Guidelines for FMEA halaman 83

Stamatis – The ASQ pocket halaman 98, 162

Potrebbero piacerti anche

- Ir Rotary Manual Up5up6 2 PDFDocumento48 pagineIr Rotary Manual Up5up6 2 PDFArun PadmanabhanNessuna valutazione finora

- Ir Rotary Manual Up5up6 2 PDFDocumento48 pagineIr Rotary Manual Up5up6 2 PDFArun PadmanabhanNessuna valutazione finora

- UP5-11-37kW Fixed Speed Compressor BrochureDocumento12 pagineUP5-11-37kW Fixed Speed Compressor BrochureMizan SarkarNessuna valutazione finora

- UP5-11-37kW Fixed Speed Compressor BrochureDocumento12 pagineUP5-11-37kW Fixed Speed Compressor BrochureMizan SarkarNessuna valutazione finora

- UP5-11-37kW Fixed Speed Compressor BrochureDocumento12 pagineUP5-11-37kW Fixed Speed Compressor BrochureMizan SarkarNessuna valutazione finora

- UP5-11-37kW Fixed Speed Compressor BrochureDocumento12 pagineUP5-11-37kW Fixed Speed Compressor BrochureMizan SarkarNessuna valutazione finora

- UP5-11-37kW Fixed Speed Compressor BrochureDocumento12 pagineUP5-11-37kW Fixed Speed Compressor BrochureMizan SarkarNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Secret of The House WTDocumento22 pagineThe Secret of The House WTPetr -50% (2)

- 1 Colmac DX Ammonia Piping Handbook 4th EdDocumento64 pagine1 Colmac DX Ammonia Piping Handbook 4th EdAlbertoNessuna valutazione finora

- Growth Developt Pearl MilletDocumento17 pagineGrowth Developt Pearl MilletdarmaNessuna valutazione finora

- TDS Versimax HD4 15W40Documento1 paginaTDS Versimax HD4 15W40Amaraa DNessuna valutazione finora

- Failures of Gabion Walls: Ganesh C. Chikute, Ishwar P. SonarDocumento7 pagineFailures of Gabion Walls: Ganesh C. Chikute, Ishwar P. SonarnavigareeNessuna valutazione finora

- How To Practice Self Care - WikiHowDocumento7 pagineHow To Practice Self Care - WikiHowВасе АнѓелескиNessuna valutazione finora

- Black Girl Magic: Over 200+ AffirmationsDocumento229 pagineBlack Girl Magic: Over 200+ AffirmationsDestiny S. Harris100% (2)

- COVID 19 Impacts On The Construction IndustryDocumento46 pagineCOVID 19 Impacts On The Construction IndustryAlemayehu DargeNessuna valutazione finora

- 8-26-16 Police ReportDocumento14 pagine8-26-16 Police ReportNoah StubbsNessuna valutazione finora

- Cipac MT 185Documento2 pagineCipac MT 185Chemist İnançNessuna valutazione finora

- Gebauer 2012Documento26 pagineGebauer 2012Seán GallagherNessuna valutazione finora

- Esaote MyLabX7Documento12 pagineEsaote MyLabX7Neo BiosNessuna valutazione finora

- PERSONS Finals Reviewer Chi 0809Documento153 paginePERSONS Finals Reviewer Chi 0809Erika Angela GalceranNessuna valutazione finora

- B.Sc. (AGRICULTURE) HORTICULTURE SYLLABUSDocumento31 pagineB.Sc. (AGRICULTURE) HORTICULTURE SYLLABUSgur jazzNessuna valutazione finora

- Theories of Motivation and Child Moral DevelopmentDocumento5 pagineTheories of Motivation and Child Moral DevelopmentPamela mirandaNessuna valutazione finora

- Lesson 1 CA 3Documento13 pagineLesson 1 CA 3myndleNessuna valutazione finora

- Indonesia Organic Farming 2011 - IndonesiaDOCDocumento18 pagineIndonesia Organic Farming 2011 - IndonesiaDOCJamal BakarNessuna valutazione finora

- 01 - 01 - SK10 - JXNipponDocumento1 pagina01 - 01 - SK10 - JXNipponredevils86Nessuna valutazione finora

- Design and Built-A4Documento2 pagineDesign and Built-A4farahazuraNessuna valutazione finora

- General Specifications: Detail ADocumento1 paginaGeneral Specifications: Detail AJeniel PascualNessuna valutazione finora

- Pet - WikipediaDocumento12 paginePet - Wikipediabdalcin5512Nessuna valutazione finora

- Strauss Dental Catalog 2013Documento74 pagineStrauss Dental Catalog 2013d3xt3rokNessuna valutazione finora

- Parasitology Lecture Hosts, Symbiosis & TransmissionDocumento10 pagineParasitology Lecture Hosts, Symbiosis & TransmissionPatricia Ann JoseNessuna valutazione finora

- Quality ImprovementDocumento3 pagineQuality ImprovementViky SinghNessuna valutazione finora

- Abortion and UtilitarianismDocumento4 pagineAbortion and UtilitarianismBrent Harvey Soriano JimenezNessuna valutazione finora

- Natural Resources in PakistanDocumento5 pagineNatural Resources in PakistanSohaib ENessuna valutazione finora

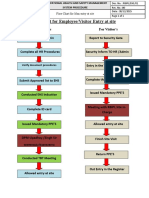

- fLOW CHART FOR WORKER'S ENTRYDocumento2 paginefLOW CHART FOR WORKER'S ENTRYshamshad ahamedNessuna valutazione finora

- AAR Maintenance 001Documento3 pagineAAR Maintenance 001prakash reddyNessuna valutazione finora

- To The OneDocumento8 pagineTo The OnePizzaCowNessuna valutazione finora

- Annex 8 Qualification of BalancesDocumento11 pagineAnnex 8 Qualification of BalancesMassimiliano PorcelliNessuna valutazione finora