Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bucket Elevator Monitor: Bearing Sensor

Caricato da

Ágost Vita0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

27 visualizzazioni2 paginedatasheet

Titolo originale

Watchdog Elite

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentodatasheet

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

27 visualizzazioni2 pagineBucket Elevator Monitor: Bearing Sensor

Caricato da

Ágost Vitadatasheet

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

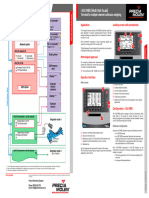

Bearing Sensor Bucket

Grease through, positive

mounting, PTC thermistor

with 176º F (80º C) trip point

Elevator

or NTC thermistor with user

adjustable trip point.

Monitor

Combined belt alignment, belt

speed, bearing temperature, pulley

alignment and plugged condition

Aux. Board Interface

monitor for bucket elevators. The Connection

RS485

system incorporates the latest dual Terminals

Plug Switch PIC microprocessors and non-volatile

Capacitance style sensor that can

detect plugged spouts, inlets and (EEPROM) memory chips. An LCD Microprocessor

outlets.

screen displays elevator status Connector

messages (available in 4 different

languages) and a super-bright LED

display shows belt speed. Calibration

Sensor

and set-up parameters are accessed Wiring

via a password and front panel Terminals

touch buttons. The system is FM

and CSA approved for class II,

division 1, groups E, F and G. Power/Control

Wiring Terminals

Pulley Alignment Sensor

Non-contacting magnetic proximity

sensor can detect the steel pulley edge

to indicate misalignment.

Simplicity, Reliability, Consistency

The system sensors are specifically designed to monitor

bucket elevators in tough environments. The extended

range magnetic motion and alignment sensors have a

user-adjustable field, which allows detection of moving

elevator buckets or bucket bolts. These sensors are

fail-safe in design and not affected by dust or material

build-up. The Watchdog Elite is easily installed and has

a menu-driven set-up, which enables use on all bucket

elevators.

RS485 Serial Communication as standard, and optional

PLC Interface Board available.

Clear, Concise Display Messages

With over 100 display and set-up messages, the

Watchdog Elite provides the operator with fast, easy to

Motion/Alignment Sensor read, real-time information on the status of the elevator,

Non-contacting magnetic sensors the monitoring system and the external wiring.

monitor belt speed and alignment.

Mounted at the boot and/or

the head, they detect the

elevator buckets

or bolts.

Some of the one hundred or more display messages.

Your Material Handling Specialists Your Material Handling Specialists

BRAIME ELEVATOR COMPONENTS LIMITED BRAIME ELEVATOR COMPONENTS LIMITED

Hunslet Road, Leeds, England, LS10 1JZ • Telephone 0113 246.1800 • Fax 0113.243.5021 • www.pressings.u-net.com • e-mail: info@braime.co.uk Hunslet Road, Leeds, England, LS10 1JZ • Telephone 0113 246.1800 • Fax 0113.243.5021 • www.pressings.u-net.com • e-mail: info@braime.co.uk

Combined Belt Alignment, Belt

Bucket Speed, Bearing Temperature, Pulley

Elevator Alignment and Plug Condition

Monitor Monitor for Bucket Elevators

Technical Specifications

Control Unit Bearing Sensors

Type ...................................Microprocessor Control Unit Type ...................................PTC or NTC Thermistor

Power Supply .................110 VAC or 240 VAC - Auto Select Style ...................................Grease through positive mounting

Power Consumption ....18 VA Power Supply .................12VDC

Alarm Relay ....................SPDT 240 VAC, 10 AMP From Control Unit

Stop Relay .......................SPDT 240 VAC, 10 AMP Trip Temperature...........PTC 80º C/176º F

Sensor Inputs..................4 at 12 VDC digital NTC user-adjustable

6 at 12 VDC analog Thread size......................1/8” NPTF

1 RS485 Comms. port Construction ..................Zinc-plated steel

Sensor Supply.................12 VDC, 100 mA Available Dimensions .....................1-1/16” hex x 1-1/2”

Speed Range ..................20-4000 Pulses-minute Weight ..............................8.5 oz. (240 g)

Construction ..................Polycarbonate enclosure Conduit Entry .................1/2” NPT

Dimensions .....................11”x10”x5” (28cm x 25cm x 13cm) Protection ........................FM & CSA Approved

Weight ..............................5 lbs., 3 oz. (2.35 kg.) Class II, Division 1 E,F,G

Conduit Entries ..............2 at 3/4”

Protection ........................FM & CSA Approved Class II, Division 1 E,F,G

Motion Alignment Sensors PLC/Alarm Interface

Type ...................................Magnetic Sensor

Type ...................................Aux. PCB Installs

Power Supply .................12VDC, 20mA

Inside Control Unit

from Control Unit

Power Supply .................5VDC From

Speed Range ..................20-2000 Pulses-minute

Control Unit

20-4000 Pulses-minute

Relay Output ..................3 x SPDT 240 VAC

Sensing Range ...............1” to 6” Ferrous object

3 AMP. Speed,

via adjustable screw pot

Misalignment,

Construction ..................Nylon, Encapsulated

Bearing Temperature

Epoxy Resin

Dimensions .....................4” x 5-1/2” x 1-1/2”

Dimensions .....................2” Dia. x 6” Long

(10cm x 14cm x 4cm)

(51mm x 152mm)

Weight ..............................5 oz. (140g)

Weight ..............................1 lb. (454g)

Protection ........................FM & CSA Approved

Conduit Entry .................1/2” NPT

Class II, Division 1 E,F,G

Protection ........................FM & CSA Approved

Class II, Division 1 E,F,G

Pulley Alignment Sensors Plug Switch

Type ...................................Magnetic Proximity Type ...................................Capacitance Proximity

Power Supply .................12VDC, 15mA Power Supply .................12VDC, 30mA

from Control Unit from Control Unit

Sensing Range ...............1” Ferrous Object Calibration.......................User adjustable Screw Pot.

Construction ..................Polycarbonate Dimensions .....................1-3/16” Dia. x 6-1/4” Long

Encapsulated (3cm x 16cm)

Epoxy Resin Weight ..............................10.5 oz. (294g)

Dimensions .....................1-3/16” Dia. x 4” Long (3cm x 10cm) Conduit Entry .................3/4” NPT with Adapter

Weight ..............................7 oz. (196g) Protection ........................FM Approved

Conduit Entry .................3/4” NPT with Adapter Class II, Division 1 E,F,G

Belt Speed Protection ........................FM & CSA Approved Class II, Division 1 E,F,G

Belt Alignment

Bearing Temperature Approved Installation/Start Up Service Available PLC Interface

24-Hour Hotline at Peoria Office Free PLC Software

Pulley Alignment

Data Sheets and Manual Available Upon Request Site Audits Undertaken

Plug Condition

Acceleration Monitoring APPROVED FOR USE IN HAZARDOUS LOCATIONS

CLASS II DIVISION 1 GROUPS E, F & G

Your Material Handling Specialists Your Material Handling Specialists

4B COMPONENTS LIMITED 4B COMPONENTS LIMITED

7 2 9 S a b r i n a D r i ve • E a s t Pe o r i a , I l l i n o i s 6 1 6 1 1 U S A • Te l e p h o n e 3 0 9 . 6 9 8 . 5 6 1 1 • Fa x 3 0 9 . 6 9 8 . 5 6 1 5 7 2 9 S a b r i n a D r i ve • E a s t Pe o r i a , I l l i n o i s 6 1 6 1 1 U S A • Te l e p h o n e 3 0 9 . 6 9 8 . 5 6 1 1 • Fa x 3 0 9 . 6 9 8 . 5 6 1 5

h t t p : / / w w w. g o 4 b . c o m E-Mail: go4b@aol.com h t t p : / / w w w. g o 4 b . c o m E-Mail: go4b@aol.com

Your Material Handling Specialists Your Material Handling Specialists

BRAIME ELEVATOR COMPONENTS LIMITED BRAIME ELEVATOR COMPONENTS LIMITED

Hunslet Road, Leeds, England, LS10 1JZ • Telephone 0113 246.1800 • Fax 0113.243.5021 • www.pressings.u-net.com • e-mail: info@braime.co.uk Hunslet Road, Leeds, England, LS10 1JZ • Telephone 0113 246.1800 • Fax 0113.243.5021 • www.pressings.u-net.com • e-mail: info@braime.co.uk

Potrebbero piacerti anche

- Battery Monitor Quick Start Guide (EN) 975-0690-01-01 - Rev-BDocumento4 pagineBattery Monitor Quick Start Guide (EN) 975-0690-01-01 - Rev-BAdewale BamgbadeNessuna valutazione finora

- Walker 7070Documento2 pagineWalker 7070bobNessuna valutazione finora

- Walker 7070Documento3 pagineWalker 7070Van KindNessuna valutazione finora

- TransducersDocumento6 pagineTransducersTenuka pereraNessuna valutazione finora

- DCRK5Documento18 pagineDCRK5general electricNessuna valutazione finora

- ARM Cortex-A7 Core Block DiagramDocumento1 paginaARM Cortex-A7 Core Block Diagram文帅宋Nessuna valutazione finora

- Installation Procedure Electronic Vessel Control D4, D6 EVC: Components, Cables and Cable HarnessesDocumento1 paginaInstallation Procedure Electronic Vessel Control D4, D6 EVC: Components, Cables and Cable HarnessesPriscilla Cardoso de BritoNessuna valutazione finora

- HC2 Brochure (L06070enga)Documento27 pagineHC2 Brochure (L06070enga)Erick Yael Alcantar MaresNessuna valutazione finora

- Synchromax: User S ManualDocumento2 pagineSynchromax: User S ManualHedayatNessuna valutazione finora

- 08-3464 Walker 7080Documento2 pagine08-3464 Walker 7080serjulica2000Nessuna valutazione finora

- Merging Unit and Process Bus Solution: Unrestricted © Siemens 2020Documento51 pagineMerging Unit and Process Bus Solution: Unrestricted © Siemens 2020Oscar Pulido SuarezNessuna valutazione finora

- DFR, DDR, Pmu, Tws FL and Class A PQ in ONE Device!: Unrivalled MultifunctionalityDocumento8 pagineDFR, DDR, Pmu, Tws FL and Class A PQ in ONE Device!: Unrivalled MultifunctionalitySentaNessuna valutazione finora

- Ip F23 02L 01e - Idm3 PDFDocumento8 pagineIp F23 02L 01e - Idm3 PDFJames RobertsNessuna valutazione finora

- Intelligent Automation Solutions Using Electrics and PneumaticsDocumento1 paginaIntelligent Automation Solutions Using Electrics and PneumaticsneonatalNessuna valutazione finora

- BmsDocumento4 pagineBmsAlan TanNessuna valutazione finora

- Quick Reference Guide Maxtesterapplication Max-800 Series English - 1082519Documento2 pagineQuick Reference Guide Maxtesterapplication Max-800 Series English - 1082519Abdulmoied OmarNessuna valutazione finora

- MT DatasheetDocumento6 pagineMT Datasheetdiyanorm2020Nessuna valutazione finora

- LOVATO Automatic Power Factor Controllers and Thyristor ModulesDocumento20 pagineLOVATO Automatic Power Factor Controllers and Thyristor ModulesMai Văn BáchNessuna valutazione finora

- Transformer Test SystemDocumento3 pagineTransformer Test SystemleivajNessuna valutazione finora

- Indicator Controller Cum TransmitterDocumento1 paginaIndicator Controller Cum TransmitterTrumen Technologies PVT LtdNessuna valutazione finora

- LectroCount3 Owners Manual 49145E PDFDocumento20 pagineLectroCount3 Owners Manual 49145E PDFLazzarus Az GunawanNessuna valutazione finora

- Delta Ia-Plc DVP TP C en 20160922Documento48 pagineDelta Ia-Plc DVP TP C en 20160922max_ingNessuna valutazione finora

- APT1405.A2.01E.V1.0 - 96600 (AE1405 Series) Product Specification - BakDocumento5 pagineAPT1405.A2.01E.V1.0 - 96600 (AE1405 Series) Product Specification - BakСергей КаревNessuna valutazione finora

- Eutech Bench 2700 Series Family BrochureDocumento8 pagineEutech Bench 2700 Series Family BrochureYuhalimih TechnicalNessuna valutazione finora

- I 410 MBS Multi Belt Scale WebDocumento2 pagineI 410 MBS Multi Belt Scale Weberik masongNessuna valutazione finora

- Controller Area Network (CAN) Implementation: Hardware and Software PerspectiveDocumento69 pagineController Area Network (CAN) Implementation: Hardware and Software PerspectiveAshokUmmadisettiNessuna valutazione finora

- Model MF4000: MEMS Mass Flow MetersDocumento13 pagineModel MF4000: MEMS Mass Flow MetersStanzaPelangiNessuna valutazione finora

- Motor Feedback Brochure PDFDocumento20 pagineMotor Feedback Brochure PDFBejo JacobNessuna valutazione finora

- Genetix ControlDocumento12 pagineGenetix ControlJuan Valenzuela V.Nessuna valutazione finora

- KatalogDocumento1 paginaKatalogPetraindo Jaya AbadiNessuna valutazione finora

- Sensitec - VTMS - System For Measurement of Dynamic Valve LiftDocumento12 pagineSensitec - VTMS - System For Measurement of Dynamic Valve Liftmn16kumarNessuna valutazione finora

- Proportional Reducing Valves Rzgo, Hzgo, Kzgo: Pilot Operated, ISO 4401 Size 06, 10Documento4 pagineProportional Reducing Valves Rzgo, Hzgo, Kzgo: Pilot Operated, ISO 4401 Size 06, 10Saad AttarNessuna valutazione finora

- Portugal-ZTE UMTS Radio Network Parameters For SNC - RNCV3.07.310 (20100427)Documento82 paginePortugal-ZTE UMTS Radio Network Parameters For SNC - RNCV3.07.310 (20100427)Nikan AminiNessuna valutazione finora

- Operating Principle of Displacer Level Sensors - Learning Instrumentation and Control EngineeringDocumento1 paginaOperating Principle of Displacer Level Sensors - Learning Instrumentation and Control EngineeringThiagarajNessuna valutazione finora

- Manual Potenciometro Denver. OpMan - Basic - Meter PDFDocumento24 pagineManual Potenciometro Denver. OpMan - Basic - Meter PDFVero VillarrealNessuna valutazione finora

- Digital Overspeed - Protection System: Short DescriptionDocumento8 pagineDigital Overspeed - Protection System: Short DescriptionYohannes S AripinNessuna valutazione finora

- Product Brief: The Evolved Diameter Signaling NetworkDocumento2 pagineProduct Brief: The Evolved Diameter Signaling NetworkbaraharbNessuna valutazione finora

- PentAir - Aquatic ECO SystemDocumento4 paginePentAir - Aquatic ECO SystemboonsomNessuna valutazione finora

- Delta Programmable Logic Controller DVP Series: Automation For A Changing WorldDocumento52 pagineDelta Programmable Logic Controller DVP Series: Automation For A Changing WorldcarlosmarciosfreitasNessuna valutazione finora

- Delta Ia-Plc DVP TP C en 20190517 WebDocumento52 pagineDelta Ia-Plc DVP TP C en 20190517 WebKashif ZakaNessuna valutazione finora

- Preamble Design and Coarse Synchronization Using CAZAC Sequence For Uplink Cable ModemDocumento5 paginePreamble Design and Coarse Synchronization Using CAZAC Sequence For Uplink Cable ModemHaji Rana ShahidNessuna valutazione finora

- PID Display ControllerDocumento13 paginePID Display ControllermilesNessuna valutazione finora

- Ifm Catalogue Control Systems GB 09Documento212 pagineIfm Catalogue Control Systems GB 09ifm electronic100% (2)

- A Neuro-Fuzzy Controller For Speed Control of A Permanent Magnet Synchronous Motor DriveDocumento8 pagineA Neuro-Fuzzy Controller For Speed Control of A Permanent Magnet Synchronous Motor DrivechichuNessuna valutazione finora

- ABB Hydro Power Brochure 2021Documento8 pagineABB Hydro Power Brochure 2021Ammar KhaleelNessuna valutazione finora

- Standard Equipment/Optional Equipment Features: Electric Straddle Stacker Capacity 1000 - 1200 KG L10AS, L12ASDocumento2 pagineStandard Equipment/Optional Equipment Features: Electric Straddle Stacker Capacity 1000 - 1200 KG L10AS, L12ASIker BasqueAdventureNessuna valutazione finora

- Testcase 6Documento15 pagineTestcase 6Naresh KumarNessuna valutazione finora

- DVP 04TC S - Instruction PDFDocumento2 pagineDVP 04TC S - Instruction PDFDiego Gil100% (1)

- JVR800 2 Three Phase Voltage Monitoring Relay ManualDocumento1 paginaJVR800 2 Three Phase Voltage Monitoring Relay ManualGrosu NicolaeNessuna valutazione finora

- Lesson: Embedded Systems I/O Analog InterfacingDocumento7 pagineLesson: Embedded Systems I/O Analog InterfacingPuspala ManojkumarNessuna valutazione finora

- Kelompok 2 Marshalling Terminal and RTU'sDocumento8 pagineKelompok 2 Marshalling Terminal and RTU'sevelynkarina45Nessuna valutazione finora

- Switchmode Power SupplyDocumento1 paginaSwitchmode Power Supplyapi-411100163Nessuna valutazione finora

- Delta Monitoring Solution: Quick, Simple, Reliable. Always Care About Your Needs !Documento3 pagineDelta Monitoring Solution: Quick, Simple, Reliable. Always Care About Your Needs !vanhuong87Nessuna valutazione finora

- Main Items BOQ Per SS: 4. Ethernet Switch 1. Control Panel & Panel Accessories 2. RTU System 5. Maintenance ToolsDocumento1 paginaMain Items BOQ Per SS: 4. Ethernet Switch 1. Control Panel & Panel Accessories 2. RTU System 5. Maintenance ToolsTarek KhafagaNessuna valutazione finora

- RMC 150 DatasheetDocumento20 pagineRMC 150 DatasheetIthanLeonardoNessuna valutazione finora

- Microprocessor Controlled Ac and DC DrivesDocumento27 pagineMicroprocessor Controlled Ac and DC DrivesnarayanNessuna valutazione finora

- Ds 80Documento2 pagineDs 80argodumilahNessuna valutazione finora

- 07 - 2017 - ACSR - China - Design of Double-Rows Sugarcane Harvester Control System Based On PLCDocumento5 pagine07 - 2017 - ACSR - China - Design of Double-Rows Sugarcane Harvester Control System Based On PLCaryoNessuna valutazione finora

- Trinamic Tmc4361a LaDocumento230 pagineTrinamic Tmc4361a LaLeoWangNessuna valutazione finora

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsDa EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsValutazione: 1 su 5 stelle1/5 (1)

- 017 A Data Governance Framework For Industry 4.0Documento10 pagine017 A Data Governance Framework For Industry 4.0Ágost VitaNessuna valutazione finora

- Reposi 2Documento3 pagineReposi 2Ágost VitaNessuna valutazione finora

- 009 Industrial IoT in 5G-And-Beyond Networks Vision, Architecture, and Design TrendsDocumento16 pagine009 Industrial IoT in 5G-And-Beyond Networks Vision, Architecture, and Design TrendsÁgost VitaNessuna valutazione finora

- 020 Internet of Things in Industry Research Profiling Application Challenges and OpportunitiesA ReviewEnergiesDocumento24 pagine020 Internet of Things in Industry Research Profiling Application Challenges and OpportunitiesA ReviewEnergiesÁgost VitaNessuna valutazione finora

- 012 Evaluating Federated Learning For Intrusion Detection in Internet of Things Review and ChallengesDocumento16 pagine012 Evaluating Federated Learning For Intrusion Detection in Internet of Things Review and ChallengesÁgost VitaNessuna valutazione finora

- 019 Hyperledger Fabric Access Control For Industrial Internet of ThingsDocumento22 pagine019 Hyperledger Fabric Access Control For Industrial Internet of ThingsÁgost VitaNessuna valutazione finora

- FT TransactionMgr Block DataDocumento18 pagineFT TransactionMgr Block DataÁgost VitaNessuna valutazione finora

- 008 Guest Editorial Industrial IoT and Sensor Networks in 5G-And-Beyond Wireless CommunicationDocumento4 pagine008 Guest Editorial Industrial IoT and Sensor Networks in 5G-And-Beyond Wireless CommunicationÁgost VitaNessuna valutazione finora

- 015 Implementation of Real Time Data Collection Process Automation Control Using IIoT ApplicationsDocumento8 pagine015 Implementation of Real Time Data Collection Process Automation Control Using IIoT ApplicationsÁgost VitaNessuna valutazione finora

- 003 Industrial Internet of Things Challenges Opportunities and DirectionsDocumento11 pagine003 Industrial Internet of Things Challenges Opportunities and DirectionsÁgost VitaNessuna valutazione finora

- Block Chain IotDocumento18 pagineBlock Chain IottennysonbaumNessuna valutazione finora

- Mobile Access To Production Information2Documento64 pagineMobile Access To Production Information2Ágost VitaNessuna valutazione finora

- 021 Production Plant and Warehouse Automation With IoT and Industry 50applied Sciences SwitzerlandDocumento34 pagine021 Production Plant and Warehouse Automation With IoT and Industry 50applied Sciences SwitzerlandÁgost VitaNessuna valutazione finora

- 005 IIoT-MEC A Novel Mobile Edge Computing Framework For 5G-Enable IIoTDocumento7 pagine005 IIoT-MEC A Novel Mobile Edge Computing Framework For 5G-Enable IIoTÁgost VitaNessuna valutazione finora

- OYSTAR Benhil Multipack3000-EDocumento6 pagineOYSTAR Benhil Multipack3000-EÁgost VitaNessuna valutazione finora

- How To Add Tags From A ControlLogix Processor To A RSSQL ConfigurationDocumento1 paginaHow To Add Tags From A ControlLogix Processor To A RSSQL ConfigurationÁgost VitaNessuna valutazione finora

- How To Add Individual I - O Points From A ControlLogix Processor To A RSSQL ConfigurationDocumento1 paginaHow To Add Individual I - O Points From A ControlLogix Processor To A RSSQL ConfigurationÁgost VitaNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Motion Control HandbookDocumento38 pagineMotion Control Handbookvincentttt100% (1)

- Seleccion Abb ServosDocumento64 pagineSeleccion Abb ServosAlexander Diaz AlvarezNessuna valutazione finora

- OYSTAR Benhil Multipack 8600 EnglishDocumento6 pagineOYSTAR Benhil Multipack 8600 EnglishÁgost VitaNessuna valutazione finora

- OYSTAR Benhil Multipack 5000 EnglishDocumento6 pagineOYSTAR Benhil Multipack 5000 EnglishÁgost VitaNessuna valutazione finora

- Iasimp Qs034 en PDocumento278 pagineIasimp Qs034 en PÁgost VitaNessuna valutazione finora

- I Cant Browse String Tags in A ControlLogix Processor From The RSSQL - FactoryTalk Transaction Manager Datapoint Definitions EditorDocumento1 paginaI Cant Browse String Tags in A ControlLogix Processor From The RSSQL - FactoryTalk Transaction Manager Datapoint Definitions EditorÁgost VitaNessuna valutazione finora

- The Basics of Motion Control-Part 2Documento3 pagineThe Basics of Motion Control-Part 2Ágost VitaNessuna valutazione finora

- t29 Virtualizing View SeDocumento33 paginet29 Virtualizing View SeCristian Román EscobedoNessuna valutazione finora

- L11 - New Techniques To Increase Efficiency With Panelview™ Plus 6 ApplicationsDocumento39 pagineL11 - New Techniques To Increase Efficiency With Panelview™ Plus 6 ApplicationsÁgost VitaNessuna valutazione finora

- Manual Book For Conversion From Siemens S7 To RSLogix5000Documento164 pagineManual Book For Conversion From Siemens S7 To RSLogix5000duniaengineering8666100% (2)

- High Performance Hmis: Mark Carrigan Vice President, Global Business Lines November 5, 2012Documento34 pagineHigh Performance Hmis: Mark Carrigan Vice President, Global Business Lines November 5, 2012Ágost VitaNessuna valutazione finora

- Ethernet Design ConsiderationsDocumento100 pagineEthernet Design ConsiderationsRobert RudmanNessuna valutazione finora

- Guide To Greyhawk PDFDocumento108 pagineGuide To Greyhawk PDFAnonymous PtMxUHm9RoNessuna valutazione finora

- Group Collaborative Activity TaskonomyDocumento2 pagineGroup Collaborative Activity TaskonomyTweeky SaureNessuna valutazione finora

- Your Heart: Build Arms Like ThisDocumento157 pagineYour Heart: Build Arms Like ThisNightNessuna valutazione finora

- Ays 082914 3331 PDFDocumento18 pagineAys 082914 3331 PDFFabian R. GoldmanNessuna valutazione finora

- Vol07 1 PDFDocumento275 pagineVol07 1 PDFRurintana Nalendra WarnaNessuna valutazione finora

- Komatsu Technical BrochurDocumento7 pagineKomatsu Technical BrochurBenjamin MossoNessuna valutazione finora

- Gcat Threathorizons Full Jan2023Documento26 pagineGcat Threathorizons Full Jan2023josbjsNessuna valutazione finora

- RE2S PE LPG CNG SPC Part 1Documento32 pagineRE2S PE LPG CNG SPC Part 1Inversiones RinocellNessuna valutazione finora

- Infrastructure Definition:: Economic Infrastructure Includes BroadlyDocumento3 pagineInfrastructure Definition:: Economic Infrastructure Includes Broadlyabraha gebruNessuna valutazione finora

- Scientific Exploration and Expeditions PDFDocumento406 pagineScientific Exploration and Expeditions PDFana_petrescu100% (2)

- Scientific American Psychology 2nd Edition Licht Test BankDocumento44 pagineScientific American Psychology 2nd Edition Licht Test Bankpurelychittra3ae3100% (24)

- Design A Roller Coaster ProjectDocumento4 pagineDesign A Roller Coaster Projectapi-3564628400% (1)

- Chapter 5: Sampling Distributions: Solve The ProblemDocumento4 pagineChapter 5: Sampling Distributions: Solve The ProblemEunice WongNessuna valutazione finora

- Recetario TransistoresDocumento23 pagineRecetario TransistoresTitán SotoNessuna valutazione finora

- Lecture 20Documento10 pagineLecture 20bilal5202050Nessuna valutazione finora

- Acer AIO Z1-752 System DisassemblyDocumento10 pagineAcer AIO Z1-752 System DisassemblySERGIORABRNessuna valutazione finora

- Icpc11 - Thermodynamics and Fluid MechanicsDocumento22 pagineIcpc11 - Thermodynamics and Fluid MechanicsAPARNANessuna valutazione finora

- Tamil NaduDocumento64 pagineTamil Nadushanpaga priyaNessuna valutazione finora

- Mobile Communication Networks: Exercices 4Documento2 pagineMobile Communication Networks: Exercices 4Shirley RodriguesNessuna valutazione finora

- FORD Falcon XA Repair ManualDocumento770 pagineFORD Falcon XA Repair ManualMark Kenzie100% (10)

- Business Model Navigator Whitepaper - 2019Documento9 pagineBusiness Model Navigator Whitepaper - 2019Zaw Ye HtikeNessuna valutazione finora

- NURS1108 Lecture 10 - Nervous System ENHANCEDDocumento40 pagineNURS1108 Lecture 10 - Nervous System ENHANCEDJacia’s SpaceshipNessuna valutazione finora

- General Anaesthesia MCQsDocumento5 pagineGeneral Anaesthesia MCQsWasi Khan100% (3)

- Chemistry Mid Term Exam 2014Documento8 pagineChemistry Mid Term Exam 2014Adham TamerNessuna valutazione finora

- Manual de Taller sk350 PDFDocumento31 pagineManual de Taller sk350 PDFLeo Perez100% (1)

- Effect of Acetylation Method On Characterization of Cellulose Acetate Based Sago "Hampas"Documento18 pagineEffect of Acetylation Method On Characterization of Cellulose Acetate Based Sago "Hampas"myrraNessuna valutazione finora

- Digital Trail Camera: Instruction ManualDocumento20 pagineDigital Trail Camera: Instruction Manualdavid churaNessuna valutazione finora

- Master of Business Administration in Aviation Management MbaamDocumento10 pagineMaster of Business Administration in Aviation Management MbaamAdebayo KehindeNessuna valutazione finora

- Tech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPDocumento39 pagineTech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPEl Mundo De Yosed100% (1)

- En LF Drivers 10nw76 8Documento3 pagineEn LF Drivers 10nw76 8ChrisNessuna valutazione finora