Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WW Treatment Objectives, Methods & Implementation

Caricato da

Bren SisonCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WW Treatment Objectives, Methods & Implementation

Caricato da

Bren SisonCopyright:

Formati disponibili

PAMANTASAN NG LUNGSOD NG MAYNILA

PAMANTASAN NGofLUNGSOD

University NG MAYNILA

the City of Manila

University

College of the City

of Engineering andofTechnology

Manila

College of Engineering

Department and

of Chemical Technology

Engineering

Department of Chemical Engineering

CHE 521: Industrial Waste Management & Control

Wastewater Treatment

Objectives, Methods

and Implementation

SUBMITTED BY:

Considerations

SANTOS, Amabelle C.

SARMIENTO, Marco M.

SISON, Bren A.

SUBMITTED TO:

Engr. April Anne S. Tigue

PROFESSOR

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

1

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

TABLE OF CONTENTS

Wastewater Treatment Objectives .................................................................................. 3

Wastewater Treatment Regulations ................................................................................ 5

DAO 2016-08: Water Quality Guidelines and General Effluent Standards……………...11

Classification of Wastewater Treatment Methods ......................................................... 28

Selection of Treatment Process Flow Diagrams ........................................................... 35

Wastewater Treatment Process Selection: An Industrial Approach .............................. 37

References .................................................................................................................... 40

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

2

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

WASTEWATER TREATMENT OBJECTIVES

The principal objective of wastewater treatment is generally to allow human and

industrial effluents to be disposed of without danger to human health or unacceptable

damage to the natural environment. Irrigation with wastewater is both disposal and

utilization and indeed is an effective form of wastewater disposal (as in slow-rate land

treatment). However, some degree of treatment must normally be provided to raw

municipal wastewater before it can be used for agricultural or landscape irrigation or for

aquaculture. The quality of treated effluent used in agriculture has a great influence on

the operation and performance of the wastewater-soil-plant or aquaculture system. In the

case of irrigation, the required quality of effluent will depend on the crop or crops to be

irrigated, the soil conditions and the system of effluent distribution adopted. Through crop

restriction and selection of irrigation systems which minimize health risk, the degree of

pre-application wastewater treatment can be reduced. A similar approach is not feasible

in aquaculture systems and more reliance will have to be placed on control through

wastewater treatment.

The most appropriate wastewater treatment to be applied before effluent use in

agriculture is that which will produce an effluent meeting the recommended

microbiological and chemical quality guidelines both at low cost and with minimal

operational and maintenance requirements (Arar 1988). Adopting as low a level of

treatment as possible is especially desirable in developing countries, not only from the

point of view of cost but also in acknowledgement of the difficulty of operating complex

systems reliably. In many locations it will be better to design the reuse system to accept

a low-grade of effluent rather than to rely on advanced treatment processes producing a

reclaimed effluent which continuously meets a stringent quality standard.

The objective of preliminary treatment is the removal of coarse solids and other

large materials often found in raw wastewater. Removal of these materials is necessary

to enhance the operation and maintenance of subsequent treatment units. Preliminary

treatment operations typically include coarse screening, grit removal and, in some cases,

comminution of large objects.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

3

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

The objective of primary treatment is the removal of settleable organic and

inorganic solids by sedimentation, and the removal of materials that will float (scum) by

skimming. Approximately 25 to 50% of the incoming biochemical oxygen demand

(BOD5), 50 to 70% of the total suspended solids (SS), and 65% of the oil and grease are

removed during primary treatment. Some organic nitrogen, organic phosphorus, and

heavy metals associated with solids are also removed during primary sedimentation but

colloidal and dissolved constituents are not affected. The effluent from primary

sedimentation units is referred to as primary effluent.

The objective of secondary treatment is the further treatment of the effluent from

primary treatment to remove the residual organics and suspended solids. In most cases,

secondary treatment follows primary treatment and involves the removal of biodegradable

dissolved and colloidal organic matter using aerobic biological treatment processes.

Aerobic biological treatment is performed in the presence of oxygen by aerobic

microorganisms (principally bacteria) that metabolize the organic matter in the

wastewater, thereby producing more microorganisms and inorganic end-products

(principally CO2, NH3, and H2O). Several aerobic biological processes are used for

secondary treatment differing primarily in the manner in which oxygen is supplied to the

microorganisms and in the rate at which organisms metabolize the organic matter.

Tertiary and/or advanced wastewater treatment is employed when specific

wastewater constituents which cannot be removed by secondary treatment must be

removed. Individual treatment processes are necessary to remove nitrogen, phosphorus,

additional suspended solids, refractory organics, heavy metals and dissolved solids.

Because advanced treatment usually follows high-rate secondary treatment, it is

sometimes referred to as tertiary treatment. However, advanced treatment processes are

sometimes combined with primary or secondary treatment (e.g., chemical addition to

primary clarifiers or aeration basins to remove phosphorus) or used in place of secondary

treatment (e.g., overland flow treatment of primary effluent).

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

4

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

WASTEWATER TREATMENT REGULATIONS

Philippine Regulations on Sanitation and Wastewater Systems

Front Cover of the Philippine Regulations on Sanitation and Wastewater Systems

The following to be presented was obtained from a book of compilation of

Philippine Regulations on Sanitation and Wastewater Systems.

Pertinent documents included here were obtained from existing laws, regulations,

and standards such as Republic Acts, Presidential Decrees, Board Resolutions,

Administrative Orders, Implementing Rules and Regulations, and other relevant statutes

which are packaged in chronological order to track down the sequence of policy

development. To maintain emphasis on sanitation and wastewater, full text is used if the

policies and guidelines are directly concerned about the subject while excerpts were

presented if otherwise.

Introduction

Sanitation, as used in the book of compilation, would mean the hygienic measures

of isolating the hazards of wastes from human contact to promote health. Wastes

generated by human beings could be excreta, urine, wastewater, solid wastes, industrial

wastes, and agricultural wastes. These wastes may contain hazards, such as microbial

pathogens and hazardous chemicals, which will be detrimental to human health if left

uncontrolled.

The emphasis of this book is on the application of sanitation to wastewater.

Wastewater elements considered are excreta, urine, sewage, storm water and other liquid

wastes generated from domestic, commercial, agricultural and industrial activities.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

5

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Systems that isolate hazards from human contact could be the application of engineering

solutions that deal with the processes of collection, transport, treatment, reuse and

recycling of wastewater; simple technology (e.g. pit latrines); or even simple handwashing

practices.

The professionals mandated by law (R.A. 1364) to deal with wastewater disposal

are the Sanitary Engineers. Related to this, a professional Sanitary Engineer in the

Philippines once said, "Only the Sanitary Engineers have the express authority to survey,

design, direct, manage, be consulted, and investigate any activity pertaining and related

to pollution, whether in water, air and land". Considering the legal mandate, it is necessary

that a Sanitary Engineer must be familiar with the concerned policies and guidelines on

environmental pollution in particular to wastewater as contained in this book so as to

maintain his good practice of sanitary engineering in the Philippines.

✓ Sanitary Engineers and Wastewater Disposal Systems - Excerpts from R.A. 1364

- SANITARY ENGINEERING LAW, (Approved, 18 June 1955)

“Sec. 2. Definition of terms. - The practice of sanitary engineering within the meaning

and intent of this Act shall embrace the following activities:

(a) Sanitary surveys, reports, design, direction, management, consultation, and

investigation of:

(1) Water purification plants, water collection and distribution systems,

reservoirs, drainage and sewer systems, sewage treatment plants, malaria

control structures, sewage disposal tanks, and other structures for public

health and welfare.”

✓ Wastewater Disposal and Drainage Provisions - Excerpts from the NATIONAL

BUILDING CODE, P.D. 1096, (Signed by President Ferdinand E. Marcos, Manila, 19

February 1977)

“Chapter IX – Sanitation

Sec. 903. Wastewater Disposal System

(a) Sanitary sewage from buildings and neutralized or pre-treated industrial

wastewater shall be discharged directly into the nearest street sanitary sewer main

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

6

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

of existing municipal or city sanitary sewerage system in accordance with the

criteria set by the Code on Sanitation and the National Pollution Control

Commission.

(b) All buildings located in areas where there are no available sanitary sewerage

system shall dispose their sewage to "Imhoff" or septic tank and subsurface

absorption field.

(c) Sanitary and industrial plumbing installations inside buildings and premises s

hall conform to the provisions of the National Plumbing Code.”

✓ Liquid Waste Disposal Provisions - Excerpts from the PHILIPPINE

ENVIRONMENT CODE, P.D. 1152 (Approved by President Ferdinand E. Marcos, 6

June 1977)

“Chapter III - Methods of Liquid Waste Disposal

Sec. 50. Liquid Waste Disposal.

Wastewater from manufacturing plants, industries, community, ordomestic

sources shall be treated either physically, biologically or chemically prior to disposal

in accordance with the rules and regulations promulgated by proper government

authority.”

✓ Effluent Water Quality Requirements - Excerpts from the NPCC Rules and

Regulations of 1978

“Sec. 70. Effluent Water Quality Requirements.

(a) Minimum Treatment - Except when the Commission finds its unnecessary, all

liquid wastes discharged into inland rivers, lakes and reservoirs, will receive a

minimum of primary treatment for inorganic wastes, except for toxic substances,

and secondary treatment for organic wastes. Liquid wastes discharged into

estuarine waters will receive secondary treatment. Liquid wastes discharged into

marine outfalls will receive a minimum of primary treatment, unless otherwise

specified by the Commission.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

7

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

The following table shows the expected performance of each treatment process:

Treatment Process and its Expected Performance

Primary Primary plus Secondary

Floating Solids Removal 95-100% 95-100%

Suspended Solids Removal 50-65% 80-95%

Settleable Solids Removal 90-95% 90-95%

BOD5 Removal 25-40% 80-95%

✓ Revised Effluent Regulations - DAO no. 35 Series of 1990

Section 9. Prohibitions.

d) Other Restrictions:

1. All water pollution control facilities/installations shall be properly and consistently

maintain an effluent quality that complies with Section 4 to 6 of these regulations.

2. No industrial or manufacturing plant shall be operated without the control

facilities or wastewater treatment system in good order or in proper operation

except with the permission of the Department Secretary when special

circumstance arise.

3. No industrial or manufacturing plant or source of pollution shall be operated at

capacities beyond the limits of operation or capability of the wastewater treatment

facility in order to maintain the effluent quality within the standards or pertinent

conditions required by law and/or stipulated in the permit to operate.

4. No person shall build, erect, install or use any equipment, contrivance or any

means the use of which will conceal and/or dilute an effluent discharge and which

otherwise constitute a violation of any provisions of these regulations or the 1978

NPCC Rules and Regulations, as amended

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

8

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

✓ Sewerage And Sanitation Provisions (Industrial Hygiene) - Excerpts from DOH

A.O. No. 111, (issued on 22 August 1991)

“e) Disposal of Industrial Wastes. The following requirements shall be complied with:

1 All wastes incident to the operation of the industrial plant shall be collected,

stored or disposed of in a manner that will prevent health hazards, nuisance and

pollution (e.g. settling ponds in the collection of effluents). Where a city or

municipal collection and disposal system exists, it shall be utilized.”

2 All industrial establishments discharging toxic wastes shall submit a copy of the

method of the treatment approved and certified by the EMB to the Department or

its duly authorized representatives

✓ Wastewater Provisions - Excerpts from the National Plumbing Code (1993-1994

Revision)

“Chapter 5 - General Regulations, Instructions and Requirements

Article V - Industrial Wastes

1. Wastes detrimental to the public sewer system or detrimental to the functioning of

the sewage treatment plant shall be treated and disposed of as found necessary and

directed by the Provincial/City/ Municipal Plumbing Official.

2. Sewage or other waste from a plumbing system which may be deleterious to surface

or subsurface waters, shall not be discharged into the ground or in any waterway

unless it has first been rendered innocuous through subjection to some acceptable

form of treatment.”

✓ Clean Water Act - R.A. 9275 - An Act Providing for a Comprehensive Water Quality

Management and for Other Purposes (Approved by President Gloria Macapagal-

Arroyo on 2 March 2004)

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

9

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Why is there for a need for Clean Water Act?

As early as 1996, only about 51% of the classified rivers are in their beneficial use

and met the water quality standards, while the rest are already polluted due to agricultural,

domestic and industrial activities.

Most studies say that about 48% of the principal cause of water pollution is coming

from domestic wastewater. However, the investments for water supply and sanitation that

goes to the sanitation and sewage system only used 3%.

Polluted water contributes 31% to causes of illnesses to Filipinos. It is clear that to

ensure health and safety for the Filipinos in terms of water consumption; it is an obligation

of the government to create and implement strategies to protect water quality.

Government Agencies Involved

• The Philippine Coast Guard shall enforce water quality standards in marine

waters, specifically from offshore sources.

• The Department of Public Works and Highways through its attached agencies

shall provide sewerage and sanitation facilities, and the efficient and safe

collection, treatment and disposal of sewage within their area of jurisdiction.

• The Department of Agriculture shall formulate guidelines for the re-use of

wastewater for irrigation and other agricultural uses and for the prevention, control

and abatement of pollution from agricultural and aquaculture activities.

• The Department of Health shall set, revise and enforce drinking water quality

standards.

• The Department of Science and Technology shall evaluate, verify, develop and

disseminate pollution prevention and cleaner production technologies.

• The Department of Education, Commission on Higher Education,

Department of Interior and Local Government, and the Philippine Information

Agency shall prepare and implement a comprehensive and continuing public

education and information program.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

10

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

DAO – 2016-08: WATER QUALITY GUIDELINES AND

GENERAL EFFLUENT STANDARDS

Pursuant to Section 19e and 19f of the Republic Act (RA) 9275, otherwise known

as the Philippine Clean Water Act of 2004, and Executive Order 192 (Providing the

Reorganization of the Department of Environment, Energy and Natural Resources;

Renaming it as the Department of Environment and Natural Resources) dated 10 June

1987, the Department of Environment and Natural Resources (DENR) hereby adopts and

promulgates these Water Quality Guidelines (WQG) and General Effluent Standards

(GES).

Section 1.0 Basic Policy

It is the policy of the State to pursue a policy of economic growth in a manner

consistent with the protection, preservation and revival of the quality of our fresh, brackish

and marine waters.

Section 3.0 Scope and Coverage

The WQG applies to all water bodies in the country: freshwaters, marine waters

and groundwater, and shall be used for classifying water bodies, determining time trends,

evaluating stages of deterioration or enhancement in water quality, and as basis for taking

positive action in preventing, controlling, or abating water pollution. Moreover, this WQG

shall be used in the process of designating Water Quality Management Area (WQMA).

Section 5.0 Classification of Water Bodies

For purposes of maintaining water quality according to its beneficial usage, the

following classification of water bodies shall be adopted.

Table 1. Water Body Classification and Usage of Freshwater

Classification Intended Beneficial Use

Class AA Public Water Supply Class I – Intended primarily for waters

having watersheds, which are uninhabited and/or otherwise

declared as protected areas, and which require only approved

disinfection to meet the latest PNSDW.

Class A Public Water Supply Class II – intended as sources of water

supply requiring conventional treatment (coagulation,

sedimentation, filtration and disinfection) to meet the latest

PNSDW.

Class B Recreational Water Class I – intended for primary contact

recreation (bathing, swimming, etc)

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

11

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Class C 1. Fishery Water for propagation and growth of fish and

other aquatic resources

2. Recreational Water Class II – for boating, fishing or

similar activities

3. For agriculture, irrigation and livestock watering

Class D Navigable Waters

Note: For unclassified water bodies, classification shall be based on the beneficial use as

determined by the Environmental Management Bureau (EMB).

Table 2. Water Body Classification Usage of Marine Waters

Classification Intended Beneficial Use

Class SA 1. Protected Waters – Waters designated as national or

local marine pars, reserves, sanctuaries and other areas

established by law (Presidential Proclamation 1801 and

other existing laws), and/or declared as such by

appropriate government agency, LGUs, etc.

2. Fishery Water Class I – suitable for shellfish harvesting

for direct human consumption

Class SB 1. Fishery Water Class II – waters suitable for commercial

propagation of shellfish and intended as spawning areas

for milkfish (Chanos chanos) and smilar species

2. Tourist Zones – for ecotourism and recreational activities

3. Recreational Water Class I – intended for primary contact

recreation (bathing, swimming, skin diving, etc.)

Class SC 1. Fishery Water Class III – for propagation and growth of

fish and other aquatic resources intended for commercial

and sustenance fishing

2. Recreational Water Class II – for boating, fishing or

similar activities

3. Marshy and/or mangrove areas declared as fish and

wildlife sanctuaries

Class SD Navigable waters

Note: For unclassified water bodies, classification shall be based on the beneficial use

as determined by the Environmental Management Bureau (EMB).

Section 6.0 Water Quality Guidelines

The rules and regulations established in this section are intended to maintain and

preserve the quality of all water bodies based on their intended beneficial usage and to

prevent and abate pollution and contamination to protect public health, aquatic resources,

crops and other living organisms.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

12

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

6.1 Guidelines for Water Quality (Freshwater and Marine Waters)

The WQG provided for in Tables 3-6 shall be maintained for each water body

classification. For purposes of this Order, the parameters defining the WQG are

categorized as primary or secondary parameters.

Primary parameters (Table 3) are the required minimum water quality parameters

to be monitored for each water body. Secondary parameters (table 4-6) are other water

quality parameters to be used in baseline assessment as part of the Environmental

Impact Assessment and other water quality monitoring purposes as defined in Table 3.1

(Recommended Parameters, Frequency and Duration of Sampling) of Ambient Water

Quality Monitoring Manual issued through EMB Memorandum Circular 2008-008.

Table 3. Water Quality Guidelines for Primary Parameters

Table 4. Water Quality Guidelines for Secondary Parameters - Inorganics

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

13

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Table 5. Water Quality Guidelines for Secondary Parameters – Metals

Table 6. Water Quality Guidelines for Secondary Parameters- Organics

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

14

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Section 7.0 General Effluent Standards

Discharges from any point source at all times meet the effluent standards

set forth in Tables 2-3 to maintain the required water quality per water body

classification. The GES shall be used regardless of the industry category.

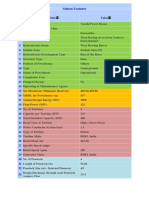

7.1 Significant Effluent Quality Parameters per Sector

For purposes of streamlining compliance and enforcement of the GES, the

significant effluent quality parameters per sector are listed in Table 8.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

15

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

16

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

17

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

18

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

19

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

20

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

21

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

22

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

23

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

24

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

7.2 Effluent Standards

Consistent with the goal of maintaining the quality of water bodies based

on their intended beneficial usages, Table 9 shall be enforced and complied with

at all times.

7.3. Effluent Standards for BOD for Strong Wastewater

For establishments with influent BOD equal to or greater than 3000 mg/L

and the receiving water body is Class C, D, SC or SD, the applicable effluent

standards in Table 10 shall at all times be enforced and complied with.

For parameters other than BOD, Table 9 shall apply.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

25

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

26

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

27

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

CLASSIFICATION OF WASTEWATER TREATMENT METHODS

Wastewater collected from municipalities and communities must ultimately be

returned to receiving waters or to the land or reused. The complex question facing the

design engineer and public health officials is: What levels of treatment must be achieved

in a given application – beyond those prescribed by discharge permits – to ensure

protection of public health and the environment? The answer to this question requires

detailed analyses of local conditions and needs, application of scientific knowledge and

engineering judgement based on past experience, and consideration of federal, state,

and local regulations. In some cases, a detailed risk assessment may be required.

The methods of treatment in which the application of physical forces predominate

are known as unit operations. The methods of treatment in which the removal of

contaminants is brought about by chemical or biological reactions are known as unit

processes. Wastewater treatment methods can be classified into three sub divisions: (A)

physical unit operations, (B) chemical unit processes, and (C) biological unit processes.

A. Physical Unit Operations

Wastewater contains large solids and grit that can interfere with treatment

processes or cause undue mechanical wear and increased maintenance on wastewater

treatment equipment. To minimize potential problems, these materials require the use of

physical unit operations to remove pollutants/contaminants by physical forces. These

physical unit operations serve as preliminary treatment consisting of screening, grit

removal, flow equalization, sedimentation, and flotation.

1. Screening

Screening is the first unit operation used at wastewater treatment plants (WWTPs).

It removes objects such as rags, paper, plastics, and metals to prevent damage and

clogging of downstream equipment, piping, and appurtenances. Some modern

wastewater treatment plants use both coarse screens and fine screens.

Types of Screens

a. Coarse Screens

Coarse screens remove large solids, rags, and

debris from wastewater, and typically have openings of

6 mm (0.25 in) or larger. Types of coarse screens

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

28

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

include mechanically and manually cleaned bar screens, including trash racks.

b. Fine Screens

Fine screens are typically used to remove

material that may create operation and maintenance

problems in downstream processes, particularly in

systems that lack primary treatment. Typical opening

sizes for fine screens are 1.5 to 6 mm (0.06 to 0.25 in).

Very fine screens with openings of 0.2 to 1.5 mm (0.01

to 0.06 in) placed after coarse or fine screens can

reduce suspended solids to levels near those achieved

by primary clarification.

2. Grit Removal

Grit includes sand, gravel, cinder, or other heavy

solid materials that are “heavier” (higher specific

gravity) than the organic biodegradable solids in the

wastewater. Grit also includes eggshells, bone chips,

seeds, coffee grounds, and large organic particles,

such as food waste. Removal of grit prevents

unnecessary abrasion and wear of mechanical

equipment, grit deposition in pipelines and channels,

and accumulation of grit in anaerobic digesters and aeration basins.

3. Flow Equalization

Flow equalization is the process of controlling

hydraulic velocity, or flow rate, through a wastewater

treatment system. The equalization of flow prevents

short term, high volumes of incoming flow, called

surges, from forcing solids and organic material out of

the treatment process. Flow equalization also controls

the flow through each stage of the treatment system,

allowing adequate time for the physical, biological and chemical processes to take place.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

29

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

4. Sedimentation

Sedimentation is a physical water treatment process using gravity to remove

suspended solids from water. Settling basins are ponds constructed for the purpose of

removing entrained solids by sedimentation. Clarifiers are tanks built with mechanical

means for continuous removal of solids being deposited by sedimentation. Settling basins

and clarifiers are designed to retain water so that suspended solids can settle. By

sedimentation principles, the suitable treatment technologies should be chosen

depending on the specific gravity, size and shear resistance of particles.

5. Flotation

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters

by the removal of suspended matter such as oil or solids. The removal is achieved by

dissolving air in the water or wastewater under pressure and then releasing the air at

atmospheric pressure in a flotation tank basin. The released air forms tiny bubbles which

adhere to the suspended matter causing the suspended matter to float to the surface of

the water where it may then be removed by a skimming device.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

30

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

B. Chemical Unit Processes

Chemicals are used during wastewater treatment in an array of processes to

expedite disinfection. These chemical processes, which induce chemical reactions, are

called chemical unit processes, and are used alongside biological and physical cleaning

processes to achieve various water standards.

1. Chemical Coagulation and Flocculation

In water treatment, coagulation occurs when a coagulant is added to water to

"destabilize" colloidal suspensions. In a colloidal suspension, particles will settle very

slowly or not at all because the colloidal particles carry surface electrical charges that

mutually repel each other. A coagulant (typically a metallic salt) with the opposite charge

is added to the water to overcome the repulsive charge and "destabilize" the suspension.

For example, the colloidal particles are negatively charged and alum is added as a

coagulant to create positively charged ions. Once the repulsive charges have been

neutralized (since opposite charges attract), the van der Waals force will cause the

particles to cling together (agglomerate) and form micro floc.

2. Chemical Oxidation

The aim of chemical oxidation is to oxidize organic pollutants to less dangerous or

harmless substances. In the best case scenario, complete oxidization of organic

substances will result in CO2 and H2O. This technique can also be used to remove

inorganic components (e.g. oxidization of cyanide). Chemical oxidization can also be

used in combination with biological purification. In this case, we refer to partial oxidization.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

31

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

The purpose of chemical oxidization as a pre-treatment technique is to either break down

difficult to degrade components and make them suitable for biological degradation or to

limit sludge production by partly oxidizing the sludge. Chemical oxidization involves

adding or generating oxidants in the wastewater. A few currently used oxidants include

ozone (O3), hydrogen peroxide (H2O2), natrium hypochlorite or bleaching liquor (NaOCl),

chlorine dioxide (ClO2), chlorine gas (Cl2), peroxyacetic acid (C2H4O3) and pure oxygen

(O2).

3. Ion Exchange

An ion-exchange process can be used

to soften the water. Calcium and magnesium

are common ions that lead to water hardness.

To soften the water, positively charged sodium

ions are introduced in the form of dissolved

sodium chloride salt, or brine. Hard calcium

and magnesium ions exchange places with

sodium ions, and free sodium ions are simply

released in the water. However, after softening

a large amount of water, the softening solution

may fill with excess calcium and magnesium

ions, requiring the solution be recharged with

sodium ions.

4. Ozone and Ultraviolet Disinfection

Ozone is an unstable gas comprising of three oxygen atoms, the gas will readily

degrade back to oxygen, and during this transition a free oxygen atom, or free radical

form. The free oxygen radical is highly reactive and short lived, under normal conditions

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

32

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

it will only survive for milliseconds. The raw water is then passed through a venturi throat

which creates a vacuum and pulls the ozone gas into the water or the air is then bubbled

up through the water being treated. Since the ozone will react with metals to create

insoluble metal oxides, post filtration is required.

Ultraviolet disinfection is a physical process that instantaneously neutralizes

microorganisms as they pass by ultraviolet lamps submerged in the effluent. The process

adds nothing to the water but UV light, and therefore, has no impact on the chemical

composition or the dissolved oxygen content of the water.

C. Biological Unit Processes

Biological wastewater treatment is a process that seems simple on the surface

since it uses natural processes to help with the decomposition of organic substances, but

in fact, it is a complex process at the intersection of biology and biochemistry — a process

not completely understood. Biological treatments rely on bacteria, nematodes, or other

small organisms to break down organic wastes using normal cellular processes.

Wastewater typically contains a buffet of organic matter, such as garbage, wastes, and

partially digested foods. It may also contain pathogenic organisms, heavy metals, and

toxins. The goal of biological wastewater treatment is creating a system in which the

decomposition results are easily collected for proper disposal.

1. Activated Sludge Process

This is the most common and oldest biotreatment process used to treat municipal

and industrial wastewater. Typically wastewater after primary treatment i.e. suspended

impurities removal is treated in an activated sludge process based biological treatment

system comprising aeration tank followed by secondary clarifier. The aeration tank is a

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

33

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

completely mixed bioreactor where specific concentration of biomass (measured as

mixed liquor suspended solids (MLSS) or mixed liquor volatile suspended solids

(MLVSS)) is maintained along with sufficient dissolved oxygen (DO) concentration

(typically 2 mg/l) to effect biodegradation of soluble organic impurities measured as

biochemical oxygen demand (BOD5) or chemical oxygen demand (COD).

2. Trickling Filters

A trickling filter is a type of wastewater

treatment system which consists of a fixed bed of

rocks, lava, coke, gravel, slag, polyurethane

foam, sphagnum peat moss, ceramic, or plastic

media over which sewage or other wastewater

flows downward and causes a layer of microbial

slime (biofilm) to grow, covering the bed of media.

Aerobic conditions are maintained by splashing,

diffusion, and either by forced-air flowing through

the bed or natural convection of air if the filter medium is porous.

The bio-film that develops in a trickling filter may become several millimetres thick

and is typically a gelatinous matrix that contains many species of bacteria, cilliates and

amoeboid protozoa, annelids, round worms and insect larvae and many other micro

fauna. This is very different from many other bio-films which may be less than 1 mm thick.

Within the thickness of the biofilm both aerobic and anaerobic zones can exist supporting

both oxidative and reductive biological processes.

3. Anaerobic Digestion

Anaerobic digestion is a collection of

processes by which microorganisms break down

biodegradable material in the absence of oxygen. The

process is used for industrial or domestic purposes to

manage waste or to produce fuels. Much of the

fermentation used industrially to produce food and

drink products, as well as home fermentation, uses

anaerobic digestion.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

34

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

SELECTION OF TREATMENT PROCESS FLOW DIAGRAMS

Factors Influencing Process Selection

The design of treatment facilities will be determined by feasibility studies,

considering all engineering, economic, energy and environmental factors. All legitimate

alternatives will be identified and evaluated by life cycle cost analyses. Additionally,

energy use between candidate processes will be considered. For the purpose of energy

consumption, only the energy purchased or procured will be included in the usage

evaluation.

• Contaminant Removal

Contaminant removal is the principal purpose of treatment for many source

waters, particularly surface waters. The quality of treated water must meet all current

water regulations.

• Source Water Quality

A comparison of source water quality and the desired finished water quality is

essential for treatment process selection. With the knowledge of the changes in water

quality that must be attained, the engineer can identify one or more treatment

processes that would be capable of attaining the quality improvement.

• Reliability

Process reliability is an important consideration and, in some cases, could be

a key aspect in deciding which process to select. Disinfection of surface water is

mandatory, so this is an example of a treatment process that should be essentially

fail-safe (Logsdon et al., 1999).

Unless the treatment plant can be taken out of service for a period of time for

maintenance and repair work, two or more of all essential items, such as pumps,

settling basins, flocculators, filters, and chemical feeders must be provided. The

degree of importance of each item must be evaluated on a case-by-case basis,

considering that safe water has to be supplied at all times (Technical Manual, 1985).

• Existing Conditions

The choice of processes to incorporate into a treatment train may be influenced

strongly by the existing processes when a treatment plant is evaluated for upgrading

or expanding. Site constraints may be crucial in process selection, especially in pre-

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

35

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

treatment when alternative clarification processes are available, some of which require

only a small fraction of the space needed for a conventional settling basin.

Hydraulic constraints can be important when retrofitting plantswith ozone or

granular activated carbon (GAC) adsorption. The extra head needed for some

treatment processes could result in the necessity for boosterpumping on-site to

accommodate the hydraulic requirements of the process. This adds to the overall cost

of the plant improvements and, in some cases, mightresult in a different process being

selected.

• Process Flexibility

The ability of a water treatment plant to accommodate changes in future

regulations or changes in source water quality is quite important. In the present

regulatory environment, water utilities must realize that more regulations are likely in

the future.

For some utilities, these future regulations may require additional treatment or

more effective treatment, such as when a previously unregulated contaminant is

present in the source water or a maximum contaminant level is lowered for a

contaminant in the utility’s source water.

• Utility Capabilities

After treatment processes are selected, designed, and on-line, the water utility

must be able to operate them successfully to attain the desired water quality. The

issue of system size versus treatment complexity becomes important with smaller

systems.

If successful treatment plant operation requires more labor than a small system

can afford, or if the level of technical skills exceeds that readily attainable in a

community, treatment failure may occur. Availability and access to service and repair

of equipment involves considerations of time and distance from service

representatives, and this may be problematic for some small, very remote water

utilities.

• Costs

Cost considerations usually are a key factor in process selection. Evaluation of

costs for alternative process trains using principles of engineering economics might at

first seem to be straightforward, but this may not be the case. When different treatment

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

36

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

trains are evaluated, their capabilities are not likely to be identical, so the resulting

treated-water quality from different trains likewise may not be identical.

• Environmental Compatibility

Environmental compatibility issues cover a broad spectrum of concerns that

include residual waste management, the fraction of source water wasted in treatment

processes, and energy requirements for treatment. The effect of water treatment

extends beyond the treatment plant. The benefits of providing safe drinking water are

very great, but caution must be taken that the treatment processes selected to provide

that safe water do not create serious environmental problems.

WASTEWATER TREATMENT PROCESS SELECTION:

An Industrial Approach

When an aqueous waste from an industrial process must be treated in order to

achieve prescribed consent limits prior to discharge, biological treatment processes are

often preferred because they are relatively inexpensive and simple to operate.

This paper illustrates the selection procedure by means of a case study that

applies established designed methods in order to evaluate the various options. The basic

steps in the procedure, some of which may be carried out in parallel, are as follows.

1. Quantify the waste effluent, or treatment

plant influent, with respect to physical,

chemical and biological properties.

2. Identify any aspects of site operation likely

to affect the quantity and composition of

the waste, such as sources of possible

contaminants, particularly pathogens or

ionic components which may prove toxic to

the biological solids, topology of plant

drains, frequency and duration of

shutdowns. These operational aspects

may have an important bearing on both the

treatment process and effluent

pretreatment process, if any.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

37

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

3. Carry out an experimental treatability study to determine the biodegradability

parameters of the waste. This step will be essential if reliable kinetic data, e.g. from

the literature, are not available.

4. Determine concentration, flow,

temperature and pH of the waste

and the variability of these, at

least with respect to average,

maximum and minimum values.

The variations may be

particularly significant if the

waste effluent is produced during

the cycle of a batch process.

5. Short-list possible treatment options. The initial selection should consider both

operability and process control requirements and the proximity of residential or

other inhabited areas, which would necessitate avoidance of mist, odours, noise

and visual pollution.

6. Carry out preliminary design and costings in order to identify the final preferred

option. The evaluation must include waste solids treatment and disposal, which

may be the single most expensive step in the whole treatment process. Landfill or

land injection may be the most suitable means of sludge disposal, provided that all

potential ground water contaminants or substances toxic to soil organisms are

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

38

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

removed from the waste sludge prior to disposal. Other sludge disposal options,

such as incineration or gasification, may be preferable because they may achieve

utilities cost savings, by means of energy recovery.

7. If appropriate, use the preliminary evaluation to decide between two of the most

basic waste treatment strategies partially treating the waste and paying for final

treatment by a publicly owned treatment works (POTW) vs. the cost of treating the

waste wholly on site to achieve final consent limits. The following case study

illustrates the procedure, with respect to treatment of an aqueous effluent from a

batch speciality chemicals process.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

39

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

REFERENCES

Davis, M. L. (2010). Drinking Water Plant Process Selection and Integration. Water and

Wastewater Engineering (pp. 16-2-16-10). McGraw-Hill Companies, Inc. Retrieved

on December 10, 2017.

Magtibay, B. B. (2006). Philippine Regulations on Sanitation and Wastewater Systems

(International Edition). Biosphere Environment and Health Systems Series (Volume

2).

Veenstra, S., Alaerts, G. J., & Bijlsma, M. (1997). Chapter 3 - Technology Selection. In

R. Helmer & I. Hespanhol (Eds.). Water Pollution Control - A Guide to the Use of

Water Quality Management Principles. E. & F. Spon. Retrieved from

http://www.who.int/water_sanitation_health/resourcesquality/ wpcchap3.pdf on

December 10, 2017.

Wastewater Treatment Objectives, Methods and Implementation Considerations

A.C.Santos, M.M.Sarmiento, B.A.Sison

40

Potrebbero piacerti anche

- Sewage Treatment PlantDocumento3 pagineSewage Treatment PlantPranshu Singh BirthalNessuna valutazione finora

- Appraisal of JnNURM Final Report Volume IIDocumento316 pagineAppraisal of JnNURM Final Report Volume IIpriyasankar7Nessuna valutazione finora

- On Master Plan - UdhampurDocumento29 pagineOn Master Plan - UdhampurAbhishekPalit50% (2)

- Process Management of Membrane Filtration SystemsDocumento2 pagineProcess Management of Membrane Filtration SystemsNur Hazirah Sadon100% (1)

- Guheshwori Wastewater Treatment Plant PDFDocumento16 pagineGuheshwori Wastewater Treatment Plant PDFRabindra RayNessuna valutazione finora

- Water Resources Engineering-IIDocumento3 pagineWater Resources Engineering-IIJitenderGoyal100% (1)

- Action Plan For Rejuvenation of River Tunga 1Documento11 pagineAction Plan For Rejuvenation of River Tunga 1anitha_mathanNessuna valutazione finora

- PWD IrrigationDocumento98 paginePWD IrrigationVijaykumar D S100% (1)

- Inventory of Flood Bund PunjabDocumento26 pagineInventory of Flood Bund PunjabguildkeyNessuna valutazione finora

- Water Distribution: Water Resources in IndiaDocumento8 pagineWater Distribution: Water Resources in India2274707Nessuna valutazione finora

- DM PlantDocumento8 pagineDM Plantvimalsoni2212Nessuna valutazione finora

- IIT Lecture Notes On HydropowerDocumento26 pagineIIT Lecture Notes On HydropowerSandip Nepal Uprety100% (1)

- SWM DPRDocumento236 pagineSWM DPRHarsha Vardhan SNessuna valutazione finora

- NWRB Iloilo GMPDocumento92 pagineNWRB Iloilo GMPMae Ann GonzalesNessuna valutazione finora

- Higher Education in Rajasthan A Quite Revolution PDFDocumento90 pagineHigher Education in Rajasthan A Quite Revolution PDFBala VishnuNessuna valutazione finora

- IS 9120 - Guidelines For Planning Layout and Design of Cavities in Underground Hydroelectric Power Stations PDFDocumento22 pagineIS 9120 - Guidelines For Planning Layout and Design of Cavities in Underground Hydroelectric Power Stations PDFthavisiNessuna valutazione finora

- CE6503 Environmental Engineering IDocumento16 pagineCE6503 Environmental Engineering Isree1072100% (1)

- DrVinitha DhupkarDocumento35 pagineDrVinitha DhupkarBajibabu ProdduturiNessuna valutazione finora

- Environmental Microbiology: Advanced Research and Multidisciplinary ApplicationsDa EverandEnvironmental Microbiology: Advanced Research and Multidisciplinary ApplicationsNessuna valutazione finora

- Sewerage Design Manual 2013 India PDFDocumento976 pagineSewerage Design Manual 2013 India PDFMd Muneer PashaNessuna valutazione finora

- Irrigation Drainage and River Engineering PDFDocumento26 pagineIrrigation Drainage and River Engineering PDFAlvaro Gamboa Pretel100% (1)

- Project Report On STPDocumento24 pagineProject Report On STPRinku SinghNessuna valutazione finora

- Thesis-Comparative Chemometric Studies of Water Quality Parameters of Drinking Underground Water of Rural & Urban Areas of District Jind, HaryanaDocumento258 pagineThesis-Comparative Chemometric Studies of Water Quality Parameters of Drinking Underground Water of Rural & Urban Areas of District Jind, HaryanaIndicum researchNessuna valutazione finora

- Micro Irrigation Report PDFDocumento84 pagineMicro Irrigation Report PDFठाकुर प्रशान्त सिंहNessuna valutazione finora

- Ashebir Kebede PDFDocumento87 pagineAshebir Kebede PDFashe zinabNessuna valutazione finora

- Course Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungDocumento50 pagineCourse Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungAnnisa MaulinaNessuna valutazione finora

- Sanitary Engineer II: Passbooks Study GuideDa EverandSanitary Engineer II: Passbooks Study GuideNessuna valutazione finora

- Operation & Maintenance Manual (O&M) OF Package Water Treatment Plant (PWTP)Documento16 pagineOperation & Maintenance Manual (O&M) OF Package Water Treatment Plant (PWTP)Ashish Nair100% (1)

- Salient FeaturesDocumento3 pagineSalient FeaturesAnonymous ESZmDGNessuna valutazione finora

- Inception Report 08-10-2015Documento39 pagineInception Report 08-10-2015Dananjaya Rajapakse100% (1)

- Variable Speed OperationDocumento10 pagineVariable Speed Operationmunagala balasubramanyamNessuna valutazione finora

- A Review Paper of Automatic Canal Gate Control of 3-° Induction Motor With PLC and VFD, Powered by Solar System and Monitoring by SCADADocumento8 pagineA Review Paper of Automatic Canal Gate Control of 3-° Induction Motor With PLC and VFD, Powered by Solar System and Monitoring by SCADAAbhay SehgalNessuna valutazione finora

- Water EngineeringDocumento10 pagineWater EngineeringdandewjangerNessuna valutazione finora

- Syllabi M.Tech. WRDMDocumento114 pagineSyllabi M.Tech. WRDMMadhab KoiralaNessuna valutazione finora

- Water Distribution Systems: Dr. MB. Samarakoon Department of Civil Engineering KDUDocumento72 pagineWater Distribution Systems: Dr. MB. Samarakoon Department of Civil Engineering KDUthareendaNessuna valutazione finora

- Sewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDocumento38 pagineSewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDhruv MudgalNessuna valutazione finora

- 14 Water BangladeshDocumento14 pagine14 Water BangladeshA S M Hefzul KabirNessuna valutazione finora

- Bike Wash ETP OfferDocumento11 pagineBike Wash ETP OfferMuhammadHanifaNessuna valutazione finora

- Assignment QuestionsDocumento5 pagineAssignment QuestionsKinson Prabu100% (2)

- Complete Syllabus Mechanical-MinDocumento191 pagineComplete Syllabus Mechanical-MinSalman Mohd HNessuna valutazione finora

- River Tapi Rejuvenation - Elevating The Ecological Corridor of SurDocumento59 pagineRiver Tapi Rejuvenation - Elevating The Ecological Corridor of SurLabdhi ShahNessuna valutazione finora

- Reclying of Waste WaterDocumento24 pagineReclying of Waste WaterYogendra PatilNessuna valutazione finora

- SedimentationDocumento37 pagineSedimentationanon_281065744Nessuna valutazione finora

- Crop Water ManegmentDocumento10 pagineCrop Water ManegmentayeshaNessuna valutazione finora

- Idamalayar Inflow OutflowDocumento12 pagineIdamalayar Inflow OutflowkarthiiasNessuna valutazione finora

- Designing of Load Response Generation Synchronized 15MW Hydropower Station and Simulation Based Electromechanical and Structural AnalysisDocumento17 pagineDesigning of Load Response Generation Synchronized 15MW Hydropower Station and Simulation Based Electromechanical and Structural AnalysismilanNessuna valutazione finora

- Urban Sector and Water Supply and Sanitation in BangladeshDocumento154 pagineUrban Sector and Water Supply and Sanitation in BangladeshIndependent Evaluation at Asian Development BankNessuna valutazione finora

- Design of Dual Media Filters To Suit Existing Water Treatment Plants in IndiaDocumento5 pagineDesign of Dual Media Filters To Suit Existing Water Treatment Plants in IndiareinpolyNessuna valutazione finora

- Conservation of Ousteri Lake in Puducherry Draft Comprehensive Management Action Plan SACON 2011 PDFDocumento118 pagineConservation of Ousteri Lake in Puducherry Draft Comprehensive Management Action Plan SACON 2011 PDFvaishnavi sivaramakrishnanNessuna valutazione finora

- A Review of Artificial Intelligence in ChemicalDocumento3 pagineA Review of Artificial Intelligence in ChemicalOsama AdlyNessuna valutazione finora

- May June July 2021Documento36 pagineMay June July 2021rammvr05Nessuna valutazione finora

- Government of Madhya Prades1Documento77 pagineGovernment of Madhya Prades1gourav.imsNessuna valutazione finora

- WaterDocumento6 pagineWaterAbhishek KumarNessuna valutazione finora

- Design of Rural Water Supply System Using Loop 4.0Documento9 pagineDesign of Rural Water Supply System Using Loop 4.0LuisAtocheGanozaNessuna valutazione finora

- Spring 4Documento10 pagineSpring 4Sai SudarsanamNessuna valutazione finora

- Solar Water Pumping: An Overview: The Green MantraDocumento13 pagineSolar Water Pumping: An Overview: The Green MantraAmit JoshiNessuna valutazione finora

- 5 A Surface Irrigation System PDFDocumento65 pagine5 A Surface Irrigation System PDFsewmehon amareNessuna valutazione finora

- AGR558 Lab Drip Irrigation SystemDocumento3 pagineAGR558 Lab Drip Irrigation SystemNoor Syazwan NasirNessuna valutazione finora

- LeachingDocumento24 pagineLeachingBren SisonNessuna valutazione finora

- Mathcad PDFDocumento14 pagineMathcad PDFBren SisonNessuna valutazione finora

- Laws and Contracts For Chemical Engineers: Origin, Nature, and Development of Law and ContractDocumento1 paginaLaws and Contracts For Chemical Engineers: Origin, Nature, and Development of Law and ContractBren SisonNessuna valutazione finora

- Methodology: Pamantasan NG Lungsod NG MaynilaDocumento3 pagineMethodology: Pamantasan NG Lungsod NG MaynilaBren SisonNessuna valutazione finora

- Basic Concepts Of: MicrobiologyDocumento29 pagineBasic Concepts Of: MicrobiologyBren SisonNessuna valutazione finora

- Particleboard Based On Rice Husk: Effect of Binder Content and Processing ConditionsDocumento6 pagineParticleboard Based On Rice Husk: Effect of Binder Content and Processing ConditionsBren SisonNessuna valutazione finora

- The Field of Engineering ManagementDocumento27 pagineThe Field of Engineering ManagementBren SisonNessuna valutazione finora

- CPI Topic OutlineDocumento2 pagineCPI Topic OutlineBren SisonNessuna valutazione finora

- Religions: Catholic Social Teaching On Building A Just Society: The Need For A Ceiling and A FloorDocumento11 pagineReligions: Catholic Social Teaching On Building A Just Society: The Need For A Ceiling and A FloorBren SisonNessuna valutazione finora

- Process Engineering Center: Job DescriptionDocumento1 paginaProcess Engineering Center: Job DescriptionBren SisonNessuna valutazione finora

- TG No. 4 Kiln Drying of RattanDocumento20 pagineTG No. 4 Kiln Drying of RattanBren SisonNessuna valutazione finora

- 92135-233797-1-PBDocumento9 pagine92135-233797-1-PBBren SisonNessuna valutazione finora

- Pharmaceutical IndustryDocumento67 paginePharmaceutical IndustryBren SisonNessuna valutazione finora

- Related Literature and Studies 1Documento22 pagineRelated Literature and Studies 1Bren SisonNessuna valutazione finora

- Expt 9Documento17 pagineExpt 9Bren SisonNessuna valutazione finora

- TestingDocumento1 paginaTestingBren SisonNessuna valutazione finora

- Emergencies Emergency Escape Route Assignments Employees EmployeesDocumento1 paginaEmergencies Emergency Escape Route Assignments Employees EmployeesBren SisonNessuna valutazione finora

- Air Conditioning EquipmentDocumento28 pagineAir Conditioning EquipmentBren SisonNessuna valutazione finora

- Pumps, Fans, Blowers, and CompressorsDocumento68 paginePumps, Fans, Blowers, and CompressorsBren SisonNessuna valutazione finora

- How To Write Chapter 3 & 4Documento35 pagineHow To Write Chapter 3 & 4Bren SisonNessuna valutazione finora

- Formal Lab Report 2Documento4 pagineFormal Lab Report 2Bren SisonNessuna valutazione finora

- Formal Lab ReportDocumento4 pagineFormal Lab ReportBren SisonNessuna valutazione finora

- Ceramic IndustryDocumento54 pagineCeramic IndustryBren SisonNessuna valutazione finora

- Pulp and Paper Industry PDFDocumento56 paginePulp and Paper Industry PDFBren SisonNessuna valutazione finora

- Strengthening MechanismsDocumento21 pagineStrengthening MechanismsBren SisonNessuna valutazione finora

- Starch and Flour IndustryDocumento39 pagineStarch and Flour IndustryBren SisonNessuna valutazione finora

- Brochure by-Pass-Units 20160216 enDocumento36 pagineBrochure by-Pass-Units 20160216 enHOryshorNessuna valutazione finora

- Lesson 14 WelderQuals - New2Documento80 pagineLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Triangle VI SpecificationsDocumento3 pagineTriangle VI Specificationscivil.jdriveroincNessuna valutazione finora

- Mastertop TC 405 W PDFDocumento3 pagineMastertop TC 405 W PDFFrancois-Nessuna valutazione finora

- Exercise 2.1 Concepts of MatterDocumento3 pagineExercise 2.1 Concepts of MatterKesuma DewiNessuna valutazione finora

- SCHNEIDER Flusarc 36 36kV Gas Insulated - enDocumento72 pagineSCHNEIDER Flusarc 36 36kV Gas Insulated - enjopsesNessuna valutazione finora

- Structural Testing of Steel Fibre Reinforced Concrete Tunnel Lining Segments in SingaporeDocumento17 pagineStructural Testing of Steel Fibre Reinforced Concrete Tunnel Lining Segments in Singaporethauwui86Nessuna valutazione finora

- Advanced Cleaning Product Formulations Volume5Documento255 pagineAdvanced Cleaning Product Formulations Volume5joe89% (35)

- Repair Procedure Slug CatcherDocumento4 pagineRepair Procedure Slug Catchershabbir626100% (1)

- ACI - 2019 Arabic - p490-521Documento32 pagineACI - 2019 Arabic - p490-521Mustafa Al-QawasmehNessuna valutazione finora

- Vane Test 1Documento4 pagineVane Test 1Pompy JoeNessuna valutazione finora

- TPM BasicDocumento14 pagineTPM Basicsweety1188Nessuna valutazione finora

- Weld Inspection SolutionsDocumento1 paginaWeld Inspection SolutionsElyJoaquinMalbuesoNessuna valutazione finora

- Stoody 104Documento1 paginaStoody 104JUAN DAVID ESPITIANessuna valutazione finora

- 5.1 - TD Interphase Spacer Cat TD-IPS - March 2009Documento5 pagine5.1 - TD Interphase Spacer Cat TD-IPS - March 2009Siddique AhmedNessuna valutazione finora

- QCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022Documento2 pagineQCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022Ravi TyagiNessuna valutazione finora

- Honeywell 221508a Modutrol IV Resistor BoardDocumento2 pagineHoneywell 221508a Modutrol IV Resistor BoardFeli AlcoserNessuna valutazione finora

- CEM-1206S Datasheet - Magnetic Buzzer - CUI Inc PDFDocumento5 pagineCEM-1206S Datasheet - Magnetic Buzzer - CUI Inc PDFLUDWINGNessuna valutazione finora

- SSDocumento10 pagineSSPrakash KaleNessuna valutazione finora

- WDFDocumento18 pagineWDFJose OrtizNessuna valutazione finora

- JISDocumento30 pagineJISImam SalehNessuna valutazione finora

- Optitome 15: Automatic Oxyacetylene and Plasma-Arc Cutting EquipmentDocumento8 pagineOptitome 15: Automatic Oxyacetylene and Plasma-Arc Cutting EquipmentFlamur HasaniNessuna valutazione finora

- Cswip 3.2 Notes 1Documento42 pagineCswip 3.2 Notes 1Sisira Chandrasoma100% (7)

- Pedestrian Cable-Stayed Bridge Project: Ce 491C - Senior Design SPRING 2000Documento35 paginePedestrian Cable-Stayed Bridge Project: Ce 491C - Senior Design SPRING 2000Ing Manolo HernandezNessuna valutazione finora

- Armstrong - Humidification Handbook PDFDocumento40 pagineArmstrong - Humidification Handbook PDFJawwadTariqNessuna valutazione finora

- FM5178R6 TBM Series EnglishDocumento2 pagineFM5178R6 TBM Series EnglishalejgonzNessuna valutazione finora

- Rate AnalysisDocumento9 pagineRate AnalysisRajesh JujareNessuna valutazione finora

- Transmission BibleDocumento10 pagineTransmission BibleSoham DeNessuna valutazione finora

- Aquaplus - PRINSDocumento18 pagineAquaplus - PRINSمحمود الديبNessuna valutazione finora

- Hazardous Area Motors Low PDFDocumento12 pagineHazardous Area Motors Low PDFreji_kNessuna valutazione finora