Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Replacing The Heating Element: No.A1321 (900M - 900L - 907 - 908 - 913 - 914 - 951 - 952)

Caricato da

navin agarwalTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Replacing The Heating Element: No.A1321 (900M - 900L - 907 - 908 - 913 - 914 - 951 - 952)

Caricato da

navin agarwalCopyright:

Formati disponibili

No.

A1321

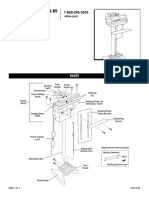

No.A1321(900M • 900L • 907 • 908 • 913 • 914 • 951 • 952 )

Replacing the Heating Element

■ 900M/L ■ 907/908/913/914 ■ 951/952

Nut Tip Enclosure Tip Nipple

Nut Tip Enclosure Tip Nipple Grounding Spring

Grounding

Glass Tube Heating Element Leads (Red) Spring

Sleeve Handle

Sleeve

Grounding Spring Heating Element Terminal Board Handle Heating Element Glass Tube Terminal Board

*HAKKO 913 and 914 are different from HAKKO 907 and 908 in shape of the handle.

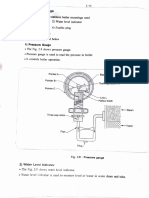

1 Checking the heating element Tip

Adjusting

1. Remove the nut, tip enclosure, tip and nipple. 1 Checking the heating element Screw Tip Enclosure

CAUTION Be sure to remove the nut before removing the 1. Remove the nut, tip enclosure, tip and nipple.

nipple. Removing the nipple first could cause the Support Fitting

CAUTION Be sure to remove the nut before removing the Nut

heater leads to twist and cause a short-circuit.

nipple. Removing the nipple first could cause the

2. Push the cord asse’y in the direction of the tip and heater leads to twist and cause a short-circuit. 1 Checking the heating element

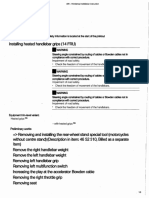

remove the terminal board from the handle. For 900M- 2. Push the cord asse’y in the direction of the tip and 1. Remove the adjusting screw and keep the support fitting

ESD/900L-ESD, move the terminal tube if it is covered remove the terminal board from the handle. apart from the housing.

with the tube. 3. Remove the grounding spring from the sleeve. CAUTION Be sure to remove the nut before removing the

3. Remove the grounding spring from the sleeve. 4. Measure the resistance values at the sensor and heating nipple. Removing the nipple first could cause the

4. Measure the resistance values at the sensor and heating element of the terminal board in normal condition. heater leads to twist and cause a short-circuit.

element of the terminal board in normal condition. 2. Remove the four screws

Resistance value of heating element (red) 2.5–3.5Ω

Resistance value of sensor (blue) 43–58Ω

securing the housing

Resistance value of heating element (red) 2.5–3.5Ω and open the housing.

Resistance value of sensor (blue) 43–58Ω If the value you get is outside this range, replace the heating element.

If the resistance value is normal, the cord asse’y may be broken. 3. Remove the grounding Resistance Resistance

If the value you get is outside this range, replace the heating element.

spring from the sleeve. Value of Value of

If the resistance value is normal, the cord asse’y may be broken. Resistance Value Resistance Value Heating Element

of Heating Element of Sensor

4. Measure the resistance Sensor

Resistance Value Resistance Value

of Heating Element of Sensor

values at the sensor and heating element of the

terminal board in normal condition.

Resistance value of heating element (red) 2.5–3.5Ω

Heating Element Leads (Red)

Resistance value of sensor (blue) 43–58Ω

Sensor Leads (Blue) If the value you get is outside this range, replace the heating element.

If the resistance value is normal, the cord asse’y may be broken.

2 Replacing the heating element 2 Replacing the heating element

1. Desolder the heating element leads and sensor leads. 1. Desolder the heating element leads and sensor leads. 2 Replacing the heating element

2. Remove the old heating element and replace it with a new 2. Remove the old heating element and replace it with a new 1. Desolder the heating element leads and sensor leads.

one. one. 2. Remove the old heating element and replace it with a new

3. Bend the leads at right angle. 3. Bend the leads at right angle. one.

4. Pass the leads through the terminal, push the lead down 4. Pass the leads through the terminal, push the lead down 3. Bend the leads at right angle.

inside the terminal board, then solder it. Be sure that the inside the terminal board, then solder it. Be sure that the 4. Pass the leads through the terminal, push the lead down

insulation covering the lead is long enough to leave NO insulation covering the lead is long enough to leave NO inside the terminal

board, then solder it. Be

exposed wire. Cut the wire to leave no more than 1 to exposed wire. Cut the wire to leave no more than 1 to

sure that the insulation

2mm from the solder joint. Move the tube back to its 2mm from the solder joint. covering the lead is long

original position for ESD safe type. • Solder in the joints must be visible from both sides of enough to leave NO exposed Bend at right angle.

• Solder in the joints must be visible from both sides of the terminal board. wire. Cut the wire to leave

64mm

the terminal board. • There is no polarity between leads of the same colors. no more than 1 to 2mm (2.52in)

• There is no polarity between leads of the same colors. Red from the solder joint.

Heating

Red • Solder in the joints must element lead

64mm (2.52in)

64mm (2.52in)

be visible from both sides

of the terminal board.

Straighten the tube. • There is no polarity between leads of the same colors.

Heating

Bend at right angle. Bend at right angle. element

Straighten the tube.

Heating

element

lead 3 Inspection after replacement

lead

3 Inspection after replacement and reassemble

3 Inspection after replacement After replacing the heating element,

and reassemble

and reassemble 1. Measure the resistance value between pins 4 & 1 and 4 &

After replacing the heating element, 2, and pins 5 & 1 and 5 & 2. If it is not infinite, the

After replacing the heating element,

1. Measure the resistance value between pins 4 & 1 and 4 & heating element and sensor are touching.

1. Measure the resistance value between pins 4 & 1 and 4 & 2. Measure the resistance value ‘a’, ‘b’, and ‘c’ to confirm

2, and pins 5 & 1 and 5 & 2. If it is not infinite, the

2, and pins 5 & 1 and 5 & 2. If it is not infinite, the that the leads are not twisted and that the

heating element and sensor are touching.

heating element and sensor are touching. grounding spring is properly connected. 3

2. Measure the resistance value ‘a’, ‘b’, and ‘c’ to confirm

2. Measure the resistance value ‘a’, ‘b’, and ‘c’ to confirm 4

that the leads are not twisted and that the a Between pins 4 & 5 (Heating Element) 2.5 - 3.5Ω (Normal) 2

that the leads are not twisted and that the b Between pins 1 & 2 (Sensor) 43 - 58Ω (Normal)

grounding spring is properly connected. 3

grounding spring is properly connected. 3 c Between pin 3 & Tip Under 2Ω 1

5

a Between pins 4 & 5 (Heating Element) 2.5 - 3.5Ω (Normal) 4

a Between pins 4 & 5 (Heating Element) 2.5 - 3.5Ω (Normal) 2

4 2 b Between pins 1 & 2 (Sensor) 43 - 58Ω (Normal) CAUTION

b Between pins 1 & 2 (Sensor) 43 - 58Ω (Normal) c Between pin 3 & Tip Under 2Ω

c Between pin 3 & Tip Under 2Ω 5 1 When reassembling, match the

5 1 convex part of the hexagon nut to

concave part of the housing.

4 Recalibrate the temperature Hexagon nut M4

To ensure accurate soldering temperatures, always calibrate the temperature after replacing the heating element. NOTE When repairs are needed, please send both the soldering iron and

Connect your iron/gun to the station for calibration. the station to your sales agent.

For HAKKO 927 • 937 * Specifications subject to change without notice.

For HAKKO 926 • 928 • 936 • 700 • 701• 702 • 702B ®

1. Set the temperature control knob to 400°C (750°F). 1. Turn the power switch on and insert the card. Set the

2. Turn the power switch on and wait until the L.E.D. heater temperature to 400°C (750°F).

lamp comes on and off. 2. Wait until the digital display indicates a tip temperature of HEAD OFFICE

4-5, SHIOKUSA 2-CHOME, NANIWA-KU, OSAKA, 556-0024 JAPAN

3. Using a straight-edge (–) or small cross point 400°C (750°F). TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

http://www.hakko.com

screwdriver, adjust the temperature calibrator (marked 3. Using a straight-edge (–) or small cross point screw- OVERSEAS AFFILIATES INDONESIA: P.T. HAKKO PRODUCTSTAMA INDONESIA.

U.S.A.: AMERICAN HAKKO PRODUCTS, INC. TEL: (778)457-459 FAX: (778)452-772

“CAL”) so that the tip temperature is 400°C (750°F). driver, adjust the temperature calibrator (marked “CAL”) TEL: (661) 294-0090 FAX: (661) 294-0096 P.T. HAKKO PRODUCTSTAMA INDONESIA

TEL: (21)532-4083 FAX: (21)532-4082

Toll Free (800)88-HAKKO

so that the tip temperature is 400°C (750°F). 4 2 5 5 6

http://www.hakkousa.com

HONG KONG: HAKKO DEVELOPMENT CO., LTD.

TEL: 2811-5588 FAX: 2590-0217

S'PORE: HAKKO PRODUCTS PTE., LTD. http://www.hakko.com.hk/

TEL: 748-2277 FAX: 744-0033

* Turn the temperature calibrator clockwise to increase the temperature and counterclockwise to reduce the temperature. MALAYSIA: HAKKO PRODUCTS SDN BHD

CHINA: HAKKO DEVELOPMENT CO., LTD.

TEL: (020)8135-0112, 8135-0113 FAX: (020)8135-0181

MALAYSIA HEAD OFFICE: PETALING JAYA

* Using the supplied hex wrench, remove the screw (M4×5mm) labeled “CAL” on the bottom of the station, and then turn the power on (HAKKO 927). TEL: (03)519-5223 FAX: (03)519-5221

TAIWAN: HAKKO DEVELOPMENT CO., LTD.

TEL: (02)2975-2600 FAX: (02)2973-9565

PENANG BRANCH: TEL: (04)507-0888 FAX: (04)507-0999

* Remove the CAL pot plug before calibrating HAKKO 936/937. JOHORE BAHRU BRANCH: TEL: (07)236-7766 FAX: (07)237-4655

PHILIPPINES: HAKKO PHILS TRADING CO., INC.

* We recommend the HAKKO 191/192 thermometer for measuring the tip temperature. TEL: (02)817-0712, 815-4993 FAX: (02)810-7649

Sep. 2001

Potrebbero piacerti anche

- Ford WiringDocumento6 pagineFord WiringGilberto Dipiento100% (1)

- 143367-Hyd Cylinder Repair GuideDocumento3 pagine143367-Hyd Cylinder Repair GuideheartofdixieNessuna valutazione finora

- AT520JK Users ManualDocumento15 pagineAT520JK Users ManualgerezairNessuna valutazione finora

- 01-Duct Pressure Drop Calculator FCU-01Documento9 pagine01-Duct Pressure Drop Calculator FCU-01Hamdy AdelNessuna valutazione finora

- Husky HRPG enDocumento136 pagineHusky HRPG envdj85Nessuna valutazione finora

- Mechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionDa EverandMechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionA. SherryValutazione: 4 su 5 stelle4/5 (5)

- Asme Boiler Inspection FormDocumento2 pagineAsme Boiler Inspection FormJose Lorenzo ToralNessuna valutazione finora

- brQnm2E4ai5C7yh3uxCdop4HADocumento1 paginabrQnm2E4ai5C7yh3uxCdop4HARobera LebamuNessuna valutazione finora

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareDa EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareNessuna valutazione finora

- Pricelist OXONE For ResellerDocumento11 paginePricelist OXONE For ResellerAdiKangdraNessuna valutazione finora

- PPM Check List: Floor: Wing: Room No: DateDocumento3 paginePPM Check List: Floor: Wing: Room No: DateMdrahaman MithuNessuna valutazione finora

- Exel Spring Reel IomDocumento12 pagineExel Spring Reel IomstephenNessuna valutazione finora

- 8-72 HP Operation Manual (ENG)Documento23 pagine8-72 HP Operation Manual (ENG)Shu Fai Li100% (3)

- Erma LA-22 ManualDocumento5 pagineErma LA-22 Manualdunn69027300Nessuna valutazione finora

- 926 Instruction ManualDocumento11 pagine926 Instruction ManualPaulo FoglianoNessuna valutazione finora

- De-Soldering Gun: Instruction ManualDocumento6 pagineDe-Soldering Gun: Instruction ManualLjubisa DjordjevicNessuna valutazione finora

- QL5, DHD350: Disassembly Exploded ViewDocumento1 paginaQL5, DHD350: Disassembly Exploded ViewJORGE C. CHAO R.Nessuna valutazione finora

- Warning!: Rough Shifts, Flares During Up Shifts & Kick Down. Rough Coast Downshifts No Pressure Rise, TCC Slip/shudderDocumento7 pagineWarning!: Rough Shifts, Flares During Up Shifts & Kick Down. Rough Coast Downshifts No Pressure Rise, TCC Slip/shudderautomaticosbrasilNessuna valutazione finora

- Mercruiser Mechanical Trim Actuator Installation - 846063A1Documento7 pagineMercruiser Mechanical Trim Actuator Installation - 846063A1JeffNessuna valutazione finora

- Instruction Manual: Soldering StationDocumento12 pagineInstruction Manual: Soldering StationSayali ParabNessuna valutazione finora

- Is RBT5005Documento6 pagineIs RBT5005dayshift5Nessuna valutazione finora

- Instruction Manual: Solderpro™Documento1 paginaInstruction Manual: Solderpro™余日中Nessuna valutazione finora

- Ih 86Documento4 pagineIh 86mishka123Nessuna valutazione finora

- Ch15runnerless MouldDocumento32 pagineCh15runnerless Mouldanukul shenoyNessuna valutazione finora

- Operator's Manual: Tb22 EcDocumento16 pagineOperator's Manual: Tb22 EcscorpiohnNessuna valutazione finora

- Instruction Sheet Is Sr2822: - Style Number Sr2822In:: Package ContentsDocumento4 pagineInstruction Sheet Is Sr2822: - Style Number Sr2822In:: Package Contentsdayshift5Nessuna valutazione finora

- Micro Swiss Installation Instructions For Cr-6 Se HotendDocumento8 pagineMicro Swiss Installation Instructions For Cr-6 Se HotendtgvfdNessuna valutazione finora

- Aoyue Repairing System en PDFDocumento10 pagineAoyue Repairing System en PDFWiwy TransmitNessuna valutazione finora

- SK Tf80Sc: Warning!Documento8 pagineSK Tf80Sc: Warning!automaticosbrasilNessuna valutazione finora

- Válvula Globo Tipo Placa - Spirax SarcoDocumento2 pagineVálvula Globo Tipo Placa - Spirax SarcodgarciabNessuna valutazione finora

- Instruction Manual: Desoldering ToolDocumento19 pagineInstruction Manual: Desoldering ToolpolitrukNessuna valutazione finora

- 909 SeriesDocumento10 pagine909 SeriesDinNessuna valutazione finora

- S100 User ManualDocumento23 pagineS100 User ManualMOROCCO LTDANessuna valutazione finora

- Adobe Scan 10 Jan 2024Documento7 pagineAdobe Scan 10 Jan 2024kesharikushalNessuna valutazione finora

- Instruction Sheet Is Tf931C - Style Number Tf931Cvb:: Package ContentsDocumento4 pagineInstruction Sheet Is Tf931C - Style Number Tf931Cvb:: Package Contentsdayshift5Nessuna valutazione finora

- Instruction Sheet Is-Rel5003 Style Number Rel5003Ic:: Package ContentsDocumento5 pagineInstruction Sheet Is-Rel5003 Style Number Rel5003Ic:: Package Contentsdayshift5Nessuna valutazione finora

- PUMA M4.3 DHD 340 TD40 Maint June 2018Documento1 paginaPUMA M4.3 DHD 340 TD40 Maint June 2018Marco LeivaNessuna valutazione finora

- Instruction Sheet Is Ie2825 - Style Number Ie2825Bn:: Package ContentsDocumento4 pagineInstruction Sheet Is Ie2825 - Style Number Ie2825Bn:: Package Contentsdayshift5Nessuna valutazione finora

- Instruction Sheet Is-Csc6882 Style Number: Csc6882Vb: Package ContentsDocumento3 pagineInstruction Sheet Is-Csc6882 Style Number: Csc6882Vb: Package Contentsdayshift5Nessuna valutazione finora

- Instruction Sheet Is-Rtd5206 Style Number: Rtd5206: Package ContentsDocumento3 pagineInstruction Sheet Is-Rtd5206 Style Number: Rtd5206: Package Contentsdayshift5Nessuna valutazione finora

- SK O9G: Reduces/Corrects/PreventsDocumento7 pagineSK O9G: Reduces/Corrects/PreventsautomaticosbrasilNessuna valutazione finora

- 864air Service Manual (06 August 2018)Documento47 pagine864air Service Manual (06 August 2018)Zeljko SofijanicNessuna valutazione finora

- M3202 Installation InstructionsDocumento12 pagineM3202 Installation Instructionsbgryph69Nessuna valutazione finora

- Instruction Sheet Is-Rrf5012 Style Number Rrf5012Sm:: Package ContentsDocumento4 pagineInstruction Sheet Is-Rrf5012 Style Number Rrf5012Sm:: Package Contentsdayshift5Nessuna valutazione finora

- Instruction Sheet Is-Rtd5006 Style Number: Rtd5006: Package ContentsDocumento3 pagineInstruction Sheet Is-Rtd5006 Style Number: Rtd5006: Package Contentsdayshift5Nessuna valutazione finora

- 2007 HD TouringDocumento68 pagine2007 HD TouringRod SturgeonNessuna valutazione finora

- Instruction Manual: High-Output, Temperature Controlled Soldering StationDocumento28 pagineInstruction Manual: High-Output, Temperature Controlled Soldering Stationalexgreen121Nessuna valutazione finora

- Instruction Sheet Is-Tf879C Style Number: Tf879Cvb: Package ContentsDocumento3 pagineInstruction Sheet Is-Tf879C Style Number: Tf879Cvb: Package Contentsdayshift5Nessuna valutazione finora

- 538 270 Thomas Series DBZ, Sizes 50 451 Disc Couplings ManualDocumento4 pagine538 270 Thomas Series DBZ, Sizes 50 451 Disc Couplings ManualpelakupasarNessuna valutazione finora

- Instruction Sheet Is Rvg5009 - Style Number Rvg5009Sm:: Package ContentsDocumento4 pagineInstruction Sheet Is Rvg5009 - Style Number Rvg5009Sm:: Package Contentsdayshift5Nessuna valutazione finora

- Instruction Sheet Is Dw5009 - Style Number Dw5009C:: Package ContentsDocumento5 pagineInstruction Sheet Is Dw5009 - Style Number Dw5009C:: Package Contentsdayshift5Nessuna valutazione finora

- Heated GripsDocumento6 pagineHeated GripsCarson McIntoshNessuna valutazione finora

- Manual Taller PDFDocumento12 pagineManual Taller PDFDiego TorresNessuna valutazione finora

- Instruction Sheet Is Fw1911 - Style Number Fw1911Wt:: Package ContentsDocumento4 pagineInstruction Sheet Is Fw1911 - Style Number Fw1911Wt:: Package Contentsdayshift5Nessuna valutazione finora

- Toshiba VTW2887Documento105 pagineToshiba VTW2887thomas-stentzelNessuna valutazione finora

- TP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓Documento11 pagineTP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓lucasloudNessuna valutazione finora

- 16" Pedestal Fan Model: PEL01924 & PEL01925Documento4 pagine16" Pedestal Fan Model: PEL01924 & PEL01925Андрей ЧепикNessuna valutazione finora

- Instruction Sheet Is Tf878C - Style Number Tf878Cvb:: Package ContentsDocumento3 pagineInstruction Sheet Is Tf878C - Style Number Tf878Cvb:: Package Contentsdayshift5Nessuna valutazione finora

- CompDocumento2 pagineCompapi-19865057Nessuna valutazione finora

- Instruction Sheet Is Rak8703 - Style Number Rak8703Is:: Package ContentsDocumento5 pagineInstruction Sheet Is Rak8703 - Style Number Rak8703Is:: Package Contentsdayshift5Nessuna valutazione finora

- SP200 Manual 1206Documento7 pagineSP200 Manual 1206eidofoorNessuna valutazione finora

- Solax Adapter Box Installation Guide EnglishDocumento2 pagineSolax Adapter Box Installation Guide EnglishGrandeXXLNessuna valutazione finora

- UMC-093 - Instruction Manual - Ver.1.02EDocumento12 pagineUMC-093 - Instruction Manual - Ver.1.02EMartin HuertaNessuna valutazione finora

- Sps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Documento7 pagineSps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Zahira Yadira Arévalo MéndezNessuna valutazione finora

- Immersion Wells and Compression Fittings: For Temperature ControllersDocumento16 pagineImmersion Wells and Compression Fittings: For Temperature ControllersShoaib-Ur -RehmanNessuna valutazione finora

- Statement of The The Problem FEU Tech Building - 3Documento3 pagineStatement of The The Problem FEU Tech Building - 3Matthew SumagueNessuna valutazione finora

- 221005, Plumbing SpecialtiesDocumento16 pagine221005, Plumbing Specialtiessrp. mohammedNessuna valutazione finora

- Comparador de Temperatura AcDocumento24 pagineComparador de Temperatura Acjose alberto nava martinezNessuna valutazione finora

- Artify More DDocumento6 pagineArtify More DSamo AbdalaNessuna valutazione finora

- Specification - Screw Chiller - DraftDocumento8 pagineSpecification - Screw Chiller - DraftSupriya RoyNessuna valutazione finora

- Piping Mto Summary Material Valves "KLB" - Yya Wellhead Platform (Modification) RFQ:STC-0682-KLB-M-010Documento3 paginePiping Mto Summary Material Valves "KLB" - Yya Wellhead Platform (Modification) RFQ:STC-0682-KLB-M-010Anatta RahardjoNessuna valutazione finora

- Hilton Plaza Hurghada Hotel - F - OfferDocumento19 pagineHilton Plaza Hurghada Hotel - F - OfferMohamedAhmedFawzyNessuna valutazione finora

- As Built DammamDocumento12 pagineAs Built DammamShah MuzzamilNessuna valutazione finora

- Pipes Fittings, Valves and Pumps (Schmidt) Page 2 of 53Documento16 paginePipes Fittings, Valves and Pumps (Schmidt) Page 2 of 53Moca PhoenixNessuna valutazione finora

- Fom Inspeksi Vibrasi PDFDocumento2 pagineFom Inspeksi Vibrasi PDFHeza FirdausNessuna valutazione finora

- ANSI Standard Pipe Data Chart - Rev 01 JMV - 03-08-18Documento6 pagineANSI Standard Pipe Data Chart - Rev 01 JMV - 03-08-18pelotoNessuna valutazione finora

- ParkerDocumento2 pagineParkerTawfiq ZidanNessuna valutazione finora

- Keterangan: Ac Ceiling Mounted Cassete Fan Coil Unit (Fcu)Documento1 paginaKeterangan: Ac Ceiling Mounted Cassete Fan Coil Unit (Fcu)zani marcelianaNessuna valutazione finora

- Septic Vault Detail: Vicinity MapDocumento1 paginaSeptic Vault Detail: Vicinity Mapysog808Nessuna valutazione finora

- 69-2794 Manual HumidificadorDocumento96 pagine69-2794 Manual HumidificadorlaboratorioNessuna valutazione finora

- Catalogo Ores Ajax BoilerDocumento2 pagineCatalogo Ores Ajax BoilerKaren Julieth Cardenas AriasNessuna valutazione finora

- HPDocumento51 pagineHPKhan Basit KhanNessuna valutazione finora

- Tesla AC TT34EXC1 1232IAW Spec 2023 ENGDocumento2 pagineTesla AC TT34EXC1 1232IAW Spec 2023 ENGLENA SPEDNessuna valutazione finora

- Fabrication of Mini BoilerDocumento7 pagineFabrication of Mini BoilerganeshNessuna valutazione finora

- Engineering Utilities 2: Building Plumbing SystemDocumento97 pagineEngineering Utilities 2: Building Plumbing SystemJhon Russel Cruz AntonioNessuna valutazione finora

- Unit 3 BoilerDocumento17 pagineUnit 3 BoilerAnonymous R7wV0zbMNessuna valutazione finora

- Indonesia 1st Store Equipment List (250 )Documento12 pagineIndonesia 1st Store Equipment List (250 )Andrian KosasihNessuna valutazione finora

- Copeland Condensing Units Selection Guide Es MX 3709200Documento283 pagineCopeland Condensing Units Selection Guide Es MX 3709200jesus garciaNessuna valutazione finora

- Wirring, Pipping Hitachi - ACDocumento27 pagineWirring, Pipping Hitachi - ACHera WatiNessuna valutazione finora