Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Determining Control Measures

Caricato da

Gaganpreet KaurCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Determining Control Measures

Caricato da

Gaganpreet KaurCopyright:

Formati disponibili

Determining Control Measures in HACCP Page 1

Safefood 360° is the provider of

compliance software for

the global food industry

W H I T E PA P E R

Determining Control Measures in HACCP

CONTENTS SUMMARY

1. Introduction

2. What are control measures?

2.1 Critical Control Point (CCP)

2.2 Prerequisite Programme (PRP)

2.3 Operational Prerequisite

Programme (oPRP)

2.4 Control Point (CP)

This whitepaper is essential

2.5 Quality Control Point (QCP)

for anyone responsible for

risk assessment and deter-

3. Determining Control Measures mination of control meas-

ures within a HACCP plan.

3.1 Requirements for determining The whitepaper will demys-

control measures tify much of the language

3.2 Risk assessments and “Significance” and complex logic normally

associated with risk assess-

3.3 Determination models

ment models and decision

trees, which prevent many

4. Definitions food companies from obtain-

ing their objective of produc-

ing robust HACCP plans.

5. References

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 2

1. Introduction not mystifying on occasion.

Since its inception, HACCP has always To put it simply, the basic principle is to

been a risk assessment and management install within the process and operation

tool designed to help food companies some control measures which are

identify specific hazards within their appropriate for the specific hazards and

process, determine their significance and the risk they pose to the final consumer.

develop appropriate controls to ensure HACCP requires the user to identify these

they do not reach the consumer. Over the potential hazards. Next, the user determines

decades numerous food safety standards, the significance of these hazards by

codes of practice, and regulatory directives applying risk assessment techniques, the

have adopted the principles of HACCP output of which is a measure of risk which

and in the process put their own unique then allows us to put in place appropriate

interpretation on how exactly these control measures. Over the decades,

principles are effected. various standards have attempted to

define how this should be done and in the

The almost ubiquitous adoption of process have introduced their own unique

HACCP as the risk tool of choice by the terms, language, scope, methodology and

food industry is a testament to its enduring workflows. Some of these have been good

scientific approach. It has facilitated the and helped the user meet requirements

development of a safer food supply chain but much of the work has served only to

and provided food safety practitioners with confuse the user leading to HACCP plans

a common work-flow, logic and language which are unnecessarily complex and hinder

from which to work and communicate. the effective management of food safety.

It has also provided one of the essential

ingredients required for objective auditing This whitepaper will breakdown much of

– a Standard. As is the case in many other the confusion and inherent weaknesses

industries, the food sector has found present in many food safety standards

an important and valuable friend in risk surrounding the determination of control

assessment and more specifically HACCP. measures in HACCP. It will take the

reader through the basic logic behind the

However as with any good, lifelong friend methodology and build from a basic model

we become aware more than others of up to a more detailed one covering all types

their inherent character uniqueness and of control measures after which a better

challenges. It does not prevent us benefiting insight and understanding of this area will

from the relationship but it can often be achieved.

make things confusing. When we speak of

HACCP it is clear that risk assessment and

determination of control measures is an

aspect which many users find difficult if

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 3

2. What are Control There are others; however, the above

Measures? represent the main ones used widely in the

food industry.

Before examining the methods for

determining the appropriate control 2.1 Critical Control Point (CCP)

measure to apply for a particular hazard,

The CCP is perhaps the most commonly

it is essential to have a clear understanding

known of all the control measures. The

of the various control measures typically

ISO defines it as a step at which control

referred to in food safety standards.

can be applied and is essential to prevent or

In the context of food safety, the eliminate a food safety hazard or reduce it

International Standards Organisation (ISO) to an acceptable level.

has defined a control measure as an action

You will note that the definition is very

or activity that can be used to prevent or

similar to the general definition of a control

eliminate a food safety hazard or reduce

measure; however, a CCP differs in the

it to an acceptable level. This definition is

fact that it relates specifically to a step in

general and can be used to describe virtually

the process e.g. cooking, cooling, freezing

any action, step, activity, job, task, process

and not a general activity or action. The

or procedure which has the intention of

definition also states that a CCP is a step at

addressing a food safety hazard. As we look

which control can be applied. Therefore, if

closer at the main food safety standards

a CCP cannot by definition apply control it

we can see that control measures become

cannot be a CCP.

categorised according to their nature, direct

relationship with the process and the level This might come into play where the

of risk to the consumer should the control control is subjective and cannot be

measure fail. In recent years the following measured accurately. In this case control

categories of control measures have is hard or impossible and would not lend

emerged: well as a critical point of control. Another

factor relating to CCP’s is the risk posed

• Critical Control Point (CCP)

by the hazard should the control not be

• Prerequisite Programme (PRP) exercised. For example, a salmonella in

cooked meat would pose a significant risk

• Operational Prerequisite to the consumer if cooking is not carried

Programme (oPRP) out to an adequate temperature and time

specification. In this case control is critical

• Control Point (CP) and designed specifically to control the

hazard.

• Quality Control Point (QCP)

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 4

• management of purchased materials

2.2 Prerequisite Programme (PRP) (e.g. raw materials, ingredients,

chemicals and packaging), supplies

The ISO defines a PRP as the basic (e.g. water, air, steam and ice),

conditions and activities that are necessary disposals (e.g. waste and sewage)

to maintain a hygienic environment and handling of products (e.g.

throughout the food chain and are suitable storage and transportation)

for the production, handling and provision

of safe end products and safe food for • measures for the prevention of cross

human consumption. contamination

There are a wide variety of PRPs depending • cleaning and sanitizing

on the particular product and process.

They are often described in certain sectors • pest control

of the industry as Good Agricultural

• personnel hygiene

Practice (GAP), Good Veterinarian Practice

(GVP), Good Manufacturing Practice The key point in regard to PRP’s is that

(GMP), Good Hygienic Practice (GHP), they are usually general to the process

Good Production Practice (GPP), Good and not focused on any particular step in

Distribution Practice (GDP) and Good the process. For example, cleaning and

Trading Practice (GTP). Examples of sanitizing are activities which can apply to

PRP’s in a food manufacturing environment all steps, rooms, items and building fabric.

highlighted in the ISO 22000 standard

would be: They also have the character that their

failure does not necessary lead to an

• construction and lay-out of immediate and imminent food safety risk.

buildings and associated utilities Generally, time and repeated failure is

required to create a critical change in the

• lay-out of premises, including

safety of the product. Stated another way,

workspace and employee facilities

they usually manage more general and lower

• supplies of air, water, energy and risk hazards.

other utilities

2.3 Operational Prerequisite

• supporting services, including waste Programme (oPRP)

and sewage disposal

The ISO defines an oPRP as a control

• the suitability of equipment and measure identified by the hazard analysis as

its accessibility for cleaning, essential in order to control the likelihood

maintenance and preventative of introducing food safety hazards and/or

maintenance the contamination or proliferation of food

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 5

safety hazards in the product(s) or in the is that it is not an intrinsic step required

processing environment. for the production of safe cooked ham.

It can be removed from the process and

As a concept of control it was introduced the company can practically still produce

by the ISO in their food safety management relatively safe products. Nonetheless,

standard ISO 22000. What is striking about its presence may be deemed essential to

this control measure and its definition is reducing the likelihood of the hazard and

the almost universal confusion users have therefore an oPRP. It is important to realise

in differentiating it from CCP’s and PRP’s. that this is simply one possible definition

The variation in the focus of the control of an oPRP which provides some working

measures appears to be based on a subtle understanding for users. It may not be the

difference in the description of hazards full definition or scope as intended by the

and risks. Users have found it hard to ISO.

understand the nature of oPRP’s and given

that that standard provides no specific 2.4 Control Point (CP)

examples, it has remained the subject of

some debate in the food safety community. A Control Point is used by some standards

to describe an oPRP. The IFS Food

In an attempt to clarify what exactly Standard for auditing quality and food

an oPRP is, it has been described as a safety of food products Version 6, for

specific action relating to the process example, defines a CP as being identical to

while not being critical for food safety; it an oPRP found in the ISO 22000.

is essential in reducing the likelihood of a

specific hazard occurring. For example, a 2.5 Quality Control Point (QCP)

cooking step in a process may be critical to

A Quality Control Point is a control

controlling the risk of a specific pathogen

measure essential in order to control quality,

surviving e.g. E. coli. This is an intrinsic

service and business risks.

step in the process for producing a cooked

product. Its removal from the process It is used in various standards including

is not possible and therefore its correct the Woolworths Standard (WQA) for

control is critical. Therefore, the control Manufactured Foods V8. In this standard,

applied at this step can be considered quality risks are provided almost equal

critical and therefore a CCP. importance as food safety.

Alternatively, we can take the same process

and look at metal detection. It too is a

specific step in the process designed to

reduce the likelihood of a hazard reaching

the consumer and arguably could be a

CCP also. However, the key difference

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 6

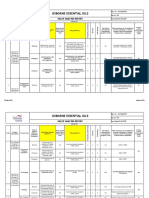

3. Determining Control 3.1 Requirements for Determining

Measures Control Measure

In order to determine which control Various Standards set out requirements

measure is appropriate for the identified for determining control points. The

hazard, you need to employ a specific following table summarizes some of these

methodology encompassing risk assessment requirements as they relate to control

followed by a decision tree. measures.

Standard Requirements

ISO 22000 7.4.4 Selection and assessment of control measures

Based on the hazard assessment of 7.4.3, an appropriate combination of

control measures shall be selected which is capable of preventing, eliminating

or reducing these food safety hazards to defined acceptable levels. In this

selection, each of the control measures as described in 7.3.5.2 shall be

reviewed with respect to its effectiveness against the identified food safety

hazards. The control measures selected shall be categorized as to whether

they need to be managed through operational PRP(s) or by the HACCP plan.

The selection and categorization shall be carried out using a logical approach

that includes assessments with regard to the following:

a) its effect on identified food safety hazards relative to the strictness applied;

b) its feasibility for monitoring (e.g. ability to be monitored in a timely manner

to enable immediate corrections);

c) its place within the system relative to other control measures;

d) the likelihood of failure in the functioning of a control measure or significant

processing variability;

e) the severity of the consequence(s) in the case of failure in its functioning;

f) whether the control measure is specifically established and applied to

eliminate or significantly reduce the level of hazard(s);

g) synergistic effects (i.e. interaction that occurs between two or more

measures resulting in their combined effect being higher than the sum of their

individual effects).

Control measures categorized as belonging to the HACCP plan shall be

implemented in accordance with 7.6.

Other control measures shall be implemented as operational PRPs according

to 7.5. The methodology and parameters used for this categorization shall be

described in documents, and the results of the assessment shall be recorded.

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 7

Standard Requirements

ISO 22000 7.5 Establishing the operational prerequisite programmes (PRPs)

The operational PRPs shall be documented and shall include the following

information for each programme:

a) food safety hazard(s) to be controlled by the programme (see 7.4.4);

b) control measure(s) (see 7.4.4);

c) monitoring procedures that demonstrate that the operational PRPs are

implemented;

d) corrections and corrective actions to be taken if monitoring shows that the

operational PRPs are not in control (see 7.10.1 and 7.10.2, respectively);

e) responsibilities and authorities;

f) record(s) of monitoring.

Woolworths Determine the Critical Control Points – for each significant hazard the Vendor

Standard (WQA) shall determine which of the control measures developed is the critical point for

Version 8 control of the hazard, including significant quality hazards/regulatory issues.

Establish a system to monitor control of the CCP and QCP – procedures for

monitoring the critical limits shall be developed, documented, implemented and

reviewed. These shall include details of what is being measured or monitored,

how this is to be carried out, the frequency at which measurements will be

undertaken, where the monitoring activity is to be undertaken and who is to be

responsible for monitoring. Monitoring activities shall be undertaken regularly so

any deviations can be detected in-line and corrected immediately.

Tesco Food Prerequisite Programmes

Manufacturing

Standard (TFMS) All environmental and operational controls that are necessary to produce safe

and legal food products must be in place. These cover good manufacturing

practices throughout the site. The control measures and monitoring procedures

for the prerequisite programme must be clearly identified and documented.

Hazard Analysis

The HACCP team must conduct a hazard analysis to identify hazards which need

to be prevented, eliminated or reduced to acceptable levels. The hazard analysis

must include:

• Likely occurrence and severity

• Survival or multiplication of micro-organisms

• Presence or production of toxins, chemicals or foreign bodies and allergens

• Potential for adulteration/deliberate contamination

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 8

Standard Requirements

Tesco Food Control Measures

Manufacturing

Standard (TFMS) The HACCP team must assess whether an existing prerequisite adequately

controls the hazard identified.

The HACCP team must also consider what control measures (if any exist) for

the remaining hazards can be applied to prevent, eliminate or reduce the risk

to acceptable levels. If no control measures have been identified the product/

process must be modified so a control measure can be applied.

Determination of CCPs

The Codex decision tree or equivalent must be used to determine if control

measures are CCPs (Critical Control Points).

BRC Standard For each hazard that requires control, control points shall be reviewed to identify

Food 6 those that are critical. This requires a logical approach and may be facilitated by

use of a decision tree. CCPs shall be those control points which are required in

order to prevent or eliminate a food safety hazard or reduce it to an acceptable

level. If a hazard is identified at a step where control is necessary for safety but

the control does not exist, the product or process shall be modified at that step,

or at an earlier or later step, to provide a control measure.

IFS Food CP – Control point

Standard for

auditing quality Identified by the hazard analysis as essential in order to control the likelihood

and food safety of introducing or proliferation of food safety hazard in the product and/or the

of food products environment. A CP can be considered as an OPRP (Operational Prerequisite

Version 6 Program), as defined in ISO 22000. The basis of the company’s food safety

control system shall be a fully implemented, systematic and comprehensive

HACCP system, based upon the Codex Alimentarius principles.

It shall take into account any legal requirements of the production and

destination countries which may go beyond such principles. The HACCP system

shall be implemented at each production site.

The determination of relevant critical control points (CCP’s) shall be facilitated by

the application of a decision tree or other tool(s), which demonstrates a logical

reasoned approach.

For all steps which are important for food safety, but which are not CCP’s, the

company shall implement and document control points (CP’s). Appropriate

control measures shall be implemented.

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 9

In general the methods now universally The benefit of this is ensuring that limited

employed in the global food industry are resources are deployed mainly to control

based on risk assessment followed by high risk hazards.

CCP determination. They are based on a

principle that not all hazards are significant 3.2 Risk Assessment and

to food safety and therefore do not need ‘Significance’

to be controlled in a rigorous manner.

The term Significant Hazard is used widely

Conversely, some hazards are significant

but often poorly understood. This is not

and may be critical to food safety. These

helpful when we set about developing

by definition require tighter control. This

HACCP plans which are capable of

methodology can be summarized in the

controlling hazards in an appropriate

following steps:

manner. The term significance is used

Figure 1: Simple model for the simply to describe those hazards which

determination of control measures present a real risk of impacting on the

consumer. It is used to separate those

hazards which require tight control from

those requiring lesser control. It may

be said that significance is essentially an

expression of Risk.

In food safety, risk (R) is a measure of the

combined severity of impact (S) from a

hazard and its probability of occurrence

(P).

R=SxP

The above model is centred on HACCP.

However, it is important to note that In its simplest form, risk is expressed as

HACCP does not clearly define this being High, Medium or Low. When it

approach which is a weakness of the comes to defining if a hazard is significant,

system. risk is usually used. For example, you can

say that any risk deemed to be high and

In the first stage, the specific hazards

medium are significant. While low risk

at specific steps are identified and

hazards are deemed to be non-significant.

characterized. This is followed by a risk

This is the basic purpose of risk assessment

assessment to determine which hazards if

in food safety and HACCP. The following

any are ‘significant’. Significant hazards are

is a simple model for risk assessment of a

then applied to a decision tree to determine

food safety and quality hazard:

if they should be controlled as a CCP, PRP,

oPRP, CP or QCP.

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 10

Probability Rating

Severity Rating

Risk Rating

Figure (above): Simple risk assessment The model is based on 3 basic questions.

model The first is whether there is in fact an

identified hazard at this step relating to

3.3 Determination Models food safety. If not, it is assumed to be a

quality issue and controlled as such. If the

We can now take the above and develop

answer to question 1 is “Yes” then a risk

further our model for determining control

assessment is conducted on the hazard

measures. In the more advanced model

to determine if it is significant. If the

below we can see clearly the role played by

hazard is deemed to be non-significant it is

risk assessment in defining the significance

then controlled as a PRP or other control

of the hazard. Non-significant hazards

measure. Note the model below does not

are controlled by definition as PRP’s

provide any guidance as to whether a non-

and oPRP’s while significant hazards are

significant hazard should be controlled as a

progressed to a CCP determination phase.

PRP or operational PRP.

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 11

Figure (above): Model for determining There are large numbers of decision trees

control measures employed and cited in various standards.

Below we have set out the more detailed

If the hazard may be deemed to be example of the decision tree found in the

significant it does not automatically follow CODEX standard for HACCP.

that it will be controlled as a CCP. This

must be determined and here our model You will notice that this decision tree

needs development. It must first go through focuses on determining whether the

a decision tree to determine if it meets hazard should be controlled as a CCP or

the criteria for a CCP. This is because not not. It does not attempt to assist the user

every hazard identified as significant can be in determining what type of control shall

controlled in a manner defined as a CCP in be employed where ‘Not a CCP’ is the

many standards. outcome. This makes it limited for most

modern food businesses seeking to develop

It may only be possible to control them a robust food safety plan.

through some other means and this may

explain why oPRP have emerged in an

effort to maintain the importance of the

control failing its suitability as a CCP.

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 12

Figure 4: CODEX Hazard Analysis and Critical Control Point (HACCP) system and

Guidelines for its application, Annex to CAC/RCP 1-1969, Rev. 3 (1997) CCP Decision Tree

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 13

In order to fully address the requirements Q2. Do control measure(s) exist for

(both implicit and explicit) and the the identified hazard(s)?

business needs of the company, a more

robust decision tree is required to clearly In this question the user is asked if control

and logically identify which control is measures have been identified. Where NO,

appropriate for any significant hazards. Q3 is answered which may lead to revisions

to the process or product. If YES, then the

The following model is an example of a user will progress to Q4.

more detailed approach to determining

the type of control measure which should Q3. Is control necessary at this step

be employed for a significant hazard. You for food safety?

will see that it covers both food safety

hazards and quality issues. When used, it If control is required then revision should

can provide a solid and logical approach to be made to the process or product.

determine control measures and will clearly

Q4. Is this step specifically designed

show an auditor how you arrived at your

to eliminate or reduce the likely

decisions.

occurrence of the hazard to an

acceptable level?

The model pictured on the following page

employs an eight question decision tree

In this question the user is asked whether

which is designed to take you through

the step is specifically designed to eliminate

the logic step by step to determine if the

or reduce the occurrence of the hazard. If

hazard should be controlled as a CCP,

YES, it will be determined as a CCP. If NO,

oPRP, PRP or QCP. You will see it builds

Q5 is asked next in the sequence.

upon the Codex model but now brings

into the decision process the other control Q5. Could contamination occur or

measures covered in other food safety increase to an unacceptable level?

standards.

If NO, it is deemed not to be a CCP and

Q1. Is there a food safety hazard(s) the process STOPS. If YES, then the user

at this step? progresses to Q6.

In this question we are again simply Q6. Will a subsequent step eliminate

confirming the fact that a hazard has been or reduce the hazard to an

identified or not. Where the answer is NO acceptable level?

it is assumed it is a quality issue and is

controlled as a QCP. If YES, then the user If YES, then the determination is NOT

progresses to Q2. A CCP and the process stops since some

control later in the process will address the

hazard. If NO, then the user progresses to

Q7.

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 14

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 15

Q7. Will a subsequent action 4 Definitions

eliminate or reduce the hazard

to an acceptable level? Action – An action is any activity, task,

job, or procedure which is designed to

In this question we now see the shift of measure or control an aspect of the process

the decision tree away from STEPS (which or the production environment.

are relevant only for CCP’s) to ACTIONS

which are more relevant for PRP’s. If QCP - Quality Control Point – A process

NO, then this step is deemed to be the step at which control is required to prevent

controlling step and therefore a CCP. If or eliminate a quality defect or reduce it to

YES, then the user will progress to Q 8 an acceptable level.

Q8. Is the action a monitoring or HACCP - A system which identifies,

measuring action, specific for evaluates, and controls hazards which are

this step? significant for food safety.

The decision tree is attempting to Control Measure - Food safety action

determine if the action is general or more or activity that can be used to prevent or

specific to the step. If YES, then it is eliminate a food safety hazard or reduce it

controlled as an oPRP and No as a general to an acceptable level.

PRP.

Prerequisite Programme (PRP)

Figure (previous page): Detailed model - basic conditions and activities that

for determination of Control Measures are necessary to maintain a hygienic

including CCP’s, PRP’s, oPRP’s, CP’s and environment throughout the food chain

QCP’s and are suitable for the production,

handling and provision of safe end

products and safe food for human

consumption.

Operational Prerequisite

Programme (oPRP) - identified by

the hazard analysis as essential in order to

control the likelihood of introducing food

safety hazards to and/or the contamination

or proliferation of food safety hazards

in the product(s) or in the processing

environment.

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 16

Critical Control Point (CCP) - step 5 References

at which control can be applied and is

essential to prevent or eliminate a food ISO 22000:2005 Food safety management

safety hazard or reduce it to an acceptable systems - Requirements for any

level organization in the food chain

Control Point (CP) - any step at which CODEX Hazard Analysis And Critical

biological, chemical, or physical factors can Control Point (HACCP) System and

be controlled. Guidelines for Its Application Annex to

CAC/RCP 1-1969, Rev. 3 (1997)

Hazard - A biological, chemical, or

physical agent that is reasonably likely to BRC Standard for Food Issue 6

cause illness or injury in the absence of its

control. IFS Food Standard for auditing quality and

food safety of food products Version 6

Hazard Analysis - The process of

collecting and evaluating information Woolworths Standard (WQA) for

on hazards associated with the food Manufactured Foods V8

under consideration to decide which are

significant and must be addressed in the

HACCP plan.

Step - A point, procedure, operation or

stage in the food system from primary

production to final consumption.

Safefood 360° contains all

elements of a robust food safety

Have you thought management system in one,

intuitive software solution

about updating your

food safety •

•

HACCP-planning

Management tools

management • PRP control

• Supply chain management

system? • Monitoring programs

• Document control

• Reporting

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Determining Control Measures in HACCP Page 17

Safefood 360° Brings It All Together™

www.safefood360.com

Safefood 360, Inc. 2014 Part of Our Professional Whitepaper Series

Potrebbero piacerti anche

- Biocontamination Control for Pharmaceuticals and HealthcareDa EverandBiocontamination Control for Pharmaceuticals and HealthcareValutazione: 5 su 5 stelle5/5 (1)

- FSMA and Food Safety Systems: Understanding and Implementing the RulesDa EverandFSMA and Food Safety Systems: Understanding and Implementing the RulesNessuna valutazione finora

- Handbook of Microbiological Criteria for FoodsDa EverandHandbook of Microbiological Criteria for FoodsNessuna valutazione finora

- Food Control System Assessment Tool: Dimension B – Control FunctionsDa EverandFood Control System Assessment Tool: Dimension B – Control FunctionsNessuna valutazione finora

- FSSC 22000 Scheme Version 6 WORDDocumento84 pagineFSSC 22000 Scheme Version 6 WORDKawtar FAOUZYNessuna valutazione finora

- Whitepaper - Microbiological Risk AssessmentDocumento9 pagineWhitepaper - Microbiological Risk AssessmentEddie Ajalcriña BocangelNessuna valutazione finora

- Zone 1 Sampling For Spp. in Fresh Produce Operations:: ListeriaDocumento10 pagineZone 1 Sampling For Spp. in Fresh Produce Operations:: Listeriaamir ShehzadNessuna valutazione finora

- Guide To Auditing TechniquesDocumento11 pagineGuide To Auditing TechniquesSofia NogueiroNessuna valutazione finora

- Fao Food Quality Safety Systems Training Manual PDFDocumento178 pagineFao Food Quality Safety Systems Training Manual PDFDavidNessuna valutazione finora

- HACCP For Yoghurt ProductionDocumento29 pagineHACCP For Yoghurt ProductionLim Che YanNessuna valutazione finora

- Listeria Monocytogenes Guidance On: Environmental Monitoring and Corrective Actions in At-Risk FoodsDocumento35 pagineListeria Monocytogenes Guidance On: Environmental Monitoring and Corrective Actions in At-Risk FoodsGaganpreet KaurNessuna valutazione finora

- FSMA-IA Final Rule Fact SheetDocumento4 pagineFSMA-IA Final Rule Fact SheetfrawatNessuna valutazione finora

- PchfHazard Analysis and Risk-Based Preventive Controls For Human Food: Guidance For Industry Guidance Full 01-17-2018Documento306 paginePchfHazard Analysis and Risk-Based Preventive Controls For Human Food: Guidance For Industry Guidance Full 01-17-2018nicole_diazrNessuna valutazione finora

- Microbial Risk AssessmentDocumento9 pagineMicrobial Risk AssessmentPamela Bórquez ReussNessuna valutazione finora

- Spice Microbiological ProfilesDocumento6 pagineSpice Microbiological ProfilesainnurkhalisNessuna valutazione finora

- Food Safety Culture in Nigeria - Pathway To Behavioural FSMS Development in Nigerian Food IndustryDocumento6 pagineFood Safety Culture in Nigeria - Pathway To Behavioural FSMS Development in Nigerian Food IndustryAdeniji Adeola StephenNessuna valutazione finora

- Critical Elements For EMPDocumento54 pagineCritical Elements For EMPGaganpreet KaurNessuna valutazione finora

- FSSC 22000: Foundation For Food Safety CertificationDocumento14 pagineFSSC 22000: Foundation For Food Safety CertificationAhmedElSayedNessuna valutazione finora

- fssc22000 Features v3.2 2015 PDFDocumento16 paginefssc22000 Features v3.2 2015 PDFApple Sirinart ThaNessuna valutazione finora

- Allergen Risk Assessment Analysis Report-StagewiseDocumento8 pagineAllergen Risk Assessment Analysis Report-StagewiseSiva SuryaNessuna valutazione finora

- Guide To Environmental Microbiological MonitoringDocumento29 pagineGuide To Environmental Microbiological MonitoringzyrtylNessuna valutazione finora

- Approved By: ClauseDocumento4 pagineApproved By: ClauseMohammed Imran100% (1)

- HACCP and SSOP BasicsDocumento35 pagineHACCP and SSOP Basicsfitria lindasariNessuna valutazione finora

- Validation of Control Measures in A Food Chain Using The FSO ConceptDocumento7 pagineValidation of Control Measures in A Food Chain Using The FSO Conceptcaraquena123Nessuna valutazione finora

- Recall Program TemplateDocumento2 pagineRecall Program TemplateJanara Aline RochaNessuna valutazione finora

- BRCGS Standard For Packaging and Packaging MaterialsDocumento6 pagineBRCGS Standard For Packaging and Packaging Materialshunain zafarNessuna valutazione finora

- The Evaluation of Microbiological Criteria For Food Products of AnimalDocumento44 pagineThe Evaluation of Microbiological Criteria For Food Products of AnimalAchara MatiyaNessuna valutazione finora

- General Standard For The Labelling of Prepackaged FoodDocumento9 pagineGeneral Standard For The Labelling of Prepackaged FoodAubreyNessuna valutazione finora

- China GB4789.40 2010 Food Microbiological Examination Enterobacter Sakazakii PDFDocumento13 pagineChina GB4789.40 2010 Food Microbiological Examination Enterobacter Sakazakii PDFmmoradi55Nessuna valutazione finora

- Gap BRCv9 BlankDocumento49 pagineGap BRCv9 BlankVasil TsonkovNessuna valutazione finora

- Quality Assessment - ManualDocumento152 pagineQuality Assessment - ManualprinceejNessuna valutazione finora

- Cleaning Validation White PaperDocumento7 pagineCleaning Validation White PaperAngga PratamaNessuna valutazione finora

- A Culture of Food SafetyDocumento54 pagineA Culture of Food SafetyMohamedNessuna valutazione finora

- Food Defense Supplier Guidelines 1 11Documento12 pagineFood Defense Supplier Guidelines 1 11Ahmed Hassan ShehataNessuna valutazione finora

- HACCP Control MeasuresDocumento4 pagineHACCP Control MeasuresAishwary SamarthNessuna valutazione finora

- Food Traceability Withdrawals and Recalls GuidanceDocumento56 pagineFood Traceability Withdrawals and Recalls GuidanceQualidade SegurançaNessuna valutazione finora

- Environmental Monitoring ProgramDocumento4 pagineEnvironmental Monitoring ProgramJoyster AvilaNessuna valutazione finora

- Emergency PreparednessDocumento14 pagineEmergency PreparednessV Subramanyam QCNessuna valutazione finora

- Introduction To Environmental Monitoring ProgramsDocumento4 pagineIntroduction To Environmental Monitoring Programsmarmaduke32Nessuna valutazione finora

- M. S. Asia Group Page 1 of 1 Document No.: SOP/ANA/PDP Effective Date: 21-6-2021 Rev. No.: 0 Document Title: Product Defense PlanDocumento1 paginaM. S. Asia Group Page 1 of 1 Document No.: SOP/ANA/PDP Effective Date: 21-6-2021 Rev. No.: 0 Document Title: Product Defense Plannurhafizah jabarNessuna valutazione finora

- Food Safety Manual Valley Sport-FS (00000003)Documento30 pagineFood Safety Manual Valley Sport-FS (00000003)Balaji Rajaraman100% (1)

- ISO 22000 Checklist Sample PDF ReportDocumento24 pagineISO 22000 Checklist Sample PDF ReportNayely GonzálezNessuna valutazione finora

- Master Auditing Document Draft With Secondary Responses - SQF Level IIDocumento95 pagineMaster Auditing Document Draft With Secondary Responses - SQF Level IIFloreid100% (1)

- FSSC 22000 FSMS Implementation Package V5.1 BrochureDocumento44 pagineFSSC 22000 FSMS Implementation Package V5.1 BrochureSutha Tamil Nambe100% (1)

- Haccp Manual DocumentsDocumento8 pagineHaccp Manual DocumentsHarits As SiddiqNessuna valutazione finora

- Bip 2127-2007Documento138 pagineBip 2127-2007clive0% (1)

- Cleaning Validation Guideline (GUI 0028) Revision Draft 201201Documento16 pagineCleaning Validation Guideline (GUI 0028) Revision Draft 201201Chang Woo JongNessuna valutazione finora

- SQFI Guidance RE: 2.8.3 Allergen Cleaning and Sanitation PracticesDocumento6 pagineSQFI Guidance RE: 2.8.3 Allergen Cleaning and Sanitation PracticesRene Bonilla LanderosNessuna valutazione finora

- BAM Chapter 18 - Yeasts, Molds and Mycotoxins - FDADocumento13 pagineBAM Chapter 18 - Yeasts, Molds and Mycotoxins - FDAsunnysatwNessuna valutazione finora

- Supplier Qualification Form v2019.02.20Documento2 pagineSupplier Qualification Form v2019.02.20Alfred RangelNessuna valutazione finora

- Basics of HACCP and Prerequisite ProgramsDocumento22 pagineBasics of HACCP and Prerequisite ProgramsAnonymous A1G77Sw59Nessuna valutazione finora

- FSMS Competence: Prepared By: Karishma Khutela, Program Officer Approved By: Neeti Bhatt, Senior Program ManagerDocumento4 pagineFSMS Competence: Prepared By: Karishma Khutela, Program Officer Approved By: Neeti Bhatt, Senior Program ManagerMonica SinghNessuna valutazione finora

- sfc2017 Environmental MonitoringDocumento74 paginesfc2017 Environmental MonitoringLuis Gutiérrez100% (2)

- ES BRCGS Packaging Materials Guia Transicion Bolsillo WebDocumento30 pagineES BRCGS Packaging Materials Guia Transicion Bolsillo WebAlejandro CarreraNessuna valutazione finora

- 12 HACCP ValidationDocumento45 pagine12 HACCP ValidationSartika MutiarasaniNessuna valutazione finora

- Food Safety System Certification 22000: FSSC 22000 FSMA Addendum For Human FoodDocumento22 pagineFood Safety System Certification 22000: FSSC 22000 FSMA Addendum For Human FoodAssane MomadeNessuna valutazione finora

- Doh Revised Guidelines On Current Good ManufacturingDocumento25 pagineDoh Revised Guidelines On Current Good Manufacturingcharlimagne100% (3)

- Quality Management Systems A Complete Guide - 2021 EditionDa EverandQuality Management Systems A Complete Guide - 2021 EditionNessuna valutazione finora

- Corrective Actions A Complete Guide - 2021 EditionDa EverandCorrective Actions A Complete Guide - 2021 EditionNessuna valutazione finora

- Bake 5 - Micro - Quality High Risk Bakery Products, NZ 2007Documento46 pagineBake 5 - Micro - Quality High Risk Bakery Products, NZ 2007Gaganpreet KaurNessuna valutazione finora

- Cake Quality and Evaluation BAKERpaperDocumento9 pagineCake Quality and Evaluation BAKERpaperGaganpreet KaurNessuna valutazione finora

- Calcium PropionateDocumento8 pagineCalcium PropionateGaganpreet KaurNessuna valutazione finora

- Canadian Guidelines For Physical HazardsDocumento4 pagineCanadian Guidelines For Physical HazardsGaganpreet KaurNessuna valutazione finora

- Bake 3 - Bakery Products, Microbial Summary, CampdenDocumento2 pagineBake 3 - Bakery Products, Microbial Summary, CampdenGaganpreet KaurNessuna valutazione finora

- CFR 2016 Title9 Vol2 Part430Documento4 pagineCFR 2016 Title9 Vol2 Part430Gaganpreet KaurNessuna valutazione finora

- 5 Guide AnceDocumento4 pagine5 Guide AnceGaganpreet KaurNessuna valutazione finora

- 12 Haccp Baking PDFDocumento32 pagine12 Haccp Baking PDFMuzammal FarooqNessuna valutazione finora

- (Polish Journal of Food and Nutrition Sciences) Implementation of Hazard Analysis Critical Control Points (HACCP) in A SME - Case Study of A BakeryDocumento13 pagine(Polish Journal of Food and Nutrition Sciences) Implementation of Hazard Analysis Critical Control Points (HACCP) in A SME - Case Study of A BakeryDarja SubotičkiNessuna valutazione finora

- Environmental Monitoring Risk Assessment PDFDocumento11 pagineEnvironmental Monitoring Risk Assessment PDFanon_675597701Nessuna valutazione finora

- Mitigation Strategies To Protect Food Against Intentional Adulteration FDA Guidance PDFDocumento159 pagineMitigation Strategies To Protect Food Against Intentional Adulteration FDA Guidance PDFscf9827Nessuna valutazione finora

- REcall Handbok PDFDocumento29 pagineREcall Handbok PDFMark A. ButlerNessuna valutazione finora

- Bakery Ind HygieneDocumento104 pagineBakery Ind Hygienelabie100% (1)

- AuRzSAyoRDe2oYeujs0x Big Dream Worksheet V1Documento2 pagineAuRzSAyoRDe2oYeujs0x Big Dream Worksheet V1Gaganpreet KaurNessuna valutazione finora

- Chlorine ArticlesDocumento7 pagineChlorine ArticlesScherjeal JangdaNessuna valutazione finora

- 817755.food Defence 16 03 2016Documento10 pagine817755.food Defence 16 03 2016Gaganpreet KaurNessuna valutazione finora

- Alchemy Academy Navigating Food InterviewDocumento6 pagineAlchemy Academy Navigating Food InterviewGaganpreet KaurNessuna valutazione finora

- A Guide To ATP Hygiene MonitoringDocumento32 pagineA Guide To ATP Hygiene MonitoringGaganpreet KaurNessuna valutazione finora

- ATP Hygiene Monitoring Do Sanitisers Really Affect MeasurementsDocumento4 pagineATP Hygiene Monitoring Do Sanitisers Really Affect MeasurementsGaganpreet KaurNessuna valutazione finora

- Precision and Accuracy in ATP Hygiene TestingDocumento3 paginePrecision and Accuracy in ATP Hygiene TestingGaganpreet KaurNessuna valutazione finora

- The Optimum Disinfection Treatment According To The Antibacterial Efficacy & Impact On Vegetable QualityDocumento51 pagineThe Optimum Disinfection Treatment According To The Antibacterial Efficacy & Impact On Vegetable QualityGaganpreet KaurNessuna valutazione finora

- Section9.Effective Cleaning and Sanitizing Procedures PDFDocumento8 pagineSection9.Effective Cleaning and Sanitizing Procedures PDFAnalyn GirasolNessuna valutazione finora

- Sanitation & Hygiene in Food ProcessingDocumento17 pagineSanitation & Hygiene in Food ProcessingAdela PopescuNessuna valutazione finora

- Exploding The Myths About ATP Hygiene MonitoringDocumento5 pagineExploding The Myths About ATP Hygiene MonitoringGaganpreet KaurNessuna valutazione finora

- Chlorine FAODocumento289 pagineChlorine FAOTrầnĐứcHùngNessuna valutazione finora

- Pocket Thermometer Calibration InstructionsDocumento3 paginePocket Thermometer Calibration InstructionsGaganpreet KaurNessuna valutazione finora

- Mock Tracebility Exercise ASQDocumento24 pagineMock Tracebility Exercise ASQspp100% (8)

- Supplier Quality & Food Safety Audit: Your LogoDocumento6 pagineSupplier Quality & Food Safety Audit: Your LogokarupukamalNessuna valutazione finora

- Microbial Safety of Minimally Processed FoodsDocumento357 pagineMicrobial Safety of Minimally Processed FoodsGaganpreet KaurNessuna valutazione finora

- Management Review ProcedureDocumento1 paginaManagement Review ProcedureGaganpreet KaurNessuna valutazione finora

- FSSC22000v5 Seminar Presentation MAGDocumento45 pagineFSSC22000v5 Seminar Presentation MAGShofi100% (1)

- ISO 22000 FSMS Compliance Summary - IsO TS 22002Documento4 pagineISO 22000 FSMS Compliance Summary - IsO TS 22002Departed Moon100% (1)

- CV Ana Ventura en 23.05.2023Documento13 pagineCV Ana Ventura en 23.05.2023Ana Cristina VenturaNessuna valutazione finora

- Panghal Et Al-2018-Journal of Food SafetyDocumento12 paginePanghal Et Al-2018-Journal of Food SafetyLoserNessuna valutazione finora

- 03 Bsi0174 - 1809 - Au - Haccp - GMP - FlyerDocumento3 pagine03 Bsi0174 - 1809 - Au - Haccp - GMP - FlyerMuhammad sajjadNessuna valutazione finora

- PR3C FSSC 22000Documento17 paginePR3C FSSC 22000faiza chenkirNessuna valutazione finora

- ISO 22000 - Documentation Requirement SummaryDocumento10 pagineISO 22000 - Documentation Requirement SummaryminhajurrehmanNessuna valutazione finora

- HSE & Compliance CV M. HMDocumento2 pagineHSE & Compliance CV M. HMrizwan ahmedNessuna valutazione finora

- NestleDocumento30 pagineNestleFarah PanjwaniNessuna valutazione finora

- ISO 22000:2018 ChecklistDocumento13 pagineISO 22000:2018 Checklist996066274497% (30)

- Technical Specification: Iso/Ts 22002-6Documento21 pagineTechnical Specification: Iso/Ts 22002-6Georgios Dallianis0% (1)

- FSSC 22000-Q: Quality ModuleDocumento9 pagineFSSC 22000-Q: Quality ModuleJose LopezNessuna valutazione finora

- Form FSSC AuditDocumento31 pagineForm FSSC AuditShofiNessuna valutazione finora

- FSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFDocumento80 pagineFSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFSyahrizal MuhammadNessuna valutazione finora

- A Microbial Assessment Scheme To MeasureDocumento13 pagineA Microbial Assessment Scheme To Measurejai soniNessuna valutazione finora

- Technical Specification: Iso/Ts 22002-5Documento8 pagineTechnical Specification: Iso/Ts 22002-5Santi PrihartiniNessuna valutazione finora

- Introduction To Iso 22000Documento30 pagineIntroduction To Iso 22000Ramasubramanian SankaranarayananNessuna valutazione finora

- KS 05-1500 2009Documento45 pagineKS 05-1500 2009Felix MwandukaNessuna valutazione finora

- FSM 002 Food Safety Quality Manual SummaryDocumento8 pagineFSM 002 Food Safety Quality Manual SummaryAliNessuna valutazione finora

- FSSC Auditor TrainingDocumento32 pagineFSSC Auditor Trainingsadbad6100% (3)

- Cases HD 2011 Including Answers PDFDocumento11 pagineCases HD 2011 Including Answers PDFAhmedElSayedNessuna valutazione finora

- Live Version For WindowsDocumento27 pagineLive Version For WindowsAsu AsuNessuna valutazione finora

- FSSC 22000 V 4Documento38 pagineFSSC 22000 V 4Asep R83% (6)

- FrameworkDocumento6 pagineFrameworkMani Rathinam RajamaniNessuna valutazione finora

- Sgs Global Food Safety Initiative Whitepaper en 11Documento28 pagineSgs Global Food Safety Initiative Whitepaper en 11asma.lounesNessuna valutazione finora

- Introduction To ISO 22000Documento30 pagineIntroduction To ISO 22000oainaNessuna valutazione finora

- Audit Checklist: Area Audited Date AuditedDocumento5 pagineAudit Checklist: Area Audited Date AuditedMohamed ShabirNessuna valutazione finora

- Course Booking Form-IsO 22000,2018 FSMSDocumento1 paginaCourse Booking Form-IsO 22000,2018 FSMSMd. Helal UddinNessuna valutazione finora

- Bamber Elezi Bamber SharpDocumento17 pagineBamber Elezi Bamber SharpJesus MolinaNessuna valutazione finora

- Tender DocumentsDocumento45 pagineTender DocumentsCHIRAG PATELNessuna valutazione finora