Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Comparison of The Various New High Modulus Fibers For Reinforcement of Advanced Composites With Polymers, Metals and Ceramics As Matrix

Caricato da

Alexander CaicedoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Comparison of The Various New High Modulus Fibers For Reinforcement of Advanced Composites With Polymers, Metals and Ceramics As Matrix

Caricato da

Alexander CaicedoCopyright:

Formati disponibili

Comparison of the Various New High Modulus Fibers

for Reinforcement of Advanced Composites

with Polymers, Metals and Ceramics as Matrix

R. J. DIEFENDORF

1 Introduction . . . . . . . . 47

2 Composite Requirements . 47

2.1 Resin Matrix Composite Reinforcement . . . . . . . . . . . . . 48

2.2 Metal Matrix Reinforcement . . . . . . . . . . . . . . . . . . . 49

2.3 Ceramic Matrix Composite Reinforcement . 50

3 Reinforcement Fibers . 52

3.1 Fiber Processes . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.2 Glass Melt Spinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.3 Chemical Vapor Deposition . . . . . . . . . . . ......... . 55

3.4 Precursor Polymeric Fiber Decomposition . . . . . . ............ . 56

3.5 Host Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.6 Organic Fibers . . . . . . . . . . . . . . . . . . . . . . ..... . 58

3.7 Whiskers........ . . . . . . . ....... . 59

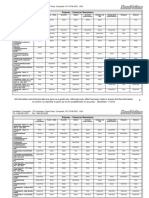

4 Comparison of Fibers . . . . . . . . . . . . . . . . . 60

4.1 Resin Matrix Composites . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.2 Metal Matrix Composites ........................... 61

5 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

46

E. Fitzer (ed.), Carbon Fibres and Their Composites

© United Nations Financing System for Science and Technology for Development 1985

1 Introduction

High modulus fibers are used mainly as fibrous reinforcement in resins, metals, or

ceramics to provide strength and stiffness. It is instructive to consider what factors

led to the development of composites. Structural designs are as likely to be limited

by the stiffness as by the strength of the construction material. Hence, engineers

have always desired stiffer, stronger, less dense and lower cost structural materials.

There are a number of materials in the upper center part of the periodic table, such

as boron, carbon, silicon carbide and alumina, which all have significantly higher

modulus/weight ratios than the common engineering metals. Theoretically, the high

modulus would result in high strength if the materials were perfect. Unfortunately,

most of the high modulus materials are covalently bonded and are brittle. Small

flaws can produce catastrophic failure at drastically reduced stresses. (The flaws may

be introduced during manufacture or during service.) Except in some unusual pro-

tected environments, primary structural elements can not be made from materials

which fail catastrophically. Composite materials offer the potential of using these

brittle materials in structures which will not fail catastrophically. The brittle mate-

rials are made into fibers to give redundancy and placed into a matrix. The matrix

serves to transfer stress into and out of the fibers. The matrix and matrix/fiber

interface must also serve to stop cracks which originate in the fibers from propagat-

ing through the solid. Hence, a localized impact may break a few fibers, but the

crack can be stopped by a ductile matrix or fiber/matrix debond. Even ceramic fiber/

ceramic matrix composites can be made which are relatively tough. The use of

composites to attain non-catastrophic failure with brittle materials has penalties.

The volume fraction of reinforcing fibers is generally 0.65 or less, and fibers only

reinforce in one direction. While fibers can be oriented in three orthogonal direc-

tions, composites offer the greatest potential if fibers are oriented predominantly

uniaxially or biaxially. Fortunately, many structures are loaded mainly in one direc-

tion.

Comparison of high modulus fibers must necessarily compare their performance

in composites. The task is made more difficult by the diverse applications, particu-

larly if non-ambient temperature uses are considered. This paper will be separated

into two parts: firstly, the requirements for fibers which are to be used in resin,

metal or ceramic matrix composites will be defined. Secondly, present fiber per-

formances will be compared to each other and the desired composite requirements.

2 Composite Requirements

The desired properties for fibers are often ranked quite differently for resin, metal

and ceramic matrix composites. Also, since metal and ceramic matrix composites

commonly are exposed to elevated temperature, (if only for processing), the high

temperatures characteristics of the fibers must also be considered.

47

Potrebbero piacerti anche

- Structure-Property Relationships in PolymersDocumento233 pagineStructure-Property Relationships in PolymersAvishkar Tambade100% (2)

- Advances in Mechanics 1Documento14 pagineAdvances in Mechanics 1yuvaraj gopalNessuna valutazione finora

- Lankeda 3d Printer Filament Catalogue 2019.02 WGDocumento7 pagineLankeda 3d Printer Filament Catalogue 2019.02 WGSamuelNessuna valutazione finora

- Epoxy Adhesion To Metals: Advances in Polymer Science January 1986Documento40 pagineEpoxy Adhesion To Metals: Advances in Polymer Science January 1986Ekrem DoğanNessuna valutazione finora

- Developement of Hybrid Composite Using Natural FiberDocumento22 pagineDevelopement of Hybrid Composite Using Natural FiberSubham TalukdarNessuna valutazione finora

- Composites Reviews by YaredDocumento25 pagineComposites Reviews by YaredYared FikreNessuna valutazione finora

- Guide To Compositesv5webpdfDocumento73 pagineGuide To Compositesv5webpdfImamRNNessuna valutazione finora

- Ahmed e Lim, 2021Documento17 pagineAhmed e Lim, 2021MilaHumeNessuna valutazione finora

- FPL 2015 Sabo001Documento31 pagineFPL 2015 Sabo001Marjory AlvarezNessuna valutazione finora

- Progress in Materials Science: Lenka Kunc Ická, Radim Kocich, Terry C. LoweDocumento49 pagineProgress in Materials Science: Lenka Kunc Ická, Radim Kocich, Terry C. LoweDaniel FridmanNessuna valutazione finora

- Glass-Fibre Reinforcement On Steel To Timber ConnectionsDocumento98 pagineGlass-Fibre Reinforcement On Steel To Timber Connectionsmaanka aliNessuna valutazione finora

- Fiber Reinforced Polymer Composites: A ReviewDocumento13 pagineFiber Reinforced Polymer Composites: A ReviewUGCJOURNAL PUBLICATIONNessuna valutazione finora

- Project Phase-1 ReportDocumento21 pagineProject Phase-1 ReportSarabjot AzrotNessuna valutazione finora

- Report of Fatigue and Fracture of Structure: Submitted byDocumento16 pagineReport of Fatigue and Fracture of Structure: Submitted byameer hamzaNessuna valutazione finora

- Construction and Building Materials: Ingrid Lande Larsen, Rein Terje ThorstensenDocumento15 pagineConstruction and Building Materials: Ingrid Lande Larsen, Rein Terje ThorstensenKhalil FanousNessuna valutazione finora

- Aço BainiticoDocumento177 pagineAço BainiticoJefferson MiersNessuna valutazione finora

- Transformations in TRIP-assisted Steels: Microstructure and PropertiesDocumento191 pagineTransformations in TRIP-assisted Steels: Microstructure and PropertiesJoanna SimmonsNessuna valutazione finora

- Roth Thesis Unsigned - 1Documento51 pagineRoth Thesis Unsigned - 1xxdeadlypancakezxxNessuna valutazione finora

- Silane Modified Epoxy ResinsDocumento2 pagineSilane Modified Epoxy ResinsChaitanya M MundheNessuna valutazione finora

- UNIT 1 NotesDocumento44 pagineUNIT 1 NotesArun KumarNessuna valutazione finora

- Netaji Subhash University of Technology: Home Assignment OnDocumento27 pagineNetaji Subhash University of Technology: Home Assignment OnParshant YadavNessuna valutazione finora

- Tsu-Wei Chou - Microstructural Design of Fiber Composites (Cambridge Solid State Science Series) (2005)Documento589 pagineTsu-Wei Chou - Microstructural Design of Fiber Composites (Cambridge Solid State Science Series) (2005)Genby Ardinugraha100% (1)

- Gurit Guide To CompositesDocumento74 pagineGurit Guide To CompositesSibin SaseendranNessuna valutazione finora

- Azide and Carboxylate As Simultaneous Coupler For Magnetic Coordination PolymersDocumento31 pagineAzide and Carboxylate As Simultaneous Coupler For Magnetic Coordination PolymersJOAO VICTOR DE SOUZA MENDESNessuna valutazione finora

- Numerical Simulation of The Impact Response of Natural Fibre CompositesDocumento178 pagineNumerical Simulation of The Impact Response of Natural Fibre CompositesFerNessuna valutazione finora

- List of Figures List of Tables: 5.0 Validation and Simulation of Collected Data .............. 24Documento44 pagineList of Figures List of Tables: 5.0 Validation and Simulation of Collected Data .............. 24shridhar chalvadiNessuna valutazione finora

- Notes On Structural Analysis of Composite Shell StructuresDocumento86 pagineNotes On Structural Analysis of Composite Shell Structureskhayat100% (1)

- Small But Stronga Review of The Mechanical Properties of Carbon Nanotube-Polymer CompositesDocumento29 pagineSmall But Stronga Review of The Mechanical Properties of Carbon Nanotube-Polymer CompositesguowzhNessuna valutazione finora

- High Frequency Induction Welding & Post-Welding Heat Treatment of Steel PipesDocumento169 pagineHigh Frequency Induction Welding & Post-Welding Heat Treatment of Steel Pipesppgl100% (1)

- Fabrication and Analysis of The Properties of Coconut Shell Ash Reinforced Aluminum356 Composite IJERTV7IS090087Documento6 pagineFabrication and Analysis of The Properties of Coconut Shell Ash Reinforced Aluminum356 Composite IJERTV7IS090087HussamNessuna valutazione finora

- 1 s2.0 S0079670008000981 MainDocumento40 pagine1 s2.0 S0079670008000981 MainMaximus Tellez LopezNessuna valutazione finora

- Project Report PDFDocumento38 pagineProject Report PDFLogic Manju71% (14)

- 2020-A Review On Performance of Polyester Fibers in Alkaline and CementitiousDocumento15 pagine2020-A Review On Performance of Polyester Fibers in Alkaline and CementitiousAmanda Camejo CoronaNessuna valutazione finora

- Chapter 1 To 5Documento47 pagineChapter 1 To 5Somanathan SubashNessuna valutazione finora

- Efektivitas Penggunaan Komposit Polimer Yang Diperkuat Serat Untuk Perbaikan Pipa Baja Bawah AirDocumento15 pagineEfektivitas Penggunaan Komposit Polimer Yang Diperkuat Serat Untuk Perbaikan Pipa Baja Bawah Air31Hanif ArdhioNessuna valutazione finora

- Lecture NotesDocumento44 pagineLecture NotesRaj KumarNessuna valutazione finora

- Report 461Documento41 pagineReport 461sanketpatil12524Nessuna valutazione finora

- 1 s2.0 S0263822321008205 MainDocumento17 pagine1 s2.0 S0263822321008205 MainRajasekar RamachandranNessuna valutazione finora

- Metal Matrix CompositesDocumento22 pagineMetal Matrix CompositesHimanshu SinghNessuna valutazione finora

- Dokumen - Pub - Fatigue and Fracture of Nanostructured Materials 1st Ed 9783030580872 9783030580889Documento436 pagineDokumen - Pub - Fatigue and Fracture of Nanostructured Materials 1st Ed 9783030580872 9783030580889nestorNessuna valutazione finora

- Electrospinning of Polymer Nanofibers - Effects On Oriented Morphology, Structures and Tensile PropertiesDocumento16 pagineElectrospinning of Polymer Nanofibers - Effects On Oriented Morphology, Structures and Tensile PropertiesCamilo A. Suárez BallesterosNessuna valutazione finora

- Composites Science and TechnologyDocumento13 pagineComposites Science and TechnologyPopeye William CapthandsomeNessuna valutazione finora

- Composite MaterialDocumento6 pagineComposite Materialali mohammedNessuna valutazione finora

- Dielectric Polymers For ElectronicsDocumento48 pagineDielectric Polymers For ElectronicsnadhimalkhamseenNessuna valutazione finora

- Reactive Processing of Textile Fiber-Reinforced Thermoplastic Composites - An OverviewDocumento16 pagineReactive Processing of Textile Fiber-Reinforced Thermoplastic Composites - An OverviewabiliovieiraNessuna valutazione finora

- Robertson DesignmanufacturingandcharacterizationofaDocumento116 pagineRobertson Designmanufacturingandcharacterizationofadursunkarali1Nessuna valutazione finora

- Construction and Building Materials: Shovona Khusru, Sabrina Fawzia, David P. Thambiratnam, Mohamed ElchalakaniDocumento16 pagineConstruction and Building Materials: Shovona Khusru, Sabrina Fawzia, David P. Thambiratnam, Mohamed ElchalakaniMazenMowafyNessuna valutazione finora

- Advanced MaterialsDocumento255 pagineAdvanced Materialsg10dra_g100% (3)

- Mechanical Properties of Nano Crystalline MaterialsDocumento130 pagineMechanical Properties of Nano Crystalline MaterialsSingh UmeshNessuna valutazione finora

- Advances in Colloid and Interface ScienceDocumento21 pagineAdvances in Colloid and Interface ScienceAna-Maria DucuNessuna valutazione finora

- Parametric Study of The Bond Between Fiber Reinforced PolymersDocumento102 pagineParametric Study of The Bond Between Fiber Reinforced PolymersLemuria TntNessuna valutazione finora

- Characterization PDFDocumento80 pagineCharacterization PDFLaura RamirezNessuna valutazione finora

- Semanarski EngleskiDocumento14 pagineSemanarski EngleskiRadovan BačaninNessuna valutazione finora

- Paper 1Documento33 paginePaper 1Tiên PhạmNessuna valutazione finora

- Magnetism: Molecules to Materials VDa EverandMagnetism: Molecules to Materials VJoel S. MillerNessuna valutazione finora

- Table of Content: Chapter I: IntroductionDocumento7 pagineTable of Content: Chapter I: IntroductionJakka hitheshiniNessuna valutazione finora

- Advances in Colloid and Interface ScienceDocumento11 pagineAdvances in Colloid and Interface ScienceHani SaadallahNessuna valutazione finora

- Computational Mesomechanics of Composites: Numerical Analysis of the Effect of Microstructures of Composites of Strength and Damage ResistanceDa EverandComputational Mesomechanics of Composites: Numerical Analysis of the Effect of Microstructures of Composites of Strength and Damage ResistanceNessuna valutazione finora

- Erbium-Doped Fiber Amplifiers: Fundamentals and TechnologyDa EverandErbium-Doped Fiber Amplifiers: Fundamentals and TechnologyValutazione: 5 su 5 stelle5/5 (3)

- FilamentDocumento35 pagineFilamentniraj hiralal sorathiyaNessuna valutazione finora

- Natural Fiber Reinforced Polymer Composites: History, Types, Advantages and ApplicationsDocumento17 pagineNatural Fiber Reinforced Polymer Composites: History, Types, Advantages and ApplicationsLamia Nour Ben abdelrahmenNessuna valutazione finora

- IKEA Restricted Substance ListDocumento21 pagineIKEA Restricted Substance ListPedro RYNessuna valutazione finora

- Ecofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaDocumento22 pagineEcofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaARYAN RATHORENessuna valutazione finora

- IntroductionDocumento2 pagineIntroductionsoumalya481Nessuna valutazione finora

- Welcome To MY Presentation: Advanced Dyeing & PrintingDocumento26 pagineWelcome To MY Presentation: Advanced Dyeing & PrintingShumi NaharNessuna valutazione finora

- Honey Kids LatestDocumento16 pagineHoney Kids LatestYogesh SharmaNessuna valutazione finora

- BambooDocumento81 pagineBambooThiyagu SundaramNessuna valutazione finora

- The Reformation Fiber Standards Methodology - ClothingDocumento2 pagineThe Reformation Fiber Standards Methodology - ClothingarchiverNessuna valutazione finora

- Project For Carbon Fiber Composite MaterialDocumento15 pagineProject For Carbon Fiber Composite MaterialAbdallah M Al-MajaliNessuna valutazione finora

- Bms PCC and RCC PDFDocumento27 pagineBms PCC and RCC PDFKeshav SethiNessuna valutazione finora

- Specific Accreditation Criteria: ISO/IEC 17025 Application Document Life Sciences - AnnexDocumento8 pagineSpecific Accreditation Criteria: ISO/IEC 17025 Application Document Life Sciences - Annexarli krisnandikaNessuna valutazione finora

- Fin Irjmets1658324268Documento7 pagineFin Irjmets1658324268Raja MalluNessuna valutazione finora

- Technical Test of FiberDocumento11 pagineTechnical Test of FiberFaysal IslamNessuna valutazione finora

- 2017 - GFRP Laminates - Beams - Ansys - Thesis PDFDocumento222 pagine2017 - GFRP Laminates - Beams - Ansys - Thesis PDFNaga PhaneendraNessuna valutazione finora

- IJRHS 2015 Vol03 Issue 04 06Documento4 pagineIJRHS 2015 Vol03 Issue 04 06aqsa imranNessuna valutazione finora

- Project Proposal: Hemp Yarn Spinning MachineDocumento36 pagineProject Proposal: Hemp Yarn Spinning MachineEren Özata100% (1)

- All Cellulose CompositeDocumento5 pagineAll Cellulose Compositeelainer2pNessuna valutazione finora

- Characterizing The Dielectric Properties of Carbon Fiber at Different Processing StagesDocumento7 pagineCharacterizing The Dielectric Properties of Carbon Fiber at Different Processing StagesHamza KhalidNessuna valutazione finora

- Superwool Plus Textiles: DescriptionDocumento2 pagineSuperwool Plus Textiles: DescriptionSagnik ChandaNessuna valutazione finora

- Petitioner Vs Vs Respondents The Solicitor General Jorge G Macapagal Counsel Aurea Aragon-CasianoDocumento8 paginePetitioner Vs Vs Respondents The Solicitor General Jorge G Macapagal Counsel Aurea Aragon-CasianoKirby MalibiranNessuna valutazione finora

- Glass Fibre Rovings For The Reinforcement of Polyester and of Epoxide Resin Systems - SpecificationDocumento13 pagineGlass Fibre Rovings For The Reinforcement of Polyester and of Epoxide Resin Systems - SpecificationBVS NAGABABUNessuna valutazione finora

- Polymer - Physical PropertiesDocumento31 paginePolymer - Physical PropertiessudarshanNessuna valutazione finora

- Textured Yarn Technology Prof. Kushal Sen Department of Textile Technology Indian Institute of Technology, Delhi Lecture - 21 Air-Jet TexturingDocumento20 pagineTextured Yarn Technology Prof. Kushal Sen Department of Textile Technology Indian Institute of Technology, Delhi Lecture - 21 Air-Jet TexturingRtr Hasan MahmudNessuna valutazione finora

- Woven Textiles TextbookDocumento124 pagineWoven Textiles TextbookBarnali Dutta100% (2)

- Waterproofing ApplicationsDocumento16 pagineWaterproofing ApplicationsTansel YılmazNessuna valutazione finora

- Challenges in Cost Modelling of Recycling Carbon Fiber CompositesDocumento8 pagineChallenges in Cost Modelling of Recycling Carbon Fiber CompositesJosip StjepandicNessuna valutazione finora

- Basic CompositesDocumento65 pagineBasic Compositessuba vNessuna valutazione finora

- InsufineMineral TDSDocumento2 pagineInsufineMineral TDSEgyp XsNessuna valutazione finora