Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rolling BeRING Rolls

Caricato da

كريم محمدDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rolling BeRING Rolls

Caricato da

كريم محمدCopyright:

Formati disponibili

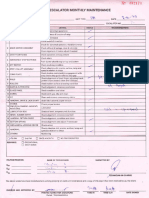

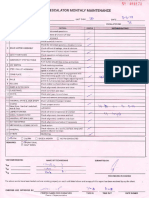

Maintenance Organization ana' Control for Multi-Plant Corporations 27

r - 4

I

1

EOUI?NENl FREOUENCV

W A N E SECTION

I SUBSECTION

1

I 1 MZi

Zpg NAN

HRS

NUYttR- , NAlNlrwrlCE 21,ss,AS lNOlCATE0 REO

Ol.lG.31 K)l Check for unusua. nolse or vlbratlon a t motor. IX I 1

Main Air I speea increaser, compressor and main o i l pump.

Lorpressor

(Uechanical) '

'

I

IO2 ' C h e c L pressure drop across oil f i l t e r

(Items 140) Vent s p u e filter and mvitcn f i l t e r s lf DP IX I

Iexceeds 35 lbs. Clean ann vent d i r t y filter.

I

I

i '

I

-

p3 Check level in oil reservoir ana ado o i l t o

1

~

I

I

brinR t o the W l MAI

Record mmounr 8ddcn.

hegal O i l A (HLO).

I

operation

08 1 Check l u b e o i l system for l e a k s M d r e p a l r dl X

possible

I

09 1i s e d r fora i r

Inspect 1erk.g~at c a s l n g ana labyrinth

ch-e in 1eAa.s.e

'

I i

10 Check l i n k w e on i n l e t butterfly valve

surge valve.Md discharge check valve for

proper lubrication ana evidence of c o r r o s i o n

Figure 2-1. Representative page from preventive maintenance manual or task book.

ance reports are issued monthly and sent to plant managers and the home

office.

At the beginning of each month, the computer prints work schedules

for all maintenance tasks due in the particular month. These schedules

cover machinery and equipment for each plant in the system. Copies are

sent to each plant manager and to the home office staff. The schedules list

Potrebbero piacerti anche

- Piper Seneca II POHDocumento334 paginePiper Seneca II POHJuan Otero100% (1)

- ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control SequencesDocumento20 pagineASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control Sequencesmdalt9180Nessuna valutazione finora

- Impromptu: Eucèhe Big0TDocumento11 pagineImpromptu: Eucèhe Big0TmaskedhombreNessuna valutazione finora

- Chap5 Open SystemDocumento19 pagineChap5 Open SystemRoberto Pu100% (4)

- Carrier 30RB-22PD Product DataDocumento96 pagineCarrier 30RB-22PD Product DataBenokNessuna valutazione finora

- Checklist ForkliftDocumento2 pagineChecklist ForkliftPRINGGO ADI SASONGKO, S.TNessuna valutazione finora

- Fdaihthhahile F (AT ($&L: Ilre Liuj LiDocumento50 pagineFdaihthhahile F (AT ($&L: Ilre Liuj LiIvan AgelovNessuna valutazione finora

- Rvpe T'Q": Monthly Maintenance UrrDocumento1 paginaRvpe T'Q": Monthly Maintenance Urrroland.bunsay.gsbmNessuna valutazione finora

- Operation Manual TPL69-A PDFDocumento65 pagineOperation Manual TPL69-A PDFмоно конечноNessuna valutazione finora

- Original Novachord Service ManualDocumento46 pagineOriginal Novachord Service ManualapakritisNessuna valutazione finora

- Administration of Company LawDocumento9 pagineAdministration of Company LawHunsikaa JainNessuna valutazione finora

- Form 108 Sample-2Documento5 pagineForm 108 Sample-2Harish Chavla50% (2)

- Rlueileilidurunr: Monthly MaintenanceDocumento1 paginaRlueileilidurunr: Monthly Maintenanceroland.bunsay.gsbmNessuna valutazione finora

- Saariaho Folia PDFDocumento9 pagineSaariaho Folia PDFPinturasNegrasNessuna valutazione finora

- Zurn Light CommercialDocumento2 pagineZurn Light CommercialmarcoplumbingNessuna valutazione finora

- Automotive Troubleshooting: Philippine Trade TrainingDocumento64 pagineAutomotive Troubleshooting: Philippine Trade TrainingLem PalinesNessuna valutazione finora

- Insp 10 11 06 1 03 07Documento2 pagineInsp 10 11 06 1 03 07api-3699433Nessuna valutazione finora

- Chieftain TankDocumento28 pagineChieftain TankTateNessuna valutazione finora

- Escalator: Monthly MaintenanceDocumento1 paginaEscalator: Monthly Maintenanceroland.bunsay.gsbmNessuna valutazione finora

- Kaneko Sangyo Co.,LtdDocumento28 pagineKaneko Sangyo Co.,LtdHuynh Thanh TamNessuna valutazione finora

- Simone Mola - Fundamentals of Vehicle DynamicsDocumento353 pagineSimone Mola - Fundamentals of Vehicle DynamicsWagner AbreuNessuna valutazione finora

- In' (/9ffi?e/e: 'L'L 1nd - Dgpl?illlgqDocumento3 pagineIn' (/9ffi?e/e: 'L'L 1nd - Dgpl?illlgqRakesh NayakNessuna valutazione finora

- MA6 Capsule Flight Operations ManualDocumento95 pagineMA6 Capsule Flight Operations ManualBob Andrepont100% (2)

- Disjoncteurs e Courant Alternatif A Haute Tension: Ii (Ternati (Lnal Electr (Ltechnical Commissi (LNDocumento36 pagineDisjoncteurs e Courant Alternatif A Haute Tension: Ii (Ternati (Lnal Electr (Ltechnical Commissi (LNemaNessuna valutazione finora

- Manual ConductimetroDocumento20 pagineManual ConductimetroadrianNessuna valutazione finora

- Monthly Maintenance: EscalatorDocumento1 paginaMonthly Maintenance: Escalatorroland.bunsay.gsbmNessuna valutazione finora

- QT 007Documento2 pagineQT 007ชวลิตศ์ จิตรเที่ยงNessuna valutazione finora

- Aircraft-Power PlantsDocumento116 pagineAircraft-Power PlantsDaniel Barbosa MotaNessuna valutazione finora

- Absorbsi GlikolDocumento11 pagineAbsorbsi GlikolSintaSofianaPutriNessuna valutazione finora

- W#19 2016 - MHJ Asdar AchmadDocumento2 pagineW#19 2016 - MHJ Asdar AchmadAsdar M AchmadNessuna valutazione finora

- F-DA7-AV - Chapter 06Documento11 pagineF-DA7-AV - Chapter 06JimyToasaNessuna valutazione finora

- Sanket Subhas MaliDocumento13 pagineSanket Subhas MaliRADHA MALINessuna valutazione finora

- Air Canada 621 Cf-Tiw Yyz 1971Documento217 pagineAir Canada 621 Cf-Tiw Yyz 1971GFNessuna valutazione finora

- Village T'auk Area No: Name SpacingDocumento1 paginaVillage T'auk Area No: Name SpacingSabari SabariNessuna valutazione finora

- Competition Notes Megh RajDocumento187 pagineCompetition Notes Megh RajB18CS143Nessuna valutazione finora

- 841Documento14 pagine841cleberNessuna valutazione finora

- SPLN 23 A1980 Reciprocating Internal Combustion Engines - Definitions of Locations of An EngineDocumento4 pagineSPLN 23 A1980 Reciprocating Internal Combustion Engines - Definitions of Locations of An EngineUpi SupriyatnaNessuna valutazione finora

- Edgar : Land Transportation OfficeDocumento2 pagineEdgar : Land Transportation OfficeSir nicNessuna valutazione finora

- Downloaded From Manuals Search EngineDocumento6 pagineDownloaded From Manuals Search Enginewilliam aNessuna valutazione finora

- Pilling Machine ChecklistDocumento3 paginePilling Machine Checklisttanoycomet100% (1)

- Adobe Scan 06 May 2023Documento10 pagineAdobe Scan 06 May 2023vasu dha5058Nessuna valutazione finora

- Capacity: of oiiln1NGDocumento24 pagineCapacity: of oiiln1NGVines Joyce NaragaNessuna valutazione finora

- Photovoltaic System Labeling RequirementsDocumento1 paginaPhotovoltaic System Labeling Requirementsabubakr MohamedNessuna valutazione finora

- Modul 2Documento1 paginaModul 209YuliaNurAisahADM 2020Nessuna valutazione finora

- Modul 2 - WatermarkDocumento1 paginaModul 2 - Watermark09YuliaNurAisahADM 2020Nessuna valutazione finora

- Montesino 943608744 12312019Documento1 paginaMontesino 943608744 12312019Louie Wăwîx RendonNessuna valutazione finora

- Inspection Report - Classic Aircraft - J Series, PA-11,12,14,15,16,& 17 MX Checklists 230-3000Documento5 pagineInspection Report - Classic Aircraft - J Series, PA-11,12,14,15,16,& 17 MX Checklists 230-3000gerard.alainxNessuna valutazione finora

- Recruitment: Criteria E P"ri"r""-Fr Eration Timi-IDocumento2 pagineRecruitment: Criteria E P"ri"r""-Fr Eration Timi-IARUP KUMAR DEYNessuna valutazione finora

- Intro To AgriDocumento2 pagineIntro To AgriNur EzlynnNessuna valutazione finora

- Experimental Analysis of Screw Compressor Noise and VibrationDocumento18 pagineExperimental Analysis of Screw Compressor Noise and VibrationBayu SuprayogiNessuna valutazione finora

- SPLN 9d 1978Documento76 pagineSPLN 9d 1978emaNessuna valutazione finora

- Lic Mod5 Part2Documento16 pagineLic Mod5 Part2Anjali S KumarNessuna valutazione finora

- Alcohol Fuel 1980 - MathewsDocumento112 pagineAlcohol Fuel 1980 - MathewsDarwinNessuna valutazione finora

- And That Task But: in The HaveDocumento3 pagineAnd That Task But: in The HaveTayssa MarquesNessuna valutazione finora

- Toyota Surf Maint SchedDocumento2 pagineToyota Surf Maint SchedPaolo A. AguilaNessuna valutazione finora

- Biovue Centrifuge Service ManualDocumento12 pagineBiovue Centrifuge Service ManualSteven Green100% (1)

- Ventilacion BloweDocumento10 pagineVentilacion Blowemarco vasquezNessuna valutazione finora

- B.A. (Programme) Principles of Macroeconomics - I sem-III (5195)Documento3 pagineB.A. (Programme) Principles of Macroeconomics - I sem-III (5195)Gauri GaherwarNessuna valutazione finora

- Dokumen - Tips Manual Industrial Overlock JackDocumento54 pagineDokumen - Tips Manual Industrial Overlock JackShadab AhmadNessuna valutazione finora

- NIA Billing and Collection Manual 1982Documento97 pagineNIA Billing and Collection Manual 1982PastidjaNessuna valutazione finora

- Noi Da Ai Rport T Ermi Nal: 1st PhaseDocumento1 paginaNoi Da Ai Rport T Ermi Nal: 1st PhaseJaimin VagadiyaNessuna valutazione finora

- Type He Wide Rudder Angle Repeat Back Unit Operator's ManualDocumento6 pagineType He Wide Rudder Angle Repeat Back Unit Operator's ManualClarence ClarNessuna valutazione finora

- Automated Stream Analysis for Process Control V1Da EverandAutomated Stream Analysis for Process Control V1Dan MankaNessuna valutazione finora

- Machinery Component Maintenance and Repair: Check Bearing Seat For Out-of-RoundDocumento1 paginaMachinery Component Maintenance and Repair: Check Bearing Seat For Out-of-Roundكريم محمدNessuna valutazione finora

- Maintenance Organization and Control For Multi-Plant CorporationsDocumento1 paginaMaintenance Organization and Control For Multi-Plant Corporationsكريم محمدNessuna valutazione finora

- "Jiffy: Machinery Component Maintenance and RepairDocumento1 pagina"Jiffy: Machinery Component Maintenance and Repairكريم محمدNessuna valutazione finora

- Maintenance Organization and Control For Multi-Plant CorporationsDocumento1 paginaMaintenance Organization and Control For Multi-Plant Corporationsكريم محمدNessuna valutazione finora

- Maintenance Organization and Control For Multi-Plant CorporationsDocumento1 paginaMaintenance Organization and Control For Multi-Plant Corporationsكريم محمدNessuna valutazione finora

- Vibration Analysisss 99Documento1 paginaVibration Analysisss 99كريم محمدNessuna valutazione finora

- Machinery Component Maintenance and Repair: Figure 2-1 1. Sample Sheet of Turbomachinery Turnaround Job PianDocumento1 paginaMachinery Component Maintenance and Repair: Figure 2-1 1. Sample Sheet of Turbomachinery Turnaround Job Pianكريم محمدNessuna valutazione finora

- Maintenance Organization Control For Multi-Plant CorporationsDocumento1 paginaMaintenance Organization Control For Multi-Plant Corporationsكريم محمدNessuna valutazione finora

- Machinery Component Maintenance and Repair: Figure 2-5. Preventive Maintenance Performance ReportDocumento1 paginaMachinery Component Maintenance and Repair: Figure 2-5. Preventive Maintenance Performance Reportكريم محمدNessuna valutazione finora

- Kilna KilniDocumento1 paginaKilna Kilniكريم محمدNessuna valutazione finora

- Machinery Component Maintenance and Repair: No.: MH Seanwine No.: No.: No.: As Use Farms inDocumento1 paginaMachinery Component Maintenance and Repair: No.: MH Seanwine No.: No.: No.: As Use Farms inكريم محمدNessuna valutazione finora

- Machinery Component Maintenance Repair: MpuieDocumento1 paginaMachinery Component Maintenance Repair: Mpuieكريم محمدNessuna valutazione finora

- Machinery Component Maintenance and Repair: Performance ReportsDocumento1 paginaMachinery Component Maintenance and Repair: Performance Reportsكريم محمدNessuna valutazione finora

- Machinery Component Maintenance and Repair: Parts DepotDocumento1 paginaMachinery Component Maintenance and Repair: Parts Depotكريم محمدNessuna valutazione finora

- Machinery Component Maintenance and Repair: Setting An Effective SystemDocumento1 paginaMachinery Component Maintenance and Repair: Setting An Effective Systemكريم محمدNessuna valutazione finora

- Order Costing Systems Are Vital For Analysis and Control of PlantDocumento1 paginaOrder Costing Systems Are Vital For Analysis and Control of Plantكريم محمدNessuna valutazione finora

- Maintenance Organization Control For Multi-Plant CorporutionsDocumento1 paginaMaintenance Organization Control For Multi-Plant Corporutionsكريم محمدNessuna valutazione finora

- Machinery Component Maintenance and Repair: Figure 2-5. Preventive Maintenance Performance ReportDocumento1 paginaMachinery Component Maintenance and Repair: Figure 2-5. Preventive Maintenance Performance Reportكريم محمدNessuna valutazione finora

- Maintenance Organization and Control For Multi-Plant Corporations 29Documento1 paginaMaintenance Organization and Control For Multi-Plant Corporations 29كريم محمدNessuna valutazione finora

- Heinz Bloch Fred GeitnerDocumento1 paginaHeinz Bloch Fred GeitnerKarim MohamedNessuna valutazione finora

- Fear Gear PDFDocumento1 paginaFear Gear PDFكريم محمدNessuna valutazione finora

- Weekly Need: Machinery Component Maintenance and RepairDocumento1 paginaWeekly Need: Machinery Component Maintenance and Repairكريم محمدNessuna valutazione finora

- Fear Gearr PDFDocumento1 paginaFear Gearr PDFكريم محمدNessuna valutazione finora

- Machinery Component Maintenance and Repair: Central Control SystemDocumento1 paginaMachinery Component Maintenance and Repair: Central Control Systemكريم محمدNessuna valutazione finora

- Replucemenr Should Ganizational Srrucrure Problems in Machinery Maintenance As Those ConDocumento1 paginaReplucemenr Should Ganizational Srrucrure Problems in Machinery Maintenance As Those Conكريم محمدNessuna valutazione finora

- Fear Gear PDFDocumento1 paginaFear Gear PDFكريم محمدNessuna valutazione finora

- As Added: Maintenance Organization and Control For Multi-Plant CorporationsDocumento1 paginaAs Added: Maintenance Organization and Control For Multi-Plant Corporationsكريم محمدNessuna valutazione finora

- Replucemenr Should Ganizational Srrucrure Problems in Machinery Maintenance As Those ConDocumento1 paginaReplucemenr Should Ganizational Srrucrure Problems in Machinery Maintenance As Those Conكريم محمدNessuna valutazione finora

- Separation ActionDocumento1 paginaSeparation Actionكريم محمدNessuna valutazione finora

- Plumbing Bank 4Documento19 paginePlumbing Bank 4Billy Joe Breakfast100% (1)

- Oregen Wasted Heat Recovery CycleDocumento6 pagineOregen Wasted Heat Recovery CyclesbiliristhodNessuna valutazione finora

- Factors Affecting PermeabilityDocumento4 pagineFactors Affecting PermeabilityMahesh RamtekeNessuna valutazione finora

- Pool FireDocumento12 paginePool Firejanelle ramdahinNessuna valutazione finora

- Heat Pipe Design Guide-2Documento15 pagineHeat Pipe Design Guide-2Stas KatzirNessuna valutazione finora

- Warman International LTD.: 3170 R/minDocumento1 paginaWarman International LTD.: 3170 R/minFlávio Carvalho FlávioNessuna valutazione finora

- Conduction: C C C CDocumento20 pagineConduction: C C C Cashok pradhanNessuna valutazione finora

- OxygendemandDocumento12 pagineOxygendemandAllenNessuna valutazione finora

- Master Thesis - VIV - Rev 2 - 2011 2 PDFDocumento67 pagineMaster Thesis - VIV - Rev 2 - 2011 2 PDFSruti SmritiNessuna valutazione finora

- Study of RefrigiratorDocumento14 pagineStudy of RefrigiratorRobo RajaNessuna valutazione finora

- Introduction To Reservoir Engineering: - Dr. PrinceDocumento19 pagineIntroduction To Reservoir Engineering: - Dr. PrinceBenyamin Elilaski NababanNessuna valutazione finora

- Air Bearing and Its StabilityDocumento3 pagineAir Bearing and Its StabilityIJEMR JournalNessuna valutazione finora

- The PhysicsDocumento378 pagineThe PhysicsUppalaiah EruguNessuna valutazione finora

- Element of Reservoir Simulation (PNG 506.2)Documento210 pagineElement of Reservoir Simulation (PNG 506.2)Chris ChijiokeNessuna valutazione finora

- CFD Abl2Documento38 pagineCFD Abl2Rahul ShuklaNessuna valutazione finora

- FTPDocumento5 pagineFTPSurendar Vejayan100% (1)

- SWAS Analyzers - SWAS Stands For Steam & Water Analysis SystemDocumento7 pagineSWAS Analyzers - SWAS Stands For Steam & Water Analysis Systemsoumen sardarNessuna valutazione finora

- HF Ranger OM Manual Oct 2002Documento22 pagineHF Ranger OM Manual Oct 2002Rafael RodríguezNessuna valutazione finora

- Name of The Expt: Performance Test On Reciprocating PumpDocumento6 pagineName of The Expt: Performance Test On Reciprocating PumpIndra Chandra RazbongshiNessuna valutazione finora

- Latest Course On RACDocumento24 pagineLatest Course On RACvipin kumarNessuna valutazione finora

- Drum Scrubber 100: Product BulletinDocumento8 pagineDrum Scrubber 100: Product Bulletinفاعل الخيرNessuna valutazione finora

- Reynolds Equation in One DimensionDocumento3 pagineReynolds Equation in One DimensionRio DermawanNessuna valutazione finora

- Acidizing Concepts-Matrix vs. Fracture Acidizing: George E. KingDocumento2 pagineAcidizing Concepts-Matrix vs. Fracture Acidizing: George E. KingRamanamurthy PalliNessuna valutazione finora

- PETE 689 Underbalanced Drilling (UBD) : Well Engineering Read: UDM Chapter 5 Pages 5.1-5.41Documento74 paginePETE 689 Underbalanced Drilling (UBD) : Well Engineering Read: UDM Chapter 5 Pages 5.1-5.41Heris SitompulNessuna valutazione finora

- Assignment 1Documento2 pagineAssignment 1Raja HindustaniNessuna valutazione finora

- Difusión MethodsDocumento5 pagineDifusión MethodsKeily VilcarromeroNessuna valutazione finora

- Waste Heat RecoveryDocumento20 pagineWaste Heat RecoveryAMIT PRAJAPATINessuna valutazione finora