Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Polymer Nanocomposites: April 2007

Caricato da

Lu HkarrTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Polymer Nanocomposites: April 2007

Caricato da

Lu HkarrCopyright:

Formati disponibili

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/259404721

Polymer Nanocomposites

Article · April 2007

DOI: 10.1557/mrs2007.229

CITATIONS READS

401 838

2 authors, including:

Karen I Winey

University of Pennsylvania

381 PUBLICATIONS 16,911 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Nanocomposites View project

polymer nanocomposites View project

All content following this page was uploaded by Karen I Winey on 03 September 2014.

The user has requested enhancement of the downloaded file.

Polymer

such as polymers containing carbon black

or fumed silica. This issue of MRS Bulletin

focuses primarily on polymer nanocompos-

ites containing nanoscale clays and vari-

ous carbon nanotubes to illustrate the status

Nanocomposites

of this rapidly evolving research and de-

velopment enterprise.

The numerous reports of large prop-

erty changes with very small additions of

nanoparticles (⬍1–5 wt%) have fueled the

Karen I. Winey and Richard A. Vaia, view that nanoparticles are a magic pixie

dust that delivers huge dividends. In fact,

Guest Editors recent market surveys have estimated

global consumption of polymer nanocom-

posites at tens of millions of pounds

Abstract (⬃$250 million), with a potential annual

Polymer nanocomposites (PNCs)—that is, nanoparticles (spheres, rods, plates) average growth rate of 24%, to almost

dispersed in a polymer matrix—have garnered substantial academic and industrial in- 100 million pounds in 2011 at a value

terest since their inception, circa 1990. This is due in large part to the incredible promise

exceeding $500–800 million.7–9 Major rev-

enues are forecast from large commercial

demonstrated by these early efforts: PNCs will not only expand the performance space

opportunities such as automobile parts,

of traditional filled polymers, but introduce completely new combinations of properties

coatings, flame retardants, and packaging,

and thus enable new applications for plastics. Low volume additions (1–5%) of nanopar-

where lower-cost, higher-performance

ticles, such as layered silicates or carbon nanotubes, provide property enhancements materials would improve durability and

with respect to the neat resin that are comparable to those achieved by conventional design flexibility while lowering unit price

loadings (15–40%) of traditional fillers. The lower loadings facilitate processing and re- and life cycle cost.

duce component weight. Most important, though, is the unique value-added properties Whatever the case for the long-term

not normally possible with traditional fillers, such as reduced permeability, optical economic growth of polymer nanocom-

clarity, self-passivation, and increased resistance to oxidation and ablation. These posites, the opportunities to deliver targeted

characteristics have been transformed into numerous commercial successes, including material performance reside with the im-

automotive parts, coatings, and flame retardants. This issue of the MRS Bulletin provides plications associated with nanoscale multi-

a snapshot of these exemplary successes, future opportunities, and the critical scientific phase systems. There are important

challenges still to be addressed for these nanoscale multiphase systems. In addition, differences when the fillers shrink from

these articles provide a perspective on the current status and future directions of microscale to nanoscale. This issue of the

polymer nanocomposite science and technology and their potential to move beyond MRS Bulletin provides a snapshot of exem-

additive concepts to designed materials and devices with prescribed nanoscale plary successes, future opportunities, and

composition and morphology. the critical scientific challenges still to be

addressed for these nanoscale multiphase

systems. In addition, these articles provide

a perspective on the current status of poly-

mer nanocomposite science and technol-

Introduction ogy as well as future directions to move

Polymers have been a part of life since expensive engineering plastic. Similarly, it beyond additive concepts to designed

the beginning of humankind. From tar and combining different polymers to form a materials and devices with prescribed

shellac, tortoise shell and horns, to today’s polymer blend or resin can increase the nanoscale composition and morphology.

synthetic offerings such as polyolefins, value of existing polymers.

epoxies, and engineering resins, polymers Polymer nanocomposites incorporate a The Nano Advantage

provide crucial materials for construction, new spectrum of fillers that extend the When fillers are nanoscopic, there are

commerce, transportation, and entertain- function and utility of polymers while advantages afforded to filled polymers and

ment across the globe. Estimates of global maintaining the manufacturing and proc- composites that lead to performance en-

polymer production range from 250 billion essing flexibility inherent to plastics, ther- hancements. These advantages result pri-

pounds to more than 400 billion pounds mosets, and resins. In particular, polymer marily from filler size reduction and the

(approximately 114–181 billion kg) annually. nanocomposites have been successful concomitant increase in surface area. The

In the majority of their diverse applica- with regard to overcoming traditionally size of the additive might drop by up to

tions, polymeric materials are not chemi- antagonistic combinations of properties. three orders of magnitude relative to con-

cally or molecularly homogenous but are Since the first reports in the late 1980s,1–6 ventional alternatives. In contrast, many

multicomponent systems. By adding fillers, the term “polymer nanocomposite” has nanotechnologies associated with electri-

such as minerals, ceramics, metals, or even evolved to refer to a multicomponent sys- cal or optical properties benefit from new

air, materials scientists can generate an infi- tem in which the major constituent is a physical phenomena arising from quan-

nite variety of materials with unique phys- polymer or blend thereof and the minor tum confinement effects induced by the

ical properties and competitive production constituent has at least one dimension below nanoscale dimensions of the material. The

costs. For example, adding filler to a com- 100 nm. Polymer nanocomposite is an ap- literature about polymer nanocomposites

modity thermoplastic such as polypropy- propriate synonym for inorganic–organic contains many discussions about the im-

lene can achieve performance levels that hybrids and molecular composites and also plications and physical manifestations of

would otherwise require a much more encompasses mature commercial products the reduction in filler length scale.10–14

314 MRS BULLETIN • VOLUME 32 • APRIL 2007 • www.mrs.org/bulletin

Polymer Nanocomposites

For example, compare a microcomposite

and a nanocomposite with the same volume

fraction of a secondary constituent (filler),

where the spherical particles have volumes

of 1 μm3 or 1 nm3 per particle, respectively.

The mean particle–particle separation is

smaller by three orders of magnitude, the

total internal interfacial area increases by

six orders of magnitude, and the number

density of constituents increases by nine

orders of magnitude in the nanocomposite.

Although these numbers alone are impres-

sive, the filler size must be viewed relative

to the size of polymer molecules to cap-

ture the full potential impact of nanoscale

fillers on composite properties.

Many properties are related to the size of

the polymer chain, which can be expressed

as the radius of gyration Rg (the second

moment of the three-dimensional distri-

bution of the monomers of the polymer

chain—approximately the expanse of the

molecule). Rg is on the order of 3–30 nm. Figure 1. The ratio of interfacial volume to the particle volume (Vinterface /Vparticle) as a function

Depending on the strength of interaction of the particle aspect ratio and the ratio of the interfacial thickness to the particle size (␦).

between the filler surface and the matrix, The aspect ratio and δ are defined in the schematic at right (r is radius, l is length, h is

the polymer chains in close proximity to the height). The interfacial thickness (red shell, t) is assumed to be independent of the particle

filler will be perturbed with respect to size. As particles decrease in size to less than 100 nm, the interfacial volume around a particle

those in the bulk (i.e., away from the in- can dominate the physical properties, and this is particularly evident for spheres and rods.

terface). The thickness t of this interfacial

region that surrounds the particle is, to the interfacial region is ⬃63 vol%, sug- Scope and Impact

first order, independent of the size of the gesting that more than half of the com- As with traditional filled plastics, an

particle. Thus, as the particle size decreases, posite is affected by the presence of the infinite variety of possible polymer–

the relative volume of this interfacial ma- second-phase particles. If the particle is in- nanoparticle combinations conceptually

terial, Vinterface, with respect to the volume creased to 20 nm in radius without chang- affords tunability. Thus, given the diver-

of the particle, Vparticle, will increase. ing the interfacial thickness or particle sity of possible properties and tolerable

Figure 1 shows this ratio, Vinterface/Vparticle, loading, the volume occupied by the in- costs, there is no universal “best” nanopar-

as a function of particle aspect ratio from terfacial region would be only ⬃1.2 vol%. ticle filler for polymer nanocomposites.

plates (aspect ratio ⬍1) to spheres to rods The importance of polymer–particle in- The best nanoparticle filler (or traditional

(aspect ratio ⬎1). The filler size is ex- teractions is amplified in polymer nanocom- filler, for that matter) is determined by

pressed as δ, the ratio of the thickness of the posites such that the interface and the meeting both a specific set of physical

interface to the smallest dimension of cooperativity between particles dominate properties and a price point associated

the particle. Micrometer-sized fillers have the macroscopic properties. For example, with a particular part or product. Table I

δ ⬃ 0.01, so that at any aspect ratio, the vol- weak forces between particles, such as compares the size, shape, properties, and

ume of the particles exceeds that of the in- van der Waals, are more pronounced for uses of traditional fillers and newer nano-

terfacial region. However, when the fillers nano-sized particles because of lower sur- scale fillers. As noted earlier, a few tradi-

are reduced to the nanoscale and δ ⬃ 1–10, face roughness, smaller average particle tional fillers have sizes below 100 nm, and

the volume of the interfacial region exceeds separations, and thus higher dispersive nanoscale fillers can access high aspect ra-

the volume of the particle. In addition, at a forces. Also, because of the nanoscopic di- tios. Although there is considerable over-

fixed value of δ, the aspect ratio has an ef- mensions of the particles, the accessible lap in the elastic moduli and thermal

fect on Vinterface/Vparticle, showing an expected aspect ratio of discrete secondary con- conductivities between the traditional and

increase from plates to rods to spheres as stituents can approach 100 or more. These nanoscale fillers, the electrical properties

the fillers change from two-dimensional high-aspect-ratio, nanoscale fillers can of the carbon-based nanofillers are in a

(plate) to one-dimensional (rod) to zero- reach percolation thresholds at ⬍1–5 vol% class by themselves, with conductivities

dimensional (sphere) objects. The magni- and thereby exhibit large increases in bulk more than 100 times higher. This sum-

tude of this change increases dramatically mechanical and transport properties at mary of fillers encourages one to imagine

as the filler size drops; for example, at δ these low loadings. The percolation many possibilities for remarkable proper-

10, Vinterface/Vparticle increases by two orders threshold is the filler concentration at ties within the broad materials class of

of magnitude between plates and spheres. which the electrical conductivity increases polymer nanocomposites.

Furthermore, these calculations demon- sharply by orders of magnitude, indicat- The first key demonstration of polymer

strate the impact that even a small volume ing that conductive pathways span the nanocomposites was provided by the pio-

fraction of filler has on the surrounding macroscopic sample. Thus, the casual ob- neering work of Okada and co-workers at

polymers. For example, by dispersing a servation that nanofillers act as pixie dust Toyota Central Research in the late

mere 1 vol% of a nanosphere (radius is firmly rooted in the implications of re- 1980s.1–4 By combining inclusion and col-

⬃2 nm) in a polymer (interfacial thickness ducing the size of the fillers by up to three loidal chemistry of mica-type layered sili-

⬃6 nm), the volume fraction occupied by orders of magnitude. cates (nanoclay) with surface-initiated

MRS BULLETIN • VOLUME 32 • APRIL 2007 • www.mrs.org/bulletin 315

316

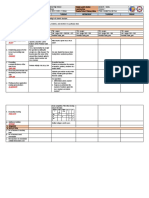

Table I: Characteristics of Traditional and Nanoscale Fillers: Shape, Size, Properties, Dimensions, and Uses.

Approximate Smallest Aspect Elastic Electrical Thermal Commercial Uses

Shapea Dimension Ratiob Modulus Conductivity Conductivity

(nm)a (GPa) (S/cm) (W/m K)

Traditional Fillers

Carbon black32 agglomerate 10–100 1–5 … 10–100 0.1–0.4 tires, hoses, shoes, elastomers

of spheres

Carbon fiber33 rods 5,000–20,000 10–50 300–800 0.1–10 100–1000 aerospace, automotive, marine,

Polymer Nanocomposites

sporting, medical

Carbon graphite34 plate 250–500 15–50 500–600 1–10 100–500 gaskets, seals

35

E-glass rod 10,000– 20–30 75 … … marine, automotive,

20,000 construction, filtration

Mineral: CaCO336 sphere 45–70 ~1 35 … 3–5 paper, paint, rubber, plastics

platelet 600–4,000 1–30

Mineral: silica37,38 agglomerate 8,000–30,000 5–10 30–200 … 1–10 reinforced plastics, thermal

of spheres insulator, paint, rubber reinforcing

agent

Mineral: talc, china platelet 5,000–20,000 5–10 1–70 … 1–10 paper, consumer goods,

clay37,39 construction

Nanoscale Fillers

Carbon nanofiber40 rod 50–100 50–200 500 700–1000 10–20 hoses, aerospace, ESD/EMI

shielding, adhesives

Carbon MWNT41 rod 5–50 100–10,000 1,000 500–10,000 100–1000 automotive, sporting, ESD/EMI

shielding

Carbon SWNT42 rod 0.6–1.8 100–10,000 1,500 1000–10,000 1000 filters, ESD/EMI shielding

Aluminosilicate plate 1–10 50–1000 200–250 … 1–10 automotive, packaging, sporting,

nanoclay43 tires, aerospace

Nano-TiO237,44 sphere 10–40 ~1 230,000 10–11–10–12 12 photocatalysis, gas sensors, paint

Nano-Al2O337,45 sphere 300 ~1 50 10–14 20–30 seal rings, furnace liner tubes,

gas laser tubs, wear pads

a

Dispersible unit.

b

Aspect ratio is defined as the long axis to short axis irrespective of shape. Note that this differs from Figure 1.

ESD is electrostatic discharge; EMI is electromagnetic interference; MWNT is multiwall carbon nanotube; SWNT is single-wall carbon nanotube.

MRS BULLETIN • VOLUME 32 • APRIL 2007 • www.mrs.org/bulletin

Polymer Nanocomposites

polymerization, they demonstrated that

only ⬃2–4 vol% of layered silicate suffi-

ciently improved the mechanical proper-

ties of nylon-6 polymer at elevated

temperatures to enable its use inside an

automotive engine compartment.

Since then, the patent and literature ac-

tivity has been astonishing (Figure 2).15

From 1992 to 2004, the number of citations

for polymer nanocomposites has doubled

every two years, indicating that these ma-

terials are still on the steep part of the tech-

nology S-curve (Figure 2a). Since 2001,

polymer nanocomposites represent ⬃43%

of the broader nanocomposite field, which

includes metals, ceramics, and thin films

(Figure 2b). Of the publicly available liter-

ature on polymer nanocomposites, the ma-

jority (80%) is in peer-reviewed journals,

whereas patents have maintained a con-

stant fraction (8–10%). Together, layered

silicates (nanoclays) and carbon nanotubes

represent almost 50% of the ongoing in-

vestigations. Polymer–clay nanocomposites,

however, might be reaching saturation, as

evidenced by a diminishing growth rate in

publications and patents per year. In con-

trast, polymer–carbon nanotube composites

have rapidly accelerated since the

availability of carbon nanotubes became

widespread in the late 1990s and are still

exhibiting a steady growth rate (Figure 2b).

After almost 20 years, the diversity in

scientific investigations, technology ad-

vancements, processing innovations, and

product development is staggering. A sig-

nificant number of excellent review papers

(e.g., clays16–23 and carbon nanotubes22–26)

and books27–30 are available that chronicle

and summarize the status of various

nanoparticle–polymer combinations and

the broad scientific and technological chal-

lenges that still need to be overcome.

This issue of MRS Bulletin provides six

articles to illustrate the breadth of activity

in polymer nanocomposites. Hunter et al.

highlight the issues in polymer–nanoclay

composites, where the most commercial

activity currently exists. Baur and Silver-

man consider the opportunities in adding

nanofillers to traditional engineering poly-

mer composites that use continuous fiber

reinforcements. Schadler and co-workers

focus on the implications and engineering

possibilities of larger interfacial areas per

unit volume. Krishnamoorti addresses the Figure 2. Growth trends of the polymer nanocomposite enterprise based on yearly pub-

issues of weak forces becoming significant lications catalogued in the CAPLUS and MEDLINE databases of the American Chemical

for nano-sized components and strategies Society.15 (a) Number of occurrences per year of the term “nanocomposite” (NC, open

for overcoming their tendency to agglom- squares) and “nanocomposite” appearing with “polymer” (PNC, solid circles). “Polymer

nanocomposites” (PNC) is further refined to those discussing “clay” PNC (red symbols)

erate. Winey et al. explore opportunities

and “nanotube” PNC (blue symbols). (b) Analysis of the number of citations per year,

for nanofillers to modify electrical and showing the total fraction of “nanocomposite” occurrences that discuss polymer nanocom-

thermal properties of polymers. Finally, posites (PNC:NC, open squares), as well as the total fraction of “polymer nanocomposite”

Hule and Pochan consider the opportuni- occurrences that are patents (PNC patents, solid circles) that discuss clay-based PNCs

ties of polymer nanocomposites in the (PNC with “clay,” red symbols) and that discuss nanotube-containing PNCs (PNC with

medical arena. “nanotube,” blue symbols).

MRS BULLETIN • VOLUME 32 • APRIL 2007 • www.mrs.org/bulletin 317

Polymer Nanocomposites

Future Outlook and piezoresistive materials for MEMs- 12. A. Bansal, H. Yang, C. Li, K. Cho, B.C.

What’s next? Where are the ground- based sensors. In addition, new proc- Benicewicz, S.K. Kumar, L.S. Schadler, Nature

breaking opportunities? What are the essing tools and on-line controls are being Materials 4, 693 (2005).

developed to either (1) uniformly distrib- 13. R. Krishnamoorti, R.A. Vaia, E.P. Giannelis,

challenges that pervade polymer nano- Chem. Mater. 9, 1728 (1996).

composites? Of extreme importance in all ute nanofiller to produce homogeneous

14. F.W. Starr, T.B. Schroeder, S.C. Glotzer,

the potential markets is the establishment bulk properties or (2) spatially vary the Macromolecules 35, 4481 (2002).

of a better, quantitative understanding of nanofiller concentration to meet specific 15. SciFinder, Chemical Abstract Service (CAS)

the occupational health risks.31 For poly- design criteria. One might refer to these of the American Chemical Society, CAPLUS

mer nanocomposites, this is particularly two classes of polymer nanocomposites and MEDLINE databases, October 8, 2006. Data

important during the production of nano- as nano-“filled” systems and nano- resulted from a keyword search on “nanocom-

sized fillers and composite fabrication, as “composite” systems, respectively. By posite” and selecting citations that included this

well as during recycling, incineration, or drawing inspiration from biology and en- concept (25,435 total citations). Results were re-

gineered fiber-reinforced composites, fined using “polymer” (10,350 total citations),

combustion.

“nanotube or nanorod” (864 total citations), or

Whereas the recent increased availabil- polymer nanocomposites with spatially

“clay or (layered silicate) or montmorillonite”

ity of the new nanoscale fillers has been a controlled morphology are beginning to (3,938 total citations). Other keyword combina-

major contributor to the rapid develop- provide viable options to critical compo- tions did not drastically modify the refined

ment of polymer nanocomposites, robust nents of active devices, such as fuel cell number of citations (⬍2–3%).

structure–property–processing relation- membranes, batteries, photovoltaics, sen- 16. E.P. Giannelis, Adv. Mater. 8, 29 (1996).

ships are critical to further market infiltra- sors, and actuators. 17. M. Alexandre, P. Dubois, Mater. Sci. Eng., R

tion. Relationships that provide a priori Polymer nanocomposites have recently 28, 1 (2000).

predictions of macroscopic properties for become part of established modern tech- 18. S.S. Ray, M. Okamoto, Prog. Polym. Sci. 2,

a given polymer, a specific nanoscale filler nologies, but the most significant accom- 1539 (2003).

plishments of these materials are still 19. M. Okamoto, “Polymer/Clay Nanocom-

(or fillers), and a particular spatial arrange- posites,” in Encyclopedia of Nanoscience and

ment of the filler are still in their infancy. ahead of us. As an increasing number of Nanotechnology, H.S. Nalwa, Ed. (American

For example, to what extent can existing scientists and engineers contribute to the Scientific, Stevenson Ranch, CA, 2004), vol. 8, p. 1.

continuum composite theories be modi- understanding of polymer nanocompos- 20. E.T. Thostenson, C. Li, T.-W. Chou, Compos.

fied to account for the implications that ites, what remains to be seen is which Sci. Technol. 65, 491 (2005).

arise when the filler is comparable to the products will be critically enhanced and 21. L.F. Drummy, H. Koerner, B.L. Farmer, R.A.

polymer in size? Are the properties cur- enabled by this broad and evolving class Vaia, Advanced Morphology Characterization of

rently being achieved in polymer nanocom- of materials. Clay-Based Polymer Nanocomposites: CMS Work-

posites as high as we can expect to obtain? shop Lecture Series (Clay Minerals Society,

Chantilly, VA, 2006) vol. 14.

However, approaches to these chal- Acknowledgments 22. S.C. Tjong, Mater. Sci. Eng., R 53, 73

lenges are not without precedent. The The authors thank Minfang Mu (Uni- (2006).

underlying science and constitutive rela- versity of Pennsylvania) for compiling the 23. F. Hussain, M. Hojjati, M. Okamoto, R.E.

tionships for these nanoscopic materials data for Table I. K.I. Winey thanks Dupont Gorga, J. Compos. Mater. 40, 1511 (2006).

should share commonality with collections for hosting her sabbatical visit and acknowl- 24. X.-L. Xie, Y.-W. Maia, X.-P. Zhou, Mater. Sci.

of nanoscopic polymer chains, whose frame- edges funding from NSF-DMR-MRSEC- Eng., R 49, 89 (2005).

work has been developed through nearly 05–20020. R.A. Vaia thanks the Materials 25. M. Moniruzzaman, K.I. Winey, Macromole-

a century of chemistry and physics and is cules (Review) 39, 5194 (2006).

Research Laboratory at the University of

the foundation of the global polymer in- 26. T.J. Pinnavaia, G.W. Beall, Polymer-Clay

California, Santa Barbara, for hosting his Nanocomposites (Wiley, New York, 2001).

dustry. Future developments toward the sabbatical visit. 27. R. Krishnamoorti, R.A. Vaia, Eds., Polymer

full potential of nanoscale multicomponent Nanocomposites: Synthesis, Characterization, Model-

polymer blends rely on these previous in- References ing (ACS Symposium Series, American Chemical

sights to tackle the ambiguities associated 1. Y. Fukushima, S. Inagaki, J. Inclusion Phenom. Society, Washington, DC, 2001).

with smaller filler sizes, where the distinc- 5, 473 (1987). 28. S.S. Ray, M. Bousmina, Polymer Nanocom-

tion between filler and polymer fade into 2. Y. Fukushima, A. Okada, M. Kawasumi, posites and Their Applications (American Scientific,

filler-molecules and polymer-molecules. T. Kurauchi, O. Kamigaito, Clays Clay Miner. 23, Stevenson Ranch, CA, 2006).

Economically, given the current diver- 27 (1988). 29. Y.-W. Mai, Z.-Z. Yu, Eds., Polymer Nanocom-

sity in nanoparticle cost (carbon black and 3. A. Usuki et al., J. Mater. Res. 8, 1174 (1993). posites CRC (Woodhead Publishing, Cambridge,

montmorillonite versus single-wall car- 4. Y. Kojima et al., J. Mater. Res. 8, 1185 UK, 2006).

(1993). 30. A.B. Morgan and C.A. Wilkie, Eds., Flame

bon nanotubes), two approaches are de-

5. R.A. Vaia, H. Ishii, E.P. Giannelis, Chem. Retardant Polymer Nanocomposites (Wiley, New

veloping based on potential markets. The Mater. 5, 1694 (1993). York, 2007).

lower-cost nanoparticles provide competi- 6. T.P. Lan, T.J. Pinnavaia, Chem. Mater. 6, 2216 31. “Environmental, Health and Safety Needs

tion to traditional filler technologies and (1994). for Engineered Nanoscale Materials” (Commit-

have important advantages in commodity 7. A. McWilliams, “Nanocomposites, Nanopar- tee on Technology, National Science and

applications, whereas the higher-cost ticles, Nanoclays, Nanotubes” (NANO21C, Technology Council, Washington, DC, 2006;

nanoparticles target higher-value indus- BCC Research, Norwalk, CT, 2006). www.nano.gov).

trial sectors such as medical and elec- 8. “Polymer Nanocomposites Create Exciting 32. J.-B. Donnet, R.C. Bansal, M.-J. Wang,

tronics. Rather than replacing existing Opportunities in the Plastics Industry” (Principia Carbon Black (Marcel Dekker, New York, ed. 2,

Partners, Jersey City, NJ, 2005). 1993); J.C. Grunlan, W.W. Gerberich, L.F.

materials and traditional filled plastics, a

9. A.M. Thayer, Chem. Eng. News 78, 36 (October Francis, Polym. Eng. Sci. 41, 1947 (2001).

common business strategy is to develop 16, 2000). 33. J.-B. Donnet, T.K. Wang, S. Rebouillat,

new applications based on the uniqueness 10. R.A. Vaia, E.P. Giannelis, MRS Bull. 26, 394 J.C.M. Peng, Carbon Fibers (Marcel Dekker, New

of polymer nanocomposites, such as (2001). York, ed. 3, 1998; www.apsci.com/home.html).

shape-memory materials for morphing 11. R.A. Vaia, H.D. Wagner, Mater. Today 7, 32 34. A. Yasmin, I.M. Daniel, Polymer 45, 8211

aircraft, self-passivating films for satellites, (November 2004). (2004); D.D.L. Chung, J. Mater. Sci. 37, 1475

318 MRS BULLETIN • VOLUME 32 • APRIL 2007 • www.mrs.org/bulletin

Polymer Nanocomposites

(2002); J.M. Keith, C.D. Hingst, M.G. Miller, 39. V. Svehlova, E. Poloucek, Angew. Makromol. Berber, Y.-K. Kwon, D. Tománek, Phys. Rev. Lett.

J.A. King, R.A. Hauser, Polym. Compos. 27, 1 Chem. 214, 91 (1994); E. Bailey, J.R. Holloway, 84, 4613 (2000); U. Dettlaff-Weglikowska et al.,

(2006). Earth. Planet. Sci. Lett. 183, 487 (2000); A. Kirak, J. Am. Chem. Soc. 127, 5125 (2005).

35. D.P.N. Vlasveld, P.P. Parlevliet, H.E.N. H. Yilmaz, S. Guler, C. Guler, J. Phys. D: Appl. 43. H.S. Jeona, J.K. Rameshwarama, G. Kimb,

Bersee, S.J. Picken, Composites Part A 36, 1 Phys. 32, 1919 (1999). D.H. Weinkauf, Polymer 44, 5749 (2003); Y.-P.

(2005); A. Pegormti, L. Fambfu, C. Migliaresi, 40. Applied Sciences Inc. Home Page, http:// Wu, Q.-X. Jia, D.-S. Yu, L.-Q. Zhang, Polym. Test.

Polym. Compos. 21, 466 (2000). www.apsci.com/home.html; H.Y. Ng, X. Lu, 23, 903 (2004); V.V. Murashov, J. Phys.: Condens.

36. K. Yang et al., Polym. Comp. 27, 443 (2006); S.K. Lau, Polym. Compos. 26, 66 (2005); C. Yu Matter. 11, 1261 (1999); T.J. Pinnavaia, G.W.

M. Lei et al., J. Cryst. Growth 294, 358 (2006); T. et al., Trans. ASME 128, 234 (2006); J. Zeng et al., Beall, Polymer-Clay Nanocomposites, Wiley Series

Ding, E.S. Daniels, M.S. El-Aasser, A. Klein, Composites Part B 35, 245 (2004); T. Morita, H. in Polymer Science (Wiley, New York, 2001).

J. Appl. Polym. Sci. 100, 4550 (2006); E. Inoue, Y. Suhara, U.S. Patent 6,565,971 (May 20, 44. S. Amarchand, T.R. Rama Mohan, P.

Ramachandran, P. Raji, K. Ramachandran, S. 2003). Ramakrishnan, Adv. Powder Technol. 11, 415

Natarajan, Cryst. Res. Technol. 41, 64 (2006). 41. J. Zeng et al., Composites Part B 35, 245 (2000); R.J. Fleming et al., IEEE Trans. Dielectrics

37. C. Clauser, E. Huenges, in Rock Physics and (2004); NanoLab Home Page, www.nano-lab. and Electrical Insulation 12, 745 (2005); The A to

Phase Relations: A Handbook of Physical Constants com/nanotubes-research-grade.html; M.-K. Z of Materials Home Page, www.azom.com/

(American Geophysical Union, Washington, Yeh, N.-H. Tai, J.-H. Liu, Carbon 44, 1 (2006); M. details.asp?ArticleID1179.

DC, 1995) p. 105. Fujii et al., Phys. Rev. Lett. 95, 065502 (2005); T.W. 45. High Precision Machining of Hard Materi-

38. L. Brabec et al., Microporous Mesoporous Ebbesen et al., Nature 382, 54 (1996). als, Insaco Inc. Home Page, www.insaco.com/

Mater. 94, 226 (2006); I. Hackman, L. Hollaway, 42. E. Bichoutskaia, M.I. Heggie, A.M. Popov, home.asp. 䊐

Composites Part A 37, 1161 (2006). Y.E. Lozovik, Phys. Rev. B 73, 045435 (2006); S.

Karen I. Winey Richard A. Vaia Jeff Baur Brian C. Benicewicz Shane E. Harton

Karen I. Winey, Guest NSF Young Investigator NanoMaterials Strategy Outstanding Engineers Jeff Baur is a senior re-

Editor for this issue of Award in 1994 and was Group and chair of the and Scientists Award search engineer for the

MRS Bulletin, is a pro- elected fellow of the NanoScience and Tech- (2006) from the Affiliate Advanced Composites

fessor of materials sci- American Physical Soci- nology (NST) Strategic Societies Council of Branch within the Air

ence and engineering at ety in 2003. Winey is Technology Team at the Dayton, Ohio. Vaia Force Research Labora-

the University of Penn- currently chair of the U.S. Air Force Research serves on the editorial tory’s Materials and

sylvania. She earned her Polymer Physics Gordon Laboratory (AFRL). He boards of Chemistry of Manufacturing Direc-

BS degree in materials Research Conference received his PhD degree Materials, Macromole- torate. His received his

science and engineering scheduled for 2010. She in materials science and cules, and Materials PhD degree from the

from Cornell University recently published an engineering at Cornell Today. He is on the MRS Massachusetts Institute

and her MS and PhD invited review article University in 1995 and board of directors, and of Technology’s pro-

degrees in polymer sci- entitled “Polymer was a distinguished is a member-at-large for gram in polymer science

ence and engineering Nanocomposites graduate from Cornell’s the Division of Poly- and technology in 1997.

from the University of Containing Carbon Air Force ROTC. meric Materials Science Baur has held re-

Massachusetts under the Nanotubes” in Vaia’s research group and Engineering of the search and management

direction of Edwin L. Macromolecules (39, focuses on polymer American Chemical So- positions within the Air

Thomas. 5194–5205, 2006). nanocomposites, pho- ciety. He has authored Force Research Lab,

Winey probes Winey can be reached tonic technologies, and more than 100 papers Borden Chemical UV

structure–property at 3231 Walnut St., Uni- their impact on develop- and patents. Coating Division, and at

relationships in versity of Pennsylvania, ing adaptive soft matter. Vaia can be reached at MIT’s Institute for Sol-

nanotube–polymer com- Philadelphia, PA His honors and awards the Air Force Research dier Nanotechnologies,

posites, ion-containing 19104-6272, USA; tel. include Air Force Out- Laboratory, 2941 and has published nu-

polymers, and block 215-898-0593, fax standing Scientist (2002); Hobson Way, Bldg. 654, merous papers in ad-

copolymers, where the 215-573-2128, and e-mail MRL Visiting Professor Wright-Patterson Air vanced electrical,

properties of interest in- winey@seas.upenn.edu. at the University of Cali- Force Base, OH optical, and mechanical

clude electrical fornia, Santa Barbara 45433-7750 USA; tel. properties of polymer

conductivity, thermal Richard A. Vaia, (2006); Air Force Office 937-255-9184, fax composites. His current

conductivity, mechanical Guest Editor for this of Scientific Research 937-255-9157, and interests are in nanocom-

properties and perme- issue of MRS Bulletin, Star Team (2003–2005, e-mail richard.vaia@ posites for improvement

ability. She received an is the lead of the 2005–2007), and the wpafb.af.mil. of fiber-reinforced

MRS BULLETIN • VOLUME 32 • APRIL 2007 • www.mrs.org/bulletin 319

Polymer Nanocomposites

Rohan A. Hule Douglas L. Hunter Karl W. Kamena Takashi Kashiwagi Ramanan

Krishnamoorti

composite structures Institute, 110 Eighth St., and the Delaware Hunter can be neering Department of

and materials for mor- Troy, NY 12180 USA; tel. Biotechnology Institute reached at Southern the University of Mary-

phing structures. 518-276-2534, fax at the University of Clay Products, 1212 land and a guest re-

Baur can be reached 518-276-6434, and e-mail Delaware. After earning Church St., Gonzales, searcher at the Fire

at AFRL/MLBCO, 2941 benice@rpi.edu. his BTech degree in TX 78629 USA; tel. Research Division of the

Hobson Way, Wright- polymer science and en- 830-672-1994 and e-mail National Institute of

Patterson Air Force Shane E. Harton is a gineering from the Uni- dhunter@scprod.com. Standards and Technol-

Base, OH 45433-7750 postdoctoral research versity Institute of ogy. Kashiwagi earned

USA; tel. 937-255-9143, scientist in the Depart- Chemical Technology in Karl W. Kamena is the his BS and MS degrees

fax 937-656-4706, and ment of Chemical Engi- Mumbai, India, Hule commercial manager of from Keio University

e-mail jeff.baur@ neering at Columbia studied rheology in the Cloisite® Nanoclays at and his PhD degree

wpafb.af.mil. University, working Complex Fluids and Southern Clay Products from Princeton Univer-

with Sanat K. Kumar. Polymer Engineering Inc. He graduated from sity in aerospace me-

Brian C. Benicewicz is Harton received his PhD Group at the National the University of Massa- chanical science. His

director of the New degree in materials sci- Chemical Laboratory in chusetts in 1965 with a research interests

York State Center for ence and engineering Pune. degree in chemical include combustion of

Polymer Synthesis and a from North Carolina Hule’s current re- engineering. polymeric materials

professor of chemistry State University in 2005 search focuses on Kamena worked with and flammability

at Rensselaer Polytech- under the advisement of organic–inorganic Dow Chemical Co. from properties of polymer

nic Institute in Troy, N.Y. Harald Ade. hybrid nanomaterials, 1965 to 1994 in a variety nanocomposites.

He received his BS de- As a graduate stu- self-assembled hydro- of technical and com- Kashiwagi can be

gree from the Florida In- dent, Harton’s work pri- gels, and understanding mercial positions. His reached at NIST, MS

stitute of Technology in marily focused on structure–property experience at Dow ranged 8665, 100 Bureau Dr.,

1976 and his PhD de- thermodynamics of relationships in bio- from product develop- Gaithersburg, MD

gree in polymer chem- highly incompatible nanomaterials using ment and project man- 20899-8665 USA; tel.

istry from the polymer/polymer inter- polymer physics tools. agement to business, 301-975-6699, fax

University of Connecti- faces, particularly the in- Hule can be reached marketing, public policy 301-975-4052, and e-mail

cut in 1980. fluences of the by e-mail at hule@ issues management, and takashi.kashiwagi@

Benicewicz held posi- deuterium isotope ef- udel.edu. government affairs. Dur- nist.gov.

tions at Celanese fect. Harton’s current ing the past ten years,

Research Co. and at work at Columbia Uni- Douglas L. Hunter is a Kamena has been in- Ramanan

Johnson & Johnson and versity focuses on ther- senior scientist at South- volved with clay/ Krishnamoorti is a pro-

was the deputy group modynamics of ern Clay Products Inc. polymer nanocomposite fessor of chemical and

leader at Los Alamos polymer/inorganic in- (SCP), where he has technologies in consult- biomolecular engineer-

National Laboratory be- terfaces, including com- worked since 1997. He ing capacities and work- ing and a professor of

fore joining Rensselaer patibilization of earned his PhD degree ing with companies. He chemistry at the Univer-

in 1997. His research polymer/inorganic in chemistry at Texas is a member of the Soci- sity of Houston (UH).

focuses on polymer nanocomposites. A&M University. Prior ety of Plastics Engineers. After earning his PhD

nanocomposites, Harton can be to SCP, he worked at Kamena can be degree in chemical engi-

controlled radical poly- reached at the Depart- Dow Chemical Co., be- reached at Cloisite® neering from Princeton

merizations, fuel cell ment of Chemical ginning in 1975. At Nanoclays, 5508 Hwy. University in 1994, he

membranes, liquid- Engineering, Columbia Dow, Hunter held a va- 290 West, Ste. 206, held postdoctoral posi-

crystalline and electrically University, 500 W. 120th riety of positions work- Austin, TX 78735 USA; tions at the California

conducting polymers, St., New York, NY ing in early-stage tel. 512-358-3108, fax Institute of Technology

and polymer synthesis. 10027 USA. catalyst and process de- 512-899-2332, and e-mail and Cornell University.

Benicewicz can be velopment and technical kkamena@scprod.com. Krishnamoorti joined

reached at the Depart- Rohan A. Hule is a service. The focus of his UH as an assistant pro-

ment of Chemistry and graduate student in the research at SCP has Takashi Kashiwagi is a fessor in 1996 and was

Chemical Biology, Department of Materials been polymer clay research professor in the promoted to professor

Rensselaer Polytechnic Science and Engineering nanocomposites. Fire Protection Engi- and appointed associate

320 MRS BULLETIN • VOLUME 32 • APRIL 2007 • www.mrs.org/bulletin

Polymer Nanocomposites

Sanat K. Kumar Sarah L. Lewis Minfang Mu Donald R. Paul Darrin J. Pochan

dean for research in phenomena, nanotech- Pennsylvania. She re- has served as editor of also serves as associate

2005. His primary nology, and polymers. ceived her BSc degree in Industrial and Engineer- editor for North Amer-

research area is in the Kumar can be reached chemistry and her MSc ing Chemistry Research, ica of Soft Matter, a new

understanding of at the Department of degree in the Depart- published by the Ameri- interdisciplinary journal

structure–processing– Chemical Engineering, ment of Macromolecular can Chemical Society, from the Royal Society

property relations for Columbia University, Science at Fudan Uni- since 1986. of Chemistry.

multicomponent poly- 500 W. 120th St., New versity, China. At Fudan Paul can be reached Pochan can be

meric materials, with re- York, NY 10027 USA; University, Mu worked at the Department of reached by e-mail at

cent extensions into tel. 212-854-2193, fax with Ming Jiang on Chemical Engineering, pochan@udel.edu.

biomaterials for drug 212-854-3054, and e-mail self-assembly of University of Texas

delivery and the devel- sk2794@ protein-graft-dextran at Austin, Austin, Linda S. Schadler is a

opment of high- columbia.edu. and polymer complexes. TX 78712 USA; tel. professor in materials

performance ceramic Currently, she is work- 512-471-5392, fax science and engineering

materials. Sarah L. Lewis is pursu- ing on the diffusion be- 512-471-0542; and e-mail at Rensselaer Polytech-

Krishnamoorti can be ing her PhD degree in havior of polymers into drp@che.utexas.edu. nic Institute. She gradu-

reached at the Depart- materials science and carbon nanotube/ ated from Cornell

ment of Chemical Engi- engineering at Rensse- polymer nanocompos- Darrin J. Pochan is an University in 1985 with

neering, University of laer Polytechnic Institute ites, as well as the associate professor in a BS degree in materials

Houston, 4800 Calhoun in Troy, N.Y. She re- preparation and charac- the Materials Science science and engineering

Rd., Houston, TX ceived her MS degree in terization of composites and Engineering De- and received a PhD de-

77204-4004 USA; tel. materials science and with cellular nanotube partment and the gree in materials science

713-743-4312, fax engineering from networks. Delaware Biotechnology and engineering in 1990

713-743-4323, and e-mail Lehigh University in Mu can be reached at Institute at the Univer- from the University of

ramanan@uh.edu. 2003 and her BSc degree the University of Penn- sity of Delaware. He Pennsylvania. Schadler

in biomedical materials sylvania, 3231 Walnut joined the department in joined Rensselaer

Sanat K. Kumar is a science from the Univer- St., Philadelphia, PA 1999 after earning his in 1996.

professor in the Chemi- sity of Manchester 19104-6272, USA; tel. PhD degree in polymer She is a current mem-

cal Engineering Depart- Institute of Science 215-898-2700 and science and engineering ber of the National Ma-

ment at Columbia and Technology in 2001. e-mail minfang@ at the University of terials Advisory Board,

University. He received Her research interests seas.upenn.edu. Massachusetts Amherst and in addition to her

his BS degree from the are in controlling and and having an NRC research focus on inter-

Indian Institute of predicting properties Donald R. Paul holds postdoctoral fellowship faces in nanocomposites,

Technology, Madras, in polymer the Ernest Cockrell Sr. at the National Institute she is the education and

in 1981 and his PhD nanocomposites. Chair in Engineering at of Standards and outreach coordinator for

degree from the Lewis can be reached the University of Texas Technology. the NSF-funded Center

Massachusetts Institute at the Department of at Austin and also is the At the University of for Directed Assembly

of Technology in 1987. Materials Science and director of the Texas Delaware, Pochan has of Nanostructures,

Kumar has held faculty Engineering, Rensselaer Materials Institute. He developed a research headquartered at Rens-

positions at the Pennsyl- Polytechnic Institute, joined the Department program around the selaer.

vania State University 110 Eighth St., Troy, NY of Chemical Engineering construction of new ma- Schadler can be

and Rensselaer Poly- 12180 USA; tel. at UT in 1967. Paul’s re- terials and nanostruc- reached at the Depart-

technic Institute. 518-276-3011, fax search interests include tures via molecular ment of Materials

His research focuses 518-276-8554, and e-mail polymer blends, mem- self-assembly mecha- Science and Engineer-

on synthetic and bio lewiss@rpi.edu. branes, processing, and nisms. His recent honors ing, Rensselaer

polymers, nanocompos- nanocomposites. He include an NSF Career Polytechnic Institute,

ites, and nanomaterials. Minfang Mu is a PhD was elected to the Na- Award, the DuPont 110 Eighth St., Troy, NY

His work impacts the degree candidate in the tional Academy of Engi- Young Faculty Award, 12180 USA; tel.

fields of biochemical Department of Materials neering in 1988 and to and the Dillon Medal 518-276-2022, fax

engineering, composite Science and Engineering the Mexican Academy of from the American 518-276-8554, and e-mail

materials, interfacial at the University of Sciences in 2000, and Physical Society. Pochan schadl@rpi.edu.

MRS BULLETIN • VOLUME 32 • APRIL 2007 • www.mrs.org/bulletin 321

Polymer Nanocomposites

chemical engineering lines for composite Grumman Space Tech-

from City College of spacecraft components nology, One Space Park,

New York and a PhD and on space environ- M/S 01/2040, Redondo

degree in chemical engi- ment effects on space- Beach, CA 90278 USA;

neering from Stanford craft materials. tel. 310-813-9374, fax

University. Silverman’s current in- 310-812-8768, and e-mail

Silverman has led the terest includes the de- edward.silverman@

development of new velopment of ngc.com. ⵧ

lightweight composite nanotechnology for

resin transfer-molded aerospace applications. www.mrs.org/bulletin

joints, isogrid reflectors, He has published more

MRS members can access

and the thermally than 50 papers in scien- full issues of MRS Bulletin,

conductive material tific journals and confer- with additional theme-

Linda S. Schadler Edward Silverman APG (annealed py- ences and has received related resources, online.

rolytic graphite). As the several awards for

Edward Silverman is development at program manager of innovative research and www.mrs.org/alerts

the advanced technol- Northrop Grumman two NASA contracts, he development. MRS Publications Alert:

ogy manager for ad- Space Technology. He compiled two hand- Silverman can be Receive advance Table of

vanced materials holds a BE degree in books on design guide- reached at Northrop Contents by e-mail.

The Materials Gateway-www.mrs.org

322 MRS BULLETIN • VOLUME 32 • APRIL 2007 • www.mrs.org/bulletin

View publication stats

Potrebbero piacerti anche

- 01 Composite Introduction For ANSYS Composite and ACP Training V14 PDFDocumento98 pagine01 Composite Introduction For ANSYS Composite and ACP Training V14 PDFLu Hkarr100% (1)

- A Review of Reverse Osmosis Membrane Materials For Desalination - Development To Date and Future PotentialDocumento23 pagineA Review of Reverse Osmosis Membrane Materials For Desalination - Development To Date and Future PotentialŞansal DikmenerNessuna valutazione finora

- Emergence of Nanotechnology in The Oil and Gas IndustryDocumento15 pagineEmergence of Nanotechnology in The Oil and Gas IndustryLeonan Dos Santos RodriguesNessuna valutazione finora

- Mady 2020Documento22 pagineMady 2020suhaimi manNessuna valutazione finora

- Dielectric Nanocomposites With Insulating PropertiesDocumento15 pagineDielectric Nanocomposites With Insulating PropertiesThanh NguyenNessuna valutazione finora

- Polymer Nanocomposite FoamsDocumento20 paginePolymer Nanocomposite FoamsNguyễn KhánhNessuna valutazione finora

- Nanocomposites: Synthesis, Structure, Properties and New Application OpportunitiesDocumento40 pagineNanocomposites: Synthesis, Structure, Properties and New Application OpportunitiesAbi Warseno100% (1)

- Advances in Polyamide Nanocomposites A ReviewDocumento20 pagineAdvances in Polyamide Nanocomposites A ReviewSalman khanNessuna valutazione finora

- A Review of Reverse Osmosis Membrane Materials For DesalinationDocumento22 pagineA Review of Reverse Osmosis Membrane Materials For DesalinationFrancisca Rojas100% (1)

- Everyday Application PDFDocumento9 pagineEveryday Application PDFTusharkanta BeheraNessuna valutazione finora

- CIVIL NANO CONCRETE Report PDFDocumento24 pagineCIVIL NANO CONCRETE Report PDFImran Mr PerfectNessuna valutazione finora

- Civil Nano Concrete ReportDocumento24 pagineCivil Nano Concrete ReportHanaNessuna valutazione finora

- Arituclo SostenibleDocumento24 pagineArituclo Sosteniblesamara navasNessuna valutazione finora

- 2020 - Manufacture of A Bio-Tissue Based On Nanocrystalline Cellulose From Chilean Bamboo Chusquea QuilaDocumento8 pagine2020 - Manufacture of A Bio-Tissue Based On Nanocrystalline Cellulose From Chilean Bamboo Chusquea QuilaPatricia OliveiraNessuna valutazione finora

- ReviewinEPL March 2020Documento32 pagineReviewinEPL March 2020Jheronimo CarvajalNessuna valutazione finora

- 1.1 Polymer NanocompositesDocumento4 pagine1.1 Polymer NanocompositesDelovita GintingNessuna valutazione finora

- Membrane-Based Technologies For Biogas SeparationsDocumento19 pagineMembrane-Based Technologies For Biogas SeparationsHaresh BhanushaliNessuna valutazione finora

- Can J Chem Eng - 2017 - Peng - Applications of Nanotechnology in Oil and Gas Industry Progress and PerspectiveDocumento10 pagineCan J Chem Eng - 2017 - Peng - Applications of Nanotechnology in Oil and Gas Industry Progress and Perspectiveanahicalvillo96Nessuna valutazione finora

- Nanocomposites Properties and ApplicationsDocumento6 pagineNanocomposites Properties and Applicationsfafy mohammedNessuna valutazione finora

- Review Polymer Nanocomposites Containing Carbon NanotubesDocumento12 pagineReview Polymer Nanocomposites Containing Carbon NanotubesAntonio BatataNessuna valutazione finora

- Exploring The Versatility of Polymer Nano-Composites: A Comprehensive Analysis of Their Diverse ApplicationsDocumento9 pagineExploring The Versatility of Polymer Nano-Composites: A Comprehensive Analysis of Their Diverse Applicationsdivya sharmaNessuna valutazione finora

- Powder Coating Expert - VoicesDocumento2 paginePowder Coating Expert - VoicesChinmoy DholeNessuna valutazione finora

- Huang 2021 Nanotechnology 32 132004Documento61 pagineHuang 2021 Nanotechnology 32 132004kedar pathakNessuna valutazione finora

- Framework For NanocompositeDocumento6 pagineFramework For NanocompositeFatima BenNessuna valutazione finora

- Nanotechnologyand Accounting IssuesDocumento8 pagineNanotechnologyand Accounting IssueskekadiegoNessuna valutazione finora

- Polymeric Filomicelles and Nanoworms Two Decades oDocumento19 paginePolymeric Filomicelles and Nanoworms Two Decades oArt BitNessuna valutazione finora

- BioRes 12 1 2143 REVIEW Hubbe FPSPR Nanocell Packaging Review 11063 PDFDocumento92 pagineBioRes 12 1 2143 REVIEW Hubbe FPSPR Nanocell Packaging Review 11063 PDFMaria Adela BertoloniNessuna valutazione finora

- CAC Geral-MainDocumento46 pagineCAC Geral-Mainrodrigo.lacelcNessuna valutazione finora

- Cluster Beam Deposition: A Tool For Nanoscale Science and TechnologyDocumento22 pagineCluster Beam Deposition: A Tool For Nanoscale Science and TechnologyJoel E ValenciaNessuna valutazione finora

- Applications of Silica and Titanium Dioxide Nanoparticles in EnhancedDocumento23 pagineApplications of Silica and Titanium Dioxide Nanoparticles in EnhancedLeonan Dos Santos RodriguesNessuna valutazione finora

- Beyond The Current State of The Syntheses and Applications of Nanofiber TechnologyDocumento57 pagineBeyond The Current State of The Syntheses and Applications of Nanofiber TechnologyEliton Medeiros Candido de MacêdoNessuna valutazione finora

- Nanocomposites and Nanotubes: 11th Annual ConferenceDocumento4 pagineNanocomposites and Nanotubes: 11th Annual Conferenceapi-53169088Nessuna valutazione finora

- Categorization System of Nanofillers To Polymer CompositesDocumento2 pagineCategorization System of Nanofillers To Polymer CompositeshemarajuNessuna valutazione finora

- 0049 0060 PDFDocumento12 pagine0049 0060 PDFManush MaranNessuna valutazione finora

- Nanomaterials For Practical Functional Uses: M.G. LinesDocumento4 pagineNanomaterials For Practical Functional Uses: M.G. LinesEmerson Rodrigues de CamargoNessuna valutazione finora

- Thermal and Mechanical Performance of Rigid PolyurDocumento9 pagineThermal and Mechanical Performance of Rigid PolyurAhmedNessuna valutazione finora

- BioRes 12 1 2143 REVIEW Hubbe FPSPR Nanocell Packaging Review 11063 PDFDocumento92 pagineBioRes 12 1 2143 REVIEW Hubbe FPSPR Nanocell Packaging Review 11063 PDFMaria Adela BertoloniNessuna valutazione finora

- Maximizing The Right Stuff-The Trade-Off Between Membrane Permeability and SelectivityDocumento12 pagineMaximizing The Right Stuff-The Trade-Off Between Membrane Permeability and SelectivityBere RuizNessuna valutazione finora

- 2007-Crosby-Polymer Nanocomposites The "Nano" EffectDocumento14 pagine2007-Crosby-Polymer Nanocomposites The "Nano" EffectTim HollandNessuna valutazione finora

- GO Vs CNT As Nanofillers For PMMA-HA Bone CementDocumento9 pagineGO Vs CNT As Nanofillers For PMMA-HA Bone CementReem MohammedNessuna valutazione finora

- 2017 - Solvent-Driven Infiltration of Polymer Into Nanoparticle PackingsDocumento5 pagine2017 - Solvent-Driven Infiltration of Polymer Into Nanoparticle Packingsanirban.majumder.iitkgpNessuna valutazione finora

- Polymeric Nanocomposite Materials: March 2011Documento21 paginePolymeric Nanocomposite Materials: March 2011Manush MaranNessuna valutazione finora

- Dpoly: Focus Topic SessionsDocumento35 pagineDpoly: Focus Topic SessionsKumail RazaNessuna valutazione finora

- Nano PDFDocumento10 pagineNano PDFVenkata DineshNessuna valutazione finora

- Trache 2017Documento24 pagineTrache 2017meshal alnefaieNessuna valutazione finora

- Nanoparticle Characterization What To MeasureDocumento26 pagineNanoparticle Characterization What To MeasureMarwaya EmamNessuna valutazione finora

- Polymer-Grafted NanoparticlesDocumento4 paginePolymer-Grafted NanoparticlesqayesNessuna valutazione finora

- The Potential Environmental Impact of Engineered NanomaterialsDocumento1 paginaThe Potential Environmental Impact of Engineered NanomaterialsLizeth Diaz BenavidesNessuna valutazione finora

- Mesoporous Silica Nanoparticles: Synthesis, Biocompatibility and Drug DeliveryDocumento31 pagineMesoporous Silica Nanoparticles: Synthesis, Biocompatibility and Drug DeliveryChemistixNessuna valutazione finora

- New Synthetic Routes Towards MOF ProductionDocumento28 pagineNew Synthetic Routes Towards MOF ProductionMuhammad SajjadNessuna valutazione finora

- Polymer Nanocomposites: Synthetic and Natural Fillers A ReviewDocumento21 paginePolymer Nanocomposites: Synthetic and Natural Fillers A ReviewFahad AbdullahtNessuna valutazione finora

- Potential Applications of NanotechnologyDocumento6 paginePotential Applications of NanotechnologyGiannis PappasNessuna valutazione finora

- Materials Research For Fusion EnergyDocumento4 pagineMaterials Research For Fusion Energydiegok64Nessuna valutazione finora

- Development of Superhydrophobic NanocoatingsDocumento22 pagineDevelopment of Superhydrophobic NanocoatingsLance HernandezNessuna valutazione finora

- 2009 Solution Blow Spinning A New Method To Produce Micro - and NanofiberspdfpdfDocumento9 pagine2009 Solution Blow Spinning A New Method To Produce Micro - and NanofiberspdfpdfEliton Medeiros Candido de MacêdoNessuna valutazione finora

- Polymers 08 00190Documento14 paginePolymers 08 00190Kishore Nayak kNessuna valutazione finora

- Nanocellulose and Nanoclay As Reinforcement Materials in Polymer Composites: A ReviewDocumento9 pagineNanocellulose and Nanoclay As Reinforcement Materials in Polymer Composites: A Reviewkrishnakant bholeNessuna valutazione finora

- PPTDocumento9 paginePPTdivya sharmaNessuna valutazione finora

- Advanced Functional Polymer MembranesDocumento47 pagineAdvanced Functional Polymer MembranescocoNessuna valutazione finora

- Clay-Containing Polymer Nanocomposites: From Fundamentals to Real ApplicationsDa EverandClay-Containing Polymer Nanocomposites: From Fundamentals to Real ApplicationsNessuna valutazione finora

- 2014 Book MultiphysicsSimulation 2Documento225 pagine2014 Book MultiphysicsSimulation 2Lu HkarrNessuna valutazione finora

- 2014 Book MultiphysicsSimulation 2Documento225 pagine2014 Book MultiphysicsSimulation 2Lu HkarrNessuna valutazione finora

- Haertel Paper 2Documento6 pagineHaertel Paper 2Lu HkarrNessuna valutazione finora

- Methodology For Topology and Shape Optimization Report PDFDocumento53 pagineMethodology For Topology and Shape Optimization Report PDFLu HkarrNessuna valutazione finora

- 151 0548 FS2017 K3 Introduction To Polymer MaterialsDocumento49 pagine151 0548 FS2017 K3 Introduction To Polymer MaterialsLu HkarrNessuna valutazione finora

- Digimat For Engineering Plastics1 4Documento12 pagineDigimat For Engineering Plastics1 4Lu HkarrNessuna valutazione finora

- Rafaely B Fundamentals of Spherical Array ProcessingDocumento201 pagineRafaely B Fundamentals of Spherical Array ProcessingLu HkarrNessuna valutazione finora

- Nitro Shock AbsorbersDocumento18 pagineNitro Shock AbsorbersPavan KumarNessuna valutazione finora

- Sheet Pile Wall IntroductionDocumento19 pagineSheet Pile Wall IntroductionSâu HeoNessuna valutazione finora

- Multi Phase Flow in WellDocumento149 pagineMulti Phase Flow in WellOmar 'Tanzania'100% (1)

- Sedimentary Structures NotesDocumento12 pagineSedimentary Structures NotesTanmay KeluskarNessuna valutazione finora

- Capacidad de ConductoresDocumento4 pagineCapacidad de ConductoresCämpänitä FentyNessuna valutazione finora

- DLL - G8 Science - Q3 - F2FDocumento2 pagineDLL - G8 Science - Q3 - F2FRAMIR BECOYNessuna valutazione finora

- Liebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0Documento4 pagineLiebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0sheron100% (2)

- Instruction Manual PHE PDFDocumento78 pagineInstruction Manual PHE PDFzniperxNessuna valutazione finora

- ST-130 - Manual PDFDocumento27 pagineST-130 - Manual PDFJean TorreblancaNessuna valutazione finora

- Physical Sciences PDFDocumento51 paginePhysical Sciences PDFfarooqi111Nessuna valutazione finora

- Overlap 2Documento22 pagineOverlap 2Anonymous fFl3xgWNessuna valutazione finora

- To Determine Resistance of A Galvanometer by Half-Deflection Method and To Find Its Figure of MeritDocumento3 pagineTo Determine Resistance of A Galvanometer by Half-Deflection Method and To Find Its Figure of Meritatikshpro3004Nessuna valutazione finora

- Principles of Refrigeration: Standard Template Options and Samples - Mar 2016 - EMR:jmk 1Documento17 paginePrinciples of Refrigeration: Standard Template Options and Samples - Mar 2016 - EMR:jmk 1JhurremNessuna valutazione finora

- Manual of Metal Bellows - 0441e S 56-77!2!04!10!20 - WebDocumento11 pagineManual of Metal Bellows - 0441e S 56-77!2!04!10!20 - Webadfafad gfadfNessuna valutazione finora

- 2nd Sessional Test - Physics For Engineers-Bph-106Documento1 pagina2nd Sessional Test - Physics For Engineers-Bph-106Saurabh Arya RspNessuna valutazione finora

- Cone CalorimeterDocumento96 pagineCone CalorimeterCleber da SilvaNessuna valutazione finora

- AQA GCSE Chemistry AnswersDocumento14 pagineAQA GCSE Chemistry AnswersErvin MetushiNessuna valutazione finora

- UNIT 1 PP UNIT 1 Math IntroDocumento64 pagineUNIT 1 PP UNIT 1 Math IntroHlulani MacksonNessuna valutazione finora

- PPSD A TT 027 0002 R0Documento14 paginePPSD A TT 027 0002 R0santosh_ms_kumar2827Nessuna valutazione finora

- 1st Grading Performance TestDocumento4 pagine1st Grading Performance TestMary Ann GellorExito EvarolaNessuna valutazione finora

- Chapter 7 Powerpoint 1225339266570076 9Documento24 pagineChapter 7 Powerpoint 1225339266570076 9venkateshyadav2116Nessuna valutazione finora

- Colonial ZF SeriesDocumento2 pagineColonial ZF SeriesmndmattNessuna valutazione finora

- Chapter 9.4 - Multiplication and Division of Radicals PDFDocumento4 pagineChapter 9.4 - Multiplication and Division of Radicals PDFBeatriz Bravo GallardoNessuna valutazione finora

- Earth EvolutionDocumento37 pagineEarth Evolutionkrish_mplNessuna valutazione finora

- Physics Paper 3 TZ1 SL MarkschemeDocumento17 paginePhysics Paper 3 TZ1 SL MarkschemeRᴇᴀʟ RᴜᴋʜsᴀʀNessuna valutazione finora

- Sulpiride MonographieDocumento3 pagineSulpiride MonographieMohamed DahmaneNessuna valutazione finora

- Convergence IndicatorDocumento21 pagineConvergence Indicatorsikandar100% (1)

- Engineering Material Specification: Approval From The Sheet Metal Tech ClubDocumento8 pagineEngineering Material Specification: Approval From The Sheet Metal Tech ClubaldairlopesNessuna valutazione finora

- 4.3 Forced WavesDocumento23 pagine4.3 Forced WavesPritib KumarNessuna valutazione finora

- General Principles of Measurement SystemsDocumento21 pagineGeneral Principles of Measurement SystemsChelseaNessuna valutazione finora