Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Q-04 Model h305 Iso Hdpe Coupling

Caricato da

mechanical 1Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Q-04 Model h305 Iso Hdpe Coupling

Caricato da

mechanical 1Copyright:

Formati disponibili

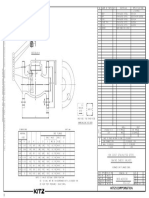

H305 ISO Q-04

MODEL H305 ISO HDPE COUPLING

The Shurjoint Model H305 ISO HDPE couplings are designed to provide

a fast and easy way to mechanically join HDPE (high polyethylene) pipe.

The Shurjoint Model H305 ISO HDPE couplings feature four bolt

housings and a series of sharply machined teeth which positively grip the

pipe as the coupling housing is tightened. The result is a leak-tight joint

that is as strong or stronger than the pipe itself. The H305 also features

a contoured housing with integral ramps along the outside diameter to

help the coupling slide over most obstacles during the relocation of pipe

runs.

H305 ISO HDPE Couplings should always be installed so that

the coupling bolt pads make metal to metal contact.

Working Pressure: Since the physical strength of the Shurjoint HDPE

couplings is much greater than HDPE pipe, working pressures are

governed by the working pressures of the HDPE pipe, which vary

depending on pipe composition, wall thickness and service temperatures.

Full warranty terms

Shurjoint HDPE couplings are not intended for use on PVC, PP or other can be found on

materials. www.shurjoint.com

Shurjoint recommends the use of a silicone based lubricant for the HDPE

series. Do not use the Shurjoint standard lubricant, which is designed for

steel pipe use. Do not use hydrocarbon based oils, grease or soap based

solutions either as this could lead join failure.

The applicable HDPE pipe for Model H305 ISO HDPE couplings are ISO

161/1, AS 1159 and DIN 8074 with pipe thickness from DR 32.5 to 7.3

(depending on size and pipe material). (The Model H305 couplings are also

available in ASTM HDPE pipe standards; refer to Shurjoint cut sheet #Q-01

for details.)

Model H305 ISO HDPE Coupling

Pipe O.D. Dimensions Coupling Bolts

Minimum Maximum A B C No. Size Weight

mm mm mm mm mm mm Kgs

50 50.5 72 115 105 4 M10 x 55 1.5

63 63.6 85 128 105 4 M10 x 55 1.9

75 75.7 97 140 105 4 M10 x 55 2.4

90 90.9 113 169 105 4 M12 x 75 3.3

110 111.0 139 181 112 4 M12 x 75 4.1

140 141.3 169 210 118 4 M12 x 75 4.5

160 161.5 190 232 118 4 M12 x 75 5.6

180 181.7 211 253 118 4 M12 x 75 7.5

200 201.8 236 305 127 4 M16 x 90 9.4

225 226.4 261 330 127 4 M16 x 90 11.3

250 252.3 289 351 134 4 M16 x 110 12.7

280 281.7 319 406 134 4 M20 x 120 18.4

315 317.9 354 438 134 4 M20 x 120 16.7

355 357.2 412 489 256 4 M24 x 110 41.2

400 402.4 462 540 256 4 M24 x 110 44.2

450 452.7 515 595 256 4 M24 x 110 57.7

*Unlisted sizes are also available. Please contact Shurjoint.

Q-04-1/2 Rev.S 20160314

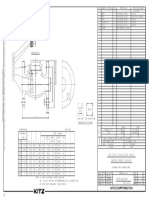

H305 ISO Q-04

MATERIAL SPECIFICATIONS

• Housing: (Option) Grade “T” Nitrile (Color code: Orange stripe)

Ductile Iron to ASTM A536, Gr. 65-45-12 and or ASTM A395, Recommended for petroleum products, air with oil vapors,

Gr. 65-45-15, min. tensile strength 65,000 psi (448 MPa). vegetable and mineral oils within the specified temperature

range. Also good for water services under +150oF

• Surface Finish: (+66oC).

Standard painted finishes in orange or RAL3000 red. Temperature range: -20 oF to +180 oF (-29 oC to +82 oC).

Electro-zinc plated (Option)

Do not use for HOT WATER above +150 oF (+66 oC) or

Epoxy Coatings in RAL3000 red or other colors (Option)

HOT DRY AIR above +140 oF (+60 oC)

Other options: Grade “O” - Fluoroelastomer.

• Rubber Gasket: Grade “L” - Silicone.

Grade “E” EPDM (Color code: Green stripe) Good for cold & hot For additional details contact Shurjoint.

water up to +230oF (+110oC). Also good for services for water

with acid, water with chlorine, deionized water, seawater and • Bolts & Nuts:

waste water, dilute acids, oil-free air and many chemicals.

Heat treated carbon manganese steel track bolts to ASTM

Not recommended for petroleum oils, minerals oils, solvents and

A449-83a (or A183 Gr. 2), minimum tensile strength 110,000 psi

aromatic hydrocarbons.

(758 MPa), Zinc electroplated, with heavy-duty hexagonal nuts to

Maximum Temperature Range: -30oF (-34oC) to +230oF

ASTM A563.

(+110oC)*.

*EPDM gaskets for water services are not recommended for

For Size 355mm to 450mm, Carbon steel Hexagon head

steam services unless couplings or components are accessible

bolts to ISO 4014 : 1999,Nickel electroplated to ISO 1456,

for frequent gasket replacement.

with hexagonal nuts to ISO 898-2-1999.

• Washers:

Carbon steel to ASTM A36, ISO 3574. Gr. A. Large size washer

to ISO 7089, DIN 25 or JIS B 1256 – 1978. Zinc Plated to ISO

4042 or JIS B1044. Hardness: HV300.

General Notes:

Field Joint Test: For one time only the system may be tested hydrostatically at 1½ times the maximum working pressure listed (AWWA C606 5.2.3).

Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

The 10 Year Limited Warranty applies to manufacturing defects only and does not cover severe service/temperature applications or wear parts.

Shurjoint reserves the right to change specifications, designs and or standard without notice and without incurring any obligations.

Shurjoint product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise

measurements, please contact Shurjoint Technical Service. Shurjoint reserves the right to change or modify product design, construction,

specifications, or materials without prior notice and without incurring any obligations to make such changes and modifications on Shurjoint

products previously subsequently sold.

Q-04-2/2 Rev.S 20160314

Potrebbero piacerti anche

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDa EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreValutazione: 4.5 su 5 stelle4.5/5 (11)

- Suspension DiagramsDocumento35 pagineSuspension Diagramsakti gonzo100% (1)

- HDB BreakersDocumento89 pagineHDB BreakersJohn Louie Mazon100% (5)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderDa EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderValutazione: 5 su 5 stelle5/5 (2)

- 432 - Rare Plastics Brochure - Web 1 Backing Ring FlangeDocumento12 pagine432 - Rare Plastics Brochure - Web 1 Backing Ring FlangePatrickKisulaNessuna valutazione finora

- Victaulic Quick Vic Rigid CouplingsDocumento7 pagineVictaulic Quick Vic Rigid Couplingsionut cerneaNessuna valutazione finora

- SIW Product CatalogDocumento88 pagineSIW Product CatalogSagar GavaneNessuna valutazione finora

- Fixfast DF12 HT DatasheetDocumento6 pagineFixfast DF12 HT DatasheetJonathan DouglasNessuna valutazione finora

- T Mech Clamp CatalogueDocumento29 pagineT Mech Clamp CatalogueKABIR CHOPRANessuna valutazione finora

- PVH Sight Glass Data SheetDocumento11 paginePVH Sight Glass Data SheetANIKET PATILNessuna valutazione finora

- Diameter / Decimal / Metric Chart For Small DiametersDocumento2 pagineDiameter / Decimal / Metric Chart For Small DiametershansNessuna valutazione finora

- Bearings & Misc PR ListDocumento2 pagineBearings & Misc PR ListengineeringNessuna valutazione finora

- X12 Self Drilling ScrewsDocumento2 pagineX12 Self Drilling ScrewsPlacekNessuna valutazione finora

- FT Unión Flexible Style 177n EspDocumento6 pagineFT Unión Flexible Style 177n EspJulian CristanchoNessuna valutazione finora

- RSERV21GTW400-Gateway J Valves S14 S15 ISODocumento11 pagineRSERV21GTW400-Gateway J Valves S14 S15 ISOgfdgdfgdfNessuna valutazione finora

- Brochure Multi Purpose CylindersDocumento10 pagineBrochure Multi Purpose Cylinderscrni rokoNessuna valutazione finora

- Victaulic Refuse-to-Fuse Coupling For Plain End HDPE Pipe Style 905Documento8 pagineVictaulic Refuse-to-Fuse Coupling For Plain End HDPE Pipe Style 905maycolvNessuna valutazione finora

- A Good Practice Guide For Flange Jointing of Polyethylene Pressure Pipes 1Documento5 pagineA Good Practice Guide For Flange Jointing of Polyethylene Pressure Pipes 1Bimal DeyNessuna valutazione finora

- Chapter02 ThimblesDocumento10 pagineChapter02 ThimblesliebofreakNessuna valutazione finora

- Catalog Universaluri, Bacuri, Flanse BERNARDO - Austria - eMasiniUnelteDocumento22 pagineCatalog Universaluri, Bacuri, Flanse BERNARDO - Austria - eMasiniUnelteExpert Masini UnelteNessuna valutazione finora

- Industry Guidelines: Metal Backing Flanges For Use With Polyethylene (Pe) Pipe Flange AdaptorsDocumento17 pagineIndustry Guidelines: Metal Backing Flanges For Use With Polyethylene (Pe) Pipe Flange AdaptorsAnthonyNessuna valutazione finora

- Standard Stud Anchor HSA: Base Materials ApprovalsDocumento1 paginaStandard Stud Anchor HSA: Base Materials ApprovalsSiti Nur AzizahNessuna valutazione finora

- Spiroplan Gear Reducer Wa/Waf 20 A: Sew-Eurodrive, IncDocumento1 paginaSpiroplan Gear Reducer Wa/Waf 20 A: Sew-Eurodrive, Inccarlos aguileraNessuna valutazione finora

- S.S. A4 m1tr Throughbolt TDS - MungoDocumento7 pagineS.S. A4 m1tr Throughbolt TDS - MungoMohammed AnwarNessuna valutazione finora

- Volvo P80 850/C70/S70/V70 320mm Front Brake ConversionDocumento18 pagineVolvo P80 850/C70/S70/V70 320mm Front Brake Conversionarwid vasilevNessuna valutazione finora

- EN 1057 Standard Product For Copper TubingDocumento9 pagineEN 1057 Standard Product For Copper TubingcakhokheNessuna valutazione finora

- Pipe Line - Spary Water 3Documento5 paginePipe Line - Spary Water 3karthimeenaNessuna valutazione finora

- BJ Model SV-5 Cement Retainer PDFDocumento2 pagineBJ Model SV-5 Cement Retainer PDFmohammad teimuriNessuna valutazione finora

- 6 Conical Spring WashersDocumento4 pagine6 Conical Spring Washersbcsf01Nessuna valutazione finora

- Diaval ST Type Rubber Lined Flanged EndsDocumento3 pagineDiaval ST Type Rubber Lined Flanged EndsMarketing RNSNessuna valutazione finora

- Komatsu SeriesDocumento22 pagineKomatsu SeriesEdU RECTIFICANessuna valutazione finora

- PN6 PN 10 PN 16 Flange Bolt Flange Bolt Flange Bolt PN 25 Flange BoltDocumento1 paginaPN6 PN 10 PN 16 Flange Bolt Flange Bolt Flange Bolt PN 25 Flange BoltStefanGramaNessuna valutazione finora

- Spiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesDocumento6 pagineSpiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesAntonio CardosoNessuna valutazione finora

- Alfa Laval Access Tank Cover - Circlar Cover Type LKDC - Product Leaflet - Ese02099Documento4 pagineAlfa Laval Access Tank Cover - Circlar Cover Type LKDC - Product Leaflet - Ese02099DanielNessuna valutazione finora

- Valvula Mariposa Con Volante Ranura 250LBS Mech D381X4Documento1 paginaValvula Mariposa Con Volante Ranura 250LBS Mech D381X4almacen911listoNessuna valutazione finora

- Catalogo Junta VictaulicDocumento7 pagineCatalogo Junta VictaulicandhucaosNessuna valutazione finora

- 10.rarebay Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesDocumento5 pagine10.rarebay Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesAbi DemeNessuna valutazione finora

- 5.dhegale Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesDocumento5 pagine5.dhegale Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesAbi DemeNessuna valutazione finora

- Ductile Iron Pipes: Company ProfileDocumento10 pagineDuctile Iron Pipes: Company ProfileSurendra ElayathambyNessuna valutazione finora

- HOTSTART Battery Wrap Silicone Pad Heater Part NumbersDocumento1 paginaHOTSTART Battery Wrap Silicone Pad Heater Part NumbersJorge Coke SilvaNessuna valutazione finora

- John Crane Type FFETDocumento6 pagineJohn Crane Type FFETUntung S PrawotoNessuna valutazione finora

- Housings and Inserts ZEN CatalogueDocumento14 pagineHousings and Inserts ZEN CatalogueKoen BidlotNessuna valutazione finora

- Mitsubishi Fuso Liner KitDocumento45 pagineMitsubishi Fuso Liner Kitchristopher Huaman SanchezNessuna valutazione finora

- Goulds GIS Series: ISO Frame & Stub Shaft PumpsDocumento7 pagineGoulds GIS Series: ISO Frame & Stub Shaft PumpsJan C. GarciaNessuna valutazione finora

- TD Ffet 8PG BW Oct2015Documento8 pagineTD Ffet 8PG BW Oct2015Nano DonchevNessuna valutazione finora

- Catalog Burgmann A510 A520Documento3 pagineCatalog Burgmann A510 A520ali abdiNessuna valutazione finora

- Sight Glass - Sight Flow Indicator and Sight Windows Global IndustriesDocumento5 pagineSight Glass - Sight Flow Indicator and Sight Windows Global IndustriesBhavin PatelNessuna valutazione finora

- BV224VDocumento1 paginaBV224VFAIYAZ AHMEDNessuna valutazione finora

- Actuador Neumático DVCDocumento16 pagineActuador Neumático DVCGabriel SandovalNessuna valutazione finora

- Xylan CoatDocumento9 pagineXylan CoatTran NguyenNessuna valutazione finora

- Bore-Well Pipes PDFDocumento6 pagineBore-Well Pipes PDFNikita KadamNessuna valutazione finora

- Metric DIN 609 SpecDocumento4 pagineMetric DIN 609 SpecCAT MINING SHOVELNessuna valutazione finora

- C Lift+Lash PointsDocumento10 pagineC Lift+Lash PointssabanimNessuna valutazione finora

- Variable Speed Unit VARIMOT DF36: Sew-Eurodrive, IncDocumento2 pagineVariable Speed Unit VARIMOT DF36: Sew-Eurodrive, Inccarlos aguileraNessuna valutazione finora

- Viking Johnson Dismantling Joint+BrochureDocumento13 pagineViking Johnson Dismantling Joint+BrochureecocadecNessuna valutazione finora

- BOLTs - Metric Hex Cap Bolt Class 8.8 and 10.9Documento3 pagineBOLTs - Metric Hex Cap Bolt Class 8.8 and 10.9fea.structureengineerNessuna valutazione finora

- Standards Pillars and Bushes2Documento136 pagineStandards Pillars and Bushes2sansagithNessuna valutazione finora

- KVC Ball ValvesDocumento1 paginaKVC Ball ValvesAlex VarHerNessuna valutazione finora

- Main Product Pipe Fittings: Hebei Xinqi Pipeline Equipment Co.,LtdDocumento21 pagineMain Product Pipe Fittings: Hebei Xinqi Pipeline Equipment Co.,Ltdmechanical 1Nessuna valutazione finora

- Specification PipaDocumento103 pagineSpecification Pipamechanical 1Nessuna valutazione finora

- 10uob 963-A20030-02 SMSDocumento1 pagina10uob 963-A20030-02 SMSmechanical 1Nessuna valutazione finora

- Leaflet Shurjoint 2018Documento2 pagineLeaflet Shurjoint 2018mechanical 1Nessuna valutazione finora

- Brosur PVCDocumento5 pagineBrosur PVCAldi ErzanuariNessuna valutazione finora

- G-01 Model K-9 Rigid Coupling Rev-LDocumento3 pagineG-01 Model K-9 Rigid Coupling Rev-LMohammed NiqrisNessuna valutazione finora

- 2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Documento217 pagine2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Thiago Schmitt De Araujo de MattosNessuna valutazione finora

- 2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Documento217 pagine2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Thiago Schmitt De Araujo de MattosNessuna valutazione finora

- 2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Documento217 pagine2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Thiago Schmitt De Araujo de MattosNessuna valutazione finora

- Check Valve KitzDocumento1 paginaCheck Valve Kitzmechanical 1Nessuna valutazione finora

- Iodate and Iodine Speciation by LC-ICPMSDocumento6 pagineIodate and Iodine Speciation by LC-ICPMSShubhamNessuna valutazione finora

- Ecological and Energetic Assessment of Re-Refining Used Oils To Base OilsDocumento104 pagineEcological and Energetic Assessment of Re-Refining Used Oils To Base OilsFernando SImonelliNessuna valutazione finora

- MTM 46 - CM - enDocumento5 pagineMTM 46 - CM - enMiguel SeguraNessuna valutazione finora

- History of The Development of Cement and Concrete (Non-HydraulicDocumento2 pagineHistory of The Development of Cement and Concrete (Non-HydraulicourebooksNessuna valutazione finora

- Top Drive - Lessons LearnedDocumento8 pagineTop Drive - Lessons LearnedRuslan ZakirovNessuna valutazione finora

- WHPL Duet GHW9100L Washer Service ManualDocumento72 pagineWHPL Duet GHW9100L Washer Service ManualEric M. OlsonNessuna valutazione finora

- Nalco Cooling Tower Presentation PDFDocumento115 pagineNalco Cooling Tower Presentation PDFAttyub100% (2)

- 1 - Catalogo Deionizador Qw-48Documento92 pagine1 - Catalogo Deionizador Qw-48Edgar Muñoz100% (1)

- Posi Test atDocumento5 paginePosi Test atsudhir5441Nessuna valutazione finora

- Helix - HX5 - 20W-50 - Ga 068Documento2 pagineHelix - HX5 - 20W-50 - Ga 068Edo EdgarNessuna valutazione finora

- EKT Mech 2014 2Documento9 pagineEKT Mech 2014 2Ravinder ReddyNessuna valutazione finora

- A-16-1-0028-K-050b - Chiller-House - Plan View - 20170303Documento1 paginaA-16-1-0028-K-050b - Chiller-House - Plan View - 20170303Danur RiswantoNessuna valutazione finora

- 6421 FulltextDocumento97 pagine6421 FulltextDaniel Camilo CanoNessuna valutazione finora

- Solved SAILMT Exam Paper For Mechanical EngineerDocumento12 pagineSolved SAILMT Exam Paper For Mechanical EngineerSudeesh BabuNessuna valutazione finora

- Range of Flocculants and Caogulants For Water and Wastewater TreatmentDocumento6 pagineRange of Flocculants and Caogulants For Water and Wastewater Treatmentginga716Nessuna valutazione finora

- Simplified Cost Models For Prefeasibility Mineral Evaluations 2005Documento4 pagineSimplified Cost Models For Prefeasibility Mineral Evaluations 2005Juan Pablo Henríquez Valencia50% (2)

- CVD-5B Metal Hardening BulletinDocumento2 pagineCVD-5B Metal Hardening BulletinSergio Gana GonzalezNessuna valutazione finora

- Iglidur X - The High-Tech Problem SolverDocumento12 pagineIglidur X - The High-Tech Problem Solvergoooga299Nessuna valutazione finora

- Aluminum Cladding Part 03Documento7 pagineAluminum Cladding Part 03Anonymous ELujOV3Nessuna valutazione finora

- Instruction: Check The Circle That Corresponds To Your AnswerDocumento2 pagineInstruction: Check The Circle That Corresponds To Your AnswerXyrile InguilloNessuna valutazione finora

- Aws - The Practical Welding Engineer PDFDocumento154 pagineAws - The Practical Welding Engineer PDFSEGO4EVER100% (5)

- Material Safety Data Sheet Drathon Industrial Maintenance: Section 1 - Chemical Product and Company IdentificationDocumento3 pagineMaterial Safety Data Sheet Drathon Industrial Maintenance: Section 1 - Chemical Product and Company IdentificationHendra Cipto SaputroNessuna valutazione finora

- AAA4000PE12Documento15 pagineAAA4000PE12POTRAZONessuna valutazione finora

- 5PS 04 Parts ListDocumento48 pagine5PS 04 Parts Listkari6uskaliNessuna valutazione finora

- RS 017 August 2014 (Welder Test Run Sheet Yudistira)Documento1 paginaRS 017 August 2014 (Welder Test Run Sheet Yudistira)Muhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- 10.6 Schedule of Accreditation: Product Certification Body Accreditation No. APC0002Documento16 pagine10.6 Schedule of Accreditation: Product Certification Body Accreditation No. APC0002erwerwerwerwewNessuna valutazione finora

- Dow Corning 111 Valve Lubricant and Sealant 10.15.10Documento7 pagineDow Corning 111 Valve Lubricant and Sealant 10.15.10Syifa Alfi HabibiNessuna valutazione finora

- Canpolat 2004 PDFDocumento5 pagineCanpolat 2004 PDFIsha PatelNessuna valutazione finora

- Ratliperl: The Modern Solution For Energy Efficient BuildingDocumento18 pagineRatliperl: The Modern Solution For Energy Efficient BuildingAdhil Ramsurup100% (1)

- Cador 300 - Manual de OperacionDocumento99 pagineCador 300 - Manual de OperacionAndreyna BreaNessuna valutazione finora