Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Msec RM

Caricato da

Azad pravesh khanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Msec RM

Caricato da

Azad pravesh khanCopyright:

Formati disponibili

MINISTRY OF MANPOWER

TECHNICAL NOTES

Metal Scaffold Erection Course

PART II

Version 2.0

20 October 2015

Workplace Safety and Health Council, Ministry of Manpower, Singapore (MOM)

All rights reserved.

This document is provided for explicit use and guidance of Learning Service Providers

(LSPs) as information resource for curriculum development and assessment purposes.

Any other use of this document or parts thereof, including reproduction, publication,

distribution, transmission, retransmission or public showing, or storage in a retrieval

system in any form, electronic or otherwise, for purposes other than that expressly stated

in this advice without the expressed permission of MOM is strictly prohibited.

1 MOM Technical Notes Part II v2.1 - MSEC

Version History

Version Effective Date Changes Author

1.0 14 Oct 2014 First issue ICB, WSH Council

Office

2.0 20 October 2015 Update ICB, WSH Council

Office

2.1 4 November 2016 Amendments ICB, WSH Council

Office

2 MOM Technical Notes Part II v2.1 - MSEC

Table of Contents: Page

1 Aim of MOM Technical Notes 4

2 MOM Technical Notes 4

3 Overview of Course Requirements 6

4 Training Delivery Advice 7

5 Assessment Advice 9

6 Facilitator and Assessor Requirements 10

7 End of Course Evaluation and Feedback 11

8 Related WSH Legislations, Industrial Code of Practice, and other 11

References

Annex A: Course Syllabus

Annex B: Course Reference Matrix

Annex C: Assessment Plan

3 MOM Technical Notes Part II v2.1 - MSEC

1 AIM OF THE MOM TECHNICAL NOTES

1.1 The MOM Technical Notes is a document listing the requirements expected of the

Learning Service Providers (LSPs), the Facilitators, course and facilities suitable for the

conduct of the WSH course. It also aims to help facilitate LSPs learning process, deliver

effective training and conduct competency-based training and assessment.

1.2 The main part of this document contains key information on the Metal Scaffold

Erection Course, including the course aim, learning objectives, target audience,

assumed skills and knowledge, course syllabus, course duration, class size, and

Facilitator/Learner ratio. It also sets forth guidelines for training delivery and assessment

for the course.

1.3 This MOM Technical Notes shall be reviewed on a regular basis and or whenever

it is deemed necessary due to changes in MOM policy and or requirements, training

syllabus and or industrial requirements.

2 MOM TECHNICAL NOTES

2.1 LSP Criteria:

• 1 full time Principal/Manager

• 1 full time facilitator & 1 associate facilitator

• 2 facilitators per language per course

• bizSAFE Level 3

• Paid up Capital $5k / $50K (SOCs)

• ACTA or DACE

• Advanced Certificate in WSH for worker level courses

• Specialist Diploma in WSH for supervisor and above courses

• 5 years of relevant industry experience

• Any other course specific requirement/s

2.2 LSP Facilities:

• Conduciveness of training facilities

• Safe

• Noise

• Lighting

• Sanitary

• Projection

• Tables/Chairs

• Ventilation

• No training in containers/portable cabins

4 MOM Technical Notes Part II v2.1 - MSEC

2.3 Metal Scaffold Erection Course (MSEC) Theory Assessment:

• 1 hour- 30 MCQ assessment

• A closed book assessment

• Each Learner shall be given a different set of assessment question paper.

• Facilitator for the class is not allowed to be the invigilator for the assessment

(same class)

• Assessment papers are to be issued in accordance with the course language

registered for only. No mix language assessment is permitted.

• Facilitator to Learner ratio is 1:18 for theory

• A certificate of successful completion of a safety pass/ card shall be issued to

each Learner who passes the assessment, by the LSP.

• All training records must be kept by LSP for period of no less than 2 years for

audit purpose.

2.4 Practical Requirement / Assessment

• For practical training, facilitators are to demonstrate the erection/dismantling of the

different types of scaffolds, as prescribed in the course. Learners are then to

erect/dismantle the different scaffolds as per the course instructions.

• For the Practical Assessment, Learners are assigned in groups to erect/dismantle

the scaffold/s. Have a documented register to account for ALL the inspections

carried out on all the PPEs and in line with WSH (Scaffold) Regulations.

LSP is to ensure Learners use and wear the appropriate personal protective

equipment and apparels during the practical sessions. LSP is also to ensure

sufficient scaffold materials and components for the Learners and proper

housekeeping carried out at all times.

Assessors must be familiar with the assessment criteria before conducting any

assessment.

Learner is to pass 100% in all the practical assignments/tests. If any Learner fails

the assessment, he is required to be re-coursed and re-assessed on a separate

occasion.

All training records must be kept by LSP for period of no less than 2 years for

audit purpose.

2.5 Checklist for LSPs:

URA approved use of venue: Commercial School (theory only) or Industrial

Training (theory and practical)

Facilitators to be approved by authority by course, language and venue

Updated register of all facilitators by course, language and venue

Facilitator certification: Advanced Certificate/Specialist Diploma in WSH for

worker/supervisor & above courses

Course information including cancellation and refund policy must be available to

public

Accountability for all test related materials including test question sets i.e. number

of sets produced / destroyed

Guidelines for invigilator and assessors

Code of conduct for Invigilators and Assessors

5 MOM Technical Notes Part II v2.1 - MSEC

Register to show production, issuance and destruction of safety

certificates/pass/card

All safety certificates/safety pass/card to be issued by LSPs to Learners no later

than one month from assessment date

End of course evaluation for each course

LSPs to have copies of Technical Notes Parts I ( Terms and Conditions) and II

(course specific) and all course related SOP/s, Facilitator and Learners’ Guides

and other related documents necessary for the conduct of the training.

3 OVERVIEW OF THE COURSE REQUIREMENTS

3.1 Learning objectives:

3.1.1 List the types of commonly used metal scaffold based on the

Characteristic and classification

3.1.2 Define the terminologies used, and the components and materials used for

metal scaffold structures

3.1.3 State the requirements for ties and braces used in scaffold erection

3.1.4 Distinguish between static and mobile tower scaffold and the requirement

3.1.5 State the requirements for tower scaffold use on work sites 3.1.6 Perform

safe work procedures, general principles and requirements in the erection

and dismantling of modular scaffold, tower scaffold, tubular independent

tied scaffold and frame scaffold, in line with WSH (Scaffold) Regulations

and CP14

3.1.7 State the rules and regulations to ensure safety in erecting and dismantling

of modular scaffold

3.2 Target audience: This course is designed for all workers working in the

construction and related industry.

3.3 Course duration: 38 hours

3.4 Maximum class size: 18 Learners

3.5 Recommended Facilitator/Learner ratio:

Theory Lesson = 1:18 max

Practical lesson= 1: 12 max

Theory Assessment = 1:18 max

Practical Assessment = 1:12 max

3.6 Course attendance: 100% attendance.

6 MOM Technical Notes Part II v2.1 - MSEC

4 TRAINING DELIVERY ADVICE

4.1 Facilitator’s guide and Learners’ workbook/handouts

4.1.1 In order to deliver more effective instruction and ensure consistency in

training, a copy of the Facilitator’s guide shall be prepared. The guide provides the

Facilitator with information on the course including:

Course aim

Learning objectives

Target audience

Assumed skills and knowledge

Course duration

Class size and Facilitator/Learner ratio

Lesson plan

Course contents and instructional materials according to the course

requirements

Training methodologies

Areas of focus/emphasis for each slide/topic

Training resource requirements

Course administration instruction

4.1.2 The LSP shall also facilitate the learning process by providing each Learner

with a Learners’ workbook/handouts to summarize (with illustrations, where

possible) key learning points of all the topics covered in the syllabus. This may be

in the form of drawings/illustrations rather than words.

4.1.3 The LSP is required to prepare and submit a course reference matrix (see

Annex B) for coverage of course contents with respect to the training slides and

the practical assessment modes. This is to facilitate cross references between

topics and training slides on the said topics.

4.1.4 It is the responsibility of the LSP to ensure that no part of the materials

used for the training infringe on patent, design, copyright and intellectual property

rights of any individual or organization.

4.1.5 The LSP shall retain an updated version of the training course syllabus,

lesson plan, Facilitator’s guide and a Learners’ workbook/handouts at all times for

inspection and verification by appointed auditors.

4.2 Training Methodology

4.2.1 Facilitators are expected to draw upon their Facilitator-training in the

development and delivery of the training programme and to apply appropriate

principles of training in the design and delivery of the course.

4.2.2 Many training delivery approaches are appropriate for this course which is

pegged at learner’s level. Training methods shall combine a wide range of delivery

methods.

7 MOM Technical Notes Part II v2.1 - MSEC

4.2.3 Some of the training methods which can be adopted for the theory lessons

are, but not limited to the following:

Classroom instruction

Case studies

Videos and photographs, other e-resources and instructional media

4.3 Training venue requirements

4.3.1 LSP is required to be equipped with sufficient and relevant practical training

equipment such as scaffold materials and accessories, PPEs, fire fighting

equipment etc.

4.3.2 For the theory training, this is to be conducted in a classroom with

supporting training slides, videos, local case studies on incidents and accidents at

the yards, and where possible, actual equipment/PPEs to enhance learning.

4.3.3 The LSP shall ensure the classroom has adequate chairs and writing tables

to be comfortably spaced for a class of up to 18 learners for conduciveness to the

learning process. There must also be adequate land space to comfortably conduct

the practical training and assessment safely. A time device e.g. clock, lightings

and ventilation must be adequate for classroom instruction. Emergency exit routes

must be clearly marked out and briefed to the course learners at the start of the

course. Necessary equipment such as projectors, multimedia player, whiteboards,

flipcharts and any other equipment essential for instruction purpose must be made

available.

4.3.4 LSP is to adhere to the conditions stipulated in the LSP Terms and

Conditions and this CDA at all times, where applicable. Adequate safety control

measures must be undertaken to ensure the safety of the Learners and

Facilitators during the conduct of the course/training at all times.

8 MOM Technical Notes Part II v2.1 - MSEC

4.4 Training Requirements:

4.4.1 Training site emergency evacuation route – to be briefed at start of course

4.4.2 Training SOP must be available before the conduct of the course

4.4.3 Photos/slides of the various types of construction-related hazards

(biological, fire, explosives, working at height, chemicals, mechanical,

electrical, radiation and gas)

4.4.5 Local case studies, where possible, relating to incidents/accidents in the

construction industry

4.4.6 Appropriate and relevant PPEs and equipment for classroom

demonstration must be made available during the course

4.5 Practical Training Requirements:

4.5.1 Scaffold equipment, materials and accessories and setup shall be designed

to simulate realistic practical demonstrations.

5 ASSESSMENT ADVICE

5.1 There shall be a one 1-hour written and one 7-hour practical assessment at

the end of the course.

5.1.1 The Learner must pass BOTH written and practical assessments in order to

be issued with the certificate of successful completion. Failure to pass either of the

assessments shall render a “Fail” outcome for the participant and he must then re-

attempt the course and assessments.

S/N Assessment Activity Method Duration Duration

(per 4 pax) (18 pax)

Test

1 Written Assessment - 1 hour

(30 MCQ)

Practical Assessment

2 Assessment - 7 hours

Total Assessment Time 8 hours

5.2 Written Assessment:

5.2.1 The LSP must administer a 30 multiple choice question (MCQ) test.

5.2.2 The total allocated time for the written assessment is 1 hour.

5.2.3 The passing mark for the written assessment is 60%.

5.2.4 During the administration of the written assessment, there shall be an

invigilator to ensure the integrity of the assessment process. The Facilitator

for the course is not permitted to be the assessor or invigilator for the same

course learners during the assessment.

5.2.5 SOP on the upkeep of the confidentiality of the written assessment

questions

9 MOM Technical Notes Part II v2.1 - MSEC

5.3 Guidelines on Practical Assessment

5.3.1 The assessment plan shall comprise the following:

Overview of the assessment tools and its duration

Clear instructions on the conduct of the assessment

SOP on the upkeep of the confidentiality of the practical assessment

questions

Instruments or tools of the practical assessment (e.g. question paper,

scaffold checklist)

Practical assessment summary record

5.4 Conduct of Practical Assessment

5.4.1 The practical assessment must be conducted strictly in accordance with the

practical assessment plan. Each Learner is expected to complete and pass

ALL the assessment requirements within the stipulated assessment time

allocated.

5.4.2 The Learner shall be assessed either “Competent” or “Not Yet Competent”.

100% pass for all the practical components is required.

5.5 Recording and reporting outcome of the Practical Assessment

5.5.1 All practical assessment outcomes must be accurately recorded in the

assessment summary record form.

5.5.2 The practical assessment outcome must be conveyed to the Learners at

the end of the assessment.

5.5.3 The LSP shall maintain a record of the assessment results for 2 years for

inspection by the authorities, when requested.

6 FACILITATOR AND ASSESSOR REQUIREMENTS

6. A Facilitator and assessor of this course should possess the following:

6.1.1 Advanced Certificate in Workplace Safety and Health

6.1.2 At least 5 years of relevant industry experience as a supervisor / foreman /

safety personnel, of which:

At least 1 year of experience in scaffold erection/supervision work for those

with Diploma in Construction/Building related course

At least 3 years of experience in scaffold erection/supervision work for

those without Diploma in Construction/Building related course

6.1.3 Advanced Certificate in Training and Assessment (ACTA) or Diploma in

Adult Continuing Education (DACE)

6.1.4 Certificate in Supervision of Metal Scaffold Erection Course

10 MOM Technical Notes Part II v2.1 - MSEC

7 END OF COURSE EVALUATION AND FEEDBACK

7.1 The LSP shall conduct an end-of-course evaluation after each course,

where Learners provide quantitative and qualitative feedback on the course

content, duration, training delivery, training materials, training venue,

training resources, quality of Facilitators and assessors.

7.2 The LSP shall analyse the feedback provided to improve the delivery of the

course. Immediate actions shall be taken to address issues with ratings

below 3. The actions taken to address issues with a rating of 1 or 2 shall be

recorded and kept for audit purpose.

1 2 3 4 5

Poor Fair Satisfactory Very Good Excellent

8 RELATED WSH LEGISLATIONS, INDUSTRIAL CODE OF PRACTICE AND

OTHER REFERENCES (the list is not exhaustive)

Workplace Safety and Health Act 2006

WSH CP:1 Code of Practice for Working Safely at Height

WSH (Risk Management) Regulations 2006

WSH (Work at Heights) Regulations 2013

WSH (Work at Heights) Regulations Amendment 2014

WSH (Construction) Regulations 2007

WSH (Scaffolds) Regulations 2011

CP14: 1996 (Code of Practice for Scaffolds)

11 MOM Technical Notes Part II v2.1 - MSEC

Annex A

Course Syllabus

Instructional Duration

Lesson No. Content

Mode (Hours)

1. Introduction to Metal Scaffolding

2. Types and classification of a scaffold system

3. Basic definition, terminology and materials for metal scaffold

4. Requirements for ties and braces

5. Static and mobile tower scaffold and their requirements

6. Safety in the erection and dismantling of modular scaffold

7. Rules and regulations in erection and dismantling

Knowledge Theory 8

Note: To include “Look, Think, Do” steps as part of the mental Risk Assessment.

(Look - Look out for Danger / Think - Think of how you can protect yourself / Do -

Do your work safely). The basic WSH rules for work such as “Working At Heights”,

“Working on Roofs” should be mentioned. Refer to WSHC website (www.wshc.sg) for

more information.

Erection and dismantling of the following scaffolds in line with safe work

procedures, general principles and requirements of WSH(Scaffold) Regulations

and CP 14

Frame scaffold

Skills Practical 22

Tubular independent tied scaffold

Tower scaffold

Modular scaffold

Sub-total Duration 30

ASSESSMENT 8. Written Assessment 1

12 MOM Technical Notes Part II v2.1 - MSEC

Instructional Duration

Lesson No. Content

Mode (Hours)

9. Practical Assessment 7

Total duration 38

Annex B

Course Reference Matrix

Coverage of Course

APPROVED TRAINING SYLLABUS

Content

Metal Scaffold Erection Course

For LSP Inputs

Indicate slide

number/topic Mode of

S/N Content Remarks Duration

e.g. Slide #2 Assessment

of topic 1

13 MOM Technical Notes Part II v2.1 - MSEC

Coverage of Course

APPROVED TRAINING SYLLABUS

Content

Metal Scaffold Erection Course

For LSP Inputs

Introduction to Metal Scaffolding

Types and classification of a scaffold system

Basic definition, terminology and materials for metal scaffold

1 Requirements for ties and braces Theory 8

Static and mobile tower scaffold and their requirements

Safety in the erection and dismantling of modular scaffold

Rules and regulations in erection and dismantling

Erection and dismantling of the following scaffold in line with safe

work procedures, general principles and requirements of

WSH(Scaffold) Regulations and CP 14

- Frame scaffold

2 Practical 22

- Tubular independent tied scaffold

- Tower scaffold

- Modular scaffold

Written 1

2 Assessment

Practical 7

TOTAL for both Theory and Practical Training 38 hours

14 MOM Technical Notes Part II v2.1 - MSEC

Declaration by LSP

I hereby declare that all the training materials and related particulars / information given are true and correct nor have I infringed

any copyright related issues in this entire accreditation process/application

____________________________ ____________________________________ ____________________________

Name of LSP Name of Applicant Designation of Applicant

__________________________________ ___________________________

Applicant’s Signature Date

___________________________ ___________________________

Head/Principal’s Signature Date

15 MOM Technical Notes Part II v2.1 - MSEC

Annex C

Assessment Plan

1 Overview

2 Assessment method and duration

3.1 Instruction for preparation of written test

3.2 Instruction for conduct of practical assessment

4 Assessment Instruments

5 Assessment Record

16 MOM Technical Notes Part II v2.1- MSEC

Annex C-1

1 Overview of Assessment Plan (listed by topics)

Lecture Practical Assessment Total

Topics

(hour) (hour) Mode (hour)

Theory

Introduction to Metal Scaffolding

Types and classification of a

scaffold system

Basic definition, terminology and

materials for metal scaffold

Requirements for ties and braces

8 WT 8

Static and mobile tower scaffold

and their requirements

Safety in the erection and

dismantling of modular scaffold

Rules and regulations in erection

and dismantling

Practical

Erection and dismantling of the

following scaffold in line with safe work

procedures, general principles and

requirements of WSH(Scaffold)

22 PP 22

Regulations and CP 14

- Frame scaffold

- Tubular independent tied scaffold

- Tower scaffold

- Modular scaffold

WRITTEN /PRACTICAL ASSESSMENT

TOTAL (Hours) – Written Assessment 1

TOTAL (Hours) – Practical Assessment 7

TOTAL (Hours) 38

WT = Written Assessment PP = Practical Performance Practical duration is

for cohort of up to 18 Learners

17 MOM Technical Notes Part II v2.1- MSEC

Annex C-2

2.1 Instruction for preparation of Written Assessment

These instructions concern the written assessment of the Learner’s

competency

Specification item Details on specifications

Learning outcome Fulfill the course learning objectives for all topics to

be assessed

Duration 1 Hour

Venue Classroom

Set up Classroom setup for 18 Learners.

Tables & chairs for individual seating

Projector and monitor

Whiteboard & markers of different colours

Whiteboard duster

2B pencil and eraser for each Learner

Printed answer sheet

Common Clock

Conduct of the Written Brief Learners to check if they have been given

Test the correct test set

Brief Learners on the time allocated for the test

Brief Learners on the close book test format.

Brief Learners that they cannot refer to any

material or notes or discuss the questions with

any other Learners during the test

Brief Learners that they are allowed to ask the

assessor to explain the question/s

Brief Learners on the 60% passing mark

requirement

2.2 Instruction for the conduct of the Practical Assessment

These instructions concern the practical assessment for the Learner’s

competency

Specification item Details on specifications

Learning outcome To perform erection and dismantling of scaffold in line

with SWP, general principles and requirements of

WSH (Scaffold) Regulations and CP 14

Duration 7 Hours

Venue LSP practical training area

Set up Learners to erect/ dismantle the scaffold

18 MOM Technical Notes Part II v2.1- MSEC

3 Assessment Instruments

Learners are required to work in groups to demonstrate to the assessor on the

erection/ dismantle the scaffold

4 Assessment Records

Metal Scaffold Erection for Scaffolders

Approved Assessment Centre: _________________________

Learner’s Name: Date of Assessment:

Learner’s NRIC/Passport/FIN:

Competency

Practical Performance Assessment Sheet Level Comments

C NYC

1. Erection/ Dismantle of scaffold

Able to identify types of scaffolding

system

Selection of scaffold materials

Check scaffolding materials

Plan scaffold erection

Erection/ tightening of various

components

Practise safety during erection

Use of PPE

Proper procedures

Handing of materials

Safety during dismantling

Housekeeping

Storage of materials

Tie knots and hitches used in scaffolding

Adding scaffolds – ways and methods of

adding

Partial removal of scaffolds –

strengthening and safety precautions

Developing the Scaffold Checklist

19 MOM Technical Notes Part II v2.1- MSEC

Overall Assessment

Written Assessment Pass / Fail (Marks: _________ %)

Practical Assessment Competent / Not Yet Competent

Overall Assessment Pass / Fail

Assessor 1: Name & Signature Assessor 2: Name & Signature

Date: Date:

Assessor Feedback: Overall performance of course Learners. For NYCs,

areas of skills gap and improvements to recommend

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

20 MOM Technical Notes Part II v2.1- MSEC

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Calculation Sheet Formula Scaffolding LTDocumento3 pagineCalculation Sheet Formula Scaffolding LTHari Haran100% (1)

- BSS Igc I Notes FinalDocumento82 pagineBSS Igc I Notes FinalAzad pravesh khanNessuna valutazione finora

- Nasc Information Membership Application Form: Revised: 1 January 2011Documento4 pagineNasc Information Membership Application Form: Revised: 1 January 2011Azad pravesh khanNessuna valutazione finora

- Calculation Sheet Formula Scaffolding LTDocumento3 pagineCalculation Sheet Formula Scaffolding LTHari Haran100% (1)

- The Design of Guide Learner-Adaptive Scaffolding in Interactive Learning EnvironmentsDocumento11 pagineThe Design of Guide Learner-Adaptive Scaffolding in Interactive Learning EnvironmentsAzad pravesh khanNessuna valutazione finora

- SCAFFOLDING SUPERVISOR UpdateDocumento3 pagineSCAFFOLDING SUPERVISOR UpdateAzad pravesh khanNessuna valutazione finora

- New Doc 2020-04-19 07.57.19Documento1 paginaNew Doc 2020-04-19 07.57.19Azad pravesh khanNessuna valutazione finora

- Nasc Information Membership Application Form: Revised: 1 January 2011Documento4 pagineNasc Information Membership Application Form: Revised: 1 January 2011Azad pravesh khanNessuna valutazione finora

- Public Access Stair Assembly Sequence ManualDocumento22 paginePublic Access Stair Assembly Sequence ManualAzad pravesh khanNessuna valutazione finora

- Scaffolding: External Referral Draft 19 December 2012Documento38 pagineScaffolding: External Referral Draft 19 December 2012Azad pravesh khanNessuna valutazione finora

- VesselsDocumento16 pagineVesselsRonald TysonNessuna valutazione finora

- Section ViewsDocumento27 pagineSection ViewsAzad pravesh khanNessuna valutazione finora

- Microllam Laminated Scaffold PlankDocumento12 pagineMicrollam Laminated Scaffold PlankhcabanillaspNessuna valutazione finora

- Supplementary Couplers and Check CouplersDocumento2 pagineSupplementary Couplers and Check CouplersAzad pravesh khanNessuna valutazione finora

- Kumar Chandan Fall2013Documento145 pagineKumar Chandan Fall2013Azad pravesh khanNessuna valutazione finora

- Calculation Sheet Formula Scaffolding LTDocumento3 pagineCalculation Sheet Formula Scaffolding LTHari Haran100% (1)

- Supplementary Couplers and Check CouplersDocumento2 pagineSupplementary Couplers and Check CouplersAzad pravesh khanNessuna valutazione finora

- Introducing TG20 13 Presentation May 2017Documento22 pagineIntroducing TG20 13 Presentation May 2017Ronn CaiNessuna valutazione finora

- Section ViewsDocumento27 pagineSection ViewsAzad pravesh khanNessuna valutazione finora

- Supplementary Couplers and Check CouplersDocumento2 pagineSupplementary Couplers and Check CouplersAzad pravesh khanNessuna valutazione finora

- Kumar Chandan Fall2013Documento145 pagineKumar Chandan Fall2013Azad pravesh khanNessuna valutazione finora

- JSA - Suface Preparationand Brush PaintingDocumento5 pagineJSA - Suface Preparationand Brush PaintingAzad pravesh khanNessuna valutazione finora

- Kumar Chandan Fall2013Documento145 pagineKumar Chandan Fall2013Azad pravesh khanNessuna valutazione finora

- Scaffolding TubeDocumento1 paginaScaffolding TubeChíld Çhïññæ ÇøôlNessuna valutazione finora

- Service Expertise - Codes Regulations PDFDocumento17 pagineService Expertise - Codes Regulations PDFAzad pravesh khanNessuna valutazione finora

- USSC - SGI-2015-ring Loc Technical Manual PDFDocumento73 pagineUSSC - SGI-2015-ring Loc Technical Manual PDFAzad pravesh khanNessuna valutazione finora

- Section ViewsDocumento27 pagineSection ViewsAzad pravesh khanNessuna valutazione finora

- Ansi Ssfi Sc100 05 05Documento47 pagineAnsi Ssfi Sc100 05 05Tehman Alam100% (1)

- Super-Scaff: Product CatalogueDocumento20 pagineSuper-Scaff: Product CatalogueAzad pravesh khanNessuna valutazione finora

- Sign Up To Accesspoint: Join The Mailing List..Documento2 pagineSign Up To Accesspoint: Join The Mailing List..Azad pravesh khanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Lean Six Sigma PrinciplesDocumento59 pagineLean Six Sigma PrinciplesAdnan TariqNessuna valutazione finora

- Hello... and Now What PDFDocumento99 pagineHello... and Now What PDFcurioscow100% (1)

- Active Citizens Global Toolkit 2011Documento146 pagineActive Citizens Global Toolkit 2011Cristina PopNessuna valutazione finora

- Peace Corps Language & Cross-Cultural Facilitator (LCF)Documento1 paginaPeace Corps Language & Cross-Cultural Facilitator (LCF)Accessible Journal Media: Peace Corps DocumentsNessuna valutazione finora

- Decision Analysis For The ProfessionalDocumento357 pagineDecision Analysis For The ProfessionalEnhbilguunNessuna valutazione finora

- Interview GuideDocumento6 pagineInterview Guidecarmela feriaNessuna valutazione finora

- Acceptance Letter-DikonversiDocumento2 pagineAcceptance Letter-DikonversiLuthfanTogarNessuna valutazione finora

- Nutrition Education in Primary Schools: Vol. 2: The ActivitiesDocumento34 pagineNutrition Education in Primary Schools: Vol. 2: The ActivitiesDaisyNessuna valutazione finora

- Tle10 - He - Beautynailcareservices - q2 - Mod1 - Applyingfootspa - v3 (30 Pages)Documento31 pagineTle10 - He - Beautynailcareservices - q2 - Mod1 - Applyingfootspa - v3 (30 Pages)Bernadeth Irma Sawal Caballa100% (2)

- Choices For Sustainable LivingDocumento140 pagineChoices For Sustainable Livingywu12460% (5)

- Audience Development StrategyDocumento23 pagineAudience Development StrategyandrushkyNessuna valutazione finora

- Feedback FormDocumento6 pagineFeedback FormSai PavanNessuna valutazione finora

- The Complete Clinical Assessment in PsychiatryDocumento274 pagineThe Complete Clinical Assessment in PsychiatryRenzo Lanfranco100% (4)

- A Guide To Participatory CommunicationDocumento43 pagineA Guide To Participatory Communication300rNessuna valutazione finora

- Teaching Childrens LiteratureDocumento6 pagineTeaching Childrens LiteratureLilian May Sorote AndoNessuna valutazione finora

- J/SHS: Activity Sheet Quarter 2 - Week 3Documento7 pagineJ/SHS: Activity Sheet Quarter 2 - Week 3ryan bañaresNessuna valutazione finora

- Calibration FAQs Guidance For HR UnitsDocumento4 pagineCalibration FAQs Guidance For HR Unitsmelimaulani-1Nessuna valutazione finora

- 2 T3 Transformative TSG PDFDocumento141 pagine2 T3 Transformative TSG PDFMam MamcomNessuna valutazione finora

- Curriculum Hardware Network Leve IVDocumento41 pagineCurriculum Hardware Network Leve IVsalah80% (5)

- G9slm3q1final For StudentDocumento22 pagineG9slm3q1final For StudentCarlynArgentinaPaitanCarduzaNessuna valutazione finora

- NLN Jeffries Simulation Theory: Brief Narrative Description: Editor's Note: This Article Is Excerpted FromDocumento2 pagineNLN Jeffries Simulation Theory: Brief Narrative Description: Editor's Note: This Article Is Excerpted FromAchmad VindoNessuna valutazione finora

- How To Develop Discussion Materials For Public DialogueDocumento28 pagineHow To Develop Discussion Materials For Public DialogueEverydayDemocracy100% (1)

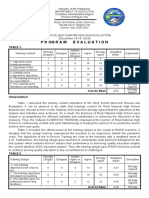

- Program Evaluation Analysis CssDocumento38 pagineProgram Evaluation Analysis CssedzNessuna valutazione finora

- A Guide To Facilitating Adult Learning PDFDocumento30 pagineA Guide To Facilitating Adult Learning PDFmarcgleb100% (1)

- Program Evaluation: Table 1Documento3 pagineProgram Evaluation: Table 1Joel HinayNessuna valutazione finora

- EDC Facilitation PracticesDocumento20 pagineEDC Facilitation PracticesEduardo CanelaNessuna valutazione finora

- PRA Training HandbookDocumento29 paginePRA Training Handbookdennyson100% (1)

- 5 Critical Skills For RCA FacilitatorsDocumento5 pagine5 Critical Skills For RCA FacilitatorsVu Hoang VanNessuna valutazione finora

- Cookery-9 q4m5 Glaiza R LadimoDocumento16 pagineCookery-9 q4m5 Glaiza R LadimoMichelle Del Rosario MercadoNessuna valutazione finora

- English 9 Activity Sheet: Quarter 2 - Melc 6Documento8 pagineEnglish 9 Activity Sheet: Quarter 2 - Melc 6Mark San AndresNessuna valutazione finora