Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Long Span Structures - Report

Caricato da

Prashant JadhavCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Long Span Structures - Report

Caricato da

Prashant JadhavCopyright:

Formati disponibili

TECH STUDIO

LONG SPAN STRUCTURES

REPORT

PRASHANT JOTIRAM JADHAV

5TH YR. B.ARCH.

ROLL NO. - 18

PILLAI HOC COLLEGE OF ARCHITECTURE

LONG SPAN STRUCTURES

INTRODUCTION:

Definition of long span building: Buildings that create unobstructed, column-free spaces

greater than 30 m (100 feet) for a variety of functions / activities. For Such structures span is

unable to be achieved with ordinary R.C.C. construction. Generally long spans result in

flexible, column-free internal spaces, reduces substructure costs and time to erect the

structure.

Examples of relevant activities:

•where visibility is important: i.e. auditoriums and covered stadiums.

•where flexibility is important: i.e. exhibition halls and certain type of manufacturing

facilities,

•where large movable objects are housed: i.e. aircraft hangars.

COMMON STRUCTURAL SYSTEMS FOR LONG SPAN STRUCTURES:

Long span Beams

Long span Trusses

Long span Roof structures

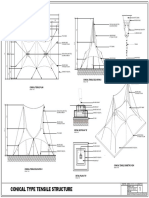

• Tensile structures

• Folded Plates

• Shell structures

• Portal Frames

LONG SPAN BEAMS:

The use of long span beams results in a range of benefits, including flexible, column-free

internal spaces, reduced foundation costs, and reduced steel erection times. Many long

span solutions are also well adapted to facilitate the integration of services without

increasing the overall floor depth. Types of Long Span Beams.

• Parallel Beam Approach

• Composite Beams with Web Openings

• Tapered Girders

• Haunched Composite Beams

Parallel beam approach:

The parallel beam approach is effective for spans up to around 20 m. Floor grids comprise

two layers of fully continuous beams running in orthogonal directions. Services running in

either direction can be integrated within these two layers, so that services passing in any

direction can be accommodated within the structural floor depth. A further benefit is that,

being fully continuous, the depth of the beams themselves is reduced without incurring the

expense and complexity of rigid, full strength connections.

Composite Beams with Web Openings:

Web openings are typically formed in beams to allow services to pass through the beam.

This enables the structural and service zones to occupy the same space, thereby reducing

the effective overall depth of floor construction for a given spanning capability. Openings

may also be formed for aesthetic reasons, for instance with cambered beams used to

support a roof. Composite beams with web openings have been shown to be a cost effective

solution for spans in the range 15-30m.

TAPERED GIRDERS:

Tapered girders can be a cost effective solution in the span range 15 m to 25 m. They are

another solution that allows services to be accommodated within the structural floor zone.

The depth of the girder increases towards mid-span, where applied moments are greatest,

and thereby facilitating hanging services under the shallower regions near the beam

supports. It is also possible to form web openings in tapered girders in regions of low shear,

towards mid-span. These provide more options for service integration.

Haunched composite beams:

Haunches may be added at the ends of a composite beam to provide moment continuity.

The stiffness and strength of the connections mean that the rest of the span can be

shallower (the bending moment diagram is 'lifted' and the effective stiffness of the beam

substantially increased), and services passed under it. In buildings where the services are

likely to need frequent replacement (for example in hospitals), hanging the services under

the beams rather than passing them through holes in the webs, or through a truss, can be

advantageous. Spans in excess of 20-30 m can readily be achieved.

LONG SPAN TRUSSES:

A truss is essentially a triangulated system of straight interconnected structural elements.

Trusses are frame works in which the members are subjected to essentially axial forces due

to externally applied load. Bending leads to compression in the top chords (or horizontal

members), tension in the bottom chords, and either tension or compression in the vertical

and diagonal members. The most common use of trusses is in buildings, where support to

roofs, the floors and internal loading such as services and suspended ceilings, are readily

provided.

The main reasons for using trusses are:

• Long span • Lightweight • Reduced deflection (compared to plain members)

• Opportunity to support considerable loads.

Types of Long Span Trusses:

• Pratt Truss

• Warren Truss

• North Light Truss

• Fink Truss

Pratt Truss:

Pratt trusses are commonly used in long span buildings ranging from 20 to 75 m in span. In a

conventional Pratt truss, diagonal members are in tension for gravity loads. This type of

truss is used where gravity loads are predominant. An alternative Pratt truss is shown where

the diagonal members are in tension for uplift loads. This type of truss is used where uplift

loads are predominant, which may be the case in open buildings such as aircraft hanger.

It is possible to add secondary members to:

•Create intermediate support points for applied loads

•Limit the buckling length of members in compression.

Warren Truss:

In this type of truss, diagonal members are alternatively in tension and in compression. The

Warren truss has equal length compression and tension web members, and fewer members

than a Pratt truss. A modified Warren truss may be adopted where additional members are

introduced to provide a node at (for example) purlin locations. Warren trusses are

commonly used in long span buildings ranging from 20 to 100 m in span. This type of truss is

also used for the horizontal truss of gantry/crane girders.

BLUE – TENSION, RED – COMPRESSION.

North Light Truss:

North light trusses are traditionally used for short spans in industrial workshop-type

buildings. They allow maximum benefit to be gained from natural lighting by the use of

glazing on the steeper pitch which generally faces north or north-east to reduce solar gain.

On the steeper sloping portion of the truss, it is typical to have a truss running

perpendicular to the plane of the North Light truss, to provide large column-free spaces.

Fink truss:

The Fink truss offers economy in terms of steel weight for short-span high-pitched roofs as

the members are subdivided into shorter elements. There are many ways of arranging and

subdividing the chords and internal members. This type of truss is commonly used to

construct roofs in houses.

Potrebbero piacerti anche

- Long Span StructuresDocumento20 pagineLong Span StructuresShrishank Rudra100% (11)

- Long Span StrcutureDocumento6 pagineLong Span StrcutureArun SahaniNessuna valutazione finora

- Long Span StructuresDocumento13 pagineLong Span StructuresVinay KatariyaNessuna valutazione finora

- Long Span StructureDocumento16 pagineLong Span StructurePrashant PalNessuna valutazione finora

- Folded Case StudyDocumento11 pagineFolded Case StudyBhavika Dabhi100% (1)

- Tensile FinalDocumento43 pagineTensile Finalnamrataavyas75% (4)

- Long Span Structures Presentation PDFDocumento70 pagineLong Span Structures Presentation PDFharshitha chandana100% (4)

- Folded PlatesDocumento11 pagineFolded PlatesPalak Kothari75% (4)

- Rahul - Long Span StructuresDocumento27 pagineRahul - Long Span Structuresjoshipra2799100% (1)

- Space Frame Structure-Stansted Airport, LondonDocumento3 pagineSpace Frame Structure-Stansted Airport, LondonPournima More67% (3)

- Shell StructuresDocumento12 pagineShell Structuresdevang92100% (1)

- Case Study of Long Span StructureDocumento6 pagineCase Study of Long Span Structuredharna garg27% (11)

- Long Span StructureDocumento94 pagineLong Span StructureMicron Macron100% (5)

- Case Study On Large Span StructureDocumento1 paginaCase Study On Large Span StructureNiladri Sekhar RoyNessuna valutazione finora

- Shelled StructureDocumento10 pagineShelled Structurenandu shahNessuna valutazione finora

- Folded Plates: Group Members: Subject: Theory of StructuresDocumento20 pagineFolded Plates: Group Members: Subject: Theory of StructuresSoham SatamNessuna valutazione finora

- Long Span Structure Portal FrameDocumento25 pagineLong Span Structure Portal Frameharish gupta100% (1)

- 16bar002,16bar005,16bar017,16bar024,16bar028 Space FrameDocumento28 pagine16bar002,16bar005,16bar017,16bar024,16bar028 Space Framenij balarNessuna valutazione finora

- Long Span Structures - Vector Active, Form Active & Pneumatic Structures.-1Documento37 pagineLong Span Structures - Vector Active, Form Active & Pneumatic Structures.-1Ritesh Lohar0% (1)

- Long Span Structure NotesDocumento56 pagineLong Span Structure NotesFazren Kamarudin100% (1)

- 5 North Light Truss and GirdersDocumento13 pagine5 North Light Truss and GirdersSatyam BhardwajNessuna valutazione finora

- Building Services Module 5 NotesDocumento28 pagineBuilding Services Module 5 NotesTrishul IsNessuna valutazione finora

- Building Construction: Assignment 1 Report On Long Span StructuresDocumento18 pagineBuilding Construction: Assignment 1 Report On Long Span StructuresPrerana CholakheNessuna valutazione finora

- Bulk Active Structural SystemDocumento30 pagineBulk Active Structural SystemRisky Manek100% (1)

- Shell Structures and Cable StructuresDocumento33 pagineShell Structures and Cable StructuresSanika Kadam100% (1)

- Brief On Tensile StructuresDocumento34 pagineBrief On Tensile StructuresShikhaNessuna valutazione finora

- Form Active StructuresDocumento12 pagineForm Active StructuresKumar Shriyanshu100% (6)

- Shell StructureDocumento18 pagineShell StructureYachika SharmaNessuna valutazione finora

- Diagrid Structural SystemDocumento21 pagineDiagrid Structural SystemRaihan AhmedNessuna valutazione finora

- Literature Case Study On Design CollegeDocumento21 pagineLiterature Case Study On Design CollegeSophia Chin100% (1)

- New PPT Presentation (13-4-20)Documento28 pagineNew PPT Presentation (13-4-20)sanket pawar100% (1)

- Long Span Beams - SalahuddinDocumento16 pagineLong Span Beams - SalahuddinSalahuddin Shaikh0% (1)

- Folded Plate StructureDocumento38 pagineFolded Plate StructurePatt Myaz100% (2)

- Method of Speedy ConstructionDocumento35 pagineMethod of Speedy ConstructionKaramjeet Singh100% (2)

- Tensile Structures (Assignment 3 Reference)Documento1 paginaTensile Structures (Assignment 3 Reference)Bhavika Dabhi100% (1)

- TOS 5 Unit 2c T Beams and L BeamsDocumento8 pagineTOS 5 Unit 2c T Beams and L BeamsKshitija100% (1)

- Form Active Tent Structure Denver International AirportDocumento5 pagineForm Active Tent Structure Denver International AirportNishika AgrawalNessuna valutazione finora

- Portal Frame-FINALDocumento11 paginePortal Frame-FINALKratiAgarwalNessuna valutazione finora

- NORTH Light Roof TrussDocumento16 pagineNORTH Light Roof Trussyogesh67% (9)

- Cable Structures (Load Transfer)Documento8 pagineCable Structures (Load Transfer)komalNessuna valutazione finora

- Space FrameDocumento15 pagineSpace FrameAnjalySinhaNessuna valutazione finora

- Vector Active St.Documento7 pagineVector Active St.zohan90% (10)

- Long Span Structure London VelodromeDocumento20 pagineLong Span Structure London VelodromeArjun Nambiar67% (3)

- Tubular Steel Monitor Roof Truss - Large Span Constructions - Civil Engineering ProjectsDocumento3 pagineTubular Steel Monitor Roof Truss - Large Span Constructions - Civil Engineering ProjectsKranthi Kumar Chowdary ManamNessuna valutazione finora

- Cable StructuresDocumento24 pagineCable StructuresUsha Sri GNessuna valutazione finora

- Case Study On Large Span Structure PDFDocumento1 paginaCase Study On Large Span Structure PDFNiladri Sekhar RoyNessuna valutazione finora

- RCC Folded Plates ShortDocumento2 pagineRCC Folded Plates ShortdeepshikhaNessuna valutazione finora

- Castellated GirderDocumento14 pagineCastellated Girderpriyesh jainNessuna valutazione finora

- Space FrameDocumento12 pagineSpace FrameSanika KadamNessuna valutazione finora

- Pneumatic StructureDocumento27 paginePneumatic StructureMilkyNessuna valutazione finora

- Portal Frame & North Light Truss DetailDocumento17 paginePortal Frame & North Light Truss DetailRemya R. Kumar33% (3)

- Folded Plates PDFDocumento8 pagineFolded Plates PDFAshneet KaurNessuna valutazione finora

- TOS 4 Unit 3 Design of R.C.C Slabs ContinuedDocumento24 pagineTOS 4 Unit 3 Design of R.C.C Slabs ContinuedSporty GameNessuna valutazione finora

- Assignment-3 Mast SupportedDocumento23 pagineAssignment-3 Mast SupportedShanmuga Priya100% (1)

- T.O.S (Surface Active Structures)Documento18 pagineT.O.S (Surface Active Structures)Riddhi Aggarwal100% (1)

- Coffered SlabDocumento22 pagineCoffered SlabEnshaS100% (2)

- Long Span Beams: Name: Ronak Rathod Sub: A.B.C.M Sem: 9ThDocumento5 pagineLong Span Beams: Name: Ronak Rathod Sub: A.B.C.M Sem: 9ThRonakNessuna valutazione finora

- Stuctures PortfolioDocumento77 pagineStuctures PortfolioIndraja RmNessuna valutazione finora

- Abcm - Long Span - ReportDocumento27 pagineAbcm - Long Span - ReportShalin KapdiNessuna valutazione finora

- Group B3 - ReportDocumento18 pagineGroup B3 - ReportAmey DeshmukhNessuna valutazione finora

- Kitchen Design GuideDocumento48 pagineKitchen Design GuideSongAn Bui100% (1)

- Satara ODF ReportDocumento27 pagineSatara ODF ReportPrashant JadhavNessuna valutazione finora

- Booklet Corporate Park - KhargharDocumento21 pagineBooklet Corporate Park - Kharghardishan soniNessuna valutazione finora

- Melghat Eco Science Park WasaliDocumento26 pagineMelghat Eco Science Park WasaliPrashant JadhavNessuna valutazione finora

- Thesis Topic StudiesDocumento3 pagineThesis Topic StudiesPrashant JadhavNessuna valutazione finora

- RD Sustain Dev PrinciplesDocumento6 pagineRD Sustain Dev PrinciplesPrashant JadhavNessuna valutazione finora

- Produced by An Autodesk Educational ProductDocumento1 paginaProduced by An Autodesk Educational ProductPrashant JadhavNessuna valutazione finora

- 127th Street BridgeDocumento4 pagine127th Street BridgePrashant JadhavNessuna valutazione finora

- Qu StionsDocumento2 pagineQu StionsPrashant JadhavNessuna valutazione finora

- Kitchen Design GuideDocumento48 pagineKitchen Design GuideSongAn Bui100% (1)

- Science + Technology Park: Knowledge Observation Experimentation Practice AimDocumento5 pagineScience + Technology Park: Knowledge Observation Experimentation Practice AimPrashant JadhavNessuna valutazione finora

- Container Final SheetDocumento1 paginaContainer Final SheetPrashant JadhavNessuna valutazione finora

- Thesis Topic StudiesDocumento3 pagineThesis Topic StudiesPrashant JadhavNessuna valutazione finora

- Fire Protection SummaryDocumento70 pagineFire Protection SummaryPrashant JadhavNessuna valutazione finora

- Kitchen Design GuideDocumento48 pagineKitchen Design GuideSongAn Bui100% (1)

- Fire Safety High Rise Building PDFDocumento25 pagineFire Safety High Rise Building PDFnunukantaNessuna valutazione finora

- Building Layout: Yard HydrantDocumento1 paginaBuilding Layout: Yard HydrantPrashant JadhavNessuna valutazione finora

- Fire StaircaseDocumento4 pagineFire StaircasePrashant JadhavNessuna valutazione finora

- Quing Pu Case StudyDocumento3 pagineQuing Pu Case StudyPrashant Jadhav75% (4)

- Lift N EscalatorDocumento1 paginaLift N EscalatorPrashant JadhavNessuna valutazione finora

- Swimming Pool DesignDocumento49 pagineSwimming Pool Designcashlover100% (1)

- SqashDocumento1 paginaSqashPrashant JadhavNessuna valutazione finora

- Fire Safety High Rise Building PDFDocumento25 pagineFire Safety High Rise Building PDFnunukantaNessuna valutazione finora

- Site AnalysisDocumento1 paginaSite AnalysisPrashant JadhavNessuna valutazione finora

- Ad Report FileDocumento14 pagineAd Report FilePrashant JadhavNessuna valutazione finora

- Site AnalysisDocumento1 paginaSite AnalysisPrashant JadhavNessuna valutazione finora

- On The Application of Metallurgical Techniques To Forensic SciencesDocumento8 pagineOn The Application of Metallurgical Techniques To Forensic Sciencesnantha kumarNessuna valutazione finora

- General Body Repairs PDFDocumento72 pagineGeneral Body Repairs PDFRADEKNessuna valutazione finora

- Exxon™ Bromobutyl 2255: RubberDocumento2 pagineExxon™ Bromobutyl 2255: RubberMaram YasserNessuna valutazione finora

- Internship Presentation: at Greenish Engineering ServicesDocumento17 pagineInternship Presentation: at Greenish Engineering ServicesThiri Poe PoeNessuna valutazione finora

- (7-1) Normal Depth and Best Hydraulic Sections of Open Channels PDFDocumento9 pagine(7-1) Normal Depth and Best Hydraulic Sections of Open Channels PDFMohamed Wayrah100% (1)

- Formability of Al Alloys - A ReviewDocumento26 pagineFormability of Al Alloys - A ReviewVigneshwaran Soundararaja perumal100% (1)

- FD72 Technical Manual 28.10.09Documento74 pagineFD72 Technical Manual 28.10.09cavgsi16vNessuna valutazione finora

- 3M Thinsulate TAI2047Documento2 pagine3M Thinsulate TAI2047Nic CheongNessuna valutazione finora

- Nikunj Investments & Home Solutions: Financial and Real Assets - Investment Advisory and ConsultancyDocumento15 pagineNikunj Investments & Home Solutions: Financial and Real Assets - Investment Advisory and ConsultancyPk JhaNessuna valutazione finora

- ASTM C 593-06 - Standard Specification For Fly Ash and Other Pozzolans For Use With LimeDocumento5 pagineASTM C 593-06 - Standard Specification For Fly Ash and Other Pozzolans For Use With Limeluisenriq33100% (1)

- NDT PDFDocumento4 pagineNDT PDFBHARANINessuna valutazione finora

- EDMDocumento5 pagineEDMNibedit NahakNessuna valutazione finora

- A Review of One-Dimensional Unsteady Friction Models For Transient Pipe FlowDocumento11 pagineA Review of One-Dimensional Unsteady Friction Models For Transient Pipe FlowBhuvanaNessuna valutazione finora

- Guidance Note Installation of Preloaded Bolts No. 7.05: ScopeDocumento6 pagineGuidance Note Installation of Preloaded Bolts No. 7.05: ScopeAli ZarkaNessuna valutazione finora

- Roof Management ReportDocumento9 pagineRoof Management ReportBer Salazar JrNessuna valutazione finora

- DVS Technical Codes and BulletinsDocumento10 pagineDVS Technical Codes and BulletinsAsif SarwarNessuna valutazione finora

- Homework #7Documento3 pagineHomework #7Sebastián SantarrosaNessuna valutazione finora

- MEEN 472 Syllabus Fall 2017Documento4 pagineMEEN 472 Syllabus Fall 2017Bacio GuidoNessuna valutazione finora

- Conveyorchains HITACHIDocumento173 pagineConveyorchains HITACHIReno MurdaNessuna valutazione finora

- Advanced Cast Products - Ductile Iron Specs-ASTM 897, ASTM A536, SAE J434Documento27 pagineAdvanced Cast Products - Ductile Iron Specs-ASTM 897, ASTM A536, SAE J434George CharitouNessuna valutazione finora

- Penetration of Bituminous PDFDocumento8 paginePenetration of Bituminous PDFMaslisa AffenddyNessuna valutazione finora

- Merik Garage Door Opener 711MBDocumento80 pagineMerik Garage Door Opener 711MBpokmarthNessuna valutazione finora

- Heat PacDocumento2 pagineHeat PacTasha GutierrezNessuna valutazione finora

- Outokumpu Dowel BarsDocumento2 pagineOutokumpu Dowel BarsAriel NemcoNessuna valutazione finora

- ProValve Cast SteelDocumento12 pagineProValve Cast SteelHarry HonchoNessuna valutazione finora

- Daso Cooling LoadDocumento31 pagineDaso Cooling LoadObakoma JosiahNessuna valutazione finora

- Theory of Indeterminate Structure by Syed Ali Rizwan PDFDocumento470 pagineTheory of Indeterminate Structure by Syed Ali Rizwan PDFZain Ashfaq100% (2)

- Vernacular Term ConstructionDocumento3 pagineVernacular Term ConstructionGregor SartinNessuna valutazione finora

- Reinforced Concrete Design - LESSON 1.1 PDFDocumento20 pagineReinforced Concrete Design - LESSON 1.1 PDFBeerRideNessuna valutazione finora

- Manual of 725HP 10KV MotorDocumento12 pagineManual of 725HP 10KV MotorduongthetinhqbNessuna valutazione finora