Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Estimating Cost For Fixed Roof Storage Tank

Caricato da

yogiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Estimating Cost For Fixed Roof Storage Tank

Caricato da

yogiCopyright:

Formati disponibili

Estimating Cost for process equipment has always been an achilles heel for process engineers including

yours truly. Everytime when I was asked to provide budgetary cost for equipment mentioned in a Front

End Engineering Design report I used to be red-faced because I just had no idea of how equipment was

costed. Fortunately in one or two organizations where I worked there was a procurement and inspection

group who knew quite a lot about equipment cost and could provide the data. But there were also

occasions where I struggled to find cost data since I had no support of a costing or procurement engineer.

Some research on the subject allowed me to find empirical methods of costing some common type of

process equipment using empirical correlations. Todays blog entry is related to costing of "Fixed Cone

Roof Carbon Steel Storage Tanks". I am presenting the equations below which can be programmed in an

excel sheet and which I have already programmed as one. I believe that the cost calculated from the

equations described below should be good enough for a +/- 25% budgetary cost. It would be appropriate

to mention the references for these equations beforehand and they are as follows:

"Estimate Costs of Heat Exchangers and Storage Tanks via Correlations" by Armando B. Corripio,

Katherine S. Chrien, and Lawrence B. Evans, Chemical Engineering magazine January 25, 1982.

Base Cost for CS Shop Fabricated tanks

SI Units

CB = EXP(7.994 + 0.6637*lnV - 0.063088*(lnV)2)

where:

CB = Base Cost of the tank, USD

V = Volume in m3, Lower Limit: 5 m 3, Upper Limit: 80 m3

USC Units

CB = EXP(2.331 + 1.3673*lnV - 0.063088*(lnV)2)

where:

CB = Base Cost of the tank, USD

V = Volume in US Gallons, Lower Limit: 1,300 gallon, Upper Limit: 21,000 gallon

Base Cost for CS Field-Erected tanks

SI Units

CB = EXP(9.369 - 0.1045*lnV + 0.045355*(lnV)2)

where:

CB = Base Cost of the tank, USD

V = Volume in m3, Lower Limit: 80 m3, Upper Limit: 45,000 m3

USC Units

CB = EXP(11.362 - 0.6104*lnV + 0.045355*(lnV)2)

where:

CB = Base Cost of the tank, USD

V = Volume in US Gallons, Lower Limit: 21,000 gallon, Upper Limit: 11,000,000 gallon

Updated Cost

CB(updated) = CB*(CICY / CIBY)

where:

CB(updated) = Updated Cost of the Tank, USD

CICY = Cost Index, Current Year

CIBY = Cost Index, Base Year

Note: Cost Index (CI) for any year can be obtained form the Chemical Engineering Plant Cost Index

(CEPCI) data.

General Notes:

1. Cost of field-erected tanks includes the costs of platforms and ladders but not of foundations and other

installation materials (piping, electrical, instrumentation etc.)

2. Cost of shop-fabricated tanks does not include any installation materials including platforms / ladders.

I also plan to put the correlations for costing "Shell & Tube" Heat Exchangers, which are somewhat

complex considering the type of head and the tube metallurgy, in my next blog entry. Let me have

comments from the members of "Cheresources". Happy reading.

Potrebbero piacerti anche

- Cost Estimation of Storage TankDocumento2 pagineCost Estimation of Storage Tankmiteshmayur84% (19)

- Tank Farm & Storage Terminal Cost EstimateDocumento3 pagineTank Farm & Storage Terminal Cost Estimateyogi100% (5)

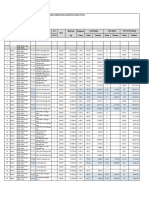

- Vessels Manhours EstimateDocumento1 paginaVessels Manhours Estimateruponline1100% (1)

- Piping Engineering Manhours Estimation Hours Per ActivityDocumento4 paginePiping Engineering Manhours Estimation Hours Per ActivityZeeshan Ahuja100% (7)

- Koel Colours FINALDocumento20 pagineKoel Colours FINALShruti Lovekar100% (1)

- Sludge Decant TankDocumento5 pagineSludge Decant TankInamullah KhanNessuna valutazione finora

- Manhours Calculations MBDocumento129 pagineManhours Calculations MBTalal Ahmed Khan100% (2)

- CIP1 Exam Preparation Guide PDFDocumento10 pagineCIP1 Exam Preparation Guide PDFrjnerdNessuna valutazione finora

- Nozzle Loads As Per Shell DEPDocumento4 pagineNozzle Loads As Per Shell DEPSarfaraz KhanNessuna valutazione finora

- ICARUS ReferenceDocumento66 pagineICARUS Referencerylar999Nessuna valutazione finora

- The Outside Diameter As Their Nominal DiameterDocumento75 pagineThe Outside Diameter As Their Nominal Diameterngutor100% (2)

- 1.tank Monitoring StatusDocumento3 pagine1.tank Monitoring StatusDuan TokcerNessuna valutazione finora

- Equipment Design BasisDocumento4 pagineEquipment Design BasisAnjani GantiNessuna valutazione finora

- Awareness Training EstimateDocumento16 pagineAwareness Training EstimatekamlNessuna valutazione finora

- API Standard Storage Tank Data Sheet Rev 0Documento3 pagineAPI Standard Storage Tank Data Sheet Rev 0Luis JaraNessuna valutazione finora

- Lang & Happel's Estimation MethodsDocumento10 pagineLang & Happel's Estimation MethodsPhan S100% (2)

- Surface Area Calculations Vessel TanksDocumento5 pagineSurface Area Calculations Vessel Tanksdhavalesh1Nessuna valutazione finora

- Vessel VolumesDocumento76 pagineVessel VolumesJosé Juan Jiménez AlejandroNessuna valutazione finora

- SP-2069 Specification For Pressure VesselsDocumento68 pagineSP-2069 Specification For Pressure Vesselsarjunprasannan7Nessuna valutazione finora

- Unit Operations Thumb RulesDocumento9 pagineUnit Operations Thumb RuleshibhavuNessuna valutazione finora

- Cost Estimate PDFDocumento44 pagineCost Estimate PDFananyo_sengupta100% (2)

- Plant Cost EstimateDocumento29 paginePlant Cost EstimateKevin J. MillsNessuna valutazione finora

- EXTERRAN Glycol DehydrationDocumento2 pagineEXTERRAN Glycol DehydrationMuhammad ImranNessuna valutazione finora

- Project Client: Pt. Caltex Pacific Indonesia Discipline: Process Engineering Subject: Deliverable List & Manhour EstimateDocumento3 pagineProject Client: Pt. Caltex Pacific Indonesia Discipline: Process Engineering Subject: Deliverable List & Manhour EstimateElias EliasNessuna valutazione finora

- API 650 Rafter DesignDocumento12 pagineAPI 650 Rafter Designrongweius100% (1)

- Refinery TankagesDocumento4 pagineRefinery Tankagesmayuresh1101100% (1)

- Storage Tank PressControl Rev1Documento46 pagineStorage Tank PressControl Rev1sachinumarye100% (2)

- CONOCO PHILLIPS SpecDocumento21 pagineCONOCO PHILLIPS SpecYuda Satria100% (1)

- Detailed Unit Rate Estimating in Aspen Capital Cost EstimatorDocumento12 pagineDetailed Unit Rate Estimating in Aspen Capital Cost EstimatorOsama El-ShafieyNessuna valutazione finora

- PVEliteDocumento580 paginePVEliteSudhanshu Shekhar100% (2)

- Project Management Man-Hour Cost Analysis: Case: Wärtsilä Energy SolutionsDocumento32 pagineProject Management Man-Hour Cost Analysis: Case: Wärtsilä Energy SolutionsAziz EL100% (1)

- Tank Pressure Vacuum ReliefDocumento1 paginaTank Pressure Vacuum ReliefalmadhagiNessuna valutazione finora

- Cost of Equipment 93851 - 20Documento7 pagineCost of Equipment 93851 - 20genergiaNessuna valutazione finora

- Nozzle Load T1011 12Documento12 pagineNozzle Load T1011 12koyahassanNessuna valutazione finora

- Storage Tank DetailDocumento22 pagineStorage Tank DetailRamu NallathambiNessuna valutazione finora

- Data Sheet Crude Oil Tank Mixer PDFDocumento3 pagineData Sheet Crude Oil Tank Mixer PDFsiska bedegul100% (1)

- Costing of PipelinesDocumento15 pagineCosting of Pipelinesalex_caballero_12100% (1)

- 3G4 Distillation CalculationsDocumento22 pagine3G4 Distillation CalculationsMahmoud Nasr0% (1)

- Tank Normal Venting (API)Documento1 paginaTank Normal Venting (API)ام يمنى ايمنNessuna valutazione finora

- (Eptco) Basic Engineering & Detail Engineering Work For Fuel Storage Tank - ElectricalDocumento6 pagine(Eptco) Basic Engineering & Detail Engineering Work For Fuel Storage Tank - ElectricalCharles Robiansyah50% (2)

- Section 22 - Sulfur RecoveryDocumento145 pagineSection 22 - Sulfur RecoveryCHANADAS100% (1)

- Process Equipment Cost EstimationDocumento80 pagineProcess Equipment Cost EstimationKSSri100% (3)

- Cost Estimation of Fixed Roof (Cone) Carbon Steel Storage TanksDocumento4 pagineCost Estimation of Fixed Roof (Cone) Carbon Steel Storage TankshamedpdmsNessuna valutazione finora

- BPCS Costing1Documento5 pagineBPCS Costing1Satya BobbaNessuna valutazione finora

- Estimating The Cost of New Construction Naval ShipDocumento39 pagineEstimating The Cost of New Construction Naval ShipCURRITOJIMENEZ100% (1)

- LCM 7 ParametricDocumento31 pagineLCM 7 ParametricZafar FarooqNessuna valutazione finora

- Activity Based CostingDocumento37 pagineActivity Based CostingnuraidaNessuna valutazione finora

- 201B Exam 2 PrepDocumento9 pagine201B Exam 2 PrepChanel NguyenNessuna valutazione finora

- MinhNguyen Q3 25jan21 02Documento103 pagineMinhNguyen Q3 25jan21 02Minh NguyễnNessuna valutazione finora

- Seminar 3 - QDocumento3 pagineSeminar 3 - QanalsluttyNessuna valutazione finora

- 3-Capital-Cost-Estimation #1 s19 Fs15 #2 Fs20Documento46 pagine3-Capital-Cost-Estimation #1 s19 Fs15 #2 Fs20Geofrey Sy BajeNessuna valutazione finora

- TUT (4) Q1: Choose The Best AnswerDocumento3 pagineTUT (4) Q1: Choose The Best AnswerElzubair EljaaliNessuna valutazione finora

- Lesson 5: Conceptual Estimates: Dr. Cho Georgia TechDocumento21 pagineLesson 5: Conceptual Estimates: Dr. Cho Georgia TechRyanNessuna valutazione finora

- Estimating The Cost of New ConstructionDocumento39 pagineEstimating The Cost of New ConstructionLukman Tarigan Sumatra100% (1)

- BA 555 Practical Business Analysis: Linear Programming (LP)Documento23 pagineBA 555 Practical Business Analysis: Linear Programming (LP)Ðệnnïs RǿmerǿNessuna valutazione finora

- EX 1 - WilkersonDocumento8 pagineEX 1 - WilkersonDror PazNessuna valutazione finora

- Cash Flow Estimation Models: Estimating Relationships and ProblemsDocumento30 pagineCash Flow Estimation Models: Estimating Relationships and ProblemsSenthil RNessuna valutazione finora

- Estimation of Capital CostDocumento47 pagineEstimation of Capital CostM RahmanNessuna valutazione finora

- Des Presentation 2012Documento12 pagineDes Presentation 2012Vaishno Ashish Singh ChauhanNessuna valutazione finora

- Lecture 9 ABC, CVP PDFDocumento58 pagineLecture 9 ABC, CVP PDFShweta SridharNessuna valutazione finora

- Busbar Sizing CalculationDocumento8 pagineBusbar Sizing CalculationCode Jon100% (1)

- Superpave Laboratory WorkshopDocumento62 pagineSuperpave Laboratory WorkshopAugusto M. ReyesNessuna valutazione finora

- C. Graciano A. Ayestarán - Steel Plate Girder Webs Under Combined Patch Loading, Bending and SheDocumento11 pagineC. Graciano A. Ayestarán - Steel Plate Girder Webs Under Combined Patch Loading, Bending and SheAsdrubal AyestaránNessuna valutazione finora

- ACI 301 XdataDocumento5 pagineACI 301 XdatadarebertNessuna valutazione finora

- HDPE MSDS English V1.1Documento7 pagineHDPE MSDS English V1.1Pradika WibowoNessuna valutazione finora

- Soil Freeze-Thaw Effects On Bank Erodibility and Stability: ElecteDocumento23 pagineSoil Freeze-Thaw Effects On Bank Erodibility and Stability: ElecteiliavaNessuna valutazione finora

- Technical Document PDFDocumento64 pagineTechnical Document PDFAdamovic InesNessuna valutazione finora

- Wiper Seal Data Sheet A02 B 11782 1 enDocumento2 pagineWiper Seal Data Sheet A02 B 11782 1 enghanNessuna valutazione finora

- X RAY Residual StressDocumento36 pagineX RAY Residual StressAnonymous oTrMza100% (1)

- CH 06Documento18 pagineCH 06Abdul Shokor Abd TalibNessuna valutazione finora

- Classification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialsDocumento5 pagineClassification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialssivaenotesNessuna valutazione finora

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForDocumento4 pagineCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForNour MasmoudiNessuna valutazione finora

- ME Vol 2 FMDocumento364 pagineME Vol 2 FMDeepak Gupta100% (4)

- Component Screening of Miconazole Nitrate Nanoemulsion: Research ArticleDocumento8 pagineComponent Screening of Miconazole Nitrate Nanoemulsion: Research ArticleSiddhant YadavNessuna valutazione finora

- GMW14872 - Cyclic Corrosion Laboratory TestDocumento22 pagineGMW14872 - Cyclic Corrosion Laboratory TestZAPSENessuna valutazione finora

- Lasers: Synthesis, Techniques and ApplicationsDocumento13 pagineLasers: Synthesis, Techniques and ApplicationsMohit BagurNessuna valutazione finora

- Hysteretic Relative Permeability EffectsDocumento8 pagineHysteretic Relative Permeability Effectshfdshy12Nessuna valutazione finora

- Notice: Applications, Hearings, Determinations, Etc.: Lin Zhi International Inc.Documento1 paginaNotice: Applications, Hearings, Determinations, Etc.: Lin Zhi International Inc.Justia.comNessuna valutazione finora

- 03 Lewabrane Manual System Design 03Documento13 pagine03 Lewabrane Manual System Design 03zamijakaNessuna valutazione finora

- Free Particle PropagatorDocumento2 pagineFree Particle PropagatorstephenbankesNessuna valutazione finora

- Counter Rust 7010 TDSDocumento2 pagineCounter Rust 7010 TDSFadhli KusumaNessuna valutazione finora

- Cooling Tower Side Stream FiltrationDocumento5 pagineCooling Tower Side Stream FiltrationChandrakant JuikarNessuna valutazione finora

- Final - Basic Lasting TechnologyDocumento137 pagineFinal - Basic Lasting TechnologySumit Kumar Singh100% (1)

- 2 - Sterilization TechniquesDocumento3 pagine2 - Sterilization Techniquesmufeesahamed2215Nessuna valutazione finora

- Electric Current and Ohm McqsDocumento77 pagineElectric Current and Ohm McqsEngrAneelKumarAkhani100% (2)

- DD ValveDocumento8 pagineDD ValveJunnaid NissarNessuna valutazione finora

- Lucas Tvs Interview QuestionsDocumento2 pagineLucas Tvs Interview QuestionsGomathi SankarNessuna valutazione finora