Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Extracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping Systems

Caricato da

Rudolph Rednose0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

665 visualizzazioni1 paginaThis document summarizes welding and inspection standards from ASME B31.8-2018 for pipelines. It outlines requirements for:

- Welding procedure and welder qualifications which must be validated for any changes to essential variables.

- Inspection of 100% of field welds on offshore pipelines, with at least 90% receiving nondestructive testing. Welds must meet acceptability standards.

- Alternative flaw acceptance limits may be established through fracture mechanics analysis.

- Stress relieving can be waived if metallurgical and mechanical properties are verified to meet standards through testing and engineering analysis.

- Piping system components must be capable of resisting the same loads as the pipe and cannot contain cast iron or ductile

Descrizione originale:

extracted

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document summarizes welding and inspection standards from ASME B31.8-2018 for pipelines. It outlines requirements for:

- Welding procedure and welder qualifications which must be validated for any changes to essential variables.

- Inspection of 100% of field welds on offshore pipelines, with at least 90% receiving nondestructive testing. Welds must meet acceptability standards.

- Alternative flaw acceptance limits may be established through fracture mechanics analysis.

- Stress relieving can be waived if metallurgical and mechanical properties are verified to meet standards through testing and engineering analysis.

- Piping system components must be capable of resisting the same loads as the pipe and cannot contain cast iron or ductile

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

665 visualizzazioni1 paginaExtracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping Systems

Caricato da

Rudolph RednoseThis document summarizes welding and inspection standards from ASME B31.8-2018 for pipelines. It outlines requirements for:

- Welding procedure and welder qualifications which must be validated for any changes to essential variables.

- Inspection of 100% of field welds on offshore pipelines, with at least 90% receiving nondestructive testing. Welds must meet acceptability standards.

- Alternative flaw acceptance limits may be established through fracture mechanics analysis.

- Stress relieving can be waived if metallurgical and mechanical properties are verified to meet standards through testing and engineering analysis.

- Piping system components must be capable of resisting the same loads as the pipe and cannot contain cast iron or ductile

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

ASME B31.

8-2018

(d) Welding procedure qualifications, as well as welder A826 INSPECTION OF WELDS

or welding operator qualifications, are valid only within

the specified limits of the welding procedure. If changes A826.2 Inspection and Tests for Quality Control of

are made in certain details, called “essential variables” or Welds on Piping Systems

“essential changes,” additional qualification is required.

API 1 1 04 essential variables shall take precedence in

A826. 2. 1 Exten t of Exam in ation . O n e - h u n d re d

percent ofthe total number offield welds on offshore pipe-

matters not affected by the underwater environment,

lines and pipeline components that are subj ected to

and AWS D 3 .6 shall govern those essential changes

loading by pipeline internal pressure shall be nondestruc-

related to the underwater welding environment and

tively inspected, if practical, but in no case shall less than

working conditions.

90% ofsuch welds be inspected. The inspection shall cover

100% of the length of such inspected welds.

A823 QUALIFICATION OF PROCEDURES AND

WELDERS A826.2.2 Standard of Acceptability. All welds that are

inspected must meet the standards of acceptability of API

Qualification of procedures and welders shall be in 1104 or the BPV Code, Section VIII, as appropriate for the

acco rdance wi th the re qui reme nts o f s e cti o n 8 2 3 , service of the weld, or be appropriately repaired and rein-

except paras. 823.1 and 823.2 do not apply offshore. spected or removed.

(a) Welding procedures and welders performing atmo-

spheric welding under this section shall be qualified under A826.2.3 Alternative Flaw Acceptance Limits. For

API 1104, except that for applications in which design, girth welds on a pipeline, alternative flaw acceptance

materials, fabrication, inspection, and testing are in accor- limits may be established based on fracture mechanics

dance with the BPV Code, Section VIII, welding procedures analyses and fitness-for-purpose criteria as described

and welders shall be qualified under the BPV Code, Section in API 1 1 0 4. Such alternative accep tance standards

IX. shall be supported by appropriate stress analyses, supple-

(b) Welding p ro cedures and welders p erfo rming mentary welding p ro cedure test requirements, and

hyperbaric welding under this section shall be qualified nondestructive examinations beyond the minimum re-

in accordance with the testing provisions of API 1104 as quirements specified herein. The accuracy of the nondes-

supplemented by AWS D3.6, Specification for Underwater tructive techniques for flaw depth measurement shall be

Welding for Type “O” Welds. verified by sufficient data to establish probabilities for the

proposed inspection error allowance.

A825 STRESS RELIEVING

A830 PIPING SYSTEM COMPONENTS AND

Stress relieving requirements may be waived, regard-

less of wall thickness, provided that it can be demon-

FABRICATION DETAILS

strated that a satisfactory welding procedure without A830.1 General

the use of postweld heat treatment has been developed.

Such a demonstration shall be conducted on materials and The purpose of sections A83 1 through A83 5 is to

under conditions that simulate, as closely as practical, the provide a set of criteria for system components to be

actual production welding. Measurements shall be taken used in an offshore application.

of the tensile, toughness, and hardness properties of the

weld and heat-affected zone. No stress relieving will be A831 PIPING SYSTEM COMPONENTS

required if

Cast iron or ductile iron shall not be used in flanges,

(a) the measurements indicate that the metallurgical

fittings, or valve shell components.

and mechanical properties are within the limits specified

All system components for offshore applications shall

for the materials and intended service, and

be capable of safely resisting the same loads as the pipe in

(b) an engineering analysis is conducted to ensure that

the run in which they are included, except “weak links”

the mechanical properties of the weldment and the resi-

(e.g., breakaway couplings) designed into a system to fail

dual stresses without postweld heat treatment are satis-

under specific loads. Consideration should be given to

fa c to r y fo r th e i n te n d e d s e rvi c e . I n s o m e c a s e s ,

minimizing stress concentrations.

measurement of residual stresses may be required.

System components that are not specifically covered in

section 831 shall be validated for fitness by either

(a) documented full scale prototype testing of the

components or special assemblies, or

108

Potrebbero piacerti anche

- Agrements TMD Recapitulatif Sept-2014Documento30 pagineAgrements TMD Recapitulatif Sept-2014aldo2306Nessuna valutazione finora

- Counter Weight Drawing MCT85Documento14 pagineCounter Weight Drawing MCT85Nirmalya SenNessuna valutazione finora

- Asme Section Ii B SB-42Documento10 pagineAsme Section Ii B SB-42Monica SuarezNessuna valutazione finora

- Gopal A Krishnan 2018Documento4 pagineGopal A Krishnan 2018Vishnu VNessuna valutazione finora

- Previews - 2033457 PIP VEFV1100MDocumento5 paginePreviews - 2033457 PIP VEFV1100Mabdulloh_99100% (1)

- Es7 PDFDocumento4 pagineEs7 PDFayoungaNessuna valutazione finora

- 516 Vs 515Documento2 pagine516 Vs 515Madan YadavNessuna valutazione finora

- ASGEpg187 PDFDocumento3 pagineASGEpg187 PDFbkprodhNessuna valutazione finora

- Mss sp-71 1997 PDFDocumento10 pagineMss sp-71 1997 PDFChotiwan RattanasatienNessuna valutazione finora

- Tweco Welding Catalogue 2001Documento84 pagineTweco Welding Catalogue 2001Andrew Schroeder0% (1)

- Curva Hidraulica KSB MegaCPK 150 - 125 - 315 PDFDocumento1 paginaCurva Hidraulica KSB MegaCPK 150 - 125 - 315 PDFAgustín TorresNessuna valutazione finora

- A New Method For Calculating The Busemann Head Coefficients For Radial ImpellersDocumento7 pagineA New Method For Calculating The Busemann Head Coefficients For Radial ImpellersIvan RaulNessuna valutazione finora

- Ipc2012 90308Documento7 pagineIpc2012 90308Marcelo Varejão CasarinNessuna valutazione finora

- DOT Pipeline SpecificationsDocumento20 pagineDOT Pipeline Specificationssect349Nessuna valutazione finora

- A743A743MDocumento7 pagineA743A743MAnonymous ggwJDMh8Nessuna valutazione finora

- Ghibson GB015Documento2 pagineGhibson GB015Jessicalba LouNessuna valutazione finora

- Ansi 36.10Documento11 pagineAnsi 36.10reyaaazNessuna valutazione finora

- 07MnMoVR Steel chn786s1 - T PDFDocumento11 pagine07MnMoVR Steel chn786s1 - T PDFAnonymous AkzeMHNTUyNessuna valutazione finora

- Ejma 10th Edition The Latest Revision 5 PDF FreeDocumento2 pagineEjma 10th Edition The Latest Revision 5 PDF FreeSgk ManikandanNessuna valutazione finora

- GPT - Honeywell Pressure SensorDocumento10 pagineGPT - Honeywell Pressure SensorKaran Bir SinghNessuna valutazione finora

- Creep of Outlet Pigtail Tubes of Steam Reformer and Grain Size Effect On Creep of An Incoloy 800H MaterialDocumento12 pagineCreep of Outlet Pigtail Tubes of Steam Reformer and Grain Size Effect On Creep of An Incoloy 800H MaterialOwais Malik100% (1)

- Vecom - Japanese BlackDocumento2 pagineVecom - Japanese Blackdiaccessltd_17172961Nessuna valutazione finora

- Table F2-1.10 Pressure-Temperature Ratings For Group 1.10 MaterialsDocumento1 paginaTable F2-1.10 Pressure-Temperature Ratings For Group 1.10 MaterialsPanchal ShaileshNessuna valutazione finora

- Piping ConstructionDocumento17 paginePiping Constructionadel rihana100% (1)

- Public-: Rev. D E English 03 / 2014Documento33 paginePublic-: Rev. D E English 03 / 2014xaviereduardoNessuna valutazione finora

- Technical Bulletin 21 PDFDocumento7 pagineTechnical Bulletin 21 PDFAgustin ParadisoNessuna valutazione finora

- Conductix Wampfler Crane Cables Festoon Systems CatalogueDocumento60 pagineConductix Wampfler Crane Cables Festoon Systems Cataloguehino_kaguNessuna valutazione finora

- 23 - Piping Glossary & DefinitionsDocumento22 pagine23 - Piping Glossary & DefinitionsAsad KhanNessuna valutazione finora

- SA/AS1548 - 7 - 460R: XlerplateDocumento3 pagineSA/AS1548 - 7 - 460R: XlerplatenavNessuna valutazione finora

- Alterations Made To Saudi Aramco Standards From 1985 - 2004Documento265 pagineAlterations Made To Saudi Aramco Standards From 1985 - 2004Saad AshrafNessuna valutazione finora

- STORAGE AND HANDLING OF ANHYDROUS AMMONIA Part 78Documento10 pagineSTORAGE AND HANDLING OF ANHYDROUS AMMONIA Part 78mah_abdelaalNessuna valutazione finora

- QM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During RegistrationDocumento8 pagineQM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During Registrationsanjayde100% (1)

- Astm A333Documento9 pagineAstm A333Andres Fitria FarrelNessuna valutazione finora

- MS 01 168Documento12 pagineMS 01 168Rawn BushNessuna valutazione finora

- Mitered Bend DesignDocumento8 pagineMitered Bend Designkamranishfaq0% (1)

- About Piping Connections - AutoCAD Plant 3D - Autodesk Knowledge NetworkDocumento1 paginaAbout Piping Connections - AutoCAD Plant 3D - Autodesk Knowledge NetworkWesleyPettyMinasNessuna valutazione finora

- Bladeless Wind TurbineDocumento4 pagineBladeless Wind TurbineIJIERT-International Journal of Innovations in Engineering Research and TechnologyNessuna valutazione finora

- Pipes. Wall Thickness Calculation According ASME B31.3Documento101 paginePipes. Wall Thickness Calculation According ASME B31.3DANNY GARCIANessuna valutazione finora

- Ni 2543Documento11 pagineNi 2543marguepaNessuna valutazione finora

- Failure Analysis of An Electric Arc Furnace Off-Gas SystemDocumento7 pagineFailure Analysis of An Electric Arc Furnace Off-Gas Systemgeraleao208Nessuna valutazione finora

- Add02 1060.1Documento14 pagineAdd02 1060.1Diego Calderón AlvaradoNessuna valutazione finora

- Stainless SteelDocumento7 pagineStainless SteelcasaeanNessuna valutazione finora

- Bray Valve Series 40-41 DimensionsDocumento2 pagineBray Valve Series 40-41 DimensionsChandravadanNessuna valutazione finora

- Asme Code Qualification of Pipe Bends With Localized Wall Thinning PDFDocumento8 pagineAsme Code Qualification of Pipe Bends With Localized Wall Thinning PDFZhiqiang GuNessuna valutazione finora

- ML 1015998765Documento42 pagineML 1015998765ডঃ শুভম চ্যাটার্জীNessuna valutazione finora

- UPA Channel SizesDocumento2 pagineUPA Channel SizesSatish Kumar100% (1)

- Integraheader: The Long-Term Chlorine Header SolutionDocumento8 pagineIntegraheader: The Long-Term Chlorine Header Solutionmanuel.ape6263Nessuna valutazione finora

- Astm A529 1972Documento5 pagineAstm A529 1972dharlanuctcom0% (1)

- API 553 Refinery Control ValvesDocumento519 pagineAPI 553 Refinery Control ValvesvasudhaNessuna valutazione finora

- Flat End PlatesDocumento4 pagineFlat End Platesb_wooNessuna valutazione finora

- Theory of PlatesDocumento88 pagineTheory of PlatesmgsabarirajNessuna valutazione finora

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionDa EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNessuna valutazione finora

- API English (58-76)Documento19 pagineAPI English (58-76)Alex Mamani calizayaNessuna valutazione finora

- Asme B31.4 - 2016 EndDocumento1 paginaAsme B31.4 - 2016 Endwilliam cordero valverdeNessuna valutazione finora

- Asme CCase N-432Documento4 pagineAsme CCase N-432julianmorantesNessuna valutazione finora

- Pages From Asme Sec Ix 2017-3Documento1 paginaPages From Asme Sec Ix 2017-3Akhtar AnsariNessuna valutazione finora

- QW 381Documento1 paginaQW 381Waqas WaqasNessuna valutazione finora

- Article 312 Inspection and Repair of Shell and Tube Heat ExchangersDocumento12 pagineArticle 312 Inspection and Repair of Shell and Tube Heat ExchangersasifNessuna valutazione finora

- Process Specification For The Manual Arc Welding of Titanium Alloy HardwareDocumento20 pagineProcess Specification For The Manual Arc Welding of Titanium Alloy HardwareFaiz NanafiNessuna valutazione finora

- Weight and COG Summary-17 Oct 18Documento10 pagineWeight and COG Summary-17 Oct 18Rudolph RednoseNessuna valutazione finora

- B Scan PDFDocumento4 pagineB Scan PDFRudolph RednoseNessuna valutazione finora

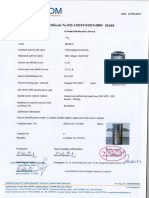

- Chứng chỉ nguồn - D2984Documento4 pagineChứng chỉ nguồn - D2984Rudolph RednoseNessuna valutazione finora

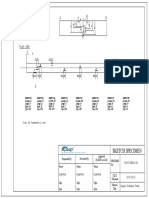

- Sketch Specimen: Approved by NDT Level Iii Prepareded by Specimen No: Name: Reviewed by Name: NameDocumento1 paginaSketch Specimen: Approved by NDT Level Iii Prepareded by Specimen No: Name: Reviewed by Name: NameRudolph RednoseNessuna valutazione finora

- Demo 6 Indication CompareDocumento23 pagineDemo 6 Indication CompareRudolph RednoseNessuna valutazione finora

- Salman Hse Green Banding Exercise: BSP Contract Ref: C181824 Competitive Feed and Proposal Development For Salman ProjectDocumento3 pagineSalman Hse Green Banding Exercise: BSP Contract Ref: C181824 Competitive Feed and Proposal Development For Salman ProjectRudolph RednoseNessuna valutazione finora

- PAUT Demo Indication SummaryDocumento1 paginaPAUT Demo Indication SummaryRudolph RednoseNessuna valutazione finora

- AcsaDocumento1 paginaAcsaRudolph RednoseNessuna valutazione finora

- Half Value ThicknessDocumento3 pagineHalf Value ThicknessRudolph RednoseNessuna valutazione finora

- Linac NDT Services Limited: Radiographic Report (Lsf2)Documento1 paginaLinac NDT Services Limited: Radiographic Report (Lsf2)Rudolph RednoseNessuna valutazione finora

- Chứn Chỉ Nguồn - S2043Documento4 pagineChứn Chỉ Nguồn - S2043Rudolph RednoseNessuna valutazione finora

- Extracted Pages From SD NOC STR 301Documento1 paginaExtracted Pages From SD NOC STR 301Rudolph RednoseNessuna valutazione finora

- Session 9 - QatarDocumento11 pagineSession 9 - QatarRudolph RednoseNessuna valutazione finora

- Mahakrishnan & CertificateDocumento4 pagineMahakrishnan & CertificateRudolph RednoseNessuna valutazione finora

- Calibration Block - Stock Checked.Documento1 paginaCalibration Block - Stock Checked.Rudolph RednoseNessuna valutazione finora

- Linac NDT Services Limited: Radiographic Report (Lsf2)Documento1 paginaLinac NDT Services Limited: Radiographic Report (Lsf2)Rudolph RednoseNessuna valutazione finora

- CTRL + D: Need To Copy A Shape? Select It and Press CTRL+DDocumento1 paginaCTRL + D: Need To Copy A Shape? Select It and Press CTRL+DRudolph RednoseNessuna valutazione finora

- ChartDocumento9 pagineChartRudolph RednoseNessuna valutazione finora

- Structural MT ReportDocumento1 paginaStructural MT ReportRudolph RednoseNessuna valutazione finora

- Flawless Project Delivery: Ken Ede Apr 2016Documento10 pagineFlawless Project Delivery: Ken Ede Apr 2016Rudolph RednoseNessuna valutazione finora

- Structural UT ReportDocumento1 paginaStructural UT ReportRudolph Rednose100% (1)

- Demo SUMDocumento27 pagineDemo SUMRudolph RednoseNessuna valutazione finora

- Extracted Pages From SVDN CPP M 0032 P11 0001 Rev.00 NDT Procedure ACCUDocumento2 pagineExtracted Pages From SVDN CPP M 0032 P11 0001 Rev.00 NDT Procedure ACCURudolph RednoseNessuna valutazione finora

- PAUT DEMO - SUMMARY of Evaluation Format Rev.1Documento1 paginaPAUT DEMO - SUMMARY of Evaluation Format Rev.1Rudolph RednoseNessuna valutazione finora

- Piping PAUT ReportDocumento21 paginePiping PAUT ReportRudolph Rednose100% (2)

- Sample ReportDocumento1 paginaSample ReportRudolph RednoseNessuna valutazione finora

- Piping PT ReportDocumento1 paginaPiping PT ReportRudolph RednoseNessuna valutazione finora

- Piping RT ReportDocumento1 paginaPiping RT ReportRudolph RednoseNessuna valutazione finora

- Flange API6A API6B API6BX Blind PDFDocumento4 pagineFlange API6A API6B API6BX Blind PDFRudolph RednoseNessuna valutazione finora

- NAGIOS Inspeção Relatório de DadosDocumento2 pagineNAGIOS Inspeção Relatório de DadosRuben QuintNessuna valutazione finora

- Linux Internet Web Server and Domain Configuration TutorialDocumento59 pagineLinux Internet Web Server and Domain Configuration Tutorialrajnishmishra2488Nessuna valutazione finora

- How To Use The R Software: July 2019Documento28 pagineHow To Use The R Software: July 2019Paul GokoolNessuna valutazione finora

- Review of Polyurea Coating ResearchesDocumento12 pagineReview of Polyurea Coating ResearchesDineshNessuna valutazione finora

- Shortcrete PDFDocumento4 pagineShortcrete PDFhelloNessuna valutazione finora

- Lim Resto (Perencanaan Pendirian Usaha Restaurant Fast Food)Documento10 pagineLim Resto (Perencanaan Pendirian Usaha Restaurant Fast Food)Walikutay IndonesiaNessuna valutazione finora

- ION 900 Series Owners ManualDocumento24 pagineION 900 Series Owners ManualParosanu IonelNessuna valutazione finora

- RBA Catalog Maltby GBR Aug 16 2023 NL NLDocumento131 pagineRBA Catalog Maltby GBR Aug 16 2023 NL NLKelvin FaneyteNessuna valutazione finora

- Lua ApiDocumento176 pagineLua Apiyaotl albores tecuautzinNessuna valutazione finora

- Maxiim Vehicle Diagnostic ReportDocumento3 pagineMaxiim Vehicle Diagnostic ReportCarlos Cobaleda GarcíaNessuna valutazione finora

- Contracts Act, 2010Documento59 pagineContracts Act, 2010Sam KNessuna valutazione finora

- GSM Controlled RobotDocumento33 pagineGSM Controlled RobotAbhishek KunalNessuna valutazione finora

- Project JavascriptDocumento58 pagineProject JavascriptashwinNessuna valutazione finora

- Siningbayan Field Book PDFDocumento232 pagineSiningbayan Field Book PDFnathaniel zNessuna valutazione finora

- File 1379580604 PDFDocumento9 pagineFile 1379580604 PDFMuhammad Salik TaimuriNessuna valutazione finora

- CorpDocumento14 pagineCorpIELTSNessuna valutazione finora

- MyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerDocumento1 paginaMyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerGeanina OlteanuNessuna valutazione finora

- Manual de Serviços QQ PDFDocumento635 pagineManual de Serviços QQ PDFLéo Nunes100% (1)

- Specification For Wrought Austenitic Stainless Steel Piping FittingsDocumento10 pagineSpecification For Wrought Austenitic Stainless Steel Piping FittingsAnilNessuna valutazione finora

- Indian - Origin Girls Bag Google Science Honour - Yahoo! India EducationDocumento3 pagineIndian - Origin Girls Bag Google Science Honour - Yahoo! India EducationRiyaz RafiqueNessuna valutazione finora

- Best Evidence Rule CasesDocumento5 pagineBest Evidence Rule CasesRemy Rose AlegreNessuna valutazione finora

- Internal/External Permanent Opportunity: P: S: $51,487.97 - $62,766.29 D: F #: TCHC#10LS29 L: # P: 1Documento3 pagineInternal/External Permanent Opportunity: P: S: $51,487.97 - $62,766.29 D: F #: TCHC#10LS29 L: # P: 1a4agarwalNessuna valutazione finora

- Electrical Engineering: Scheme of Undergraduate Degree CourseDocumento2 pagineElectrical Engineering: Scheme of Undergraduate Degree CourseSuresh JainNessuna valutazione finora

- Vande Bharat Exp Chair Car (CC) : Electronic Reserva On Slip (ERS)Documento2 pagineVande Bharat Exp Chair Car (CC) : Electronic Reserva On Slip (ERS)Subhash KumarNessuna valutazione finora

- Bot LuckygamesDocumento16 pagineBot LuckygamesMokkaNessuna valutazione finora

- Project 2 - Home InsuranceDocumento15 pagineProject 2 - Home InsuranceNaveen KumarNessuna valutazione finora

- 54 Sale1Documento6 pagine54 Sale1vakilarunNessuna valutazione finora

- Asap 2020Documento21 pagineAsap 2020KarenNessuna valutazione finora

- Ujar10 10434839Documento11 pagineUjar10 10434839Fitryane LihawaNessuna valutazione finora