Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Concrete Cheat Sheat PDF

Caricato da

Jonathan YambaoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Concrete Cheat Sheat PDF

Caricato da

Jonathan YambaoCopyright:

Formati disponibili

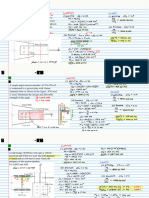

Beams

Rectangle T-Beams

Analysis Design Analysis Design

Cracking Moment Dimensions: Check: Find:

Minimum thickness beff=1/4 beam span beff=1/4 beam span

from ACI Table 9.5a 8*hf + bw 8*slab thickness + bw

Where: Width= ½ thickness ½ Clear distance ½ Clear distance

Mcr= Moment As min

fr=7.5 Weight:

Ig= Moment of Inertia w= Find:

Yt=distance from centroid to tensile

fiber Assume large of:

Elastic Stresses – Concrete Cracked Calculate:

N.A

Where: ρ (assuming ∅=0.9) If N.A. is in flange:

Trial Steel Area:

n=modular ratio Compare with As min

E=modulus of elasticity

Select

Transformed Area Reinforcement:

New Z

Where: Check:

b=base

d=distance from center of steel to top

compressive fiber

x=distance from top compressive fiber

to neutral axis For Slabs: If N.A. is not in flange:

As=Area of Steel Shrink & Temp. Steel

Moment of Inertia

Bending Stresses

Doubly Reinforced Beams

Analysis Design

Until As is consistent then compare

Find: Find:

with As min

Ultimate Flexural Moments

Find:

’

Strength Analysis If sy:

Check Safety Factor: ’ ’ ’ ’

If s0.00207 fs =fy otherwise fs =s Es

’

If sy:

Solve for c

If bars are different sizes:

Then find: Solve for c

If not strong enough use smaller

compressive steel.

Development Lengths Shear Columns Footings

Is reinforcement needed: Axially Loaded: Wall-

Calculate Vu at distance d from Find Area of Concrete (Ag): Assume 12 in h with d=8.5in

support

Where: Calculate:

cb=Center of tension bar to nearest Assuming Ast=0.02Ag

concrete surface or center to If stirrups are needed Then Find Ast with selected Ag

center spacing

Ktr=0 (ACIU 12.2.3) Calculate: Ties- =0.65 Find Required Depth

Theoretical stirrup spacing- Spacing of ties = lesser of

16*longitudinal bar diameter or

48*tie diameter (#3bar ties for

If Bundled Bars: #10 or smaller long. Bars, #4 for

Imaginary bar centroid is used Where

larger) Where bw =base width (assumed 1ft for wall

Development +20% for 3 bars Maximum spacing for min area – footing)

+40% for 4 bars Spiral-=0.75 If d is met-

Find Ac (area of core inside the

For Hooks: Max Spacing: spiral)

Where a is the column width

Length after turn: Solve for spacing (s) Find steel as usual

90 degree = 12db

Where Find Development Length

180 degree = 4db

Longitudinal Temp & Shrinkage steel

Eccentricly Loaded:

For Compression: Check V at different distances for

Plastic Centroid-

spacing changes.

Simple Beam Deflections Rectangular footings-

Instantaneous dead load-

Reduction Factor:

Design-

Splices , Depth Required for 2 way (punch)

If MaMcr Ma=Mcr

Compresssion:

,

for 60kpsi or less Find Transformed area &

for 60kpsi moment of inertia as on the ,

front. Find ρg on Interaction diagram

Tension:

Calculate:

Depth Required for 1 way shear

Otherwise:

Crack Width (Gergely-Lutz) Span Formulas

Inst. Dead + Live: Simple- If all depths are ok-

As with dead only

Where:

Βh=ratio of distance to NA from

Inst. Live

extreme tensile concrete to Combined footing:

Fixed-

extreme tensile steel Find Center of gravity-

fs=0.6fy

Long Term

dc=Outermost cover to centroid of

bar Cantilever- Footing length =2x+distance to property line

A=tension area of concrete- Footing Width = x

Where:

centroid of bars to outer layer Create sheer & Moment diagrams solve as

=Time factor (2 for 5+yrs, 1.4

divided by the number of bars Rectangular footing.

for 1 yr, 1.2 for 0.5yr, 1 for 3

Properties months)

’

ρ =compression steel

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Etrade Bank-StatementDocumento5 pagineEtrade Bank-StatementMark Galanty100% (4)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Lot Plan and Vicinity PlanDocumento1 paginaLot Plan and Vicinity PlanJonathan Yambao100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Reflected Ceiling Plan PDFDocumento1 paginaReflected Ceiling Plan PDFJonathan YambaoNessuna valutazione finora

- Cibse TM65 (2020)Documento67 pagineCibse TM65 (2020)Reli Hano100% (1)

- MOEMS 2020 Questions Paper Division EDocumento20 pagineMOEMS 2020 Questions Paper Division EHarleenaDivs50% (4)

- Schedule of Doors and WindowsDocumento1 paginaSchedule of Doors and WindowsJonathan YambaoNessuna valutazione finora

- Steel Design Chapter 3.2 Simple ConnectionsDocumento5 pagineSteel Design Chapter 3.2 Simple ConnectionsJonathan YambaoNessuna valutazione finora

- Evaluate The Benefits and Risks of Using Genetically Modified OrganismDocumento15 pagineEvaluate The Benefits and Risks of Using Genetically Modified OrganismJonathan YambaoNessuna valutazione finora

- Terms 5Documento4 pagineTerms 5Jonathan YambaoNessuna valutazione finora

- Preboard Exam 2nd HGE Nov 2022Documento8 paginePreboard Exam 2nd HGE Nov 2022Jonathan YambaoNessuna valutazione finora

- Steel Design Chapter 3.1 Tensile StrengthDocumento7 pagineSteel Design Chapter 3.1 Tensile StrengthJonathan YambaoNessuna valutazione finora

- Genetic Engineering: Title CardDocumento10 pagineGenetic Engineering: Title CardJonathan YambaoNessuna valutazione finora

- "Wanted: Dead or Alive?": Department of EducationDocumento16 pagine"Wanted: Dead or Alive?": Department of EducationJonathan YambaoNessuna valutazione finora

- Bamboo ProcessDocumento1 paginaBamboo ProcessJonathan YambaoNessuna valutazione finora

- "We Heal As One": Department of EducationDocumento11 pagine"We Heal As One": Department of EducationJonathan YambaoNessuna valutazione finora

- Subject:: Guidelines For The On-the-Job Training (OJT) of The College of Engineering and Technology For (Summer 2020)Documento3 pagineSubject:: Guidelines For The On-the-Job Training (OJT) of The College of Engineering and Technology For (Summer 2020)Jonathan YambaoNessuna valutazione finora

- Plumbing LegendDocumento1 paginaPlumbing LegendJonathan YambaoNessuna valutazione finora

- Floor and Clean Out DetailDocumento1 paginaFloor and Clean Out DetailJonathan YambaoNessuna valutazione finora

- LEED and Conventional Vs Green BuildingDocumento20 pagineLEED and Conventional Vs Green BuildingJonathan YambaoNessuna valutazione finora

- Floor Plan: Bedroom 2 Bedroom 3 Kitchen T & BDocumento1 paginaFloor Plan: Bedroom 2 Bedroom 3 Kitchen T & BJonathan YambaoNessuna valutazione finora

- Isometric Plumbing-Lay-OutDocumento1 paginaIsometric Plumbing-Lay-OutJonathan YambaoNessuna valutazione finora

- Building PerspectiveDocumento1 paginaBuilding PerspectiveJonathan YambaoNessuna valutazione finora

- Urban Canal Garbage Catcher Using Drainage Trash Trap NetDocumento1 paginaUrban Canal Garbage Catcher Using Drainage Trash Trap NetJonathan YambaoNessuna valutazione finora

- SchedulesDocumento1 paginaSchedulesJonathan YambaoNessuna valutazione finora

- Jesus I Need You Chords by Hillsong at Ultimate GuitarDocumento2 pagineJesus I Need You Chords by Hillsong at Ultimate GuitarJonathan YambaoNessuna valutazione finora

- Chapter8 Concrete Pavement 19 22Documento13 pagineChapter8 Concrete Pavement 19 22Jonathan YambaoNessuna valutazione finora

- Prose 2 - Lost Spring - Important QADocumento5 pagineProse 2 - Lost Spring - Important QADangerous GamingNessuna valutazione finora

- Lecture Note On Photovoltaic CellDocumento1 paginaLecture Note On Photovoltaic CellHaseeb NawazNessuna valutazione finora

- Science - Sound DiffractionDocumento12 pagineScience - Sound DiffractionElissah S PabilonaNessuna valutazione finora

- Introduction To Game Theory: Analysis of GamesDocumento13 pagineIntroduction To Game Theory: Analysis of GamesAoiNessuna valutazione finora

- Unit 9: Cities of The World I. ObjectivesDocumento4 pagineUnit 9: Cities of The World I. ObjectivesTrang Hoang NguyenNessuna valutazione finora

- IG Client Sentiment Report 2020-12-03 12 - 00 PDFDocumento36 pagineIG Client Sentiment Report 2020-12-03 12 - 00 PDFEno Ronaldfrank OguriNessuna valutazione finora

- Morphometric Characterization of Jatropha Curcas Germplasm of North-East IndiaDocumento9 pagineMorphometric Characterization of Jatropha Curcas Germplasm of North-East IndiafanusNessuna valutazione finora

- LED Personal Portable Desk - Group 7-Imtiaz - 31072021Documento8 pagineLED Personal Portable Desk - Group 7-Imtiaz - 31072021SYED AMIRUL NAZMI BIN SYED ANUARNessuna valutazione finora

- Language Focus. Past Simple or Past ContinuousDocumento3 pagineLanguage Focus. Past Simple or Past ContinuoustotydnrNessuna valutazione finora

- Filled System Temperature Recorders & Recorder Controllers: SpecificationDocumento2 pagineFilled System Temperature Recorders & Recorder Controllers: SpecificationdencryNessuna valutazione finora

- Stelma & Cameron PDFDocumento35 pagineStelma & Cameron PDFCatarinaNessuna valutazione finora

- T. Murugan: Post Applied For Well Testing OperatorDocumento5 pagineT. Murugan: Post Applied For Well Testing Operatorjohn MNessuna valutazione finora

- CCR Control System Interface HandbookDocumento17 pagineCCR Control System Interface Handbooklcastrey23Nessuna valutazione finora

- Oct2020 GCE Final PDFDocumento30 pagineOct2020 GCE Final PDFGavinNessuna valutazione finora

- BS9266 2013 Adaptable HousingDocumento46 pagineBS9266 2013 Adaptable HousingGrant MastersonNessuna valutazione finora

- 17333Documento2 pagine17333Nithya RaviNessuna valutazione finora

- HPB Brochure 0708Documento12 pagineHPB Brochure 0708musaluddinNessuna valutazione finora

- Links of XII Physics Investigatory Project Allowtment 2Documento3 pagineLinks of XII Physics Investigatory Project Allowtment 2yashtomarsoop07Nessuna valutazione finora

- Sherman Notes PDFDocumento213 pagineSherman Notes PDFAbdul Hamid Bhatti100% (1)

- SAP EHSM - Risk Assessment - User Guide - Help FilesDocumento15 pagineSAP EHSM - Risk Assessment - User Guide - Help FilesKishor Kolhe50% (2)

- D6588Documento6 pagineD6588Pulak DebnathNessuna valutazione finora

- Geometallurgical Modelling of The Collahuasi Flotation CircuitDocumento6 pagineGeometallurgical Modelling of The Collahuasi Flotation CircuitFrancisco CampbellNessuna valutazione finora

- Daftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceDocumento2 pagineDaftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceMochammad Fauzian RafsyanzaniNessuna valutazione finora

- Stylus - Pro - 4400 201 300 (067 100)Documento34 pagineStylus - Pro - 4400 201 300 (067 100)Joso CepuranNessuna valutazione finora

- Optimal Control Development System For ElectricalDocumento7 pagineOptimal Control Development System For ElectricalCRISTIAN CAMILO MORALES SOLISNessuna valutazione finora

- Pro Tester ManualDocumento49 paginePro Tester ManualRobson AlencarNessuna valutazione finora

- Bistable Relays RXMVB 2, RXMVB 4: FeaturesDocumento4 pagineBistable Relays RXMVB 2, RXMVB 4: FeaturesGabriel Maxo PapagalloNessuna valutazione finora