Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Wim Correction l3 Mc091 - 2016

Caricato da

PK KDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Wim Correction l3 Mc091 - 2016

Caricato da

PK KCopyright:

Formati disponibili

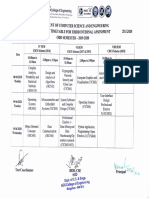

SUMMARY OF TRAINING DURATION FOR INDUSTRIAL AUTOMATION ENGINEERING SYSTEMS ASSEMBLY (LEVEL 3)

MASA MASA

COMPETENCY UNIT HOURS

NO. ID WORK ACTIVITIES BERSEMUKA P PMT T BERSEMUKA K PMA TOTAL (HRS)

TITLE (A) + (B)

TEORI (A) AMALI (B)

1. Prepare CAD application system installation 5 1/7 1/7 1/7 11 1/14 1/14 15

2. Develop two dimension (2D) industrial automation (2/14)(3/14) (2/14)(3/14)

(mechanical) CAD drawing

8 2/7 2/7 2/7 18

(4/14) (4/14)

26

3. Develop two dimension (2D) industrial automation (5/14)(6/14) (5/14)(6/14)

INDUSTRIAL (electrical/electronic) CAD schematic drawing

8 (3/7)(4/7) (3/7)(4/7) (3/7)(4/7) 19

(7/14) (7/14)

27

MC-091-3:2015-C01 AUTOMATION CAD 135

ASSEMBLY DRAWING 4. Develop three dimension (3D) industrial automation (8/14)(9/14) (8/14)(9/14)

CAD drawing

8 (5/7) (5/7) (5/7) 19

(10/14) (10/14)

27

5. Develop CAD assembly drawing 7 6/7 6/7 6/7 15 (11/14)(12/14) (11/14)(12/14) 22

1.

6. Prepare Industrial Automation

CAD assembly Mechanical

drawing System

documentation 6 7/7 7/7 7/7 13 (13/14)(14/14) (13/14)(14/14) 19

Assembling Requirements

(1/15)(2/15) (1/15)(2/15)

7 1/5 1/5 1/5 17

(3/15) (3/15)

24

2. Perform Industrial Automation Mechanical System (4/15)(5/15) (4/15)(5/15)

7 2/5 2/5 2/5 26 33

Assembling Work (6/15)(7/15) (6/15)(7/15)

INDUSTRIAL

AUTOMATION 3. Perform Industrial Automation Mechanical System (8/15)(9/15) (8/15)(9/15)

MC-091-3:2015-C02

MECHANICAL SYSTEM Assembling Testing

7 3/5 3/5 3/5 21

(10/15) (10/15)

28 150

ASSEMBLING

4. Perform Industrial Automation Mechanical System (11/15)(12/15) (11/15)(12/15)

Assembling Adjustment

7 4/5 4/5 4/5 24

(13/15) (13/15)

31

5. Prepare

1. Prepare Industrial

Industrial Automation

Automation Electrical

Mechanical System

and

AssemblingSystems

Report Assembling Requirements

7 5/5 5/5 5/5 17 (14/15)(15/15) (14/15)(15/15) 25

Electronic

5 1/5 1/5 1/5 13 (1/13)(2/13) (1/13)(2/13) 18

2. Perform Industrial Automation Electrical and (3/13)(4/13) (3/13)(4/13)

Electronic Systems Assembling

9 2/5 2/5 2/5 22

(5/13) (5/13)

32

INDUSTRIAL

AUTOMATION

3. Perform Industrial Automation Electrical and (6/13)(7/13) (6/13)(7/13)

MC-091-3:2015-C03 ELECTRICAL /

Electronic Systems Assembling Testing

8 3/5 3/5 3/5 18

(8/13) (8/13)

26 128

ELECTRONIC SYSTEM

ASSEMBLING 4. Perform Industrial Automation Electrical and (9/13)(10/13) (9/13)(10/13)

Electronic Systems Assembling Troubleshooting

9 4/5 4/5 4/5 21

(11/13) (11/13)

30

5. Prepare Industrial Automation Electrical and

Electronic Systems Assembling Report

7 5/5 5/5 5/5 15 (12/13)(13/13) (12/13)(13/13) 22

1. Prepare Industrial Automation System Calibration

4 1/5 1/5 1/5 10 (1/10)(2/10) (1/10)(2/10) 14

Report

2. Plan Industrial Automation System Calibration Activity 6 2/5 2/5 2/5 15 (3/10)(4/10) (3/10)(4/10) 21

INDUSTRIAL

AUTOMATION 3. Perform Industrial Automation System Calibration

MC-091-3:2015-C04 6 3/5 3/5 3/5 15 (5/10)(6/10) (5/10)(6/10) 21 91

MECHANICAL SYSTEM Activity

CALIBRATION

4. Test Calibrated Industrial Automation System 6 4/5 4/5 4/5 15 (7/10)(8/10) (7/10)(8/10) 21

5. Prepare Industrial Automation System Calibration

4 5/5 5/5 5/5 10 (9/10)(10/10) (9/10)(10/10) 14

Requirements

1. Prepare Industrial Automation System maintenance

4 1/6 1/6 1/6 8 (1/10) (1/10) 12

requirements

2. Perform Industrial Automation System Mechanical

6 2/6 2/6 2/6 15 (2/10)(3/10) (2/10)(3/10) 21

maintenance

INDUSTRIAL 3. Perform Industrial Automation System Electrical

6 3/6 3/6 3/6 13 (4/10)(5/10) (4/10)(5/10) 19

AUTOMATION maintenance

MC-091-3:2015-C05 103

SYSTEMS 4. Perform Industrial Automation System Electronic

MAINTENANCE 6 4/6 4/6 4/6 13 (6/10)(7/10) (6/10)(7/10) 19

maintenance

5. Perform Industrial Automation Control System

6 5/6 5/6 5/6 13 (8/10)(9/10) (8/10)(9/10) 19

maintenance

6. Prepare Industrial Automation System maintenance

4 6/6 6/6 6/6 10 (10/10) (9/10) 14

report.

1. Prepare Industrial Automation Control Systems

4 1/5 1/5 1/5 7 (1/10) (1/10) 14

software setup requirements

2. Prepare Industrial Automation Control Systems

6 2/5 2/5 2/5 15 (2/10)(3/10) (2/10)(3/10) 21

hardware setup requirements

INDUSTRIAL

AUTOMATION 3. Perform Industrial Automation Control Systems (4/10)(5/10) (4/10)(5/10)

MC-091-3:2015-C06 9 3/5 3/5 3/5 20 29 107

CONTROL SYSTEM Programming (6/10) (6/10)

PROGRAMMING

4. Perform Industrial Automation Control Systems (7/10)(8/10) (7/10)(8/10)

8 4/5 4/5 4/5 20 29

Programming Verification (9/10) (9/10)

5. Prepare Industrial Control Systems Programming

4 5/5 5/5 5/5 7 (10/10) (10/10) 14

Report

1. Perform Industrial Automation Engineering Support

3 1/5 1/5 1/5 7 (1/9) (1/9) 10

Service routine briefing.

2. Perform subordinate performance appraisal exercise 4 2/5 2/5 2/5 7 (2/9) (2/9) 11

INDUSTRIAL

AUTOMATION

3. Perform Industrial Automation Engineering support (3/9)(4/9) (3/9)(4/9)

MC-091-3:2015-C07 ENGINEERING 7 3/5 3/5 3/5 20 27 94

service unit performance measurement. (5/9) (5/9)

SYSTEMS SUPPORT

SUPERVISION 4. Perform unit work area housekeeping resources (6/9)(7/9) (6/9)(7/9)

7 4/5 4/5 4/5 20 27

allocation (8/9) (8/9)

5. Monitor unit work area housekeeping activities. 4 5/5 5/5 5/5 7 (9/9) (9/9) 11

CORE ABILITIES Z-009-3:2015 80

TOTAL HOURS 870 870

xii

Potrebbero piacerti anche

- Ijesrt: Hardware Implementation of Automated Pantry Order System Using ZIGBEEDocumento7 pagineIjesrt: Hardware Implementation of Automated Pantry Order System Using ZIGBEEMohammed AnsafNessuna valutazione finora

- Curriculum Plan - MENG ProgramDocumento1 paginaCurriculum Plan - MENG ProgramAbdulkarim H.Nessuna valutazione finora

- ANNEX A LDIP Alignment FormDocumento5 pagineANNEX A LDIP Alignment FormMarieta AlejoNessuna valutazione finora

- European Contract Electronics Assembly Industry - 1993-97: A Strategic Study of the European CEM IndustryDa EverandEuropean Contract Electronics Assembly Industry - 1993-97: A Strategic Study of the European CEM IndustryNessuna valutazione finora

- CAD Analysis - PDFDocumento24 pagineCAD Analysis - PDFAbhay PatelNessuna valutazione finora

- O363798v21 160992A6G8 202106Documento86 pagineO363798v21 160992A6G8 202106AlbertNessuna valutazione finora

- Case Tools Lab-Manual PDFDocumento113 pagineCase Tools Lab-Manual PDFpavithraNessuna valutazione finora

- Complete PCB Design Using OrCAD Capture and PCB EditorDa EverandComplete PCB Design Using OrCAD Capture and PCB EditorValutazione: 5 su 5 stelle5/5 (1)

- Laser Rangefinders GLM 150 CDocumento72 pagineLaser Rangefinders GLM 150 CRama Chandran RNessuna valutazione finora

- 02 0 Tools - EDocumento11 pagine02 0 Tools - Eetri CahyaNessuna valutazione finora

- QA Checks On Project DeliverablesDocumento1 paginaQA Checks On Project DeliverablesjasolanoroNessuna valutazione finora

- GE Healthcare: Innova Igs 520/530/540 With Autoright Final StudyDocumento21 pagineGE Healthcare: Innova Igs 520/530/540 With Autoright Final Studycirrosis7Nessuna valutazione finora

- Camd 3331906 PDFDocumento7 pagineCamd 3331906 PDFjayyadavvpcNessuna valutazione finora

- Road Map EPCDocumento33 pagineRoad Map EPCBehnaz MotamedNessuna valutazione finora

- O331245v21 160992A5JG 202001Documento58 pagineO331245v21 160992A5JG 202001xdd broNessuna valutazione finora

- Gant ChartDocumento3 pagineGant ChartAmliz HasanNessuna valutazione finora

- Department of Computer Science and Engineering Timetable For Third Internal Assessment ODD SEMESTER-2019-2020Documento1 paginaDepartment of Computer Science and Engineering Timetable For Third Internal Assessment ODD SEMESTER-2019-2020Bhavya ShettyNessuna valutazione finora

- Academic Calendar 2018 19Documento12 pagineAcademic Calendar 2018 19Harry GoswamiNessuna valutazione finora

- 3DX 2017x Portfolio On Premise LRDocumento1 pagina3DX 2017x Portfolio On Premise LRAlfonso MedinaNessuna valutazione finora

- Aip FormDocumento80 pagineAip FormNelette JumawanNessuna valutazione finora

- You Are Provisionally Admitted To The Interview For The Post of SalesmenDocumento3 pagineYou Are Provisionally Admitted To The Interview For The Post of SalesmenSridharan ThulasiNessuna valutazione finora

- VODAFONE IDEA LTD (Telecom Carriers) : Earnings & Estimates Market DataDocumento3 pagineVODAFONE IDEA LTD (Telecom Carriers) : Earnings & Estimates Market DataRachit WadhwaNessuna valutazione finora

- Isaac ChavezDocumento1 paginaIsaac ChavezIsaac ChávezNessuna valutazione finora

- Adjusted Version Interoperability 2016 V7Documento1 paginaAdjusted Version Interoperability 2016 V7Luis Alberto SEquera FloresNessuna valutazione finora

- SoHo Network - Editable Network Diagram Template On CreatelyDocumento5 pagineSoHo Network - Editable Network Diagram Template On CreatelyAhmad ZahinNessuna valutazione finora

- GO ListChap-22 23 2sem 1testeDocumento1 paginaGO ListChap-22 23 2sem 1testeJosé C. RochaNessuna valutazione finora

- Latest Results Result Declaration Schedule: RecruitmentDocumento6 pagineLatest Results Result Declaration Schedule: Recruitmentmail 4yourinboxNessuna valutazione finora

- Resume 10 - 23Documento1 paginaResume 10 - 23Isaac ChávezNessuna valutazione finora

- PM InterfacesSpecCAM en 3.0.0Documento24 paginePM InterfacesSpecCAM en 3.0.0TraianDajmaNessuna valutazione finora

- Excel Gantt Chart TemplateDocumento8 pagineExcel Gantt Chart Templateakscool87Nessuna valutazione finora

- Revised V Module TimetableDocumento1 paginaRevised V Module TimetableANKITNessuna valutazione finora

- Omkar Shende: Education SkillsDocumento1 paginaOmkar Shende: Education Skillseema yoNessuna valutazione finora

- 8 Technical Data and Dimension Sheets For AC Motors: 8.1 DesignsDocumento100 pagine8 Technical Data and Dimension Sheets For AC Motors: 8.1 DesignsThomas TellerNessuna valutazione finora

- Asme Sec Ii-D-C Int Vol 62 - 2013Documento6 pagineAsme Sec Ii-D-C Int Vol 62 - 2013Guido KünstlerNessuna valutazione finora

- Dell Inspiron 1545 Wistron Dr1 Roberts Uma 48 4aq01 031 08212 3 PDFDocumento59 pagineDell Inspiron 1545 Wistron Dr1 Roberts Uma 48 4aq01 031 08212 3 PDFrafael vidalNessuna valutazione finora

- Microsoft PowerPoint - 03 SoftwareDocumento11 pagineMicrosoft PowerPoint - 03 SoftwareคุณทองดำNessuna valutazione finora

- VN - TAS Training V2Documento73 pagineVN - TAS Training V2kemdoNessuna valutazione finora

- SOFT ENG Lab Index + RubricsDocumento2 pagineSOFT ENG Lab Index + Rubricsmuhammad.hannan24621Nessuna valutazione finora

- Ldip 2019Documento34 pagineLdip 2019Carl Malone TolentinoNessuna valutazione finora

- Omkar Shende: Education SkillsDocumento1 paginaOmkar Shende: Education Skillseema yoNessuna valutazione finora

- What Is Computational Fluid Dynamics (CFD) ? - SimScale - SimScaleDocumento13 pagineWhat Is Computational Fluid Dynamics (CFD) ? - SimScale - SimScaleMicheleFontanaNessuna valutazione finora

- Vis 11Documento6 pagineVis 11mg_catanaNessuna valutazione finora

- SAP Basis Training IDocumento22 pagineSAP Basis Training IAmarnath100% (19)

- Chapter 1 - Introduction: Sr. No. QuestionsDocumento27 pagineChapter 1 - Introduction: Sr. No. QuestionsPratik VishwakarmaNessuna valutazione finora

- Audi Investor Relations Insight 07-12-2020Documento27 pagineAudi Investor Relations Insight 07-12-2020Stephen PermanaNessuna valutazione finora

- Audi Investor Relations Insight 07-12-2020Documento27 pagineAudi Investor Relations Insight 07-12-2020Stephen PermanaNessuna valutazione finora

- Integration of Cad Cam System Towards High Speed Machining Challenges and Remedies IJERTV2IS50405Documento9 pagineIntegration of Cad Cam System Towards High Speed Machining Challenges and Remedies IJERTV2IS50405HOD MechanicalNessuna valutazione finora

- Adams 2020 Training 701 CoursenotesDocumento368 pagineAdams 2020 Training 701 CoursenotesThanthorn PrachasermsartNessuna valutazione finora

- Support Structure Design ReportDocumento31 pagineSupport Structure Design ReportnavinzhereNessuna valutazione finora

- Software Engineering: Requirements Traceability Matrix (RTM) : Template and ExamplesDocumento4 pagineSoftware Engineering: Requirements Traceability Matrix (RTM) : Template and ExamplesVarun GuptaNessuna valutazione finora

- HSMD Inventory Details 2015-16 PDFDocumento535 pagineHSMD Inventory Details 2015-16 PDFMCS SBINessuna valutazione finora

- Solutions For The Exercises: Simatic S7Documento39 pagineSolutions For The Exercises: Simatic S7Alex FariasNessuna valutazione finora

- Etp Milestone (May 2017)Documento1 paginaEtp Milestone (May 2017)heng junhaoNessuna valutazione finora

- GP1S73P 74PDocumento6 pagineGP1S73P 74PzakreaNessuna valutazione finora

- ASME Section VIII - Div. 2 - Interpretations Volume 63Documento16 pagineASME Section VIII - Div. 2 - Interpretations Volume 63Luis Arturo RodríguezNessuna valutazione finora

- MC-091-02 Cu2 Industrial Automation Fundamental Control ProgrammingDocumento16 pagineMC-091-02 Cu2 Industrial Automation Fundamental Control ProgrammingPK KNessuna valutazione finora

- PLC HistoryDocumento6 paginePLC HistoryPK KNessuna valutazione finora

- Basic PLC TrainingDocumento78 pagineBasic PLC TrainingPK KNessuna valutazione finora

- Inside PLCDocumento6 pagineInside PLCPK KNessuna valutazione finora

- Basic PLC 1Documento6 pagineBasic PLC 1PK KNessuna valutazione finora

- Sequence ControlDocumento5 pagineSequence ControlPK KNessuna valutazione finora

- PLC History: in The Late 1960'S Plcs Were First Introduced To Replace Complicated Relay Based Control SystemsDocumento77 paginePLC History: in The Late 1960'S Plcs Were First Introduced To Replace Complicated Relay Based Control SystemsPK KNessuna valutazione finora

- 96 Rotary Encoder HN38-06-N PDFDocumento2 pagine96 Rotary Encoder HN38-06-N PDFPK KNessuna valutazione finora

- Question: Stepper Operated Rewinding MechanismDocumento4 pagineQuestion: Stepper Operated Rewinding MechanismPK KNessuna valutazione finora

- Quiz AssignmentDocumento1 paginaQuiz AssignmentPK KNessuna valutazione finora

- Revision STEP & PUL & - Input Decimal # - Input Hex: Cp1E-EncoderDocumento5 pagineRevision STEP & PUL & - Input Decimal # - Input Hex: Cp1E-EncoderPK KNessuna valutazione finora

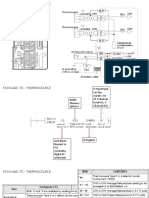

- FX1N-4AD - TC ThermocoupleDocumento5 pagineFX1N-4AD - TC ThermocouplePK KNessuna valutazione finora

- Introduction To Stepper Motors: RevisionDocumento25 pagineIntroduction To Stepper Motors: RevisionPK KNessuna valutazione finora

- SEIKO D-TRAN Robot Kit MaintenanceDocumento1 paginaSEIKO D-TRAN Robot Kit MaintenancePK KNessuna valutazione finora

- Minit Mesyuarat Meka - 5 Nov 2019Documento2 pagineMinit Mesyuarat Meka - 5 Nov 2019PK KNessuna valutazione finora

- Assignment 18th AprilDocumento1 paginaAssignment 18th AprilPK KNessuna valutazione finora

- Agenda 4th Dec 2019Documento1 paginaAgenda 4th Dec 2019PK KNessuna valutazione finora

- Kausilya Project ParaphrasedDocumento12 pagineKausilya Project ParaphrasedPK KNessuna valutazione finora

- Triz Application D1 18 Sep 2019 PDFDocumento2 pagineTriz Application D1 18 Sep 2019 PDFPK KNessuna valutazione finora

- Internet of Things For Smart ManufacturingDocumento3 pagineInternet of Things For Smart ManufacturingPK KNessuna valutazione finora

- Kausilya Project ParaphrasedDocumento12 pagineKausilya Project ParaphrasedPK KNessuna valutazione finora

- Meeting AgendaDocumento2 pagineMeeting AgendaPK KNessuna valutazione finora

- Fulltext01 PDFDocumento63 pagineFulltext01 PDFPK KNessuna valutazione finora

- IR 4.0 JustificationDocumento3 pagineIR 4.0 JustificationPK KNessuna valutazione finora

- Proposal Correction 23rd AprilDocumento16 pagineProposal Correction 23rd AprilPK KNessuna valutazione finora

- Bersemuka LDocumento7 pagineBersemuka LPK K0% (1)

- Summary of Litreature ReviewDocumento1 paginaSummary of Litreature ReviewPK KNessuna valutazione finora

- Triz Application D1 18 Sep 2019Documento2 pagineTriz Application D1 18 Sep 2019PK KNessuna valutazione finora

- Data Set Test Rig Setup & Image Aquisition: Phase MethodDocumento1 paginaData Set Test Rig Setup & Image Aquisition: Phase MethodPK KNessuna valutazione finora

- Tools EquipmentDocumento8 pagineTools EquipmentPK KNessuna valutazione finora

- Triggers - SQL Server - CodeProjectDocumento5 pagineTriggers - SQL Server - CodeProjectmasterpiecemanishNessuna valutazione finora

- Edocument Romania: Einvoice-Prerequisites For Sap Note 3221581Documento4 pagineEdocument Romania: Einvoice-Prerequisites For Sap Note 3221581LiviuNessuna valutazione finora

- GDI-OpenGL v1.1Documento14 pagineGDI-OpenGL v1.1Matija JanicNessuna valutazione finora

- KCS501 Solution2022 - 23Documento25 pagineKCS501 Solution2022 - 23itsrishabh0703Nessuna valutazione finora

- SCADA OverviewDocumento38 pagineSCADA Overviewameet_ngangomNessuna valutazione finora

- The Adventures in Harmony CourseDocumento183 pagineThe Adventures in Harmony CourseSeth Sulman100% (10)

- Lab 03: C Programming in Linux by Using GCC: A. Learning OutcomeDocumento3 pagineLab 03: C Programming in Linux by Using GCC: A. Learning OutcomeDuc FilanNessuna valutazione finora

- ravaत किस्मत बदल देते हैं रावण संहिता के ये 10 तांत्रिक उपाय Patrika Hindi NewsDocumento12 pagineravaत किस्मत बदल देते हैं रावण संहिता के ये 10 तांत्रिक उपाय Patrika Hindi NewspuneetNessuna valutazione finora

- 4 1 Forecasting - SL Ps ForecastnDocumento78 pagine4 1 Forecasting - SL Ps Forecastnapi-232697860Nessuna valutazione finora

- Mlinaric Mario FPZ 2016 Diplo SveucDocumento76 pagineMlinaric Mario FPZ 2016 Diplo SveucAdrian Marian RosuNessuna valutazione finora

- Application of Graph Theory in Web 2Documento9 pagineApplication of Graph Theory in Web 2Maria Benedetta VitalesNessuna valutazione finora

- Clinical Data Management SystemsDocumento29 pagineClinical Data Management SystemshimaNessuna valutazione finora

- Configuring Status Profile in SAP SDDocumento3 pagineConfiguring Status Profile in SAP SDrohan_juanNessuna valutazione finora

- WT4 Server Side TechnologyDocumento18 pagineWT4 Server Side TechnologySagun Raj Basnet75% (4)

- Aiml-Dsa BCSL305 ManualDocumento54 pagineAiml-Dsa BCSL305 ManualAdarsh KumarNessuna valutazione finora

- Unit 6 TEST Test Z Widocznymi-PunktamiDocumento6 pagineUnit 6 TEST Test Z Widocznymi-Punktaminie lubię ludziNessuna valutazione finora

- Introduction To Plant SimulationlDocumento16 pagineIntroduction To Plant SimulationlLeon SakiNessuna valutazione finora

- Thinking Outside The SOX: 3 Simple Steps To Ensure "IPE" SOX ComplianceDocumento2 pagineThinking Outside The SOX: 3 Simple Steps To Ensure "IPE" SOX ComplianceShekharNessuna valutazione finora

- Some Important T-Codes in WM: ReportsDocumento6 pagineSome Important T-Codes in WM: ReportsP RajendraNessuna valutazione finora

- Desktop PublishingDocumento11 pagineDesktop PublishingMANISHA S GANGURDENessuna valutazione finora

- 7000 Um150g en P Jan07Documento478 pagine7000 Um150g en P Jan07harlyganNessuna valutazione finora

- Chapter 04. AutomataDocumento46 pagineChapter 04. Automatakims3515354178Nessuna valutazione finora

- Aws Sysops FinalDocumento19 pagineAws Sysops FinalRishav GuptaNessuna valutazione finora

- Supermarket Detailed Design DocumentsDocumento9 pagineSupermarket Detailed Design Documentsதமிழ லரசன்Nessuna valutazione finora

- DMIS Short TutorialDocumento6 pagineDMIS Short TutorialDallas WinstonNessuna valutazione finora

- Brosur Dan Spek BT-350Documento3 pagineBrosur Dan Spek BT-350dr novi kurniasariNessuna valutazione finora

- Acm IcpcDocumento3 pagineAcm IcpcSivaramakrishna Markandeya GuptaNessuna valutazione finora

- Interface Clavier PicDocumento27 pagineInterface Clavier Picblaiso2020Nessuna valutazione finora

- WifiteDocumento4 pagineWifitetrou12Nessuna valutazione finora

- EWM Simple Inbound - TestedDocumento6 pagineEWM Simple Inbound - TestedNikhil kumarNessuna valutazione finora