Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

United States Patent (19) : Hathway (45) May 24, 1977

Caricato da

Byron Vivanco0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

8 visualizzazioni5 pagineThis patent describes a process for separating para-xylene from mixtures containing it and other xylene isomers. The process involves chilling the mixture to form crystals, then separating the para-xylene crystals from crystals of other components using classification based on differences in crystal size and shape. A preferred embodiment is a two-stage process where the mixture is chilled and crystals separated in the first stage. The mother liquor and para-xylene crystals are then chilled and crystals separated again in the second stage to further isolate para-xylene.

Descrizione originale:

PROCESS P-XILENE

Titolo originale

OUP-PATENT

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis patent describes a process for separating para-xylene from mixtures containing it and other xylene isomers. The process involves chilling the mixture to form crystals, then separating the para-xylene crystals from crystals of other components using classification based on differences in crystal size and shape. A preferred embodiment is a two-stage process where the mixture is chilled and crystals separated in the first stage. The mother liquor and para-xylene crystals are then chilled and crystals separated again in the second stage to further isolate para-xylene.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

8 visualizzazioni5 pagineUnited States Patent (19) : Hathway (45) May 24, 1977

Caricato da

Byron VivancoThis patent describes a process for separating para-xylene from mixtures containing it and other xylene isomers. The process involves chilling the mixture to form crystals, then separating the para-xylene crystals from crystals of other components using classification based on differences in crystal size and shape. A preferred embodiment is a two-stage process where the mixture is chilled and crystals separated in the first stage. The mother liquor and para-xylene crystals are then chilled and crystals separated again in the second stage to further isolate para-xylene.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

United States Patent (19) 1 l) 4,025,573

Hathway (45) May 24, 1977

54) SEPARATION PROCESS 56) References Cited

(75) Inventor: John Trevor Hathway, UNITED STATES PATENTS

Middlesbrough, England 3,544,646 12/1970 Brougton et al............... 260/674. A

3,643,453 2/1972 Groothuis et al. ............. 260/674. A

73 Assignee: Imperial Chemical Industries 3,758,601 9/1973 Wylie ............................ 260/674. A

Limited, London, England 3,798,282 3/1974 Bemis et al. ................... 260/674. A

22 Filed: Nov. 13, 1975 Primary Examiner-C. Davis

Attorney, Agent, or Firm-Cushman, Darby &

21 Appl. No.: 631,607 Cushman

30 Foreign Application Priority Data (57) ABSTRACT

Nov. 21, 1974 United Kingdom ............. 50444/74 Para-xylene is obtained from a eutectic mixture by

chilling the mixture and separating the resulting crys

52 U.S. C. .............................. 260/674 A; 62/532 tals by crystal classification.

51 Int. C.’........................................... C07C 7/14

58 Field of Search .............. 260/674 A; 62/58 XY 10 Claims, 1 Drawing Figure

U.S. Patent May 24, 1977 4,025,573

1 4,025,573 2

The feedstock for the process of this invention may

SEPARATION PROCESS be any mixture of p-xylene with one or more of the

other isomers, in which mixture the components are

This invention relates to a separation process. Para present in amounts substantially at or close to their

xylene is now produced in large quantities at many eutectic ratios. Preferably, the feedstock is the mother

plants throughout the world. The methods of produc liquor produced in the primary crystallisation stage of a

tion employed to make this chemical usually produce a xylenes manufacturing process. Hitherto, this mother

mixture of it with one or more of the other two xylene liquor has been used as the feedstock for xylenes

isomers and/or ethylbenzene. Para-xylene is the most isomerisation processes. Preferably the feedstock con

widely used of these four compounds and consequently 10 tains the three xylene isomers in substantially their

processes have been developed which attempt to effi eutectic ratios, viz. p-xylene 5.4 to 8.2%, o-xylene 27.9

ciently separate it from the other three compounds. to 30.4%, m-xylene 61.4 to 66.7% (all by weight). In

Processes have also been developed to increase the the case of a feedstock containing only two of the xy

yield of p-xylene by isomerisation of the co-produced lene isomers, for example p-xylene an m-xylene, the

o-xylene, m-xylene and ethylbenzene. 15isomers are suitable present in substantially their eutec

It is relatively easy to separate o-xylene and ethylben tic ratio, viz. p-xylene 12 to 16%, m-xylene 84 to 88%

zene from their mixtures with p-xylene and m-xylene by (both by weight). Optionally, the feedstock may con

fractional distillation. However, the difference in boil tain ethyl benzene, toluene and/or Cs aromatic hydro

ing point between p-xylene and m-xylene is only 0.8°C carbons.

and separation of these two isomers by fractional distil 20 Preferably, the feedstock is cooled in one or more

lation is impractical. Fortunately, the two isomers can stages to a temperature in each stage which is in the

be separated relatively successfully by fractional crys range -65 to -103°C, resulting in partial crystallisa

tallisation. Processes have been developed, therefore, tion of all of the xylene isomers present therein. The

based on fractional crystallisation alone or on a combi crystals are then separated in each stage by crystal

nation of fractional crystallisation and fractional distill 25 classification according to the process of the invention.

lation. However, even fractional crystallisation has its Suitably, in the case of a feedstock containing the three

difficulties and disadvantages. Mixtures of xylene iso xylene isomers the para-xylene crystals are separated

mers, with or without the presence of ethylbenzene, together with mother liquor leaving a mixture of m

tend to form eutectic mixtures when they are subjected xylene and o-xylene crystals. We have found that the

to fractional crystallisation. Thus, although it may be 30 latter mixture contains little or no p-xylene. Conve

possible to separate a large proportion of the p-xylene niently, it is passed to an isomeriser for conversion of

from a mixture containing it, a significant amount of the m- and o-xylene to p-xylene. Alternatively the m

p-xylene will remain in the mother liquor as a eutectic and o-xylene may be separated from each other by

mixture with one or more of the C isomers. For exam distillation. The slurry of para-xylene crystals and

ple, the eutectic mixture formed between the three 35 mother liquor may be filtered or centrifuged to recover

xylene isomers contains 8 to 9% p-xylene. The two the para-xylene crystals. The filtrate of mother liquor,

component eutectic mixture formed between para- and enriched in non-xylene isomer components of the feed

meta-xylene contains about 14% of p-xylene. stock may then be passed for further processing, for

In addition, because the eutectic mixture is usually example to remove ethylbenzene, benzene, toluene and

passed to an isomerisation reactor to convert the other 40 other aromatic hydrocarbons which may be present.

isomers to p-xylene, the presence of p-xylene in this Preferred forms of the invention comprise processes

isomeriser feed inevitably reduces the capacity of the of two to four stages in which the first stage comprises

isomerisation reactor for converting the isomers to chilling of the feedstock and separation of crystals

p-xylene. formed. In the second stage and in each of the remain

We have now surprisingly found that it is possible to 45 ing (if any) stages, mother liquor and, optionally, crys

separate significantly greater proportions than hitherto tals from the immediately preceding stage are chilled

of p-xylene from mixtures containing it and one or followed by separation of crystals. In the case of a

more of the other C alkyl aromatic isomers. two-stage process, the feedstock is chilled in the first

According to the present invention a process for stage so as to form a slurry of crystals and mother li

separating para-xylene from a solution or slurry of a 50 quor in which the mother liquor still contains apprecia

mixture comprising para-xylene and at least one other ble amounts of para-xylene and at least one of the other

component which is a xylene isomer present in xylene isomers. The crystals present in the slurry are

amounts substantially at or close to their eutectic ratios separated according to the process of the invention,

comprises chilling the solution or slurry to form a mix that is by crystal classification so that the crystals of o

ture of crystals and liquid, and separating crystals of 55 and m-xylene are separated from the crystals of p

para-xylene from crystals of the other component(s) by xylene and mother liquor. The mother liquor and p

classifying the crystals according to their respective xylene crystals are then passed to the second stage of

sizes and/or shapes. the process where they are chilled to a lower tempera

We have found that there are significant differences ture than that of the first stage of the process. Prefer

in crystal size between p-xylene and the other isomers. 60 ably, the chilling in the second stage is sufficient to

As a result, in a liquid mixture containing the various cause crystallisation of a large proportion of the para

isomers the settling rate of p-xylene crystals is signifi xylene and meta- and/or ortho-xylene present in the

cantly different from the settling rates of the other mother liquor from the first stage. The crystals ob

isomers. These differences in physical characteristics tained are again separated by crystal classification so

enable the crystals of the isomers to be separated from 65 that o- and/or m-xylene are separated from the crystals

one another according to their respective sizes and/or of p-xylene and mother liquor. The o- and/or m-xylene

shapes in suitable equipment by, for example centri crystals separated in both stages will generally contain

fuge, screens, elutriation, settling, and hydrocyclones. little or no p-xylene. Suitably, these crystals are melted

3

4,025,573 4

and then recycled for isomerisation. The slurry of para dium in heat exchanger 6 is low pressure ethylene. In

xylene crystals and mother liquor from the second the centrifuge 4 the cake of o- and/or m-xylene which

stage may be filtered and the mother liquor, enriched in is formed is removed along line 7 to a melter (not

non-xylenes but which will still contain significant pro shown). The remaining crystals of p-xylene together

portions of xylenes, may be treated to recover any with mother liquor are passed along line 8 to a second

ethylbenzene or other aromatic hydrocarbons present holding stage 9 in which further chilling is effected by

therein. The temperature of chilling in the first stage is cooling coils (not shown). As in the case of holding

preferably in the range -65 to -75° C. In the second stage 1, chilling may be effected in holding stage 9 or

stage, the temperature of chilling is preferably in the alternatively by passage of crystals and mother liquor

range -75° to -103 C. Processes involving more than 10 along line 12, through heat exchanger 13 and back to

two stages may be operated in a similar fashion. The holding stage 9. After chilling, the slurry of crystals is

number of stages used depends to some extent on the passed along line 10 to a second screen-bowl centrifuge

amount of crystallisable material being handled. The 11. The cake of o- and/or m-xylene which is formed in

slurries formed in the process become difficult to han centrifuge 11 is removed along line 14 to a melter (not

dle above a certain concentration of solids and so it is 15 shown) and combined with the o- and/or m-xylene

the practice to employ a plurality of stages to effect removed along line 7 before passage to an isomeriser

crystallisation and produce slurries which can be han (not shown). The crystals of p-xylene and the mother

dled easily. liquor are passed to a vacuum filter or centrifuge 15

Optionally, separation stages employing crystal clas along line 16. The para-xylene crystals are removed, if

sification and operated according to the process of this 20 necessary for further purification, along line 17. The

invention may be combined with one or more separa mother liquor leaves the vacuum filter or centrifuge 15

tion stages employing prior art methods, for example a by line 18. If desired a portion of the mother liquor may

method employing the supercooling characteristics of be recycled along 19 to the second holding stage 9

the xylene isomers and which allow one isomer, for and/or to the first holding stage 1 to assist in obtaining

example para-xylene, to be crystallised and separated 25 an optimim composition for the slurries undergoing

while one or more other isomers, for example meta chilling. The remaining mother liquor is removed along

xylene, remain in solution. line 20 for further processing, for example fraction

In the process of this invention it is preferred to sepa ation, to recover its constituents.

rate the crystals using a centrifuge, for example a In a typical case, a mother liquor from the primary

screen-bowl or solid-bowl centrifuge. If the process is 30

crystallisation stage of a xylenes manufacturing process

operated in a screen-bowl or solid-bowl centrifuge, the and comprising a substantially eutectic mixture of the

ortho- and meta-xylene isomers are deposited against three xylene isomers was passed along line 2 to the

the bowl as a cake which may be removed by a suitable chiller 1. The mother had the following composition

scroll. Substantially all the p-xylene crystals and (all parts by weight):

mother liquor are conveniently removed through the 35 p-xylene: 8.2%

overflow ports of the centrifuge. The para-xylene crys m-xylene: 56.4%

tals may subsequently be separated from the mother o-xylene: 26.1% ethylbenzene: 7.0%

liquor in a vacuum filter. non-C material: 2.3%

One alternative to centrifugation is to separate the

crystals by screening methods using any one or more of 40 passed mother

The

to the

liquor was chilled to -70° C and then

screen bowl centrifuge 4. Para-xylene

several proprietary vibrating sieve devices. The recov crystals and mother liquor separated in the centrifuge 4

ery of the desired xylene isomer can be controlled by were passed to the second holding stage 9. The compo

adopting a sieve having an appropriately large or small

sieve size. For example in separating para-xylene from sition of the slurry (i.e. para-xylene + mother liq.)

a mixture comprising para-xylene, meta-xylene and 45 entering holding stage 9 was as follows (all parts by

ethlbenzene, we have found that choosing a suitably weight): p-xylene: 13.1%

large aperture enables almost all the p-xylene crystals m-xylene: 48.5%

to pass through the sieve, accompanied by very small o-xylene: 23.6%

amounts of other crystals. The larger crystals retained

on the sieve include virtually no p-xylene crystals. 50 ethylbenzene: 11.1%

In one embodiment of the invention an indirect liquid Toluene/Caromatics: 3.7%

refrigerant which is immiscible with xylenes may be % p-xylene solids in slurry: 7.0%

used to assist in chilling the feedstock. The liquid re The chilled slurry was passed to centrifuge 11 in

frigerant may also serve as a medium for suspending which the o- and m-xylene crystals were separated from

the crystals which are formed. A suitable refrigerant is 55 the p-xylene crystals and mother liquor. The mother

methanol/water. In using a liquid refrigerant, care must liquor obtained from vacuum filter or centrifuge 15

be taken to ensure that the refrigerant is used at tem contained (all parts by weight):

peratures above its own freezing point. p-xylene: 4.2%

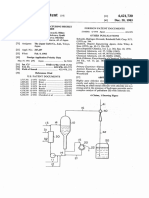

One embodiment of the invention will now be de m-xylene: 37.8%

scribed with reference to the accompanying diagram. 60 o-xylene: 17.6%

In this embodiment feedstock enters a holding stage ethylbenzene: 30.4%

1, for example a residence tank or length of pipe, along toluene/Caromatics: 10.0%

line 2. The holding stage 1 may be fitted with cooling In another embodiment of the invention, a mixture of

coils (not shown) and after chilling the feedstock is para-xylene and meta-xylene crystals in ethylbenzene

passed along line 3 to a first screen bowl centrifuge 4. 65 solution was fed to a 160 micron sieve, with facilities to

Alternatively, chilling may be effected by passing feed prevent blinding of the sieve by coarse crystals. The

stock along line 5 through heat exchanger 6 and back apparatus was immersed in methanol (DRIKOLD re

to the holding stage 1. A suitable heat exchange me frigerant (DRIKOLD is a Registered Trade Mark) and

5

4,025,573 6

maintained isothermally at -73.2 C. Analysis of the component or components, and which comprises, in

feed, overflow and underflow appears in Table 1. the remaining stage or successive stages, chilling of the

Table 1 mother liquor from the immediately preceding stage to

Ethyl

a temperature which is lower than that of the first stage

Weight/100 Para-xylene Meta-xy- benzene 5 followed by separation of the crystals formed, separa

parts feed (wt %) lene (wt %) (wt %) tion of the crystals in at least one stage of the process

Feed 100 6.9 50.8 42.3 being by classification of the crystals according to their

Underflow

Overflow

S4

46

7.2

6.7

45.6

55.7

46.3

37.6

respective sizes, respective shapes or both.

2. A process as claimed in claim 1 in which the feed

O stock mixture comprises the mother liquor produced in

Further analysis showed that the smaller para-xylene the primary crystallisation stage of a xylene manufac

crystals had passed preferentially through the sieve to turing process.

give a solids-phase in the underflow which contained 3. A process as claimed in claim 1 in which the re

considerably more paraxylene than the solids fed, as maining stage or stages comprises chilling of the

15 mother liquor and crystals from the immediately pre

shown in Table 2.

Table 2 ceding stage followed by separation of crystals formed.

Wt solids Wt % para-xylene in

4. A process as claimed in claim 1 in which chilling is

present solids phase carried out at a temperature in the range -65 to -103

C.

Feed 10.1 17.8 20

Underflow 1.6 96.3 5. A process as claimed in claim 1 in which the pro

Overflow 20.0 10.5 cess is carried out in two stages, the chilling tempera

ture in the first stage lying in the range of-65 to -75

Thus, some 46.3% of the para-xylene solids fed to the C and the chilling temperature in the second stage lying

sieve were recovered to the underflow, compared with 25 in the range -75° to -103° C.

a recovery of only 0.4% to underflow for the meta 6. A process as claimed in claim 1 in which the mix

xylene crystals in the feed. The recovery of para-xylene ture comprises ortho-xylene, meta-xylene and para

to underflow could be further increased by use of a xylene and para-xylene crystals together with mother

larger aperture sieve. liquor are separated in the first stage from the meta

The recovery of the p-xylene present in the original 30 xylene and ortho-xylene crystals.

feedstock by the process of this invention means that 7. A process as claimed in claim 1 in which separa

the feed requiring isomerisation contains essentially tion of crystals of the xylene isomers is effected in a

only meta- and/or ortho-xylenes. The load on the iso centrifuge, screening apparatus, eluttiation apparatus,

meriser is therefore considerably reduced. Moreover, settling apparatus or a hydrocyclone.

8. A process as claimed in claim 3 in which the pro

as the isomeriser feedstock contains little or no ethyl 35 cess

benzene, p-xylene or heavy ends, feedstock efficiency whichis stages

effected in two or more stages, in at least one of

separation of crystals is effected by crystal

is improved and the laydown of coke on the isomeriser

catalyst may possibly be reduced. In addition, the im classification

of crystals is

and in at least one other stage separation

effected by a method employing the super

purities such as ethylbenzene and heavy ends are re

cooling characteristics of the xylene isomers in which

moved by distillation of the final mother liquor from 40 method

the process of the invention. Hitherto, these impurities one or more one isomer is crystallised and separated while

had to be removed by distillation of the isomeriser other isomers remain in solution.

product. Hence the load on the final distillation stage 9. A process as claimed in claim 1 in which an indi

has also been considerably reduced and the ethylben rect liquid refrigerant is used to assist the chilling.

zene mixtures obtained are much more easily purified 45 10. A process as claimed in claim 1 for separating

than hitherto since the xylenes/ethylbenzene mixtures para-xylene from a mixture comprising para-xylene,

contain more ethylbenzene. meta-xylene and orth-oxylene present in amounts sub

In the case where a new plant for xylenes production stantially at or close to their eutectic ratios, which

is being erected, adoption of the process of the present comprises, in the first stage, chilling the feedstock mix

invention will mean that both the associated isomeriser 50 ture to a temperature in the range of -65 to -103°C

and distillation facilities can be smaller than would be to form a mixture of crystals and liquid, separating

the case in a conventional plant. If such a new plant is crystals of para-xylene from crystals of the other two

erected alongside an existing conventional plant, capi xylene isomers by classifying the crystals according to

tal and operating costs may be saved by integrating the their respective sizes, respective shapes, or both, pass

refrigeration systems for the two plants. 55 ing the thus-separated crystals of para-xylene together

I claim: with the mother liquor to a second stage in which the

1. A process for separating para-xylene from a mix mixture of mother liquor and para-xylene crystals is

ture comprising para-xylene and at least one other chilled to a temperature in the range of -65° to -103

component which is a xylene isomer present in C which is lower than that used in the first stage, and

amounts substantially at or about their eutectic ratios, 60 separating crystals of para-xylene from crystals of the

which process is conducted in at least two stages com other two xylene isomers by classifying the crystals

prising in the first stage, chilling the feedstock mixture according to their respective sizes, respective shapes or

to form a mixture of crystals and liquid, and separating both.

crystals of para-xylene from the crystals of the other sk is sk: sk

65

Potrebbero piacerti anche

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesDa EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNessuna valutazione finora

- Xylenes and EthylbenzeneDocumento13 pagineXylenes and EthylbenzeneAbhishek SinghNessuna valutazione finora

- Experimental Techniques For BioDocumento6 pagineExperimental Techniques For BioMariam AsgharNessuna valutazione finora

- Organic Synthesis - 2: Plenary Lectures Presented at the Second International Symposium on Organic SynthesisDa EverandOrganic Synthesis - 2: Plenary Lectures Presented at the Second International Symposium on Organic SynthesisS. SarelNessuna valutazione finora

- Separación de AzeotropoDocumento2 pagineSeparación de AzeotropoLaura GarciaNessuna valutazione finora

- Biochemistry Applied to Beer Brewing - General Chemistry of the Raw Materials of Malting and BrewingDa EverandBiochemistry Applied to Beer Brewing - General Chemistry of the Raw Materials of Malting and BrewingValutazione: 4 su 5 stelle4/5 (1)

- Ulllted States Patent (19) (11) Patent Number: 5,849,981: Kulprathipanja (45) Date of Patent: Dec. 15, 1998Documento8 pagineUlllted States Patent (19) (11) Patent Number: 5,849,981: Kulprathipanja (45) Date of Patent: Dec. 15, 1998rifkynoviyantoNessuna valutazione finora

- US4174976Documento3 pagineUS4174976Elaine PolilloNessuna valutazione finora

- Us 6489527Documento6 pagineUs 6489527Gracelia IrmalindaNessuna valutazione finora

- Reactive AdsorptionDocumento9 pagineReactive AdsorptionLinhXuânPhạmNessuna valutazione finora

- Us 4608340Documento6 pagineUs 4608340akhwaNessuna valutazione finora

- Lab Report Experiment 2 CHM457Documento9 pagineLab Report Experiment 2 CHM457lala lalaNessuna valutazione finora

- US4115424Documento6 pagineUS4115424Muhammad Akbar FahleviNessuna valutazione finora

- Us 3862122Documento9 pagineUs 3862122Emillie KarlaNessuna valutazione finora

- Experiment 5 - : Preparation and Purification of AcetanilideDocumento6 pagineExperiment 5 - : Preparation and Purification of AcetanilideFluoruro De PotasioNessuna valutazione finora

- United States Patent (19) : 11 Patent Number: 6,123,810 (45) Date of Patent: Sep. 26, 2000Documento7 pagineUnited States Patent (19) : 11 Patent Number: 6,123,810 (45) Date of Patent: Sep. 26, 2000arjunanpnNessuna valutazione finora

- Us 7601311Documento10 pagineUs 7601311Văn Đại - BKHNNessuna valutazione finora

- US3903185Documento6 pagineUS3903185Muhammad Akbar FahleviNessuna valutazione finora

- Xylene From MethylationDocumento8 pagineXylene From Methylationalicia1990Nessuna valutazione finora

- Formal Report Extraction of Total Lipids From Chicken Egg Yolk and ColumnDocumento2 pagineFormal Report Extraction of Total Lipids From Chicken Egg Yolk and ColumnNorjem Villanueva100% (1)

- Yeast NaohDocumento9 pagineYeast NaohffwwfNessuna valutazione finora

- 4,7-Dichloroquinoline: Molecular Formula: Molecular Weight: Cas NumberDocumento5 pagine4,7-Dichloroquinoline: Molecular Formula: Molecular Weight: Cas NumberShankar kumar royNessuna valutazione finora

- Yeast PatentDocumento14 pagineYeast PatentffwwfNessuna valutazione finora

- Us 3717672Documento5 pagineUs 3717672eschim.civNessuna valutazione finora

- United States Patent (19) : Acrylate Copolymer ThusDocumento6 pagineUnited States Patent (19) : Acrylate Copolymer Thusهیمن مNessuna valutazione finora

- ) Pergamon: Energy Com, Ers. MGMTDocumento6 pagine) Pergamon: Energy Com, Ers. MGMTyemresimsekNessuna valutazione finora

- Abdulrazzaq Et al-AIChE JournalDocumento8 pagineAbdulrazzaq Et al-AIChE JournalTanvir AhmedNessuna valutazione finora

- 459 - ANN509 Lecture Note - A - PDFDocumento10 pagine459 - ANN509 Lecture Note - A - PDFIonela HoteaNessuna valutazione finora

- Us 5154800Documento3 pagineUs 5154800Lukas EstivaresNessuna valutazione finora

- Glucose o ToluidineDocumento21 pagineGlucose o ToluidinetorokpeterNessuna valutazione finora

- Exp10 PDFDocumento3 pagineExp10 PDFعمر العنزيNessuna valutazione finora

- Synthesis of Aspirin (Lab Report)Documento13 pagineSynthesis of Aspirin (Lab Report)ORRYZA MUTIARA ILLAHI -Nessuna valutazione finora

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsDocumento6 pagineWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic Compoundsrajesh kothariNessuna valutazione finora

- Plant PhysiologyDocumento15 paginePlant PhysiologyJason Kenneth MaxwellNessuna valutazione finora

- Osazones of The Uncommonly Encountered Reducing Sugars: Vinod Babu S, Santhi Silambanan, KrithikaDocumento6 pagineOsazones of The Uncommonly Encountered Reducing Sugars: Vinod Babu S, Santhi Silambanan, KrithikaDaris UntoroNessuna valutazione finora

- CHM303LAB1Documento7 pagineCHM303LAB1Darvin YiNessuna valutazione finora

- United States Patent (19) : (52) U.S. C.260/583 KDocumento5 pagineUnited States Patent (19) : (52) U.S. C.260/583 KkurniawanNessuna valutazione finora

- United States Patent (19) : Symon Et Al. 45) Feb. 21, 1984Documento5 pagineUnited States Patent (19) : Symon Et Al. 45) Feb. 21, 1984EceNessuna valutazione finora

- Process For Preparing PolyesterDocumento8 pagineProcess For Preparing PolyesterAnh Đức PhạmNessuna valutazione finora

- 1 s2.0 S0032579119428526 MainDocumento4 pagine1 s2.0 S0032579119428526 Mainrajeshtalukdar420Nessuna valutazione finora

- Lipid Oxidation in Glassy and Rubbery-State Starch ExtrudatesDocumento8 pagineLipid Oxidation in Glassy and Rubbery-State Starch ExtrudatesBryam David Ramirez ErazoNessuna valutazione finora

- Chapter 15 Crystpx Modern Crystallization Technology For para Xylene ProductionDocumento9 pagineChapter 15 Crystpx Modern Crystallization Technology For para Xylene Productionooimooi1111Nessuna valutazione finora

- ISO 1735 Cheese Determination of Fat Content - Gravimetric MethodDocumento20 pagineISO 1735 Cheese Determination of Fat Content - Gravimetric MethodJocilene DantasNessuna valutazione finora

- VanillinDocumento14 pagineVanillinReksy WibowoNessuna valutazione finora

- Conversion of Glycerol To Light Olefins and Gasoline PrecursorsDocumento6 pagineConversion of Glycerol To Light Olefins and Gasoline PrecursorsAnonymous Wcj4C3jNessuna valutazione finora

- From The Laboratories of The Rockefeller Institute For Medical ResearchDocumento14 pagineFrom The Laboratories of The Rockefeller Institute For Medical ResearchNur AnindyaNessuna valutazione finora

- Epoxidation of CholosterolDocumento25 pagineEpoxidation of CholosterolAzharNessuna valutazione finora

- United States Patent: 6, 1989 Patent Number: Date of Patent: Shimuzu Et AlDocumento8 pagineUnited States Patent: 6, 1989 Patent Number: Date of Patent: Shimuzu Et AlEsat KostakNessuna valutazione finora

- Método SoxhletDocumento8 pagineMétodo SoxhletVíctor YanalaNessuna valutazione finora

- US20100148117A1Documento8 pagineUS20100148117A1Buat DijualNessuna valutazione finora

- Bagan Dan Penjelasan PDFDocumento3 pagineBagan Dan Penjelasan PDFYonatan AdiNessuna valutazione finora

- Batch Distillation - Lab ReportDocumento21 pagineBatch Distillation - Lab ReportAngelica Joyce Benito100% (1)

- 4PL2PP89dvAHuD31bFqea6o0gdOSN 4wzp2IJk-Sw6MDocumento7 pagine4PL2PP89dvAHuD31bFqea6o0gdOSN 4wzp2IJk-Sw6MUřvah AbbasNessuna valutazione finora

- Us 5261Documento3 pagineUs 5261tajudinNessuna valutazione finora

- 2-12-23 Prepare Latent Curing Agent For PUaDocumento8 pagine2-12-23 Prepare Latent Curing Agent For PUaQuynh HoangNessuna valutazione finora

- Acidos GrasosDocumento8 pagineAcidos GrasosCristián Cerda BarreraNessuna valutazione finora

- US PatentDocumento4 pagineUS PatentfhafizfrNessuna valutazione finora

- Preparation of 4-Methylcyclohexene From Dehydration of 4-MethylcyclohexanolDocumento8 paginePreparation of 4-Methylcyclohexene From Dehydration of 4-MethylcyclohexanolHidayu AdnanNessuna valutazione finora

- The Cellulase Trichoderma: of VirideDocumento9 pagineThe Cellulase Trichoderma: of ViriderahulshtyNessuna valutazione finora

- Effect of Particle Size and Grinding Time On Gold Dissolution in Cyanide SolutionDocumento9 pagineEffect of Particle Size and Grinding Time On Gold Dissolution in Cyanide SolutionByron VivancoNessuna valutazione finora

- Activated Sulfating Roasting of The Chalcopyrite Concentrate For Sulfuricacid LeachingDocumento3 pagineActivated Sulfating Roasting of The Chalcopyrite Concentrate For Sulfuricacid LeachingByron VivancoNessuna valutazione finora

- Thiourea-Thiocyanate Leaching System For GoldDocumento6 pagineThiourea-Thiocyanate Leaching System For GoldfamansilNessuna valutazione finora

- Pyrolysis of Sewage Sludge in A Fixed and A Bubbling Fluidized Bed - Estimation and Experimental Validation of The Pyrolysis TimeDocumento9 paginePyrolysis of Sewage Sludge in A Fixed and A Bubbling Fluidized Bed - Estimation and Experimental Validation of The Pyrolysis TimeByron VivancoNessuna valutazione finora

- Pyrolysis of Sewage Sludge in A Fixed and A Bubbling Fluidized Bed - Estimation and Experimental Validation of The Pyrolysis TimeDocumento9 paginePyrolysis of Sewage Sludge in A Fixed and A Bubbling Fluidized Bed - Estimation and Experimental Validation of The Pyrolysis TimeByron VivancoNessuna valutazione finora

- Techno-Economical Feasibility Studies On Establishing Petro Refineries and Their Advantages in IranDocumento10 pagineTechno-Economical Feasibility Studies On Establishing Petro Refineries and Their Advantages in IranByron VivancoNessuna valutazione finora

- Estuido EsDocumento9 pagineEstuido EsByron VivancoNessuna valutazione finora

- Jean-Philippe Ansermet, Sylvain D. Brechet - Principles of Thermodynamics-Cambridge University Press (2019)Documento542 pagineJean-Philippe Ansermet, Sylvain D. Brechet - Principles of Thermodynamics-Cambridge University Press (2019)kc100% (1)

- FERROCIANUROSDocumento27 pagineFERROCIANUROSByron VivancoNessuna valutazione finora

- Yoon1992 R8Documento11 pagineYoon1992 R8Bekraoui KeltoumNessuna valutazione finora

- Hyrdosheer Suncare PresentationDocumento26 pagineHyrdosheer Suncare PresentationicraoNessuna valutazione finora

- Notes: Novel Synthesis of Tris (Acetylacetonato) Iron (Documento2 pagineNotes: Novel Synthesis of Tris (Acetylacetonato) Iron (Rupesh GaonkarNessuna valutazione finora

- Experiment 2 OrgChem - EditedDocumento8 pagineExperiment 2 OrgChem - EditedAntonio CharismaNessuna valutazione finora

- Effect of Fermentation On NutrientsDocumento28 pagineEffect of Fermentation On NutrientsMichelle MuliawidjajaNessuna valutazione finora

- A Preliminary LCA Case Study: Comparison of Different Pathways To Produce Purified Terephthalic Acid Suitable For Synthesis of 100 % Bio-Based PETDocumento9 pagineA Preliminary LCA Case Study: Comparison of Different Pathways To Produce Purified Terephthalic Acid Suitable For Synthesis of 100 % Bio-Based PETAbdullah JavedNessuna valutazione finora

- Volcanic AshDocumento3 pagineVolcanic AshErman DeanoNessuna valutazione finora

- Cordycepin Production by C.militaris Cultivation On Spent Brewery GrainsDocumento9 pagineCordycepin Production by C.militaris Cultivation On Spent Brewery GrainsChongtham Allaylay Devi (SBSR Assistant Professor)Nessuna valutazione finora

- 4 - Carboxylic Acids and Its Derivatives (Booklet-1)Documento16 pagine4 - Carboxylic Acids and Its Derivatives (Booklet-1)kraken monsterNessuna valutazione finora

- Worksheet - Arenes AnswersDocumento6 pagineWorksheet - Arenes AnswersAbdul AhadhNessuna valutazione finora

- Experiment No.4 CHM143Documento7 pagineExperiment No.4 CHM143MaiSakurajimaNessuna valutazione finora

- Detailed Lesson Plan Template. 19 SeptemberDocumento3 pagineDetailed Lesson Plan Template. 19 SeptemberrutendoNessuna valutazione finora

- History of Coordination CompoundsDocumento18 pagineHistory of Coordination CompoundsIlmu Kimia CNessuna valutazione finora

- Grade ChartDocumento4 pagineGrade ChartGopal ChavanNessuna valutazione finora

- Adinoll Cliptec - XHS - 280 - English PDFDocumento6 pagineAdinoll Cliptec - XHS - 280 - English PDFCleiton Luiz CordeiroNessuna valutazione finora

- Chemistry Past Paper Ch1.7Documento12 pagineChemistry Past Paper Ch1.7Raymond ChanNessuna valutazione finora

- Organic Chemistry Laboratory: Report 6: Reflux ReactionDocumento7 pagineOrganic Chemistry Laboratory: Report 6: Reflux ReactionPhú NguyễnNessuna valutazione finora

- Genetics MCQDocumento8 pagineGenetics MCQRitik ShuklaNessuna valutazione finora

- United States Patent (191: Yamamoto, Shibukawa SyukiDocumento6 pagineUnited States Patent (191: Yamamoto, Shibukawa SyukiUntung SetiawanNessuna valutazione finora

- Minimum Design Criteria For The Permitting of Gravity SewersDocumento2 pagineMinimum Design Criteria For The Permitting of Gravity SewerslaikienfuiNessuna valutazione finora

- Germanica) - This Study Was Limited To Cockroach (Blattella Germanica) As The Insect To BeDocumento8 pagineGermanica) - This Study Was Limited To Cockroach (Blattella Germanica) As The Insect To BeAnonymous eMOb79RNt5Nessuna valutazione finora

- Orson Chemicals Private LimitedDocumento6 pagineOrson Chemicals Private LimitedPriyanka BankaNessuna valutazione finora

- Fast Screening For Volatile Organic Compounds in Water Using Solid Phase Microextraction (SPME)Documento5 pagineFast Screening For Volatile Organic Compounds in Water Using Solid Phase Microextraction (SPME)Oh No PotatoNessuna valutazione finora

- MSDS SwakDocumento4 pagineMSDS Swaktolkien9Nessuna valutazione finora

- HaloalkanesDocumento46 pagineHaloalkanesPrashant ZadeNessuna valutazione finora

- Rubel BS, Impression Materials A Comparative Review of Impression Materials Most Commonly Used in Restorative Dentistry Dent Clin N Am.Documento14 pagineRubel BS, Impression Materials A Comparative Review of Impression Materials Most Commonly Used in Restorative Dentistry Dent Clin N Am.Bavilonia K PaolaNessuna valutazione finora

- Informed-Choice Summary List 22 November 2019Documento13 pagineInformed-Choice Summary List 22 November 2019nakul PandeyNessuna valutazione finora

- Characterization of CarbohydratesDocumento3 pagineCharacterization of CarbohydratesHyvieNessuna valutazione finora

- Reactivos de FlotacionDocumento13 pagineReactivos de Flotacionjoseph ayronNessuna valutazione finora

- Refrigerants - Physical PropertiesDocumento3 pagineRefrigerants - Physical PropertiesEder PereiraNessuna valutazione finora