Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Basf-Masterrheobuild 2000 Oct - 2016 en

Caricato da

Konax Lihysd MandeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Basf-Masterrheobuild 2000 Oct - 2016 en

Caricato da

Konax Lihysd MandeCopyright:

Formati disponibili

MasterRheobuild 2000

Hyperplasticizing admixture to produce exceptionally high-strength rheoplastic con-

crete with low water/cement ratio.

DESCRIPTION AND WHERE TO USE air entraining agent MasterAir to improve frost/thaw re-

MasterRheobuild 2000 is a water-soluble, sulphonated pol- sistance (exposure class XF1 to XF4, EN 206-1)

ymer based admixture. Adding MasterRheobuild 2000 to silica fume MasterRoc MS 610 for high performance con-

concrete, the molecules of the polymer with a negative crete and improve durability in chemical aggressive envi-

charge adsorb onto the surface of cement grains, cause a ronments (exposure class XA1 to XA3, EN 206-1)

repulsion among cement particles, thus making their dis- curing agent MasterKure against too quick evaporation

persion in water easier and, consequently, the mix much of mixing water.

more fluid. MasterRheobuild 2000 continues its action,

even if blended cement based on Portland cement clinker DIRECTIONS FOR USE

and other materials, such as pozzolans, fly ash and slags, MasterRheobuild 2000 is introduced into the mixer together

are used. with mixing water.

The plasticizing effect or water reduction is higher if the ad-

MasterRheobuild 2000 is chloride free, meets UNI EN 934- mixture is added to the damp concrete after 80-90% of the

2 UNI EN 480 (1-2), UNI 10765, ASTM C 494-92 require- mixing water has been added. The addition of MasterRhe-

ments for Type F and it is also compatible with all cements obuild 2000 to dry aggregate or cement is not recom-

meeting the UNI EN 197-1 and ASTM standards. mended.

extend mixing, 1 to 2 min., after the addition of the last

BENEFITS quantity of water until bleeding water is completely elimi-

MasterRheobuild 2000 allows rheoplastic concrete flowable nated;

and non-segregating) to be manufactured with a water/ce- reduce the last quantity of water so that a slightly lower

ment ratio even lower than that obtained with ordinary su- slump (150 to 220 mm) is achieved;

perplasticizers. reduce dosage of MasterRheobuild 2000 to 1.5%.

Therefore MasterRheobuild 2000 is meant for the produc-

tion of very high quality rheoplastic concrete having much Since MasterRheobuild 2000 is designed for the production

higher strengths at early and later ages. Moreover, the re- of very high-quality concrete, the recommended dosage of

duction in water/cement ratio guarantees the improvement cement is relatively high (not lower than 300-350 kg/m3).

of all the other properties of hardened concrete (imperme- The use of fly ash or silica fume, where these materials are

ability, durability, bond to steel, dimensional stability, etc.). available, is especially beneficial in the production of very

cohesive and self-levelling concrete, which is particularly

COMPATIBILITY useful for underwater pours. In this case fly ash or silica

In order to optimise special requirements the use of the fol- fume can be added at the same time as cement.

lowing complementary additives is suggested:

Technical Information

Form Liquid, dark brown

Relative density (g/ml at 20°C) 1.160 – 1.220

MasterRheobuild 2000

Hyperplasticizing admixture to produce exceptionally high-strength rheoplastic con-

crete with low water/cement ratio.

DOSAGE

The optimum dosage of MasterRheobuild 2000 is ranging PACKAGING AND STORAGE

from 0.8 to 2.0 litres/100 kg of cement. MasterRheobuild 2000 is available in 1.000L containers

and bulk.

Other dosages may be recommended in special cases ac- MasterRheobuild 2000 must be stored in a place where

cording to specific job site conditions. In these cases please temperature does not drop below 5°C.

consult our Technical Service In case of freezing, warm up and homogenise the admixture

solution before using.

From 16/12/1992 BASF Construction Chemicals Italia Spa operates under For further information, please consult your local BASF Construction Chem-

the Quality System in compliance with European Standard UNI-EN ISO icals Italia Spa representative.

9001. The environmental management system of BASF Construction Chem- The technical advice on how to use our products, either written or verbally

icals Italia Spa is certified accordingly to UNI EN ISO 14001 and the System given, are based on the present state of our best scientific and practical

of Safety Management is certified accordingly to OHSAS 18001. Environ- knowledge, and no guarantee and/or implicit or explicit responsibility are as-

ment sustainability: Partner Green Building Council since 2009. sumed on final results of works executed by the use of our products.

The owner, his representative, or the contractor is responsible for checking

BASF Construction Chemicals Italia Spa

the suitability of our products as to the intended use and aims.

Via Vicinale delle Corti, 21 – 31100 Treviso – Italy

T +39 0422 429200 F +39 0422 421802

Supersedes all prior issues on this product.

http:// www.master-builders-solutions.basf.it e-mail: infomac@basf.com

October 2016

Potrebbero piacerti anche

- BASF-MasterGlenium SKY 690 Jan - 17 enDocumento2 pagineBASF-MasterGlenium SKY 690 Jan - 17 enJohn GiannakopoulosNessuna valutazione finora

- RHEOMIX 200 Oct-11 EN BASFDocumento2 pagineRHEOMIX 200 Oct-11 EN BASFKarl FarrugiaNessuna valutazione finora

- Master Rheobuild 3202Documento2 pagineMaster Rheobuild 3202sufian100% (2)

- TDS - Glenium Ace 340Documento3 pagineTDS - Glenium Ace 340Alexi ALfred H. TagoNessuna valutazione finora

- Rheobuild 2000PFDocumento2 pagineRheobuild 2000PFdana setiawanNessuna valutazione finora

- TDS - Glenium Ace 30Documento2 pagineTDS - Glenium Ace 30Alexi ALfred H. TagoNessuna valutazione finora

- TDS - Glenium Ace 30 PDFDocumento2 pagineTDS - Glenium Ace 30 PDFAlexi ALfred H. TagoNessuna valutazione finora

- MasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGDocumento3 pagineMasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGvahab_shaikNessuna valutazione finora

- TDS - MasterRheobuilld 1100Documento2 pagineTDS - MasterRheobuilld 1100Taposh PaulNessuna valutazione finora

- Basf Masterglenium Sky 920 Tds PDFDocumento4 pagineBasf Masterglenium Sky 920 Tds PDFvikasNessuna valutazione finora

- MasterCell 10ME TDSDocumento2 pagineMasterCell 10ME TDSعلي عثمانNessuna valutazione finora

- TDS MasterRheobuild 2000 PF PDFDocumento3 pagineTDS MasterRheobuild 2000 PF PDFRogerNessuna valutazione finora

- TDS - Rheobuild 1100Documento3 pagineTDS - Rheobuild 1100Alexi ALfred H. Tago100% (1)

- ADDMIX 215 STv2 PDFDocumento3 pagineADDMIX 215 STv2 PDFAnkita Baban GavadeNessuna valutazione finora

- TDS - Rheobuild sp1Documento2 pagineTDS - Rheobuild sp1Alexi ALfred H. TagoNessuna valutazione finora

- Cemtec 120 SPDocumento2 pagineCemtec 120 SPpravi3434Nessuna valutazione finora

- Emaco R302: Cementitious Repair Mortar For Non Structural Cosmetic RepairsDocumento2 pagineEmaco R302: Cementitious Repair Mortar For Non Structural Cosmetic RepairsFrancois-Nessuna valutazione finora

- Cico Plast Super C804Documento2 pagineCico Plast Super C804ASRAR AHMED KHANNessuna valutazione finora

- Masterrheobuild 2270: High Range, Water-Reducing, Superplasticising Admixture For The Production of Rheoplastic ConcreteDocumento2 pagineMasterrheobuild 2270: High Range, Water-Reducing, Superplasticising Admixture For The Production of Rheoplastic ConcreteMahmoud AhmedNessuna valutazione finora

- MasterRheobuild 1100 v1Documento2 pagineMasterRheobuild 1100 v1Vivek GaurNessuna valutazione finora

- BASF MasterRheobuild 2000PF TdsDocumento3 pagineBASF MasterRheobuild 2000PF TdsSuranga GayanNessuna valutazione finora

- Masterrheobuild 890 tds-2 PDFDocumento2 pagineMasterrheobuild 890 tds-2 PDFBnbdbbdbhhbbbvvffffnhebrbbrNessuna valutazione finora

- 6 2 3 6 3 Polybond Ac PDFDocumento2 pagine6 2 3 6 3 Polybond Ac PDFHtun ZarniNessuna valutazione finora

- Rheocell 10 ME: A Liquid Admixture For The Production of Lightweight ConcreteDocumento2 pagineRheocell 10 ME: A Liquid Admixture For The Production of Lightweight ConcreteCivil SanamNessuna valutazione finora

- Masterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteDocumento2 pagineMasterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteweamNessuna valutazione finora

- TDS - Rheobuild 850Documento2 pagineTDS - Rheobuild 850nischal_babuNessuna valutazione finora

- Masterrheobuild 1126 v2Documento2 pagineMasterrheobuild 1126 v2Shub KotiNessuna valutazione finora

- Mastercrete 1000 TdsDocumento2 pagineMastercrete 1000 Tdsaruncg2Nessuna valutazione finora

- TDS - Glenium Ace 415Documento3 pagineTDS - Glenium Ace 415Alexi ALfred H. TagoNessuna valutazione finora

- Thermax Construction Chemicals - Product Summary GuideDocumento16 pagineThermax Construction Chemicals - Product Summary GuideKarthik AmbatiNessuna valutazione finora

- Basf Masterseal 550 TdsDocumento3 pagineBasf Masterseal 550 Tdsraza102Nessuna valutazione finora

- Cemtec 190 SPDocumento2 pagineCemtec 190 SPpravi3434Nessuna valutazione finora

- Brochure Product Summary Guide BFL PDFDocumento33 pagineBrochure Product Summary Guide BFL PDFTanvir Ahmed KhanNessuna valutazione finora

- Rheobuild 890Documento2 pagineRheobuild 890Ahmed ZidanNessuna valutazione finora

- MS For Honeycomb rectification-RFMS 010Documento17 pagineMS For Honeycomb rectification-RFMS 010Chamux skalNessuna valutazione finora

- Rheobuild 1030: High Range Water ReducerDocumento2 pagineRheobuild 1030: High Range Water ReducerFrancois-Nessuna valutazione finora

- MasterTop BSFDocumento3 pagineMasterTop BSFnawazkhan23Nessuna valutazione finora

- Dynamonmr2100 UaeDocumento2 pagineDynamonmr2100 Uaediv_bamaniaNessuna valutazione finora

- Rheomac® 707Documento4 pagineRheomac® 707M HAFEEZ RAJANessuna valutazione finora

- Concrete Admixture Rheobuild Ld80Documento3 pagineConcrete Admixture Rheobuild Ld80Anonymous 2ILZCrTM5Nessuna valutazione finora

- Superflo 2000SCCDocumento2 pagineSuperflo 2000SCCKerron RekhaNessuna valutazione finora

- Superflo 2000SCCDocumento2 pagineSuperflo 2000SCCKerron RekhaNessuna valutazione finora

- Masterflow 150 v1Documento2 pagineMasterflow 150 v1vinayNessuna valutazione finora

- Alccofine 1108SRDocumento2 pagineAlccofine 1108SRLaxmana PrasadNessuna valutazione finora

- 18 - Tds - Emaco r202 NBDocumento3 pagine18 - Tds - Emaco r202 NBaahtagoNessuna valutazione finora

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDocumento3 pagineMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNessuna valutazione finora

- Alccofine 1203Documento2 pagineAlccofine 1203Bijaya RaulaNessuna valutazione finora

- Rheobuild 850Documento2 pagineRheobuild 850Haresh BhavnaniNessuna valutazione finora

- Basf Masterpolyheed 8840 TdsDocumento2 pagineBasf Masterpolyheed 8840 Tdssattar12345Nessuna valutazione finora

- Glenium b276 Suretec v1Documento2 pagineGlenium b276 Suretec v1hegvinuNessuna valutazione finora

- Masterbrace Adh 2200 TdsDocumento2 pagineMasterbrace Adh 2200 TdsarchahmedassafNessuna valutazione finora

- Masterpozzolith® MR 25s (Formerly Known As Pozzolith® MR 25 S)Documento3 pagineMasterpozzolith® MR 25s (Formerly Known As Pozzolith® MR 25 S)RajNessuna valutazione finora

- SikaTop® Armatec®-110 EpoCem® - PDS - GCC - (10-2016) - 2 - 1Documento3 pagineSikaTop® Armatec®-110 EpoCem® - PDS - GCC - (10-2016) - 2 - 1kamran abbasiNessuna valutazione finora

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Water-Based Paint Formulations, Vol. 3Da EverandWater-Based Paint Formulations, Vol. 3Valutazione: 4.5 su 5 stelle4.5/5 (6)

- Data Book of Thermoset Resins for Composites: Edition 1Da EverandData Book of Thermoset Resins for Composites: Edition 1Nessuna valutazione finora

- Polyurethanes: Science, Technology, Markets, and TrendsDa EverandPolyurethanes: Science, Technology, Markets, and TrendsValutazione: 1 su 5 stelle1/5 (1)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisDa EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisValutazione: 5 su 5 stelle5/5 (1)

- Specifications: BumperDocumento5 pagineSpecifications: BumperKonax Lihysd MandeNessuna valutazione finora

- Group40 EmbragueDocumento12 pagineGroup40 EmbragueKonax Lihysd MandeNessuna valutazione finora

- Upper Body Dimensions Front Body Straaght - Line Dimensions: Fronl Fender Mounting Hole Front Fender Mountrng HoleDocumento18 pagineUpper Body Dimensions Front Body Straaght - Line Dimensions: Fronl Fender Mounting Hole Front Fender Mountrng HoleKonax Lihysd MandeNessuna valutazione finora

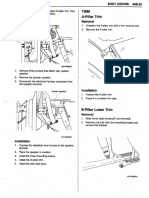

- Trim A-Pillar Trim RemovalDocumento5 pagineTrim A-Pillar Trim RemovalKonax Lihysd MandeNessuna valutazione finora

- Upper Body Dimensions: (2 Door)Documento18 pagineUpper Body Dimensions: (2 Door)Konax Lihysd MandeNessuna valutazione finora

- Aire Acondicionado 1Documento10 pagineAire Acondicionado 1Konax Lihysd MandeNessuna valutazione finora

- Group62-3 Aire AcondicionadoDocumento9 pagineGroup62-3 Aire AcondicionadoKonax Lihysd MandeNessuna valutazione finora

- Group62-3 Aire AcondicionadoDocumento9 pagineGroup62-3 Aire AcondicionadoKonax Lihysd MandeNessuna valutazione finora

- William HazensDocumento1 paginaWilliam HazensKonax Lihysd MandeNessuna valutazione finora

- Group62-2 Aire AcondicionadoDocumento10 pagineGroup62-2 Aire AcondicionadoKonax Lihysd MandeNessuna valutazione finora

- Warn HubsDocumento4 pagineWarn HubsKonax Lihysd MandeNessuna valutazione finora

- Lateral Problems¡ Hec RasDocumento2 pagineLateral Problems¡ Hec RasKonax Lihysd MandeNessuna valutazione finora

- EulaDocumento21 pagineEulaFNessuna valutazione finora

- William HazensDocumento1 paginaWilliam HazensKonax Lihysd MandeNessuna valutazione finora

- ACI 302.1R-96 Guide For Concrete Floor and Slab ConstructionDocumento67 pagineACI 302.1R-96 Guide For Concrete Floor and Slab ConstructionForbes KambaNessuna valutazione finora

- S-CONCRETE Version 7.02Documento3 pagineS-CONCRETE Version 7.02Hussein Bou SalehNessuna valutazione finora

- Type 42Documento5 pagineType 42Muhamad Aris HabibiNessuna valutazione finora

- M-25 Cement Concrete Mix Design: Test Results On CementDocumento4 pagineM-25 Cement Concrete Mix Design: Test Results On CementvenkatNessuna valutazione finora

- Fundamentals of ConcreteDocumento54 pagineFundamentals of ConcreteNolan PillayNessuna valutazione finora

- R.c.c.road EstimateDocumento5 pagineR.c.c.road EstimateUJJWAL SUTHARNessuna valutazione finora

- BRTC II TEST StatementDocumento2 pagineBRTC II TEST StatementsheetalNessuna valutazione finora

- Tabla de Tipos de CementosDocumento1 paginaTabla de Tipos de CementosHumberto MorenoNessuna valutazione finora

- GlassDocumento4 pagineGlassSan SahirNessuna valutazione finora

- PDVSA lstc-001Documento5 paginePDVSA lstc-00175bm73Nessuna valutazione finora

- Section 321313 - Concrete Paving: Part 1 - GeneralDocumento13 pagineSection 321313 - Concrete Paving: Part 1 - Generalery achjariNessuna valutazione finora

- Max Fajardo Complete 2ndedDocumento153 pagineMax Fajardo Complete 2ndedBenjamin Benicarlo Juanillo IIINessuna valutazione finora

- Chapter 3 Example Set 6Documento6 pagineChapter 3 Example Set 6alaa altaeeNessuna valutazione finora

- Manpower DeploymentDocumento18 pagineManpower DeploymentKrm ChariNessuna valutazione finora

- Alkali-Activated Fly Ash-Slag: ConcreteDocumento17 pagineAlkali-Activated Fly Ash-Slag: ConcreteTushar GuptaNessuna valutazione finora

- Manual For Precast Concrete Construction: by Ananda DevelopmentDocumento1 paginaManual For Precast Concrete Construction: by Ananda DevelopmentThanit ThanadirekNessuna valutazione finora

- Etabs Improtant LearningDocumento322 pagineEtabs Improtant LearningSYED SOHAILNessuna valutazione finora

- 16-Properties of Different Pumice Grades Blended With Cement Ramasamy2017Documento7 pagine16-Properties of Different Pumice Grades Blended With Cement Ramasamy2017afzal taiNessuna valutazione finora

- Chemical Admixtures For Concrete - An OverviewDocumento11 pagineChemical Admixtures For Concrete - An OverviewMoatz HamedNessuna valutazione finora

- CENG 2111 - Course OutlineDocumento2 pagineCENG 2111 - Course OutlinetrfuawlachewNessuna valutazione finora

- Slab 2355Documento1 paginaSlab 2355kevoroyalprinzNessuna valutazione finora

- Jurnal PenelitianDocumento13 pagineJurnal PenelitianAgustiniNessuna valutazione finora

- Adobe Scan 03 Dec 2021Documento4 pagineAdobe Scan 03 Dec 2021RAJKUMAR CHATTERJEE. (RAJA.)Nessuna valutazione finora

- F.QC.22 Checklist Diafragma WallDocumento40 pagineF.QC.22 Checklist Diafragma WallAndre SitumeangNessuna valutazione finora

- University of The East - Manila: BS Civil Engineering On-the-Job Training On-The-Job Training / Practicum Weekly ReportDocumento4 pagineUniversity of The East - Manila: BS Civil Engineering On-the-Job Training On-The-Job Training / Practicum Weekly ReportJoshua TesoroNessuna valutazione finora

- Bond Behaviour of Structural Lightweight Concrete: January 2018Documento10 pagineBond Behaviour of Structural Lightweight Concrete: January 2018SameerKareeeemNessuna valutazione finora

- Quantity Take Off Bored Pile and King PostDocumento4 pagineQuantity Take Off Bored Pile and King PostSANJAY SBNessuna valutazione finora

- Reinforced Concrete One Way Slab DesignDocumento4 pagineReinforced Concrete One Way Slab DesignIzzan SabelloNessuna valutazione finora

- PC I Beams 12Documento6 paginePC I Beams 12Shahbaz ManzoorNessuna valutazione finora

- Mortar Hollow Block: ConcreteDocumento25 pagineMortar Hollow Block: ConcretevabNessuna valutazione finora