Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Canrig torque wrench specifications

Caricato da

aris4silveyraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Canrig torque wrench specifications

Caricato da

aris4silveyraCopyright:

Formati disponibili

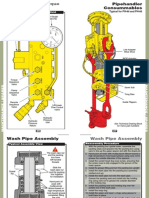

SECTION 3: OPERATING SPECIFICATIONS

Wrench Specifications ..............................................................................................................3-3

Tool Joint Torque Specification Tables.....................................................................................3-4

Revision August 2007 3-1

Canrig Torque-Matic Floor Wrench

3-2 Revision August 2007

Section 3: Operating Specifications

TM-80 SPECIFICATIONS

Arm Carriage

Weight 6000 lbs Weight 5000 lbs

Dimensions Dimensions

Tong Range: 2 7/8” – 8” inches

Make-Up Torque: 0 – 60,000 ft/lbs

Break-Out Torque: 0 – 80,000 ft/lbs

Cycle speed: 17 seconds on a 5-inch drill pipe

Travel: ” retracted to hole-center, 30” vertical

Spinner 4 Roller drive

Roller speed: 100 rpm

Range: 2 7/8” – 11”

Retracts 18 inches from hole center to torque up Kelly bar (Optional)

Control Fully automated PLC control system with joystick manual override

Operator touch screen interface with torque readout

Radio controlled and driller console controlled

Power Pack Hydraulic – nominal 2,500 psi at 60 gpm, peak 5,000 psi

Electric – 480-volt or 600-volt, 3-phase, 60 cycle, 50-horse power TEFC

Proportional control valve with manual override

Safety Specification Electric system lockout, Emergency Shut Down

Function Interlocks

Hydraulic valves – Class 1, Division 1

Electrical enclosures – Class 1, Division 2

Electrical Rating

Operator interface screen – Class 1, Division 2

Optional Class 1, Division 1 for electrical enclosures

Revision August 2007 3-3

Canrig Torque-Matic Floor Wrench

TM-120 SPECIFICATIONS

Arm Carriage

Weight 8000 lbs Weight 7000 lbs

Dimensions Dimensions

Tong Range: 2 7/8” – 11” inches

Make-Up Torque: 0 – 90,000 ft/lbs

Break-Out Torque: 0 – 120,000 ft/lbs

Cycle speed: 17 seconds on a 5-inch drill pipe

Travel: ” retracted to hole-center, 30” vertical

Spinner 4 Roller drive

Roller speed: 100 rpm

Range: 2 7/8” – 11”

Retracts 18 inches from hole centre to torque up Kelly bar (Optional)

Control Fully automated PLC control system with joystick manual override

Operator touch screen interface with torque readout

Radio controlled and driller console controlled

Power Pack Hydraulic – nominal 2,500 psi at 60 gpm, peak 5,000 psi

Electric – 480-volt or 600-volt, 3-phase, 60 cycle, 50-horse power TEFC

Proportional control valve with manual override

Safety Specification Electric system lockout, Emergency Shut Down

Function Interlocks

Hydraulic valves – Class 1, Division 1

Electrical enclosures – Class 1, Division 2

Electrical Rating

Operator interface screen – Class 1, Division 2

Optional Class 1, Division 1 for electrical enclosures

3-4 Revision August 2007

Section 3: Operating Specifications

TOOL JOINT TORQUE SPECIFICATION TABLES

Please consult pipe manufacture for exact torque specifications for each type of pipe.

1

Recommended Make-Up Torque Values For Rotary Shouldered Drill Collar Connections Metric Units - Table 2.1

(See footnotes for use of this table on page 3-7.)

1 2 3 4 5 6 7 8 9 10 11 12 13

Connection Minimum Make-up Torque N/m2

Bore of Drill Collar, millimeters

Size, mm Type OD, mm 25.4 31.8 38.1 44.5 50.8 57.2 63.5 71.4 76.2 95.3

API NC 23 76.20 *3 469 *3 469 * 3 469

79.38 *4 605 *4 605 3 661

82.55 5 532 4 684 3 661

60.33 Regular 76.20 *3 099 *3 099 2 419

79.38 *4 188 3 560 2 419

82.55 4 543 3 560 2 419

73.03 PAC3 76.20 *5 251 *5 251 4 047

79.38 *6 868 5 741 4 047

82.55 7 200 5 741 4 047

60.33 API IF 88.90 *6 370 *6 370 5 113

API NC 26 95.25 7 608 6 456 5 113

73.03 Regular 88.90 *5 308 *5 308 *5 308

95.25 7 974 6 847 5 535

98.43 7 974 6 847 5 535

73.03 Slim Hole

73.03 Extra Hole 95.25 *5 655 *5 655 *5 655

88.90 Dbl. Streamline 98.43 *7 402 *7 402 *7 402

73.03 Mod. Open 104.78 *11 146 *11 146 10 280

73.03 API IF 98.43 *6 417 *6 417 *6 417 *6 417

API NC 31 104.78 *10 220 *10 220 *10 220 9 478

88.90 Regular 104.78 *8 942 *8 942 *8 942 *8 942 7 862

107.95 *10 906 *10 906 *10 906 9 840 7 862

114.30 14 481 13 158 11 609 9 840 7 862

88.90 Slim Hole 107.95 *12 251 *12 251 11 287 9 478 7 456

114.30 14 226 12 872 11 287 9 478 7 456

API NC 35 114.30 *12 500 *12 500 *12 500 10 249

120.65 16 974 14 972 12 726 10 249

127.00 16 974 14 972 12 726 10 249

88.90 Extra Hole 107.95 *7 138 *7 138 *7 138 7 138

101.60 Slim Hole 114.30 *11 726 *11 726 *11 726 11 494

88.90 Mod. Open 120.65 *16 698 16 324 14 029 11 494

127.00 18 370 16 324 14 029 11 494

133.35 18 370 16 324 14 029 11 494

88.90 API IF 120.65 *13 811 *13 811 *13 811 *13 811 11 500

API NC 38 127.00 *19 291 *19 291 17 850 15 181 11 500

114.30 Slim Hole 133.35 22 414 20 251 17 850 15 181 11 500

139.70 22 414 20 251 17 850 15 181 11 500

88.90 H-904 120.65 *12 151 *12 151 *12 151 *12 151 *12 151

127.00 *17 694 *17 694 *17 694 *17 694 14 394

133.35 23 641 23 413 20 934 18 188 14 394

139.70 25 616 23 413 20 934 18 188 14 394

101.60 Full Hole 127.00 *15 089 *15 089 *15 089 *15 089 *15 089

API NC 40 133.35 *21 146 *21 146 *21 146 20 702 16 769

101.60 Mod. Open 139.70 27 639 26 119 23 550 20 702 16 769

114.30 Dbl. Streamline 146.05 28 405 26 119 23 550 20 702 16 769

152.40 28 405 26 119 23 550 20 702 16 769

H-904 133.35 *17 412 *17 412 *17 412 *17 412 *17 412

139.70 *24 066 *24 066 *24 066 *24 066 22 869

146.05 *31 160 *31 160 30 030 27 028 22 869

152.40 35 139 32 737 30 030 27 028 22 869

158.75 35 139 32 737 30 030 27 028 22 869

114.30 API Regular 139.70 *21 542 *21 542 *21 542 *21 542 *21 542

146.05 *28 502 *28 502 *28 502 27 108 22 998

152.40 35 138 32 758 30 079 27 108 22 998

158.75 35 138 32 758 30 079 27 108 22 998

API NC 44 146.05 *28 898 *28 898 *28 898 *28 898 25 117

152.40 *36 584 35 280 32 491 29 398 25 117

158.75 37 756 35 280 32 491 29 398 25 117

165.10 37 756 35 280 32 491 29 398 25 117

114.30 API Full Hole 139.70 *17 942 *17 942 *17 942 *17 942 *17 942

146.05 *25 059 *25 059 *25 059 *25 059 24 756

152.40 *32 646 *32 646 30 465 27 551 24 756

158.75 37 748 34 951 30 465 27 551 24 756

165.10 37 748 34 951 30 465 27 551 24 756

(Continues on following page.)

Revision August 2007 3-5

Canrig Torque-Matic Floor Wrench

1

Recommended Make-Up Torque Values For Rotary Shouldered Drill Collar Connections Metric Units - Table 2.1

(Continued from previous page. See footnotes for use of this table on page 3-7.)

1 2 3 4 5 6 7 8 9 10

Connection Minimum Make-up Torque N/m2

Bore of Drill Collar, millimeters

Size, mm Type OD, mm 57.2 63.5 71.4 76.2 82.6 88.9 95.3

114.30 Extra Hole 146.05 *24 532 *24 532 *24 532 *24 532

API NC 46 152.40 *32 393 *32 393 31 015 28 090

101.60 API IF 158.75 38 753 35 510 31 015 28 090

114.30 Semi IF 165.10 38 753 35 510 31 015 28 090

127.00 Dbl. Streamline 171.45 38 753 35 510 31 015 28 090

114.30 Mod. Open

114.30 H-904 146.05 *24 920 *24 920 *24 920 *24 920

152.40 *32 751 *32 751 32 029 29 114

158.75 39 736 36 507 32 029 29 114

165.10 39 736 36 507 32 029 29 114

171.45 39 736 36 507 32 029 29 114

127.00 H-904 158.75 *35 073 *35 073 *35 073 *35 073 33 175

165.10 *44 111 *44 111 40 660 37 572 33 175

171.45 48 809 45 397 40 660 37 572 33 175

177.80 48 809 45 397 40 660 37 572 33 175

114.30 API IF 158.75 *31 815 *31 815 *31 815 *31 815 *31 815

API NC 50 165.10 *41 046 *41 046 *41 046 *41 046 36 892

127.00 Extra Hole 171.45 *50 814 49 545 44 639 41 443 36 892

127.00 Mod. Open 177.80 53 078 49 545 44 639 41 443 36 892

139.70 Dbl. Streamline 184.15 53 078 49 545 44 639 41 443 36 892

127.00 Semi IF 190.50 53 078 49 545 44 639 41 453 36 892

139.70 H-904 171.45 *47 725 *47 725 *47 725 47 218 42 570

177.80 *58 076 55 482 50 481 47 218 42 570

184.15 59 080 55 482 50 481 47 218 42 570

190.50 59 080 55 482 50 481 47 218 42 570

139.70 API Regular 171.45 *44 174 *44 174 *44 174 *44 174 42 175

177.80 *54 516 *54 516 50 113 46 839 42 175

184.15 58 751 55 135 50 113 46 839 42 175

190.50 58 751 55 135 50 113 46 839 42 175

139.70 API Full Hole 177.80 *45 310 *45 310 *45 310 *45 310 *45 310

184.15 *56 700 *56 700 *56 700 *56 700 *56 700

190.50 *68 681 *68 681 66 047 62 498 57 440

196.85 75 394 71 483 66 047 62 498 57 440

API NC 56 184.15 *56 009 *56 009 *56 009 *56 009

190.50 *67 850 66 690 63 175 58 166

196.85 72 075 66 690 63 175 58 166

203.20 72 075 66 690 63 175 58 166

168.28 API Regular 190.50 *64 170 *64 170 *64 170 *64 170

196.85 *76 932 73 778 70 124 64 912

203.20 79 375 73 778 70 124 64 912

209.55 79 375 73 778 70 124 64 912

168.28 H-904 190.50 *64 322 *64 322 *64 322 *64 322

196.85 *77 044 *77 044 74 169 68 949

203.20 83 424 77 826 74 169 68 949

209.55 83 424 77 826 74 169 68 949

API NC 61 203.20 *76 246 *76 246 *76 246 *76 246

209.55 *90 501 *90 501 *90 501 85 226

215.90 100 503 94 594 90 734 85 226

222.25 100 503 94 594 90 734 85 226

228.60 100 503 94 594 90 734 85 226

139.70 API IF 203.20 *78 335 *78 335 *78 335 *78 335 *78 335

209.55 *92 845 *92 845 *92 845 87 656 81 634

215.90 103 208 97 193 93 264 87 656 81 634

222.25 103 208 97 193 93 264 87 656 81 634

228.60 103 208 97 193 93 264 87 656 81 634

234.95 103 208 97 193 93 264 87 656 81 634

168.28 API Full Hole 215.90 *93 752 *93 752 *93 752 *93 752 *93 752 92 915

222.25 *110 009 *110 009 *110 009 106 084 99 717 92 915

228.60 122 509 116 161 112 011 106 084 99 717 92 915

234.95 122 509 116 161 112 011 106 084 99 717 92 915

241.30 122 509 116 161 112 011 106 084 99 717 92 915

API NC 70 228.60 *104 805 *104 805 *104 805 *104 805 *104 805 *104 805

234.95 *122 813 *122 813 *122 813 *122 813 *122 813 *122 813

241.30 141 556 141 556 141 556 139 831 133 064 125 831

247.65 157 261 150 527 146 124 139 831 133 064 125 831

254.00 157 261 150 527 146 124 139 831 133 064 125 831

260.35 157 261 150 527 146 124 139 831 133 064 125 831

API NC 77 254.00 *149 632 *149 632 *149 632 *149 632 *149 632 *149 632

260.35 *171 563 *171 563 *171 563 *171 563 *171 563 *171 563

266.70 194 299 194 299 194 299 194 295 186 870 178 926

273.05 213 393 206 019 201 193 194 295 186 870 178 926

279.40 213 393 206 019 201 193 194 295 186 870 178 926

177.80 H-904 203.20 *73 927 *73 927 *73 927 *73 927 *73 927 *73 927

209.55 *88 150 *88 150 *88 150 *88 150 84 323 77 976

215.90 *103 003 99 667 95 793 90 264 84 323 77 976

(Continues on following page.)

3-6 Revision August 2007

Section 3: Operating Specifications

1

Recommended Make-Up Torque Values For Rotary Shouldered Drill Collar Connections

Metric Units - Table 2.1

(Continued from previous page. See footnotes for use of this table.)

1 2 3 4 5 6 7 8 9 10

Connection Minimum Make-up Torque N/m2

Bore of Drill Collar, millimeters

Size, mm Type OD, mm 57.2 63.5 71.4 76.2 82.5 88.9 95.3

193.68 API Regular 215.90 *83 536 *83 536 *83 536 *83 536 *83 536 *83 536

222.25 *99 810 *99 810 *99 810 *99 810 *99 810 *99 810

228.60 *116 783 *116 783 *116 783 116 478 109 998 103 074

234.95 133 184 126 728 122 506 116 478 109 998 103 074

241.30 133 184 126 728 122 506 116 478 109 998 103 074

193.68 H-904 228.60 *100 983 *100 983 *100 983 *100 983 *100 983 *100 983

234.95 *118 946 *118 946 *118 946 *118 946 *118 946 *118 946

241.30 *137 620 *137 620 *137 620 *137 620 *137 620 133 162

219.08 API Regular 254.00 *151 224 *151 224 *151 224 *151 224 *151 224 *151 224

260.35 *173 239 *173 239 *173 239 *173 239 *173 239 172 922

266.70 *196 064 *196 064 195 188 188 290 180 865 172 922

219.08 H-904 260.35 *156 946 *156 946 *156 946 *156 946 *156 946 *156 946

266.70 *179 877 *179 877 *179 877 *179 877 *179 877 *179 877

177.80 H-904 222.25 *94 128 *94 128 93 016 86 915 80 395

(with low torque face) 228.60 102 667 98 692 93 016 86 915 80 395

193.68 API Regular 234.95 *101 096 *101 096 *101 096 *101 096

(with low torque face) 241.30 *119 578 *119 578 114 038 106 891

247.65 126 944 120 725 114 038 106 891

254.00 126 944 120 725 114 038 106 891

193.68 H-904 247.65 *126 775 *126 775 *126 775 *126 775 *126 775

(with low torque face) 254.00 *146 958 *146 958 *146 958 144 068 136 646

260.35 161 966 157 456 151 007 144 068 136 646

266.70 161 966 157 456 151 007 144 068 136 646

219.08 API Regular 273.05 *156 117 *156 117 *156 117 *156 117

(with low torque face) 279.40 *180 719 *180 719 *180 719 *180 719

285.75 204 153 196 981 189 258 180 995

219.08 H-904 273.05 *128 564 *128 564 *128 564 *128 564

(with low torque face) 279.40 *153 210 *153 210 *153 210 *153 210

285.75 *178 688 *178 688 *178 688 *178 688

Notes:

• Torque figures preceded by an asterisk (*) indicate that the weaker member for the corresponding outside diameter (OD) and bore

is the BOX. For all other torque values the weaker member is the PIN.

• In each connection size and type group, torque values apply to all connection types in this group, when used with the same drill

collar OD and bore, i.e. 2 3/8 API IF, API NC26 and 2 7/8 Slim Hole connections used with 3 1/2 X 1 1.4 drill collars all have the

same minimum make-up torque of 4600 ft-lb, and the BOX is the weaker member.

• Stress relief features are disregarded for make-up torque.

1

Basis of calculations for recommended make-up torque assumed the use of a thread compound containing 40-60% by weight of finely

powdered metallic zinc or 60% by weight of finely powdered metallic lead, with not more than 0.3% total active sulfur (Reference the

caution below.) applied thoroughly to all threads and shoulders.

2

Normal torque range is tabulated value plus 10%. Higher torque values may be used in extreme conditions.

3

Make-up torque for 2 7/8 PAC connection is based on 87 500 psi stress and other factors listed in footnote 1.

4

Make-up torque for H-90 connection is based on 56 200 psi stress and other factor listed in footnote 1.

CAUTION: Thread compounds made according to API Bul 5A2 will produce excess make-up

and are not recommended for use on rotary shouldered connections.

This information has been duplicated in its entirety from API RP 7G Table 14 and API Spec. 7, Appendix F

and is current as of the publication of this Manual. However, it is likely that the data will be updated several

times during the life of a Top Drive unit. Consult API Recommended Practices or IADC Drilling Manual to be

certain that this information is current.

Revision August 2007 3-7

Canrig Torque-Matic Floor Wrench

1

Recommended Make-Up Torque Values For Rotary Shouldered Drill Collars Imperial Units - Table 2.2

(See footnotes for use of this table on Page 3-10.)

1 2 3 4 5 6 7 8 9 10 11 12 13

Connection Minimum Make-up Torque ft-lb2

Bore of Drill Collar, inches

Size, in. Type OD, in. 1 1 1/4 1 1/2 1 3/4 2 2 1/4 2 1/2 2 13/16 3 3 3/4

API NC 23 3 *2 508 *2 508 *2 508

3 1/8 *3 330 *3 330 2 647

3 1/4 4 000 3 387 2 647

2 3/8 Regular 3 *2 241 *2 241 1 749

3 1/8 *3 028 2 574 1 749

3 1/4 3 285 2 574 1 749

2 7/8 PAC3 3 *3 797 *3 797 2 926

3 1/8 *4 966 4 151 2 926

3 1/4 5 206 4 151 2 926

2 3/8 API IF 3 1/2 *4 606 *4 606 3 697

API NC 26 3 3/4 5 501 4 668 3 697

2 7/8 Regular 3 1/2 *3 838 *3 838 *3 838

3 3/4 5 766 4 951 4 002

3 7/8 5 766 4 951 4 002

2 7/8 Slim Hole

2 7/8 Extra Hole 3 3/4 *4 089 *4 089 *4 089

3 1/2 Dbl. Streamline 3 7/8 *5 352 *5 352 *5 352

2 7/8 Mod. Open 4 1/8 *8 059 *8 059 7 433

2 7/8 API IF 3 7/8 *4 640 *4 640 *4 640 *4 640

API NC 31 4 1/8 *7 390 *7 390 *7 390 6 853

3 1/2 Regular 4 1/8 *6 466 *6 466 *6 466 *6 466 5 685

4 1/4 *7 886 *7 886 *7 886 7 115 5 685

4 1/2 10 471 9 514 8 394 7 115 5 685

3 1/2 Slim Hole 4 1/4 *8 858 *8 858 8 161 6 853 5 391

4 1/2 10 286 9 307 8 161 6 853 5 391

API NC 35 4 1/2 *9 038 *9 038 *9 038 7 411

4 3/4 12 273 10 826 9 202 7 411

5 12 273 10 826 9 202 7 411

3 1/2 Extra Hole 4 1/4 *5 161 *5 161 *5 161 *5 161

4 Slim Hole 4 1/2 *8 479 *8 479 *8 479 8 311

3 1/2 Mod. Open 4 3/4 *12 074 11 803 10 144 8 311

5 13 283 11 803 10 144 8 311

5 1/4 13 283 11 803 10 144 8 311

3 1/2 API IF 4 3/4 *9 986 *9 986 *9 986 *9 986 8 315

API NC 38 5 *13 949 *13 949 12 907 10 977 8 315

4 1/2 Slim Hole 5 1/4 16 207 14 643 12 907 10 977 8 315

5 1/2 16 207 14 643 12 907 10 977 8 315

3 1/2 H-904 4 3/4 *8 786 *8 786 *8 786 *8 786 *8 786

5 *12 794 *12 794 *12 794 *12 794 10 408

5 1/4 *17 094 16 929 15 137 13 151 10 408

5 1/2 18 522 16 929 15 137 13 151 10 408

4 Full Hole 5 *10 910 *10 910 *10 910 *10 910 *10 910

API NC 40 5 1/4 *15 290 *15 290 *15 290 14 969 12 125

4 Mod. Open 5 1/2 *19 985 18 886 17 028 14 969 12 125

4 1/2 Dbl. Streamline 5 3/4 20 539 18 886 17 028 14 969 12 125

6 20 539 18 886 17 028 14 969 12 125

H-904 5 1/4 *12 590 *12 590 *12 590 *12 590 *12 590

5 1/2 *17 401 *17 401 *17 401 *17 401 16 536

5 3/4 *22 531 *22 531 21 714 19 543 16 536

6 25 408 23 671 21 714 19 543 16 536

6 1/4 25 408 23 671 21 714 19 543 16 536

4 1/2 API Regular 5 1/2 *15 576 *15 576 *15 576 *15 576 *15 576

5 3/4 *20 609 *20 609 *20 609 19 601 16 629

6 25 407 23 686 21 749 19 601 16 629

6 1/4 25 407 23 686 21 749 19 601 16 629

API NC 44 5 3/4 *20 895 *20 895 *20 895 *20 895 18 161

6 *26 453 25 510 23 493 21 257 18 161

6 1/4 27 300 25 510 23 493 21 257 18 161

6 1/2 27 300 25 510 23 493 21 257 18 161

4 1/2 API Full Hole 5 1/2 *12 973 *12 973 *12 973 *12 973 *12 973

5 3/4 *18 119 *18 119 *18 119 *18 119 17 900

6 *23 605 *23 605 23 028 19 921 17 900

6 1/4 27 294 25 272 22 028 19 921 17 900

6 1/2 27 294 25 272 22 028 19 921 17 900

(Continues on following page.)

3-8 Revision August 2007

Section 3: Operating Specifications

Recommended Make-Up Torque1 Values For Rotary Shouldered Drill Collars Imperial Units - Table 2.2

(Continued from previous page. See footnotes for use of this table on Page 3-10.)

1 2 3 4 5 6 7 8 9 10

Connection Minimum Make-up Torque ft-lb2

Bore of Drill Collar, inches

Size, in. Type OD, in. 2 1/4 2 1/2 2 13/16 3 3 1/4 3 1/2 3 3/4

4 1/2 Extra Hole 5 3/4 *17 738 *17 738 *17 738 *17 738

API NC 46 6 *23 422 *23 422 22 426 20 311

4 API IF 6 1/4 28 021 25 676 22 426 20 311

4 1/2 Semi IF 6 1/2 28 021 25 676 22 426 20 311

5 Dbl. Streamline 6 3/4 28 021 25 676 22 426 20 311

4 1/2 Mod. Open

4 1/2 H-904 5 3/4 *18 019 *18 019 *18 019 *18 019

6 *23 681 *23 681 23 159 21 051

6 1/4 28 732 26 397 23 159 21 051

6 1/2 28 732 26 397 23 159 21 051

6 3/4 28 732 26 397 23 159 21 051

5 H-904 6 1/4 *25 360 *25 360 *25 360 *25 360 23 988

6 1/2 *31 895 *31 895 29 400 27 167 23 988

6 3/4 35 292 32 825 29 400 27 167 23 988

7 35 292 32 825 29 400 27 167 23 988

4 1/2 API IF 6 1/4 *23 004 *23 004 *23 004 *23 004 *23 004

API NC 50 6 1/2 *29 679 *29 679 *29 679 *29 679 26 675

5 Extra Hole 6 3/4 *36 742 35 824 32 277 29 966 26 675

5 Mod. Open 7 38 379 35 824 32 277 29 966 26 675

5 1/2 Dbl. Streamline 7 1/4 38 379 35 824 32 277 29 966 26 675

5 Semi IF 7 1/2 38 379 35 824 32 277 29 973 26 675

4

5 1/2 H-90 6 3/4 *34 508 *34 508 *34 508 34 142 30 781

7 *41 993 40 117 36 501 34 142 30 781

7 1/4 42 719 40 117 36 501 34 142 30 781

7 1/2 42 719 40 117 36 501 34 142 30 781

5 1/2 API Regular 6 3/4 *31 941 *31 941 *31 941 *31 941 30 495

7 *39 419 *39 419 36 235 33 868 30 495

7 1/4 42 481 39 866 36 235 33 868 30 495

7 1/2 42 481 39 866 36 235 33 868 30 495

5 1/2 API Full Hole 7 *32 762 *32 762 *32 762 *32 762 *32 762

7 1/4 *40 998 *40 998 *40 998 *40 998 *40 998

7 1/2 *49 661 *49 661 47 756 45 190 41 533

7 3/4 54 515 51 687 47 756 45 190 41 533

API NC 56 7 1/4/ *40 498 *40 498 *40 498 *40 498

7 1/2 *49 060 48 221 45 680 42 058

7 3/4 52 115 48 221 45 680 42 058

8 52 115 48 221 45 680 42 058

6 5/8 API Regular 7 1/2 *46 399 *46 399 *46 399 *46 399

7 3/4 *55 627 53 346 50 704 46 936

8 57 393 53 346 50 704 46 936

8 1/4 57 393 53 346 50 704 46 936

6 5/8 H-904 7 1/2 *46 509 *46 509 *46 509 *46 509

7 3/4 *55 708 *55 708 53 629 49 855

8 60 321 56 273 53 629 49 855

8 1/4 60 321 56 273 53 629 49 855

API NC61 8 *55 131 *55 131 *55 131 *55 131

8 1/4 *65 438 *65 438 *65 438 61 624

8 1/2 72 670 68 398 65 607 61 624

8 3/4 72 670 68 398 65 607 61 624

9 72 670 68 398 65 607 61 624

5 1/2 API IF 8 *56 641 *56 641 *56 641 *56 641 *56 641

8 1/4 *67 133 *67 133 *67 133 63 381 59 027

8 1/2 74 626 70 277 67436 63 381 59 027

8 3/4 74 626 70 277 67436 63 381 59 027

9 74 626 70 277 67436 63 381 59 027

9 1/4 74 626 70 277 67436 63 381 59 027

6 5/8 API Full Hole 8 1/2 *67 789 *67 789 *67 789 *67 789 *67 789 67 184

8 3/4 *79 544 *79 544 *79 544 76 706 72 102 67 184

9 88 582 83 992 80 991 76 706 72 102 67 184

9 1/4 88 582 83 992 80 991 76 706 72 102 67 184

9 1/2 88 582 83 992 80 991 76 706 72 102 67 184

API NC 70 9 *75 781 *75 781 *75 781 *75 781 *75 781 *75 781

9 1/4 *88 802 *88 802 *88 802 *88 802 *88 802 *88 802

9 1/2 *102 354 *102 354 *102 354 101 107 96 214 90 984

9 3/4 113 710 108 841 105 657 101 107 96 214 90 984

10 113 710 108 841 105 657 101 107 96 214 90 984

10 1/4 113 710 108 841 105 657 101 107 96 214 90 984

API NC77 10 *108 194 *108 194 *108 194 *108 194 *108 194 *108 194

10 1/4 *124 051 *124 051 *124 051 *124 051 *124 051 *124 051

10 1/2 *140 491 *140 491 *140 491 140 488 135 119 129 375

10 3/4 154 297 148 965 145 476 140 488 135 119 129 375

11 154 297 148 965 145 476 140 488 135 119 129 375

7 H-904 8 *53 454 *53 454 *53 454 *53 454 *53 454 *53 454

8 1/4 *63 738 *63 738 *63 738 *63 738 60 971 56 382

8 1/2 *74 478 72 066 69 265 65 267 60 971 56 382

(Continues on following page.)

Revision August 2007 3-9

Canrig Torque-Matic Floor Wrench

1

Recommended Make-Up Torque Values For Rotary Shouldered Drill CollarsImperial Units - Table 2.2

(Continued from previous page. See footnotes for use of this table.)

1 2 3 4 5 6 7 8 9 10

Connection Minimum Make-up Torque ft-lb2

Bore of Drill Collar, inches

Size, in. Type OD, in. 2 1/4 2 1/2 2 13/16 3 3 1/4 3 1/2 3 3/4

7 5/8 API Regular 8 1/2 *60 402 *60 402 *60 402 *60 402 *60 402 *60 402

8 3/4 *72 169 *72 169 *72 169 *72 169 *72 169 *72 169

9 *84 442 *84 442 *84 442 84 221 79 536 74 529

9 1/4 96 301 91 633 88 580 84 221 79 536 74 529

9 1/2 96 301 91 633 88 580 84 221 79 536 74 529

7 5/8 H-904 9 *73 017 *73 017 *73 017 *73 017 *73 017 *73 017

9 1/4 *86 006 *86 006 *86 006 *86 006 *86 006 *86 006

9 1/2 *99 508 *99 508 *99 508 *99 508 *99 508 96 285

8 5/8 API Regular 10 *109 345 *109 345 *109 345 *109 345 *109 345 *109 345

10 1/4 *125 263 *125 263 *125 263 *125 263 *125 263 125 034

10 1/2 *141 767 *141 767 141 134 136 146 130 777 125 034

8 5/8 H-904 10 1/4 *113 482 *113 482 *113 482 *113 482 *113 482 *113 482

10 1/2 *130 063 *130 063 *130 063 *130 063 *130 063 *130 063

4

7 H-90 8 3/4 *68 061 *68 061 67 257 62 845 58 131

(with low torque face) 9 74 235 71 361 67 257 62 845 58 131

7 5/8 API Regular 9 1/4 *73 099 *73 099 *73 099 *73 099

(with low torque face) 9 1/2 *86 463 *86 463 82 457 77 289

9 3/4 91 789 87 292 82 457 77 289

10 91 789 87 292 82 457 77 289

7 5/8 H-904 9 3/4 *91 667 *91 667 *91 667 *91 667 *91 667

(with low torque face) 10 *106 260 *106 260 *106 260 104 171 98 804

10 1/4 117 112 113 851 109188 104 171 98 804

10 1/2 117 112 113 851 109188 104 171 98 804

8 5/8 API Regular 10 3/4 *112 883 *112 883 *112 883 *112 883

(with low torque face) 11 *130 672 *130 672 *130 672 *130 672

11 1/4 147 616 142 430 136 846 130 871

8 5/8 H-904 10 3/4 *92 960 *92 960 *92 960 *92 960

(with low torque face) 11 *110 781 *110 781 *110 781 *110 781

11 1/4 *129 203 *129 203 *129 203 *129 203

Notes:

• Torque figures preceded by an asterisk (*) indicate that the weaker member for the corresponding outside diameter (OD) and bore

is the BOX. For all other torque values the weaker member is the PIN.

• In each connection size and type group, torque values apply to all connection types in this group, when used with the same drill

collar OD and bore, i.e. 2 3/8 API IF, API NC26 and 2 7/8 Slim Hole connections used with 3 1/2 X 1 1.4 drill collars all have the

same minimum make-up torque of 4600 ft-lb, and the BOX is the weaker member.

• Stress relief features are disregarded for make-up torque.

1

Basis of calculations for recommended make-up torque assumed the use of a thread compound containing 40-60% by weight of finely

powdered metallic zinc or 60% by weight of finely powdered metallic lead, with not more than 0.3% total active sulfur (Reference the

caution below.) applied thoroughly to all threads and shoulders.

2

Normal torque range is tabulated value plus 10%. Higher torque values may be used in extreme conditions.

3

Make-up torque for 2 7/8 PAC connection is based on 87 500 psi stress and other factors listed in footnote 1.

4

Make-up torque for H-90 connection is based on 56 200 psi stress and other factor listed in footnote 1.

CAUTION: Thread compounds made according to API Bul 5A2 will produce excess make-up

and are not recommended for use on rotary shouldered connections.

This information has been duplicated in its entirety from API RP 7G Table 14 and API Spec7, Appendix F

and is current as of the publication of this Manual. However, it is likely that the data will be updated several

times during the life of a Top Drive unit. Consult API Recommended Practices or IADC Drilling Manual to be

certain that this information is current.

3-10 Revision August 2007

Section 3: Operating Specifications

Recommended Minimum OD* and Make-Up Torque of Weld-On Type Tool Joints by Class Metric Units - Table 2.3

(See footnotes for use of this table on page 3-13.)

1 2 3 4 5 6 7 8 9 10 11 12 13

Drill Pipe New Tool Joint Data Premium Class Class 2

Nom NomWt. Type Connection New OD New ID Make-up Min OD Min Box Make-up Min OD Min Box Make-up

Size, Kg/m Upset mm mm Torque6 Tool Joint Shoulder Torque for Tool Joint Shoulder Torque for

mm and mm mm. with Min OD mm with Min OD

Grade Eccentric Tool Joint Eccentric Tool Joint

Wear N-m Wear N-m

mm mm

60.33 0.67 EU 75 NC 26 85.73 44.45 5,705 B 79.38 1.19 2,690 78.58 0.79 2,336

0.67 EU 75 W.O. 85.73 50.80 3,576 P 77.79 1.59 2,758 76.99 1.19 2,415

0.67 EU 75 2 3/8 ONLW 79.38 50.80 3,752 P 76.20 1.59 2,531 75.41 1.19 2,198

0.67 EU 75 2 3/8 SL-H90 82.55 50.80 4,251 P 75.41 1.59 2,760 74.61 1.19 2,387

60.33 0.92 IU 75 2 3/8 PAC2 73.03 34.93 3,890 P 70.64 3.57 3,395 69.06 2.78 2,842

0.92 EU 75 NC 26 85.73 44.45 5,705 B 80.96 1.98 3,412 80.17 1.59 3,048

0.92 EU 75 2 3/8 SL-H90 82.55 50.80 4,251 P 76.99 2.38 3,525 75.41 1.59 2,760

0.92 EU 75 2 3/8 OHSW 82.55 44.45 5,381 B 77.79 2.38 3,214 76.99 1.98 2,870

60.33 0.92 EU 95 NC 26 85.73 44.45 5,705 B 82.55 2.78 4,156 81.76 2.38 3,781

2

60.33 0.92 EU 105 NC 26 85.73 44.45 5,705 B 83.34 3.18 4,535 82.55 2.78 4,156

73.03 0.95 EU 75 NC 31 104.78 53.98 9,850 P 93.66 1.98 4,362 254.79 1.59 3,878

0.95 EU 75 2 7/8 WO 104.78 61.91 5,972 P 92.08 1.98 4,448 91.28 1.59 3,978

0.95 EU 75 2 7/8 OHLW 2 95.25 61.91 4,634 P 88.90 2.78 4,560 87.31 1.98 3,687

0.95 EU 75 2 7/8 SL-H90 98.43 61.91 6,327 P 88.90 2.38 4,698 87.31 1.59 3,687

73.03 1.44 EU 75 NC 31 104.78 53.98 9,850 P 96.84 3.57 6,358 95.25 2.78 5,348

1.44 IU 75 2 7/8 XH 107.95 47.63 11,021 P 94.46 3.57 6,026 92.87 2.78 5,067

1.44 IU 75 NC 262 85.73 44.45 5,705 B 85.73 4.37 5,705 84.93 3.97 5,309

1.44 EU 75 2 7/8 OHSW 2 98.43 54.77 7,288 P 91.28 3.97 5,910 90.49 2.78 5,450

1.44 EU 75 2 7/8 SL-H90 98.43 54.77 9,367 P 91.28 3.57 6,264 89.69 2.78 5,214

1.44 IU 75 2 7/8 PAC2 79.38 38.10 4,756 P 79.38 5.95 4,756 79.38 5.95 4,756

73.03 1.44 EU 95 NC 31 104.78 50.80 10,951 P 99.22 4.76 7,919 97.63 3.97 6,872

1.44 EU 95 2 7/8 SL-H902 98.43 54.77 9,367 P 93.66 4.76 7,886 92.08 3.97 6,797

73.03 1.44 EU 105 NC 31 104.78 50.80 10,951 P 100.01 5.16 8,450 98.43 4.37 7,392

73.03 1.44 EU 135 NC 31 111.13 41.28 14,061 P 103.19 6.75 10,641 101.60 5.95 9,533

88.90 1.31 EU 75 NC 38 120.65 76.20 10,633 P 111.92 3.18 7,984 110.33 2.38 6,634

1.31 EU 75 NC 38 120.65 68.26 15,025 P 111.92 3.18 7,984 110.33 2.38 6,634

1.31 EU 75 3 1/2 OHLW 120.65 76.20 9,982 P 108.74 3.18 7,385 107.95 2.78 6,732

1.31 EU 75 3 1/2 SL-H90 117.48 76.20 10,489 P 106.36 2.78 7,636 105.57 2.38 6,919

88.90 1.84 EU 75 NC 38 120.65 68.26 15,025 P 114.30 4.37 10,060 112.71 3.57 8,669

1.84 IU 75 NC 312 104.78 53.98 9,850 P 101.60 5.95 9,533 100.01 5.16 8,450

1.84 EU 75 3 1/2 OHSW 120.65 68.26 14,365 P 111.92 4.76 10,065 110.33 3.97 8,712

1.84 EU 75 3 1/2 H90 133.35 69.85 19,777 P 115.09 3.18 9,770 114.30 2.78 8,972

1.84 EU 95 NC 38 127.00 65.09 16,867 P 116.68 5.56 12,201 115.09 4.76 10,767

1.84 EU 95 3 1/2 SL-H902 117.48 68.26 15,402 P 111.13 5.16 12,090 109.54 4.37 10,576

1.84 EU 95 3 1/2 H90 133.35 69.85 19,777 P 117.48 4.37 12,206 115.89 3.57 10,574

88.90 1.84 EU 105 NC 38 127.00 61.91 18,433 P 118.27 6.35 13,663 116.68 5.56 12,201

88.90 1.84 EU 135 NC 40 136.53 61.91 24,836 P 127.00 7.14 17,383 124.62 5.95 14,892

1.84 EU 135 NC 38 127.00 53.98 22,002 P 122.24 8.33 17,445 119.86 7.14 15,155

88.90 2.14 EU 75 NC 38 127.00 65.09 16,867 P 115.09 4.76 10,767 113.51 3.97 9,362

88.90 2.14 EU 95 NC 38 127.00 61.91 18,433 P 118.27 6.35 13,663 116.68 5.56 12,201

88.90 2.14 EU 105 NC 38 127.00 53.98 22,002 P 119.86 7.14 15,154 117.48 5.95 12,928

2.14 EU 105 NC 40 133.35 65.09 23,035 P 125.41 6.35 15,715 123.03 5.16 13,270

88.90 2.14 EU 135 NC 40 139.70 57.15 27,336 P 129.38 8.33 19,941 126.21 6.75 16,545

101.60 1.64 EU 75 NC 46 152.40 82.55 27,902 P 132.56 2.78 10,847 130.97 1.98 8,956

1.64 EU 75 4 WO 146.05 87.31 23,905 P 132.56 2.78 10,847 130.97 1.98 8,956

1.64 EU 75 4 OHLW 133.35 88.11 18,236 P 127.00 3.57 10,879 125.41 2.78 9,118

1.64 IU 75 4 H90 139.70 71.44 29,353 P 123.83 2.78 10,552 123.03 2.38 9,628

(Continues on following page.)

Revision August 2007 3-11

Canrig Torque-Matic Floor Wrench

Recommended Minimum OD and Make-Up Torque of Weld-On Type Tool Joints by Class

Metric Units - Table 2.3

(Continued from previous page. See footnotes for use of this table on page 3-13.)

1 2 3 4 5 6 7 8 9 10 11 12 13

Drill Pipe New Tool Joint Data Premium Class Class 2

Nom Size NomWt. Type Connection New OD New ID Make-up Min OD Min Box Make-up Min OD Min Box Make-up

mm. Kg/m Upset mm mm Torque6 Tool Joint Shoulder Torque for Tool Joint Shoulder Torque for

and mm mm. with Min OD mm with Min OD

Grade Eccentric Tool Joint Eccentric Tool Joint

Wear N-m Wear N-m

mm mm

101.60 1.94 IU 75 NC 40 133.35 71.44 19,489 P 122.24 4.76 12,471 120.65 3.97 10,894

1.94 EU 75 NC 46 152.40 82.55 27,902 P 134.14 3.57 12,769 132.56 2.78 10,847

1.94 IU 75 4 SH2 117.48 71.44 12,588 P 112.71 5.95 12,146 111.13 5.16 10,811

1.94 EU 75 4 OHSW 139.70 0.00 22,571 P 128.59 4.37 12,628 127.00 3.57 10,841

1.94 IU 75 4 H90 139.70 76.20 29,353 P 125.41 3.57 12,428 123.83 2.78 10,552

101.60 1.94 IU 95 NC40 139.70 68.26 21,304 P 125.41 6.35 15,715 123.03 5.16 13,270

1.94 EU 95 NC 46 152.40 82.55 27,902 P 136.53 4.76 15,715 134.94 3.97 13,743

1.94 IU 95 4 H90 139.70 71.44 29,353 P 127.79 4.76 15,303 126.21 3.97 13,378

101.60 1.94 IU 105 NC40 133.35 61.91 24,988 P 127.00 7.14 17,383 124.62 5.95 14,892

1.94 EU 105 NC 46 152.40 82.55 27,902 P 138.11 5.56 17,720 135.73 4.37 14,725

1.94 IU 105 4 H90 139.70 71.44 29,353 P 129.38 5.56 17,261 127.79 4.76 15,303

101.60 1.94 EU 135 NC 46 152.40 76.20 32,553 P 141.29 7.14 21,833 139.70 6.35 19,760

101.60 2.17 IU 75 NC40 133.35 68.26 21,304 P 123.83 5.56 14,078 121.44 4.37 11,678

2.17 EU 75 NC 46 152.40 82.55 27,902 P 134.94 3.97 13,743 133.35 3.18 11,804

2.17 IU 75 4 H90 139.70 71.44 29,353 P 126.21 3.97 13,378 124.62 3.18 11,486

101.60 2.17 IU 95 NC40 139.70 61.91 24,988 P 127.00 7.14 17,383 124.62 5.95 14,892

2.17 EU 95 NC 46 152.40 76.20 27,902 P 138.11 5.56 17,720 135.73 4.37 14,725

2.17 IU 95 4 H90 139.70 71.44 29,353 P 129.38 5.56 17,261 127.79 4.76 15,303

101.60 2.17 EU 105 NC 46 152.40 76.20 32,553 P 138.91 5.95 18,736 137.32 5.16 16,714

2.17 IU 105 4 H90 139.70 71.44 29,353 P 130.97 6.35 19,254 128.59 5.16 16,278

101.60 2.17 IU 135 NC 46 152.40 66.68 37,316 B 143.67 8.33 25,009 140.49 6.75 20,793

2.17 EU 135 NC 46 152.40 73.03 34,738 P 143.67 8.33 25,009 140.49 6.75 20,793

114.30 2.30 IEU 75 4 1/2 FH 152.40 76.20 28,860 P 136.53 5.16 16,769 134.14 3.97 13,930

2.30 IEU 75 NC 46 158.75 82.55 28,208 P 137.32 5.16 16,714 135.73 4.37 14,725

2.30 IEU 75 4 1/2 OHSW 149.23 95.25 22,607 P 138.11 5.16 16,405 136.53 4.37 14,349

2.30 EU 75 NC 50 168.28 95.25 31,582 P 145.26 3.97 16,029 144.46 3.57 14,899

2.30 IEU 75 4 1/2 H90 152.40 82.55 32,300 P 135.73 4.76 16,893 134.14 3.97 14,718

114.30 2.30 IEU 95 4 1/2 FH 152.40 69.85 32,975 P 139.70 6.75 20,669 137.32 5.56 17,731

2.30 IEU 95 NC 46 158.75 82.55 28,208 P 140.49 6.75 20,793 138.11 5.56 17,720

2.30 EU 95 NC 50 168.28 95.25 31,582 P 148.43 5.56 20,643 146.84 4.76 18,318

2.30 IEU 95 4 1/2 H90 152.40 76.20 37,467 P 138.91 6.35 21,355 136.53 5.16 18,120

114.30 2.30 IEU 105 4 1/2 FH 152.40 69.85 32,975 P 141.29 7.54 22,669 138.91 6.35 19,681

2.30 IEU 105 NC 46 158.75 76.20 32,908 P 142.08 7.54 22,883 139.70 6.35 19,760

2.30 EU 105 NC 50 168.28 95.25 31,582 P 150.02 6.35 23,003 147.64 5.16 19,475

2.30 IEU 105 4 1/2 H90 152.40 76.20 37,467 P 139.70 6.75 22,493 138.11 5.95 20,226

114.30 2.30 IEU 135 NC 46 158.75 69.85 37,235 P 146.84 9.92 29,361 143.67 8.33 25,009

2.30 EU 135 NC 50 168.28 88.90 37,446 P 153.99 8.33 29,067 151.61 7.14 25,402

114.30 2.77 IEU 75 4 1/2 FH 152.40 76.20 28,860 P 138.91 6.35 19,681 136.53 5.16 16,769

2.77 IEU 75 NC 46 158.75 76.20 32,908 P 139.70 6.35 19,760 137.32 5.16 16,714

2.77 EU 75 NC 50 168.28 92.08 34,565 P 147.64 5.16 19,475 146.05 4.37 17,170

2.77 IEU 75 4 1/2 H90 152.40 76.20 37,467 P 137.32 5.56 19,106 135.73 4.76 16,893

114.30 2.77 IEU 95 4 1/2 FH 152.40 63.50 36,731 P 142.88 8.33 24,702 140.49 7.14 21,665

2.77 IEU 95 NC 46 158.75 69.85 37,235 P 143.67 8.33 25,009 141.29 7.14 21,833

2.77 EU 95 NC 50 168.28 88.90 37,446 P 150.81 6.75 24,198 149.23 5.95 21,818

2.77 IEU 95 4 1/2 H90 152.40 76.20 37,467 P 141.29 7.54 24,796 138.91 6.35 21,355

114.30 2.77 IEU 105 NC 46 158.75 63.50 41,183 P 145.26 9.13 27,168 142.88 7.94 23,941

2.77 EU 105 NC 50 168.28 88.90 37,446 P 153.19 7.94 27,836 150.02 6.35 23,003

114.30 2.77 IEU 135 NC 50 168.28 73.03 50,338 P 157.96 10.32 35,362 154.78 8.73 30,307

127.00 2.70 IEU 75 NC 50 168.28 95.25 31,582 P 149.23 5.95 21,818 147.64 5.16 19,475

127.00 2.70 IEU 95 NC 50 168.28 88.90 37,446 P 153.19 7.94 27,836 150.81 6.75 24,198

2.70 IEU 95 5 H90 165.10 82.55 42,989 P 148.43 7.54 27,469 146.05 6.35 23,671

(Continues on following page.)

3-12 Revision August 2007

Section 3: Operating Specifications

Recommended Minimum OD and Make-Up Torque of Weld-On Type Tool Joints by Class Metric Units - Table 2.3

(Continued from previous page. See footnotes for use of this table.)

1 2 3 4 5 6 7 8 9 10 11 12 13

Drill Pipe New Tool Joint Data Premium Class Class 2

Nom Size NomWt. Type Connection New OD New ID Make-up Min OD Min Box Make-up Min OD Min Box Make-up

mm. kg/m Upset mm mm Torque6 Tool Joint Shoulder Torque for Tool Joint Shoulder Torque for

and mm mm. with Min OD mm with Min OD

Grade Eccentric Tool Joint Eccentric Tool Joint

Wear N-m Wear N-m

mm mm

127.00 2.70 IEU 105 NC 50 168.28 82.55 42,908 P 154.78 8.73 30,307 152.40 7.54 26,614

2.70 IEU 105 5 H90 165.10 76.20 48,459 P 150.02 8.33 30,048 147.64 7.14 26,194

127.00 2.70 IEU 135 NC 50 168.28 69.85 52,615 P 160.34 11.51 39,251 157.16 9.92 34,084

2.70 IEU 135 5 1/2 FH 184.15 88.90 60,147 P 171.45 9.53 39,743 168.28 7.94 33,762

127.00 3.54 IEU 75 NC 50 168.28 88.90 37,446 P 153.19 7.94 27,836 150.81 6.75 24,198

3.54 IEU 75 5 1/2 FH 177.80 88.90 52,197 B 165.10 6.35 27,944 162.72 5.16 23,687

127.00 3.54 IEU 95 NC 50 168.28 76.20 47,962 P 157.96 10.32 35,362 154.78 8.73 30,307

3.54 IEU 95 5 1/2 FH 177.80 88.90 52,197 B 169.07 8.33 35,243 166.69 7.14 30,833

127.00 3.54 IEU 105 NC 50 168.28 69.85 52,615 P 159.54 11.11 37,945 156.37 9.53 32,816

3.54 IEU 105 5 1/2 FH 184.15 88.90 60,147 P 170.66 9.13 38,233 168.28 7.94 33,762

127.00 3.54 IEU 135 5 1/2 FH 184.15 82.55 65,319 B 176.21 11.91 49,022 173.04 10.32 42,794

139.70 3.03 IEU 75 5 1/2 FH 177.80 101.60 46,413 P 164.31 5.95 26,515 162.72 5.16 23,687

139.70 3.03 IEU 95 5 1/2 FH 177.80 95.25 52,197 B 168.28 7.94 33,762 165.89 6.75 29,383

3.03 IEU 95 5 1/2 H90 177.80 88.90 49,033 P 157.16 8.33 33,765 154.78 7.14 29,526

139.70 3.03 IEU 105 5 1/2 FH 184.15 88.90 60,147 P 170.66 9.13 38,233 167.48 7.54 32,293

139.70 3.03 IEU 135 5 1/2 FH 190.50 76.20 73,717 P 176.21 11.91 49,022 162.72 10.32 42,794

139.70 3.42 IEU 75 5 1/2 FH 177.80 101.60 46,413 P 166.69 7.14 30,833 164.31 5.95 26,515

139.70 3.42 IEU 95 5 1/2 FH 184.15 88.90 60,147 P 170.66 9.13 38,233 167.48 7.54 32,293

139.70 3.42 IEU 105 5 1/2 FH 184.15 88.90 60,147 P 172.24 9.92 41,263 169.86 8.73 36,732

139.70 3.42 IEU 135 5 1/2 FH 190.50 76.20 72,334 P 178.59 13.10 53,800 174.63 11.11 45,888

168.28 3.49 IEU 75 6 5/8 FH 203.20 127.00 61,123 P 188.91 6.35 37,078 187.33 5.56 33,330

0.00 IEU 95 6 5/8 FH 203.20 127.00 61,123 P 193.68 8.73 48,597 190.50 7.14 40,870

0.00 IEU 105 6 5/8 FH 209.55 120.65 71,559 P 195.26 9.53 52,530 192.88 8.33 46,649

0.00 IEU 135 6 5/8 FH 215.90 107.95 90,635 P 200.82 12.30 66,666 197.64 10.72 58,517

168.28 3.83 IEU 75 6 5/8 FH 203.20 127.00 61,123 P 190.50 7.14 40,870 188.12 5.95 35,199

0.00 IEU 95 6 5/8 FH 209.55 120.65 71,559 P 195.26 9.53 52,530 192.09 7.94 44,711

0.00 IEU 105 6 5/8 FH 209.55 120.65 71,559 P 196.85 10.32 56,509 194.47 9.13 50,557

0.00 IEU 135 6 5/8 FH 215.90 107.95 90,635 P 203.20 13.49 72,903 188.52 11.51 62,568

Notes:

1

The use of outside diameters (OD) smaller than those listed in the table may be acceptable due to special service requirements.

2

Tool Joint with dimensions shown has lower torsional yield ratio than the 0.80 which is generally used.

3

Recommended make-up torque is based on 72,000 psi stress.

4

In calculation of torsional strengths to tool joints, both new and worn, the bevels of the tool joint shoulders are disregarded. The

thickness measurement should be made in the plane of the face from the ID of the counter bore to the outside diameter of the box,

disregarding the bevels.

5

Any tool joint with an outside diameter less than API bevel diameter should be provided with a minimum 1/32” depth X 45º bevel on the

outside and inside diameter of the box shoulder and outside diameter of the pin shoulder.

6

P=Pin limit, B=Box limit.

*Tool joint diameters specified are required to retain torsional strength in the tool joint comparable to the torsional strength of the attached

drill pipe. These should be adequate for all service. Tool joints with torsional strengths considerably below that of the drill pipe may be

adequate for much drilling service.

This information has been duplicated in its entirety from API RP 7G Table 10 and is current as of the

publication of this Manual. However, it is likely that the data will be updated several times during the life of a

Top Drive unit. Consult API Recommended Practices or IADC Drilling Manual to be certain that this

information is current.

Revision August 2007 3-13

Canrig Torque-Matic Floor Wrench

Recommended Minimum OD* and Make-Up Torque of Weld-On Type Tool Joints by Class Imperial Units - Table 2.4

(See footnotes for use of this table on Page 3-16.)

1 2 3 4 5 6 7 8 9 10 11 12 13

Drill Pipe New Tool Joint Data Premium Class Class 2

Nom NomWt. Type Connection New OD New ID Make-up Min OD Min Box Make-up Min OD Min Box Make-up

Size, Lb/ft Upset in in Torque6 Tool Joint Shoulder Torque for Tool Joint Shoulder Torque for

in. and in in. with Min OD in with Min OD

Grade Eccentric Tool Joint Eccentric Tool Joint

Wear ft-lb Wear ft-lb

in in

2 3/8 4.85 EU 75 NC 26 3 3/8 1 3/4 4,125 B 3 1/8 3/64 1,945 3 3/32 1/32 1,689

4.85 EU 75 W.O. 3 3/8 2 2,586 P 3 1/16 1/16 1,994 3 1/32 3/64 1,746

4.85 EU 75 2 3/8 ONLW 3 1/8 2 2,713 P 3 1/16 1,830 2 31/32 3/64 1,589

4.85 EU 75 2 3/8 SL-H90 3 1/4 2 3,074 P 2 31/32 1/16 1,996 2 15/16 3/64 1,726

2 3/8 6.65 IU 75 2 3/8 PAC2 2 7/8 1 3/8 2,813 P 2 25/32 9/64 2,455 2 23/32 7/64 2,055

6.65 EU 75 NC 26 3 3/8 1 3/4 4,125 B 3 3/16 5/64 2,467 3 5/32 1/16 2,204

6.65 EU 75 2 3/8 SL-H90 3 1/4 2 3,074 P 3 1/32 3/32 2,549 2 31/32 1/16 1,996

6.65 EU 75 2 3/8 OHSW 3 1/4 1 3/4 3,891 B 3 1/16 3/32 2,324 3 1/32 5/64 2,075

2 3/8 6.65 EU 95 NC 26 3 3/8 1 3/4 4,125 B 3 1/4 7/64 3,005 3 7/32 3/32 2,734

2

2 3/8 6.65 EU 105 NC 26 3 3/8 1 3/4 4,125 B 3 9/32 1/8 3,279 3 1/4 7/64 3,005

2 7/8 6.85 EU 75 NC 31 4 1/8 2 1/8 7,122 P 3 11/16 5/64 3,154 10 1/32 1/16 2,804

6.85 EU 75 2 7/8 WO 4 1/8 2 7/16 4,318 P 3 5/8 5/64 3,216 3 19/32 1/16 2,876

6.85 EU 75 2 7/8 OHLW 2 3 3/4 2 7/16 3,351 P 3 1/2 7/64 3,297 3 7/16 5/64 2,666

6.85 EU 75 2 7/8 SL-H90 3 7/8 2 7/16 4,575 P 3 1/2 3/32 3,397 3 7/16 1/16 2,666

2 7/8 10.40 EU 75 NC 31 4 1/8 2 1/8 7,122 P 3 13/16 9/64 4,597 3 3/4 7/64 3,867

10.40 IU 75 2 7/8 XH 4 1/4 1 7/8 7,969 P 3 23/32 9/64 4,357 3 21/32 7/64 3,664

10.40 IU 75 NC 262 3 3/8 1 3/4 4,125 B 3 3/8 11/64 4,125 3 11/32 5/32 3,839

10.40 EU 75 2 7/8 OHSW 2 3 7/8 2 5/32 5,270 P 3 19/32 5/32 4,273 3 9/16 7/64 3,941

10.40 EU 75 2 7/8 SL-H90 3 7/8 2 5/32 6,773 P 3 19/32 9/64 4,529 3 17/32 7/64 3,770

10.40 IU 75 2 7/8 PAC2 3 1/8 1 1/2 3,439 P 3 1/8 15/64 3,439 3 1/8 15/64 3,439

2 7/8 10.40 EU 95 NC 31 4 1/8 2 7,918 P 3 29/32 3/16 5,726 3 27/32 5/32 4,969

10.40 EU 95 2 7/8 SL-H902 3 7/8 2 5/32 6,773 P 3 11/16 3/16 5,702 3 5/8 5/32 4,915

2 7/8 10.40 EU 105 NC 31 4 1/8 2 7,918 P 3 15/16 13/64 6,110 3 7/8 11/64 5,345

2 7/8 10.40 EU 135 NC 31 4 3/8 1 5/8 10,167 P 4 1/16 17/64 7,694 4 15/64 6,893

3 1/2 9.50 EU 75 NC 38 4 3/4 3 7,688 P 4 13/32 1/8 5,773 4 11/32 3/32 4,797

9.50 EU 75 NC 38 4 3/4 2 11/16 10,864 P 4 13/32 1/8 5,773 4 11/32 3/32 4,797

9.50 EU 75 3 1/2 OHLW 4 3/4 3 7,218 P 4 9/32 1/8 5,340 4 1/4 7/64 4,868

9.50 EU 75 3 1/2 SL-H90 4 5/8 3 7,584 P 4 3/16 7/64 5,521 4 5/32 3/32 5,003

3 1/2 13.30 EU 75 NC 38 4 3/4 2 11/16 10,864 P 4 1/2 11/64 7,274 4 7/16 9/64 6,268

13.30 IU 75 NC 312 4 1/8 2 1/8 7,122 P 4 15/64 6,893 3 15/16 13/64 6,110

13.30 EU 75 3 1/2 OHSW 4 3/4 2 11/16 10,387 P 4 13/32 3/16 7,278 4 11/32 5/32 6,299

13.30 EU 75 3 1/2 H90 5 1/4 2 3/4 14,300 P 4 17/32 1/8 7,064 4 1/2 7/64 6,487

13.30 EU 95 NC 38 5 2 9/16 12,196 P 4 19/32 7/32 8,822 4 17/32 3/16 7,785

13.30 EU 95 3 1/2 SL-H902 4 5/8 2 11/16 11,137 P 4 3/8 13/64 8,742 4 5/16 11/64 7,647

13.30 EU 95 3 1/2 H90 5 1/4 2 3/4 14,300 P 4 5/8 11/64 8,826 4 9/16 9/64 7,646

3 1/2 13.30 EU 105 NC 38 5 2 7/16 13,328 P 4 21/32 1/4 9,879 4 19/32 7/32 8,822

3 1/2 13.30 EU 135 NC 40 5 3/8 2 7/16 17,958 P 5 9/32 12,569 4 29/32 15/64 10,768

13.30 EU 135 NC 38 5 2 1/8 15,909 P 4 13/16 21/64 12,614 4 23/32 9/32 10,958

3 1/2 15.50 EU 75 NC 38 5 2 9/16 12,196 P 4 17/32 3/16 7,785 4 15/32 5/32 6,769

3 1/2 15.50 EU 95 NC 38 5 2 7/16 13,328 P 4 21/32 1/4 9,879 4 19/32 7/32 8,822

3 1/2 15.50 EU 105 NC 38 5 2 1/8 15,909 P 4 23/32 9/32 10,957 4 5/8 15/64 9,348

15.50 EU 105 NC 40 5 1/4 2 9/16 16,656 P 4 15/16 1/4 11,363 4 27/32 13/64 9,595

3 1/2 15.50 EU 135 NC 40 5 1/2 2 1/4 19,766 P 5 3/32 21/64 14,419 4 31/32 17/64 11,963

4 11.85 EU 75 NC 46 6 3 1/4 20,175 P 5 7/32 7/64 7,843 5 5/32 5/64 6,476

11.85 EU 75 4 WO 5 3/4 3 7/16 17,285 P 5 7/32 7/64 7,843 5 5/32 5/64 6,476

11.85 EU 75 4 OHLW 5 1/4 3 15/32 13,186 P 5 9/64 7,866 4 15/16 7/64 6,593

11.85 IU 75 4 H90 5 1/2 2 13/16 21,224 P 4 7/8 7/64 7,630 4 27/32 3/32 6,962

(Continues on following page.)

3-14 Revision August 2007

Section 3: Operating Specifications

Recommended Minimum OD* and Make-Up Torque of Weld-On Type Tool Joints by Class Imperial Units - Table 2.4

(Continued from the previous page. See footnotes for use of this table on page 3-16.)

1 2 3 4 5 6 7 8 9 10 11 12 13

Drill Pipe New Tool Joint Data Premium Class Class 2

Nom Size NomWt. Type Connection New OD New ID Make-up Min OD Min Box Make-up Min OD Min Box Make-up

in. Lb/ft Upset in in Torque6 Tool Joint Shoulder Torque for Tool Joint Shoulder Torque for

and in in. with Min OD in with Min OD

Grade Eccentric Tool Joint Eccentric Tool Joint

Wear ft-lb Wear ft-lb

in in

4 14.00 IU 75 NC 40 5 1/4 2 13/16 14,092 P 4 13/16 3/16 9,017 4 3/4 5/32 7,877

14.00 EU 75 NC 46 6 3 1/4 20,175 P 5 9/32 9/64 9,233 5 7/32 7/64 7,843

14.00 IU 75 4 SH2 4 5/8 2 13/16 9,102 P 4 7/16 15/64 8,782 4 3/8 13/64 7,817

14.00 EU 75 4 OHSW 5 1/2 16,320 P 5 1/16 11/64 9,131 5 9/64 7,839

14.00 IU 75 4 H90 5 1/2 3 21,224 P 4 15/16 9/64 8,986 4 7/8 7/64 7,630

4 14.00 IU 95 NC40 5 1/2 2 11/16 15,404 P 4 15/16 1/4 11,363 4 27/32 13/64 9,595

14.00 EU 95 NC 46 6 3 1/4 20,175 P 5 3/8 3/16 11,363 5 5/16 5/32 9,937

14.00 IU 95 4 H90 5 1/2 2 13/16 21,224 P 5 1/32 3/16 11,065 4 31/32 5/32 9,673

4 14.00 IU 105 NC40 5 1/4 2 7/16 18,068 P 5 9/32 12,569 4 29/32 15/64 10,768

14.00 EU 105 NC 46 6 3 1/4 20,175 P 5 7/16 7/32 12,813 5 11/32 11/64 10,647

14.00 IU 105 4 H90 5 1/2 2 13/16 21,224 P 5 3/32 7/32 12,481 5 1/32 3/16 11,065

4 14.00 EU 135 NC 46 6 3 23,538 P 5 9/16 9/32 15,787 5 1/2 1/4 14,288

4 15.70 IU 75 NC40 5 1/4 2 11/16 15,404 P 4 7/8 7/32 10,179 4 25/32 11/64 8,444

15.70 EU 75 NC 46 6 3 1/4 20,175 P 5 5/16 5/32 9,937 5 1/4 1/8 8,535

15.70 IU 75 4 H90 5 1/2 2 13/16 21,224 P 4 31/32 5/32 9,673 4 29/32 1/8 8,305

4 15.70 IU 95 NC40 5 1/2 2 7/16 18,068 P 5 9/32 12,569 4 29/32 15/64 10,768

15.70 EU 95 NC 46 6 3 20,175 P 5 7/16 7/32 12,813 5 11/32 11/64 10,647

15.70 IU 95 4 H90 5 1/2 2 13/16 21,224 P 5 3/32 7/32 12,481 5 1/32 3/16 11,065

4 15.70 EU 105 NC 46 6 3 23,538 P 5 15/32 15/64 13,547 5 13/32 13/64 12,085

15.70 IU 105 4 H90 5 1/2 2 13/16 21,224 P 5 5/32 1/4 13,922 5 1/16 13/64 11,770

4 15.70 IU 135 NC 46 6 2 5/8 26,982 B 5 21/32 21/64 18,083 5 17/32 17/64 15,035

15.70 EU 135 NC 46 6 2 7/8 25,118 P 5 21/32 21/64 18,083 5 17/32 17/64 15,035

4 1/2 16.60 IEU 75 4 1/2 FH 6 3 20,868 P 5 3/8 13/64 12,125 5 9/32 5/32 10,072

16.60 IEU 75 NC 46 6 1/4 3 1/4 20,396 P 5 13/32 13/64 12,085 5 11/32 11/64 10,647

16.60 IEU 75 4 1/2 OHSW 5 7/8 3 3/4 16,346 P 5 7/16 13/64 11,862 5 3/8 11/64 10,375

16.60 EU 75 NC 50 6 5/8 3 3/4 22,836 P 5 23/32 5/32 11,590 5 11/16 9/64 10,773

16.60 IEU 75 4 1/2 H90 6 3 1/4 23,355 P 5 11/32 3/16 12,215 5 9/32 5/32 10,642

4 1/2 16.60 IEU 95 4 1/2 FH 6 2 3/4 23,843 P 5 1/2 17/64 14,945 5 13/32 7/32 12,821

16.60 IEU 95 NC 46 6 1/4 3 1/4 20,396 P 5 17/32 17/64 15,035 5 7/16 7/32 12,813

16.60 EU 95 NC 50 6 5/8 3 3/4 22,836 P 5 27/32 7/32 14,926 5 25/32 3/16 13,245

16.60 IEU 95 4 1/2 H90 6 3 27,091 P 5 15/32 1/4 15,441 5 3/8 13/64 13,102

4 1/2 16.60 IEU 105 4 1/2 FH 6 2 3/4 23,843 P 5 9/16 19/64 16,391 5 15/32 1/4 14,231

16.60 IEU 105 NC 46 6 1/4 3 23,795 P 5 19/32 19/64 16,546 5 1/2 1/4 14,288

16.60 EU 105 NC 50 6 5/8 3 3/4 22,836 P 5 29/32 1/4 16,633 5 13/16 13/64 14,082

16.60 IEU 105 4 1/2 H90 6 3 27,091 P 5 1/2 17/64 16,264 5 7/16 15/64 14,625

4 1/2 16.60 IEU 135 NC 46 6 1/4 2 3/4 26,923 P 5 25/32 25/64 21,230 5 21/32 21/64 18,083

16.60 EU 135 NC 50 6 5/8 3 1/2 27,076 P 6 1/16 21/64 21,017 5 31/32 9/32 18,367

4 1/2 20.00 IEU 75 4 1/2 FH 6 3 20,868 P 5 15/32 1/4 14,231 5 3/8 13/64 12,125

20.00 IEU 75 NC 46 6 1/4 3 23,795 P 5 1/2 1/4 14,288 5 13/32 13/64 12,085

20.00 EU 75 NC 50 6 5/8 3 5/8 24,993 P 5 13/16 13/64 14,082 5 3/4 11/64 12,415

20.00 IEU 75 4 1/2 H90 6 3 27,091 P 5 13/32 7/32 13,815 5 11/32 3/16 12,215

4 1/2 20.00 IEU 95 4 1/2 FH 6 2 1/2 26,559 P 5 5/8 21/64 17,861 5 17/32 9/32 15,665

20.00 IEU 95 NC 46 6 1/4 2 3/4 26,923 P 5 21/32 21/64 18,083 5 9/16 9/32 15,787

20.00 EU 95 NC 50 6 5/8 3 1/2 27,076 P 5 15/16 17/64 17,497 5 7/8 15/64 15,776

20.00 IEU 95 4 1/2 H90 6 3 27,091 P 5 9/16 19/64 17,929 5 15/32 1/4 15,441

4 1/2 20.00 IEU 105 NC 46 6 1/4 2 1/2 29,778 P 5 23/32 23/64 19,644 5 5/8 5/16 17,311

20.00 EU 105 NC 50 6 5/8 3 1/2 27,076 P 6 1/32 5/16 20,127 5 29/32 1/4 16,633

4 1/2 20.00 IEU 135 NC 50 6 5/8 2 7/8 36,398 P 6 7/32 13/32 25,569 6 3/32 11/32 21,914

5 19.50 IEU 75 NC 50 6 5/8 3 3/4 22,836 P 5 7/8 15/64 15,776 5 13/16 13/64 14,082

5 19.50 IEU 95 NC 50 6 5/8 3 1/2 27,076 P 6 1/32 5/16 20,127 5 15/16 17/64 17,497

19.50 IEU 95 5 H90 6 1/2 3 1/4 31,084 P 5 27/32 19/64 19,862 5 3/4 1/4 17,116

Revision August 2007 3-15

Canrig Torque-Matic Floor Wrench

Recommended Minimum OD and Make-Up Torque of Weld-On Type Tool Joints by Class Imperial Units - Table 2.4

(Continued from previous page. See footnotes for use of this table.)

1 2 3 4 5 6 7 8 9 10 11 12 13

Drill Pipe New Tool Joint Data Premium Class Class 2

Nom Size NomWt. Type Connection New OD New ID Make-up Min OD Min Box Make-up Min OD Min Box Make-up

in. Lb/ft Upset in in Torque6 Tool Joint Shoulder Torque for Tool Joint Shoulder Torque for

and in in. with Min OD in with Min OD

Grade Eccentric Tool Joint Eccentric Tool Joint

Wear ft-lb Wear ft-lb

in in

5 19.50 IEU 105 NC 50 6 5/8 3 1/4 31 025 P 6 3/32 11/32 21 914 6 19/64 19 244

19.50 IEU 105 5 H90 6 1/2 3 35 039 P 5 29/32 21/64 21 727 5 13/16 9/32 18 940

5 19.50 IEU 135 NC 50 6 5/8 2 3/4 38 044 P 6 5/16 29/64 28 381 6 3/16 25/64 24 645

19.50 IEU 135 5 1/2 FH 7 1/4 3 1/2 43 490 P 6 3/4 3/8 28 737 6 5/8 5/16 24 412

5 25.60 IEU 75 NC 50 6 5/8 3 1/2 27 076 P 6 1/32 5/16 20 127 5 15/16 17/64 17 497

25.60 IEU 75 5 1/2 FH 7 3 1/2 37 742 B 6 1/2 1/4 20 205 6 13/32 13/64 17 127

5 25.60 IEU 95 NC 50 6 5/8 3 34 680 P 6 7/32 13/32 25 569 6 3/32 11/32 21 914

25.60 IEU 95 5 1/2 FH 7 3 1/2 37 742 B 6 21/32 21/64 25 483 6 9/16 9/32 22 294

5 25.60 IEU 105 NC 50 6 5/8 2 3/4 38 044 P 6 9/32 7/16 27 437 6 5/32 3/8 23 728

25.60 IEU 105 5 1/2 FH 7 1/4 3 1/2 43 490 P 6 23/32 23/64 27 645 6 5/8 5/16 24 412

5 25.60 IEU 135 5 1/2 FH 7 1/4 3 1/4 47 230 B 6 15/16 15/32 35 446 6 13/16 13/32 30 943

5 1/2 21.90 IEU 75 5 1/2 FH 7 4 33 560 P 6 15/32 15/64 19 172 6 13/32 13/64 17 127

5 1/2 21.90 IEU 95 5 1/2 FH 7 3 3/4 37 742 B 6 5/8 5/16 24 412 6 17/32 17/64 21 246

21.90 IEU 95 5 1/2 H90 7 3 1/2 35 454 P 6 3/16 21/64 24 414 6 3/32 9/32 21 349

5 1/2 21.90 IEU 105 5 1/2 FH 7 1/4 3 1/2 43 490 P 6 23/32 23/64 27 645 6 19/32 19/64 23 350

5 1/2 21.90 IEU 135 5 1/2 FH 7 1/2 3 53 302 P 6 15/16 15/32 35 446 6 13/32 13/32 30 943

5 1/2 24.70 IEU 75 5 1/2 FH 7 4 33 560 P 6 9/16 9/32 22 294 6 15/32 15/64 19 172

5 1/2 24.70 IEU 95 5 1/2 FH 7 1/4 3 1/2 43 490 P 6 23/32 23/64 27 645 6 19/32 19/64 23 350

5 1/2 24.70 IEU 105 5 1/2 FH 7 1/4 3 1/2 43 490 P 6 25/32 25/64 29 836 6 11/16 11/32 26 560

5 1/2 24.70 IEU 135 5 1/2 FH 7 1/2 3 52 302 P 7 1/32 33/64 38 901 6 7/8 7/16 33 180

6 5/8 25.20 IEU 75 6 5/8 FH 8 5 44 196 P 7 7/16 1/4 26 810 7 3/8 7/32 24 100

IEU 95 6 5/8 FH 8 5 44 196 P 7 5/8 11/32 35 139 7 1/2 9/32 29 552

IEU 105 6 5/8 FH 8 1/4 4 3/4 51 742 P 7 11/16 3/8 37 983 7 19/32 21/64 33 730

IEU 135 6 5/8 FH 8 1/2 4 1/4 65 535 P 7 29/32 31/64 48 204 7 25/32 27/64 42 312

6 5/8 27.70 IEU 75 6 5/8 FH 8 5 44 196 P 7 1/2 9/32 29 552 7 13/32 15/64 25 451

IEU 95 6 5/8 FH 8 1/4 4 3/4 51 742 P 7 11/16 3/8 37 983 7 9/16 5/16 32 329

IEU 105 6 5/8 FH 8 1/4 4 3/4 51 742 P 7 3/4 13/32 40 860 7 21/32 23/64 36 556

IEU 135 6 5/8 FH 8 1/2 4 1/4 65 535 P 8 17/32 52 714 7 27/64 29/64 45 241

Notes:

1

The use of outside diameters (OD) smaller than those listed in the table may be acceptable due to special service requirements.

2

Tool Joint with dimensions shown has lower torsional yield ratio than the 0.80 which is generally used.

3

Recommended make-up torque is based on 72,000 psi stress.

4

In calculation of torsional strengths to tool joints, both new and worn, the bevels of the tool joint shoulders are disregarded. The

thickness measurement should be made in the plane of the face from the ID of the counter bore to the outside diameter of the box,

disregarding the bevels.

5

Any tool joint with an outside diameter less than API bevel diameter should be provided with a minimum 1/32” depth X 45º bevel on the

outside and inside diameter of the box shoulder and outside diameter of the pin shoulder.

6

P=Pin limit, B=Box limit.

*Tool joint diameters specified are required to retain torsional strength in the tool joint comparable to the torsional strength of the attached

drill pipe. These should be adequate for all service. Tool joints with torsional strengths considerably below that of the drill pipe may be

adequate for much drilling service.

This information has been duplicated in its entirety from API RP 7G Table 10 and is current as of the

publication of this Manual. However, it is likely that the data will be updated several times during the life of

the equipment. Consult API Recommended Practices or IADC Drilling Manual to be certain that this

information is current.

3-16 Revision August 2007

Potrebbero piacerti anche

- TM 120 Daily and Weekly Inspection and Maintenance TasksDocumento23 pagineTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNessuna valutazione finora

- CDS - Operations Guide - 883003Documento38 pagineCDS - Operations Guide - 883003mustafaNessuna valutazione finora

- TDM 100 Mechanical Systems Manual Revision March 2010Documento63 pagineTDM 100 Mechanical Systems Manual Revision March 2010Chaouki BoukhamlaNessuna valutazione finora

- HH-Rotary Table ZP175 - ZP205 PDFDocumento3 pagineHH-Rotary Table ZP175 - ZP205 PDFYosed L SantosNessuna valutazione finora

- EMSCO Drwks. ELECTROHOIST V C&O PDFDocumento186 pagineEMSCO Drwks. ELECTROHOIST V C&O PDFalex albinoNessuna valutazione finora

- D-GASSERS Orizontal + Vertical PDFDocumento2 pagineD-GASSERS Orizontal + Vertical PDFciucalata880% (1)

- SEC6 Partes y PlanosDocumento380 pagineSEC6 Partes y PlanosJohn Suarez100% (1)

- IDS 350PE Top DriveDocumento2 pagineIDS 350PE Top Drivealan camposNessuna valutazione finora

- Top DriveDocumento314 pagineTop Drivesebastian zorroNessuna valutazione finora

- Universal Tool and Cutter Grinder Manual Low ResDocumento16 pagineUniversal Tool and Cutter Grinder Manual Low ResDale Wade100% (1)

- Drawing Package Crown Block: CB-375-7-50-1 3/8 Serial Number:0058Documento5 pagineDrawing Package Crown Block: CB-375-7-50-1 3/8 Serial Number:0058Noureddine AdjNessuna valutazione finora

- Make a Battery-Powered Antique Auto for Your ChildrenDocumento22 pagineMake a Battery-Powered Antique Auto for Your ChildrenLuis Baracchi100% (1)

- 1000012667-PIB Shot PinDocumento3 pagine1000012667-PIB Shot PinAdrian CantaragiuNessuna valutazione finora

- BUW Removal & AssemblyDocumento20 pagineBUW Removal & AssemblyashadNessuna valutazione finora

- TC104 00天车图册-EDocumento16 pagineTC104 00天车图册-EKaleem UllahNessuna valutazione finora

- National Oilwell Varco, in - SEC Filing 10KDocumento116 pagineNational Oilwell Varco, in - SEC Filing 10Kcaballero_tigreNessuna valutazione finora

- TDS1000AInstallationManual 03May28AbridgedDocumento20 pagineTDS1000AInstallationManual 03May28Abridgedbwd104Nessuna valutazione finora

- Iron Roughnecks BrochureDocumento9 pagineIron Roughnecks BrochureMahmoud MorsiNessuna valutazione finora

- Washpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)Documento12 pagineWashpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)osvaldoNessuna valutazione finora

- Torq-Matic Automated Floor Wrench: Preventive Maintenance Guide (Model TM120-110/125)Documento1 paginaTorq-Matic Automated Floor Wrench: Preventive Maintenance Guide (Model TM120-110/125)Alejandra Noguera GiraldoNessuna valutazione finora

- Sparepart ManualDocumento364 pagineSparepart ManualEkoNessuna valutazione finora

- HHF-1600HL Drilling Pump Parts ListDocumento27 pagineHHF-1600HL Drilling Pump Parts ListDaniel RinconNessuna valutazione finora

- Canrig TD 4 Inch Actuator ManualDocumento42 pagineCanrig TD 4 Inch Actuator ManualAshrafNessuna valutazione finora

- 3119049Documento10 pagine3119049Sug E QalanderNessuna valutazione finora

- HHF-1600L Drilling Pump Set Parts ListDocumento21 pagineHHF-1600L Drilling Pump Set Parts ListAhmed SaeedNessuna valutazione finora

- Wild Well Control - Technical Date BookDocumento57 pagineWild Well Control - Technical Date Bookgabriel851007Nessuna valutazione finora

- Re-certified TDS-8S Top Drive SystemDocumento2 pagineRe-certified TDS-8S Top Drive Systemahmed farhNessuna valutazione finora

- 6923 PDFDocumento5 pagine6923 PDFMEHDINessuna valutazione finora

- SEC6 (1) PartsDocumento401 pagineSEC6 (1) PartsCarlos Alberto Perdomo100% (2)

- TDS 04 09 PibDocumento11 pagineTDS 04 09 PibNavin SinghNessuna valutazione finora

- PS 1000 ManualDocumento117 paginePS 1000 Manualnoormanmubarak100% (3)

- Sec4abc PDFDocumento86 pagineSec4abc PDFAnibal Jose Cruz LarezNessuna valutazione finora

- Onshore Product Reference Guide PDFDocumento44 pagineOnshore Product Reference Guide PDFPedro RiveraNessuna valutazione finora

- Operator'S Manual: Bop Control System With Air Remote ControlDocumento12 pagineOperator'S Manual: Bop Control System With Air Remote ControlagusNessuna valutazione finora

- SEC5 (1) WashpipeDocumento22 pagineSEC5 (1) WashpipeCarlos Alberto PerdomoNessuna valutazione finora

- Product Bulletin No.: TDS-03-16 Release Top Drive Drilling SystemDocumento8 pagineProduct Bulletin No.: TDS-03-16 Release Top Drive Drilling Systemahmedsaid85Nessuna valutazione finora

- TM 120 Commissioning Manual - Rev.01 REVISADODocumento32 pagineTM 120 Commissioning Manual - Rev.01 REVISADOjaimeNessuna valutazione finora

- HPU Parts ListDocumento35 pagineHPU Parts ListJohn SimancaNessuna valutazione finora

- 06b AppendixB2 (1000HPRig) 1582535891879Documento103 pagine06b AppendixB2 (1000HPRig) 1582535891879Harsh TiwariNessuna valutazione finora

- Sec6 PDFDocumento424 pagineSec6 PDFAlex Ramirez100% (1)

- AC Top Drive System OverviewDocumento93 pagineAC Top Drive System OverviewBRAHIM FEKAOUNINessuna valutazione finora

- Farr KT7585Documento132 pagineFarr KT7585wfcenda2603Nessuna valutazione finora

- 3092834-Varco Bulletin On TDSDocumento9 pagine3092834-Varco Bulletin On TDSSushil GuptaNessuna valutazione finora

- Catalogo - Ge752 - Curvas PDFDocumento61 pagineCatalogo - Ge752 - Curvas PDFjuanpnuss100% (1)

- TDS Manual-TescoDocumento33 pagineTDS Manual-TescoQAMAR ALI KHAN100% (1)

- 355 TDS-11S Parts Manual CC Rev1 GDSDocumento170 pagine355 TDS-11S Parts Manual CC Rev1 GDSrig602.mechanicNessuna valutazione finora

- IND Drawworks DLS 163Documento11 pagineIND Drawworks DLS 163Jose Luis MazzoniNessuna valutazione finora

- Auto DrillerDocumento2 pagineAuto DrillersrpadronNessuna valutazione finora

- Drilling Accessories DHOT - Catalog - 11 - 11 - 12 PDFDocumento59 pagineDrilling Accessories DHOT - Catalog - 11 - 11 - 12 PDFyacine15100% (3)

- Slips Maintenance, Inspection, & Wear Data PDFDocumento3 pagineSlips Maintenance, Inspection, & Wear Data PDFcorsini999100% (1)

- Canrig Product InfoDocumento69 pagineCanrig Product InfoGiorgiana Rosu83% (6)

- Access Manual ToolsDocumento72 pagineAccess Manual ToolsJinhichi Molero Rodriguez0% (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignDa EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNessuna valutazione finora

- Bits Catalog PDFDocumento87 pagineBits Catalog PDFHarsha ChowdaryNessuna valutazione finora

- VR Series Jumbo PresentationDocumento22 pagineVR Series Jumbo PresentationTomás Díaz GuerreroNessuna valutazione finora

- Drilling BitsDocumento9 pagineDrilling BitsArbaz MulaniNessuna valutazione finora

- Drill Pipe Make/Break Machines and Spinners by Hawk IndustriesDocumento3 pagineDrill Pipe Make/Break Machines and Spinners by Hawk IndustriesShandiPrasetyoNessuna valutazione finora

- Especificaciones Del Jumbo DD 311Documento4 pagineEspecificaciones Del Jumbo DD 311RimbertNessuna valutazione finora

- Study of Dies and InsertsDocumento14 pagineStudy of Dies and InsertstraidenNessuna valutazione finora

- Automated Power CatwalkDocumento6 pagineAutomated Power CatwalkianherzogNessuna valutazione finora

- Torque TDS4 Pocket Guide-2 PDFDocumento5 pagineTorque TDS4 Pocket Guide-2 PDFHaridev50% (2)

- Hi Kal Catalogue New OptDocumento16 pagineHi Kal Catalogue New Optask101Nessuna valutazione finora

- Power Slip Lifter Systems CatalogDocumento36 paginePower Slip Lifter Systems CatalogAdrian Cantaragiu100% (1)

- TDS 93 1 Pib PDFDocumento6 pagineTDS 93 1 Pib PDFMohamed HashemNessuna valutazione finora

- INSTRUMENT - AUTODRILLER - AOI - TECH MANUAL - IOM-111 Automatic Drilling Control SystemDocumento53 pagineINSTRUMENT - AUTODRILLER - AOI - TECH MANUAL - IOM-111 Automatic Drilling Control SystemKapil AgarwalNessuna valutazione finora

- Subsection 5: Optional Equipment: Top Drive Drilling SystemDocumento57 pagineSubsection 5: Optional Equipment: Top Drive Drilling SystemHector BarriosNessuna valutazione finora

- Manual Canrig 3Documento16 pagineManual Canrig 3sertecs polNessuna valutazione finora

- Ection Perating Pecifications: Revision November 2009Documento18 pagineEction Perating Pecifications: Revision November 2009Anibal Jose Cruz LarezNessuna valutazione finora

- Drift Indicator System Manual - 2019Documento140 pagineDrift Indicator System Manual - 2019aris4silveyraNessuna valutazione finora

- Field inspection updates 1999Documento6 pagineField inspection updates 1999aris4silveyraNessuna valutazione finora

- Field Inspection of New Casing, Tubing, and Plain-End Drill PipeDocumento6 pagineField Inspection of New Casing, Tubing, and Plain-End Drill Pipearis4silveyraNessuna valutazione finora

- WS41-14 DPPSDocumento2 pagineWS41-14 DPPSRobertok1234100% (1)

- Weights Annular B.O.PDocumento1 paginaWeights Annular B.O.Paris4silveyraNessuna valutazione finora

- ASTM A193: GradesDocumento1 paginaASTM A193: GradesRamon MendozaNessuna valutazione finora

- Metric to Inch Pipe Size Conversion ChartDocumento1 paginaMetric to Inch Pipe Size Conversion ChartZaquie Mohamed JeffNessuna valutazione finora

- OPSS 932 Nov09 PDFDocumento13 pagineOPSS 932 Nov09 PDFraunak upadhyayaNessuna valutazione finora

- My Life With Hoppers, IncDocumento47 pagineMy Life With Hoppers, IncGilbert Gia100% (1)

- Supersafe Electromec PVT LTD: Delivery ChallanDocumento2 pagineSupersafe Electromec PVT LTD: Delivery Challansanju939Nessuna valutazione finora

- 09 Electric Tool UpdateDocumento30 pagine09 Electric Tool UpdateAji KaNessuna valutazione finora

- Rideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardDocumento45 pagineRideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardpaolaNessuna valutazione finora

- Drill Class 1 DeskDocumento19 pagineDrill Class 1 DeskomkardashetwarNessuna valutazione finora

- Dremel 4000 High Performance Rotary ToolDocumento64 pagineDremel 4000 High Performance Rotary Toolwdowiuue100% (1)

- 029 Mechanized Bolting and ScreeningDocumento4 pagine029 Mechanized Bolting and ScreeningKenny CasillaNessuna valutazione finora

- Guía de Cirugía Guiada MIS MGUIDEDocumento22 pagineGuía de Cirugía Guiada MIS MGUIDEharum avakianNessuna valutazione finora

- S03 Rock Drill HLX5 MaintenanceDocumento16 pagineS03 Rock Drill HLX5 MaintenancereynaldoNessuna valutazione finora

- Building ConstDocumento38 pagineBuilding ConstRoyal BlueNessuna valutazione finora

- Microcell™ Installation Manual: CautionDocumento44 pagineMicrocell™ Installation Manual: Caution6612poolNessuna valutazione finora

- Ffa08 - g02 - en (Assembly Machinery)Documento78 pagineFfa08 - g02 - en (Assembly Machinery)GetziNessuna valutazione finora

- Parallel Clamp Plans: Build Your Own Adjustable Woodworking ClampsDocumento19 pagineParallel Clamp Plans: Build Your Own Adjustable Woodworking ClampsMartin MartinezNessuna valutazione finora

- HYDX-4 Operation Manual 201103Documento29 pagineHYDX-4 Operation Manual 201103jorge squellaNessuna valutazione finora

- Module 1b One Piece Pattern (Flatback)Documento6 pagineModule 1b One Piece Pattern (Flatback)CookieLovelyNessuna valutazione finora

- Teacher-Made Learner'S Home Task: Division of CebuDocumento8 pagineTeacher-Made Learner'S Home Task: Division of CebuMael Dublin-PunayNessuna valutazione finora

- Converting From Cadence Allegro To Agilent ADSDocumento12 pagineConverting From Cadence Allegro To Agilent ADSGaetano CosentinoNessuna valutazione finora

- Hilti Equidist Diamond Core Bits for Unmatched Drilling PerformanceDocumento32 pagineHilti Equidist Diamond Core Bits for Unmatched Drilling PerformanceHCStepNessuna valutazione finora

- DT13 PDFDocumento328 pagineDT13 PDFRaul CostiniucNessuna valutazione finora

- Frame Upgrade TridentDocumento9 pagineFrame Upgrade TridentNghia PhanNessuna valutazione finora

- Hitachi Dh40ma DrillDocumento7 pagineHitachi Dh40ma DrillRafael MoraisNessuna valutazione finora