Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MKI-DS-J-001-A4 - Rev A Data Sheet PCV

Caricato da

FIRMANSYAHTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MKI-DS-J-001-A4 - Rev A Data Sheet PCV

Caricato da

FIRMANSYAHCopyright:

Formati disponibili

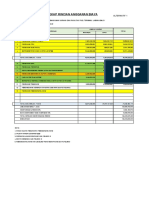

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 4 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

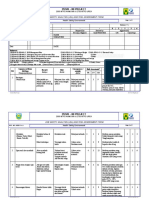

1 Tag No. PCV-1006

2 Service Inlet Hidrate Inhibitor Pumps (P-0102A)

GENERAL

3 Line No. 1/2" SS Tubing

4 P & ID MKI-DG-P-020-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 1/2" In

8 Tubing Material SS

TUBING

9 Tubing Insulation No

10 Operating Pressure 2700 Psig

11 Operating Temperature 80 - 100 °F

12 Process Fluid LIQUID

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD 15.00

15 Inlet Pressure psig 1200

16 Pressure Drop psig 200

PROCESS CONDITION

17 Inlet Temperature °F 71.78

18 Inlet Viscosity cP 0.64

19 Inlet Density lb/ft3 3.8575

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio 1.279

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig 575.47

25 Molecular Mass

26

27

28 Calculated Cv 13.724 Note 1

CALCULATE

D RESULTS

29 Travel Note 1

30 Sound Pressure Lavel < 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model N/A N/A

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity N/A

35 Body Size 4 in Note 1 68 Local Manufacture Reset N/A

36 End Connection & Rating RF 900# 69 Area Classification N/A

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body N/A

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part N/A

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation N/A

40 Packing Material PTFE 73 Tag. No N/A

41 Extension Bonnet Note 1 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 99 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MFR. STD MFR. STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model N/A N/A 92 Marking & Identification No

POTENSIONER

60 Potensioner Type N/A 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output N/A N/A 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max N/A 95

63 Enclosure / Area Classification N/A 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass N/A 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn N/A 98

1. Note : Vendor to Advice

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 5 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-1007

2 Service Inlet Hidrate Inhibitor Pumps (P-0102B)

GENERAL

3 Line No. 1/2" SS Tubing

4 P & ID MKI-DG-P-020-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 1/2" In

8 Tubing Material SS

TUBING

9 Tubing Insulation No

10 Operating Pressure 2700 Psig

11 Operating Temperature 80 - 100 °F

12 Process Fluid LIQUID

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD 15.00

15 Inlet Pressure psig 1000

16 Pressure Drop psig 200

PROCESS CONDITION

17 Inlet Temperature °F 71.73

18 Inlet Viscosity cP 0.64

19 Inlet Density lb/ft3 3.8575

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio 1.279

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig 3206

25 Molecular Mass

26

27

28 Calculated Cv 13.535 Note 1

CALCULATE

D RESULTS

29 Travel Note 1

30 Sound Pressure Lavel < 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model N/A N/A

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity N/A

35 Body Size 4 in Note 1 68 Local Manufacture Reset N/A

36 End Connection & Rating RF 900# 69 Area Classification N/A

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body N/A

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part N/A

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation N/A

40 Packing Material PTFE 73 Tag. No N/A

41 Extension Bonnet Note 1 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 99 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MFR. STD MFR. STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model N/A N/A 92 Marking & Identification No

POTENSIONER

60 Potensioner Type N/A 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output N/A N/A 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max N/A 95

63 Enclosure / Area Classification N/A 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass N/A 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn N/A 98

1. Note : Vendor to Advice

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 6 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

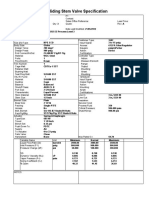

1 Tag No. PCV-1101

2 Service From Wallhead toIndirect Fire Heater (H-1101)

GENERAL

3 Line No. 6"-PG-0003-C-F

4 P & ID MKI-DG-P-021-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 6 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation No

10 Design Pressure 1350 Psig

11 Design Temperature 100 °F

12 Process Fluid Flare

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD

15 Inlet Pressure psig

16 Pressure Drop psig

PROCESS CONDITION

17 Inlet Temperature °F

18 Inlet Viscosity cP

19 Inlet Density lb/ft3

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv 13.05 (max), 12.45 (nom), 11.81 (min) Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel < 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 4 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 900# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No Note 1

41 Extension Bonnet Note 1 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 176 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MFR. STD MFR. STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 Ma dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn Note 1 98

1. Note : Vendor to Advice

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 7 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-H1102

2 Service From Fuel Gas Filter

GENERAL

3 Line No. 1"

4 P & ID MKI-DG-P-021-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 1 In

8 Pipe Material

PIPE

9 Pipe Insulation No

10 Design Pressure 1350 Psig

11 Design Temperature 100 °F

12 Process Fluid Gas

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD

15 Inlet Pressure psig

16 Pressure Drop psig

PROCESS CONDITION

17 Inlet Temperature °F

18 Inlet Viscosity cP

19 Inlet Density lb/ft3

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv Note 1 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel Note 1 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model N/A N/A

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity N/A

35 Body Size 4 in Note 1 68 Local Manufacture Reset N/A

36 End Connection & Rating RF 900# 69 Area Classification N/A

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body N/A

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part N/A

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation N/A

40 Packing Material PTFE 73 Tag. No N/A

41 Extension Bonnet Note 1 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 176 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MFR. STD MFR. STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model N/A N/A 92 Marking & Identification No

POTENSIONER

60 Potensioner Type N/A 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output N/A N/A 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max N/A 95

63 Enclosure / Area Classification N/A 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass N/A 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn N/A 98

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 8 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-H1103

2 Service From Fuel Gas Filter

GENERAL

3 Line No. 1"

4 P & ID MKI-DG-P-021-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 1 In

8 Pipe Material

PIPE

9 Pipe Insulation No

10 Design Pressure 1350 Psig

11 Design Temperature 100 °F

12 Process Fluid Gas

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD

15 Inlet Pressure psig

16 Pressure Drop psig

PROCESS CONDITION

17 Inlet Temperature °F

18 Inlet Viscosity cP

19 Inlet Density lb/ft3

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv Note 1 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel Note 1 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model N/A N/A

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity N/A

35 Body Size 4 in Note 1 68 Local Manufacture Reset N/A

36 End Connection & Rating RF 900# 69 Area Classification N/A

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body N/A

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part N/A

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation N/A

40 Packing Material PTFE 73 Tag. No N/A

41 Extension Bonnet Note 1 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 176 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MFR. STD MFR. STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model N/A N/A 92 Marking & Identification No

POTENSIONER

60 Potensioner Type N/A 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output N/A N/A 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max N/A 95

63 Enclosure / Area Classification N/A 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass N/A 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn N/A 98

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 9 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-1010

2 Service From Fuel Gas Scrubber to Condensate Tank (T-0101-A)

GENERAL

3 Line No. 1"-PG-0309-A-A

4 P & ID MKI-DG-P-025-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 1 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation No

10 Design Pressure Note 1 Psig

11 Design Temperature Note 1 °F

12 Process Fluid Flare

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD

15 Inlet Pressure psig

16 Pressure Drop psig

PROCESS CONDITION

17 Inlet Temperature °F

18 Inlet Viscosity cP

19 Inlet Density lb/ft3

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv Note 1 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel Note 1 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model N/A N/A

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity N/A

35 Body Size 4 in Note 1 68 Local Manufacture Reset N/A

36 End Connection & Rating RF 900# 69 Area Classification N/A

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body N/A

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part N/A

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation N/A

40 Packing Material PTFE 73 Tag. No N/A

41 Extension Bonnet Note 1 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MFR. STD MFR. STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model N/A N/A 92 Marking & Identification No

POTENSIONER

60 Potensioner Type N/A 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output N/A N/A 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max N/A 95

63 Enclosure / Area Classification N/A 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass N/A 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn N/A 98

1. Note : Vendor to Advice

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 10 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-1011

2 Service From Wallhead to HP Separator (V-0101)

GENERAL

3 Line No. 1"-FG-0309-A-A

4 P & ID MKI-DG-P-025-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 1 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation No

10 Design Pressure Psig

11 Design Temperature °F

12 Process Fluid Flare

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD

15 Inlet Pressure psig

16 Pressure Drop psig

PROCESS CONDITION

17 Inlet Temperature °F

18 Inlet Viscosity cP

19 Inlet Density lb/ft3

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv 12.99 (max), 12.39 (nom), 6.31 (min) Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel < 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model N/A N/A

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity N/A

35 Body Size 4 in Note 1 68 Local Manufacture Reset N/A

36 End Connection & Rating RF 900# 69 Area Classification N/A

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body N/A

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part N/A

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation N/A

40 Packing Material PTFE 73 Tag. No N/A

41 Extension Bonnet Note 1 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 176 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MFR. STD MFR. STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model N/A N/A 92 Marking & Identification No

POTENSIONER

60 Potensioner Type N/A 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output N/A N/A 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max N/A 95

63 Enclosure / Area Classification N/A 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass N/A 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn N/A 98

1. Note : Vendor to Advice

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 11 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. LCV-1003

2 Service From HP Separator (V-0101) To MP Separator (V-0103)

GENERAL

3 Line No. 3"-PL-0015-A-D

4 P & ID MKI-DG-P-022-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 3 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation No

10 Design Pressure 900 Psig

11 Design Temperature -2 to 150 °F

12 Process Fluid Process Liquid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate barrel/day 381.00

15 Inlet Pressure psig 799.94

16 Pressure Drop psig 99.88

PROCESS CONDITION

17 Inlet Temperature °F 70.25

18 Inlet Viscosity cP 0.97

19 Inlet Density lb/ft3

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv 1.1115 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 600# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No LY-1003

41 Extension Bonnet Note 1 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 2.75 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 Ma dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn N/A 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 12 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

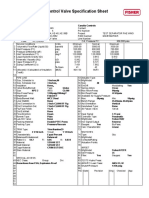

1 Tag No. PCV-1008

2 Service From HP Separator (V-0101) To HP Flare System

GENERAL

3 Line No. 3"-PG-0012-C-D

4 P & ID MKI-DG-P-022-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 3 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 900 Psig

11 Design Temperature 150 °F

12 Process Fluid Gas

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD 0.5

15 Inlet Pressure psig 770

16 Pressure Drop psig 100

PROCESS CONDITION

17 Inlet Temperature °F 70.25

18 Inlet Viscosity cP 0.01

19 Inlet Density lb/ft3 2.86

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio 1.2821

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv 1.0126 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 600# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No PY-1008

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 11 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

1/4"

AIR FILTER

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 Ma dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 13 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. LCV-1004

2 Service From HP Scrubber (D-0102) to MP Separator (V-0103)

GENERAL

3 Line No. 2"-PL-0024-A-D

4 P & ID MKI-DG-P-022-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 2 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 900 Psig

11 Design Temperature -2 to 150 °F

12 Process Fluid Process Liquid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate barrel/day 20

15 Inlet Pressure psig 800

16 Pressure Drop psig 99.882

PROCESS CONDITION

17 Inlet Temperature °F 70.19

18 Inlet Viscosity cP 0.10

19 Inlet Density lb/ft3

20 Specific Gravity 0.99903

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio -

23 Inlet Vapor Pressure Psig -

24 Critical pressure Psig 2696.8

25 Molecular Mass

26

27

28 Calculated Cv 0.58548 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 600# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No LY-1004

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 2.75 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 14 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. LCV-1005

2 Service From MP Separator (V-0103) to LP Separator

GENERAL

3 Line No. 2"-PL-0031-A-A

4 P & ID MKI-DG-P-023-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 2 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 350 Psig

11 Design Temperature 150 °F

12 Process Fluid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate barrel/day 357

15 Inlet Pressure psig 200

16 Pressure Drop psig 99.882

PROCESS CONDITION

17 Inlet Temperature °F 70.25

18 Inlet Viscosity cP 0.97

19 Inlet Density lb/ft3

20 Specific Gravity 0.99902

21 Inlet Compressibility Factor 0.09

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv 1.0451 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1.5 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 300# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No LY-1005

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 2.75 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 15 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-1009

2 Service From MP Separator (V-0103) to Fuel Gas System

GENERAL

3 Line No. 3"-FG-0028-C-B

4 P & ID MKI-DG-P-023-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 3 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 350 Psig

11 Design Temperature 150 °F

12 Process Fluid Process Liquid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD 0.5

15 Inlet Pressure psig 200

16 Pressure Drop psig 100

PROCESS CONDITION

17 Inlet Temperature °F 70.25

18 Inlet Viscosity cP

19 Inlet Density lb/ft3 0.81

20 Specific Gravity 0.03

21 Inlet Compressibility Factor 0.95

22 Inlet Specific Heat Ratio 1.2821

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig 676.66

25 Molecular Mass

26

27

28 Calculated Cv 2.5986 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1.5 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 300# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No PY-1009

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 44 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 16 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-1011

2 Service From LP Separator (V-0104) to Flare Header

GENERAL

3 Line No. 3"-FL-0036-A-A

4 P & ID MKI-DG-P-024-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 3 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 100 Psig

11 Design Temperature 90 °F

12 Process Fluid Gas

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD 0.5

15 Inlet Pressure psig 30

16 Pressure Drop psig 10

PROCESS CONDITION

17 Inlet Temperature °F 70.25

18 Inlet Viscosity cP

19 Inlet Density lb/ft3 0.15

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio 1.2821

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig 676.66

25 Molecular Mass

26

27

28 Calculated Cv 15.527 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1.5 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 150# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No PY-1011

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 44 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 17 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. LCV-1006

2 Service From LP Separator (V-0104) to Separator pond

GENERAL

3 Line No. 2"-PW-0110-A-A

4 P & ID MKI-DG-P-024-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 2 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 100 Psig

11 Design Temperature 90 °F

12 Process Fluid Gas

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate barrel/day

15 Inlet Pressure psig

16 Pressure Drop psig

PROCESS CONDITION

17 Inlet Temperature °F

18 Inlet Viscosity cP

19 Inlet Density lb/ft3

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv Note 1 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel Note 1 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1.5 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 150# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No LY-1006

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page18 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. LCV-1007

2 Service From LP Separator (V-0104) to Condensate Tank

GENERAL

3 Line No. 2"-PL-0038-A-A

4 P & ID MKI-DG-P-024-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 2 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 100 Psig

11 Design Temperature -2 to 150 °F

12 Process Fluid Process Luquid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate barrel/day 215

15 Inlet Pressure psig 30

16 Pressure Drop psig 0.5

PROCESS CONDITION

17 Inlet Temperature °F 70.19

18 Inlet Viscosity cP 0.97

19 Inlet Density lb/ft3

20 Specific Gravity 0.99903

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig 2696.8

25 Molecular Mass

26

27

28 Calculated Cv 9.0353 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1.5 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 150# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No LY-1007

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 24.75 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 19 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. LCV-3001

2 Service From Inlet Scrubber (V-0301) To Condensate Receiving Tank

GENERAL

3 Line No. 3"-PL-0050-A-A

4 P & ID MKI-DG-P-027-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 3 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 600 Psig

11 Design Temperature 150 °F

12 Process Fluid Fuel Gas

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate barrel/day 2

15 Inlet Pressure psig 480

16 Pressure Drop psig 100

PROCESS CONDITION

17 Inlet Temperature °F 71.62

18 Inlet Viscosity cP 0.95

19 Inlet Density lb/ft3

20 Specific Gravity 0.99887

21 Inlet Compressibility Factor 0.91

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig 0.93

25 Molecular Mass

26

27

28 Calculated Cv 0.0059998 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 2 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 150# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No LY-3001

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 24.75 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 20 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-3001

2 Service From Inlet Scrubber (V-0301) To Custody Meter

GENERAL

3 Line No. 3"-PG-0064-A-B

4 P & ID MKI-DG-P-027-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 3 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 675 Psig

11 Design Temperature 200 °F

12 Process Fluid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD 2.5

15 Inlet Pressure psig 480

16 Pressure Drop psig 30

PROCESS CONDITION

17 Inlet Temperature °F 70.25

18 Inlet Viscosity cP 0.01

19 Inlet Density lb/ft3 1.73

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio 1.2821

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig 676.66

25 Molecular Mass

26

27

28 Calculated Cv 11.793 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 4 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 300# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No PY-3001

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 44 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 21 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-3002

2 Service From Inlet Scrubber (V-0301) To Custody Meter (M-303)

GENERAL

3 Line No. 4"-PG-0065-A-B

4 P & ID MKI-DG-P-027-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 4 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 675 Psig

11 Design Temperature 200 °F

12 Process Fluid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD 12.5

15 Inlet Pressure psig 480

16 Pressure Drop psig 30

PROCESS CONDITION

17 Inlet Temperature °F 70.25

18 Inlet Viscosity cP

19 Inlet Density lb/ft3 1.73

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio 1.2821

23 Inlet Vapor Pressure Psig -

24 Critical pressure Psig 676.66

25 Molecular Mass

26

27

28 Calculated Cv 57.393 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 6 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 300# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No PY-3002

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 176 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 22 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-4001

2 Service Fuel Gas From MP Separator to Fuel Gas Scrubber (V-0401)

GENERAL

3 Line No. 3"-PG-0300-A-B

4 P & ID MKI-DG-P-028-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 3 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 100 Psig

11 Design Temperature 150 °F

12 Process Fluid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD 0.5

15 Inlet Pressure psig 200

16 Pressure Drop psig 150

PROCESS CONDITION

17 Inlet Temperature °F 70.25

18 Inlet Viscosity cP

19 Inlet Density lb/ft3 0.72

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio 1.2821

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig 676.66

25 Molecular Mass

26

27

28 Calculated Cv 3.6716 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1.5 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 300# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No PY-4001

41 Extension Bonnet No 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 176 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 23 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. PCV-4002

2 Service Fuel Gas From Dehydration ti Fuel Gas Scrubber (V-0401)

GENERAL

3 Line No. 3"-PG-0045-A-D

4 P & ID MKI-DG-P-028-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 3 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 100 Psig

11 Design Temperature 150 °F

12 Process Fluid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD 0.5

15 Inlet Pressure psig 200

16 Pressure Drop psig 152

PROCESS CONDITION

17 Inlet Temperature °F 70.25

18 Inlet Viscosity cP

19 Inlet Density lb/ft3 0.72

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio 1.2821

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig 676.66

25 Molecular Mass

26

27

28 Calculated Cv 3.6716 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1.5 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 300# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No PY-4002

41 Extension Bonnet Note 1 74 MFR Model N/A N/A

SWITCHES

42 Trim Type Single Seated 75 Type Quantity N/A N/A

43 Trim Size Note 1 76 Contact / Rating N/A

44 Rated Cv 176 Note 1 77

45 Characteristic Equal Precentage 78 MFR Model VTA VTA

46 Rated Travel Note 1 79 Air Set Yes

47 Plug / Ball / Disc Material 316 SS 80 Filter Gauge Yes Yes

REGULATOR

AIR FILTER

1/4"

48 Seat Material 316 SS 81 End Connection

NPTF

49 Case Material Stem Material 316 SS 316 SS 82 Body Alumunium

50 MFR Model Note 1 Note 1 83 Trim 316 SS

51 Type Size Diaphragm Note 1 84 Packing PTFE

52 Close At Open At MTR STD MTR STD 85

ACTUATOR

53 On-Off Modulating N/A Yes 86

54 Req'd Air Supply Press 80 - 272 Psig 87 Handwheel No

OTHER ACC

55 Failure Position Closed 88 Lubricator Fitting No

56 Act.Orientation Vertical Up 89 Lock-up System Yes

57 Stroke Speed Travel Indicator Note 1 Yes 90 Quick Exhaust Valve No

58 Flow Action To Open 91 Speed Control No

59 MFR Model Note 1 Note 1 92 Marking & Identification No

POTENSIONER

60 Potensioner Type Smart E/P Potensioner 93 Body Paint & Color Note 1

PAINT

61 Signal Input Output 4 - 20 mA dc Note 1 94 Actuator Paint & Color Note 1

62 Air Supply Min/Norm/Max 80/100/272 Psig 95

63 Enclosure / Area Classification NEMA 7 and NEMAA 4X 96 Hydro.Pressure Yes

TESTS

64 Filter Reg / Gauge / Bypass Yes / Yes / Note 2 97 Leakage ANSI FCI70-2

65 Electrical/ Phenumatic Conn 1/2" NPT /1/4" NPT 98

Note :

1. Vendor to Advice

2. Potensioner Pressure Gauge made from Stainless Steel complete with glycerin filled case scale in bar g for supply, input and output signals,

A Issued For Review 16/11/2012 TSP BAS ASM

BY CHKD APVD

REV DESCRIPTION DATE

CONTRACTOR MKI

MANHATTAN KALIMANTAN

INVESTMENT

DATA SHEET CONTROL VALVE

GAS PRODUCTION FACILITY BAYAN-TARAKAN

DATA SHEET CONTROL VALVE

DOCUMENT NUMBER Rev CONTRACT NUMBER

Page 24 of 33

MKI-DS-J-002 A 4600.PK/DIR-UT/PGAS/2012

1 Tag No. FCV-4001

2 Service Inlet Fuel Gas Scrubber (V-0401)

GENERAL

3 Line No. 3"-PG-0303-A-A

4 P & ID MKI-DG-P-028-A3

5 Area Classification Division 1, Group D, and T3

6 Seat Leakage class Class VI

7 Line Size 3 In

8 Pipe Material Carbon Steel

PIPE

9 Pipe Insulation None

10 Design Pressure 100 Psig

11 Design Temperature 150 °F

12 Process Fluid

@Maximum

13 Units @Normal Flow @Minimum Flow

Flow

14 Flow Rate MMSCFD

15 Inlet Pressure psig

16 Pressure Drop psig

PROCESS CONDITION

17 Inlet Temperature °F

18 Inlet Viscosity cP

19 Inlet Density lb/ft3

20 Specific Gravity

21 Inlet Compressibility Factor

22 Inlet Specific Heat Ratio

23 Inlet Vapor Pressure Psig

24 Critical pressure Psig

25 Molecular Mass

26

27

28 Calculated Cv Note 1 Note 1

CALCULATED

RESULTS

29 Travel Note 1

30 Sound Pressure Lavel 85 dBa

31

32

33 MFR Model Note 1 Note 1 66 MFR Model Note 1 Note 1

SELONOID VALVE

34 Body Type Material Globe Carbon Steel 67 Quantity 1 Ea

35 Body Size 1.5 in Note 1 68 Local Manufacture Reset No

36 End Connection & Rating RF 300# 69 Area Classification Class 1 Div.2 Gr.D

37 Bonnet Type Material Standard Carbon Steel 70 Material / Trim Body 316 SS / 316 SS

38 Flow Direction Flow to Open Note 1 71 Body Size / No. of Part 1/2" NPTF / 3 Way Univ.

BODY AND TRIM

39 Bolt & Nut Material ASTM A194 2H 72 Cable Entry / Coil Installation 1/2" NPTF / Class H

40 Packing Material PTFE 73 Tag. No PY-4001