Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2271 Aaa JSM 301 - B PDF

Caricato da

NorgjieDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2271 Aaa JSM 301 - B PDF

Caricato da

NorgjieCopyright:

Formati disponibili

Project N° Unit Document Code Serial N° Rev.

Page

2271 AAA JSM 301 B 1/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

PROJECT PROCEDURE

FOR PLANNING, SCHEDULING,

PROGRESS CONTROL AND REPORTING

which it is specifically furnished or outside the extent of the agreed upon right of use.

B ISSUE FOR FEED C. BERNARDEL F. FORNACI G. ZERBONI / E. BARONE

A 28.09.2007 ISSUE FOR REVIEW/COMMENTS C. BERNARDEL F. FORNACI G. ZERBONI / E. BARONE

REV. DATE STATUS WRITTEN BY CHECKED BY APPROV./AUTHOR. BY

(name & visa) (name & visa) (name & visa)

DOCUMENT REVISIONS

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 2/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

TABLE OF CONTENTS

Page

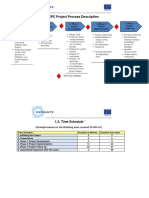

1. PURPOSE ........................................................................................................................ 3

1.1. Purpose ............................................................................................................................ 3

2. DEFINITIONS ................................................................................................................... 3

2.1. Definitions ......................................................................................................................... 3

3. RESPONSIBILITIES ......................................................................................................... 3

3.1. Responsibilities ................................................................................................................. 3

4. PROCEDURE ................................................................................................................... 3

4.1. Introduction ....................................................................................................................... 3

4.2. Planning and Scheduling .................................................................................................. 4

4.3. Progress Planning .......................................................................................................... 13

4.4. Progress Reporting ......................................................................................................... 17

4.5. Progress Meetings .......................................................................................................... 22

5. RECORDS...................................................................................................................... 23

5.1. Records .......................................................................................................................... 23

ATTACHMENT 1 - EPC packages composition and TYPICAL WORK BREAKDOWN

STRUCTURE for each package (WBS) ...................................................................................... 24

ATTACHMENT 2 - PROJECT CONTROL DOCUMENTATION INDEX ........................................ 26

ATTACHMENT 3 - PHOTOGRAPHY LIMITATIONS .................................................................... 28

ATTACHMENT 4 – EXAMPLE OF DETAILED TESTING SCHEDULE ........................................ 29

ATTACHMENT 5 – EXAMPLE OF LOOP CHECKING SCHEDULE............................................. 31

ATTACHMENT 6 – PROJECT PROGRESS ASSESSMENT SCHEDULE BASED ON QC

ACHIEVEMENT (construction) ..................................................................................................... 32

ATTACHMENT 7 – STATISTIC FOR ENGINEERING DELIVERABLES ...................................... 65

which it is specifically furnished or outside the extent of the agreed upon right of use.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 3/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

1. PURPOSE

1.1. Purpose

1.1.1. This Procedure covers Planning, Scheduling, Progress Control and reporting

requirements to be followed by EPC Contractor in order to grant a common Progress

evaluation and Reporting tool for the entire JER Project during all the phases of the

Project i.e.:

• Detailed Design and Engineering.

• Procurement.

• Construction and Precommissioning.

2. DEFINITIONS

2.1. Definitions

2.1.1. “Project Milestones” shall mean the Critical Milestone Dates predefined by COMPANY,

as specified in Contract.

3. RESPONSIBILITIES

3.1. Responsibilities

CONTRACTOR's Project Control Management shall be responsible for the

preparation, approval and implementation of CONTRACTOR's Project Control

Procedures. The Project Controls Manager shall ensure that a suitably qualified and

experienced project control team is established to operate the services and reporting

requirements as set out in this procedure.

4. PROCEDURE

which it is specifically furnished or outside the extent of the agreed upon right of use.

4.1. Introduction

4.1.1. CONTRACTOR's Project Control Procedures shall cover planning, scheduling,

progress control and progress reporting and trending. They shall be issued within

thirty (30) calendar days of the effective date of this Contract for COMPANY's

approval.

CONTRACTOR's Project Control Procedure shall permit the:

• Identification and analysis of all CONTRACTOR's, Subcontractors' and Vendors'

activities.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 4/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

• Progress monitoring and trending of these activities through bar charts, progress

curves, histograms and follow-up tables.

• Prompt planning, early identification of any schedule delay and implementation of

corrective actions to recover any delay, whenever required.

• Validation of progress and Project Milestones achieved, as part of the invoice

approval process.

The overall Project Control System shall be based on a Work Breakdown Structure

WBS (see Attachment 1 for reference of Package typical composition a lower details).

CONTRACTOR shall provide COMPANY with access to all relevant planning and

progress documents. CONTRACTOR shall provide copies of all Subcontractors' and

Vendors' schedules and relevant planning data/information.

CONTRACTOR shall ensure that all reporting schedule information is an accurate

record of the WORK status as determined from the Project Control System. All such

information shall be subject to audit by COMPANY.

CONTRACTOR shall provide , free of charge, the necessary computer hardware and

software to allow electronic transfer of CONTRACTOR's project control data, for

analysis and verification by COMPANY, including back up of native files.

CONTRACTOR's Project Control System shall follow COMPANY requirements as

detailed hereafter.

4.2. Planning and Scheduling

4.2.1. General

Where necessary, CONTRACTOR's standard planning and scheduling procedures

shall be modified to incorporate COMPANY's requirements. The following section

describes the essential requirements of COMPANY, but does not exclude the addition

of enhancements by CONTRACTOR.

which it is specifically furnished or outside the extent of the agreed upon right of use.

The planning and scheduling procedures shall be based on detailed logic networks,

using Primavera Project Planner (P3) for Windows - Version 3.1 or later software for

critical path analysis. The detail shall support and be compatible with the WBS and the

higher levels of planning used for management reporting both to COMPANY and within

CONTRACTOR's organisation.

All schedules are to be provided in a consistent and compatible format and the format,

coding, activity ID numbering and reporting criteria shall be coordinated with the

COMPANY prior to WORK Schedule submission.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 5/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

4.2.2. Work Breakdown Structure

The Work Breakdown Structure (WBS) shall be a framework of the total scope of work

for project management and control. The WBS shall allow the integration of all WORK

functions and shall define the manner in which the WORK shall be managed and

progressed.

The WBS shall encompass the complete scope of WORK divided into discreet,

identifiable Work Packages, to provide the necessary level of detail for effective

progress measurement, accountability and control.

The WBS shall require the establishment of a natural hierarchy for summarisation, the

top level representing the 'total project', the lower levels reflect successively increasing

detail which shall illustrate the manner in which the WORK shall be divided and

implemented. In developing the WBS, CONTRACTOR shall address the following:

• Project parts where Plants/Units geographical areas are apparent.

• Project phases, i.e., Engineering, Procurement, Construction, Precommissioning

and Commissioning.

• Construction areas.

• Electronic Model Design file sizes and boundaries.

• Engineering disciplines and construction trades.

• Equipment groups and material commodities.

• Subcontractors.

• Precommissioning Systems.

The WBS shall be consistently applied in all project control documents.

• Planning Hierarchy

• Reporting Levels

CONTRACTOR's planning shall be based on the following hierarchy of planning

reporting levels:

• Project Milestone Schedule Level I

which it is specifically furnished or outside the extent of the agreed upon right of use.

• Project Summary Schedule Level II

• Critical Path Method (CPM) Network Schedule

comprising Detailed Engineering, Procurement,

Construction (EPC) and Precommissioning activities Level III

• Detailed Schedules and Control Documents Level IV

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 6/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

(1) Project Milestone Schedule - Level I

The Level I Schedule shall be the summary bar chart for the project. It shall be

based on the WBS structure and project phase, and shall identify the Project

Milestones. As such, it shall define the parameters for all lower levels of

scheduling. The Level I shall be of sufficient detail to illustrate how

CONTRACTOR can achieve completion of the WORK within the target dates

required in the CONTRACT. Additional activities, key dates and interfaces shall

be shown where this helps to demonstrate critical or high risk elements of the

WORK.

Typically, the Level I Schedule shall be a logical presentation on a single page

(capable of legible reduction to A4 or A3 size), containing 50 to 60 lines. It shall

summarise for each Level I WBS element the main phases for each Level II

WBS element. Project Milestones shall be shown and shall be supplemented

with additional milestones to highlight key events and interfaces.

The Level I Schedule shall be issued to COMPANY for approval within thirty (30)

calendar days of the effective date of Contract. It shall not be changed without

the written consent of COMPANY.

The Level I Schedule shall be updated and reissued monthly, using a 'time now'

(data date) line, to show actual progress which shall be derived from the lower

level schedules as described below. A forecast bar line shall show the remaining

duration to illustrate the time to completion of the WORK.

(2) Project Summary Schedule - Level II

The Level II Schedule shall be an expansion of the Level I Schedule to the level

of detail necessary, within the main elements of the WBS, to identify the Project

Milestones, key events and to depict the logical sequence and relationships of

activities between disciplines/trades and WORK phases. Its principal purpose is

to:

• Show the relationships between Engineering, Procurement, Construction,

Precommissioning and Mechanical Completion.

• Monitor the progress of all major phases, Subcontracts, long lead

equipment, critical activities and high risk activities within the WBS structure.

which it is specifically furnished or outside the extent of the agreed upon right of use.

• Set up the framework for detailed Level III Networks and resource analysis.

• Demonstrate to COMPANY, CONTRACTOR's understanding of the

complete WORK scope and schedule objectives.

Typically, the Level II Schedule shall be a multi-page bar-chart, capable of legible

reduction to A3 or A4 size. A page for each Level I WBS element shall contain

50 to 60 lines of activities which show the main Discipline / Trade / Subcontract

activities within each Phase. The Level II Schedule shall be updated and

reissued monthly, using a 'time now' line, to show actual progress which shall be

derived from the lower level schedules described below.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 7/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

The Level II Schedule shall include separate start or finish milestones pertaining

to each of the interfaces affecting the work as specified in the relevant interface

schedule .The interface milestone shall clearly identify the interface reference

number in the activity description.

The Level II Schedule shall be issued to COMPANY for approval within thirty (30)

calendar days of effective date of the Contract. The Level II Schedule shall be

revised by CONTRACTOR as the Level III Schedules are developed and/or to

reflect the improved definition of the latter phases of the WORK. Such revision

shall require written approval by COMPANY.

(3) Detailed Mobilisation Schedule - Level III

A Mobilisation Schedule detailing the planned activities for the first three (3)

months of the project shall be submitted to COMPANY for approval within ten

(10) calendar days of effective date of the Contract. This schedule shall

supplement the Level III schedules during their preparation and shall enable a

controlled start to the Contract.

This schedule shall detail specific mobilisation activities, in addition to the initial

engineering and early procurement activities. These shall include, but not be

limited to:

• The provision of CONTRACTOR's and COMPANY's facilities.

• Mobilisation of personnel and equipment.

• The establishment of communications and computer facilities.

• The preparation, submission and approval of all required Project

Management, QA, Project Control and Procurement procedures, manuals,

documentation and Project Execution Plans.

• COMPANY provided data and/or decisions which CONTRACTOR requires to

undertake the design work.

which it is specifically furnished or outside the extent of the agreed upon right of use.

This schedule shall develop the detail from the framework within the overall

WORK Schedule and in line with the WBS. It shall be updated and reissued

every week, using a 'time now' line, to show actual progress achieved, until such

time that it is included in the Level III Schedules.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 8/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

(4) Detailed Engineering, Procurement, Construction and Precommissioning

Schedules - Level III

A Level III Schedule in the form of detailed precedence network(s) and based on

the Work Packages of the WBS shall be prepared by CONTRACTOR and

submitted for COMPANY review within thirty (30) calendar days of effective date

of Contract.

The Level III networks shall be a 'live' model of the WORK and shall be the tool

for schedule analysis, providing identification of float, critical path(s) and resource

bottlenecks. They shall be developed to embrace the total life and scope of the

Contract from the effective date to Mechanical Completion and shall provide the

schedule windows for the Level IV Detailed Schedules and Control Documents.

All Project Milestones shall be clearly identified and integrated into the network

logic, as shall Subcontractors' and Vendors' schedules, ensuring the inclusion of

all activities necessary to achieve completion.

In developing the network detail, CONTRACTOR shall ensure that descriptions

of activities include area/facilities identification. Including this information in an

“intelligent activity ID number” or an activity code or in associated activities is

insufficient. For example, Develop P&IDs, Prepare Plot Plan, Loop Check, Install

Piping, Install Switchgear, and Terminate Cables are all unacceptable

descriptions. Prepare Unit XXX Plot Plan and Install Switchgear in Substation

YYY would be acceptable descriptions.

All the activities with a total float less than 25 days will be considered critical for

network point of view. The baseline will have less than 10% of critical activities.

Finish to Start links will be maximized. Exceptions and lags will be explained in

the narrative to be issued together each issue of the schedule where basis,

assumption, main productivities used and critical path will be explained.

Typically, the network shall be between 1500 and 2500 activities and shall detail

the production of deliverables for construction directed at the Level I elements of

the WBS.

The Level III network shall individually identify all major contract milestones and

which it is specifically furnished or outside the extent of the agreed upon right of use.

milestones identifying all interfaces with other contractors.

Detailed interface schedule shall be developed within ninety (90) calendar days

from effective date of this Contract.

The Level III network and associated reports shall be updated at least monthly

and issued to COMPANY. Every issue shall include an electronic issue to enable

COMPANY review using Primavera. CONTRACTOR shall prepare standard

reports from the network, which clearly demonstrate the current performance

against the approved WORK Schedule. These shall include bar charts and

tabulations, the format of which shall be agreed with COMPANY. Following

monthly time analysis, CONTRACTOR shall identify the critical path and shall,

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 9/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

throughout the duration of the WORK, update the critical path. All changes

made to the networks as part of the monthly update shall be reported to

COMPANY together with the critical path analysis.

Once an activity has been added to the schedule, it shall remain in the schedule.

If the scope of an activity changes, the activity shall be replaced with new

activities using new activity ID’s. Log entries shall be made in the old and new

activities’ logs to explain the changes. If it is determined that the activity is no

longer required or is to be replaced, the word ‘deleted’ shall be added to the

activity description, all relationships shall be deleted, the original duration set at

zero (0), a log entry made explaining the deletion.

As part of each monthly progress report, CONTRACTOR shall produce a 90 day

Look Ahead schedule. The schedule will be extracted from the network and shall

include all activities scheduled to start and finish within the next 90 days.

The Construction Level III has to comply also with the rules listed below that are

based on the following definitions:

Work Class

A set of elements that can be assimilated for work phases and measurement

units, and an element of subsequent construction activity analysis for the Zone.

Discipline

A set of Work Classes that can be assimilated for material typology and

implementation details, utilised for the planning and control of work loads with

homogeneous commitment of resources.

Work Steps

Elementary work phases

Plant/Unit

Functional Zone blocks

Zone

The total number of “piping areas” indicated on the Detailed Key Plan, identified

geographically.

which it is specifically furnished or outside the extent of the agreed upon right of use.

For buildings, a zone corresponds to a building or a group of buildings

Work completion according to schedule and optimisation of manpower are the

two main objectives of construction activity planning. To achieve these

objectives, the construction plan must:

• Match CONTRACTOR(S) Project WBS;

• be the result of constructability analysis;

• include all activities to be carried out for project completion;

• contain reliable and updated information;

• attribute to each network activity a physical quantity and the number of man-

hours required for its completion;

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 10/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

• order and link activities in erection sequences with schedule definition;

• allocate the necessary manpower in the most suitable manner to avoid

scarcity or excess.

The planning criteria to be used by Contractor are:

• The Construction Plan is developed on the basis of the completion sequence

defined by COMPANY.

• CONTRACTOR(S) Plant/Units, Zones and Areas must be defined right from

the start of the project in the Key Plans and must be common to the

Engineering, Procurement Construction and Start-Up departments, so that

the various documents needed for preparing and updating the Construction

Plan are congruous.

• Zones are identified geographically. Their component “piping areas” are the

smallest geographical element for the development of Piping Engineering

layout drawings.

• Each building (or group of buildings, case by case) constitutes a Zone.

• The items contained in each Zone must be defined in terms of physical

quantities and construction man-hours.

• Quantities for items with extended spatial dimensions (i.e. a concrete

conduit, a duct bank) must be subdivided into the various Zones through

which they cross.

• Items with extended spatial dimensions that cannot be physically divided into

various Zones (i.e. power and instrument cables) must be assigned to the

most significant Zone which will identify them (a cable will be assigned to

Zone of the user to which it is connected; if the cable connects two

substations, it is attributed to the end one, which is considered as the end

user).

•

which it is specifically furnished or outside the extent of the agreed upon right of use.

For vertical works, whose implementation depends on the correct

construction sequence of the various floors (i.e. concrete structures, steel

structures, buildings with several levels) each level constitutes a section of

the work. In such cases, each level/work section becomes an item.

• Each Work Class has its relative weight, i.e. a percentage value given by the

ratio between the estimated man-hours for completion of the Class and the

estimated man-hours for the completion of the Discipline to which it belongs.

• Within any Work Class, each item has a relative weight, given by the ratio

between the physical quantity attributed to it and the total physical quantity

estimated for completion of the related Work Class.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 11/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

• The construction/installation of each single item is subdivided into

elementary Work Steps, whose proper implementation has been checked

and documented on Quality Control Forms (QCF): each of these has a

relative weight given by the ratio between the man-hours needed for

implementing the phase and the total man-hours required for completing the

item, both estimated according to established standards.

• “Earth-moving” activities are the sole exception, since their final acceptance

is tied to inspection and certification.

• When possible, the Work Steps are subdivided into work lots, which are also

singly certifiably. In such cases, a relative weight is attributed to the work lot

(given by the ratio of the lot itself to the total number of lots). The related

QCF for each Work Step is established – for all Work Classes – in the

project Quality Control Plan (see 2271-AAA-JSM-501).

• The implementation of any Work Step is controlled by one or more

documented Quality Control Steps, and its relative weight contributes to the

physical progress of the item. For each step therefore, physical progress is

defined as the number of work lots singly verified and documented over the

total number of work lots making up the step. If a Work Step cannot be

subdivided, it is verified and documented with a single QCF, with a physical

progress of 0 (zero)% prior to issue, and of 100% after.

• The list of Disciplines and Work Classes is indicated in the “Progress

Evaluation Table”, Attachment 7. The document also describes the

assessment method for the works carried out, the definition of the relative

weights attributed to the Work Steps and Quality Audits.

(5) Detailed Schedules and Control Documents - Level IV

Level IV Detailed Schedules and Control Documents shall be prepared by

CONTRACTOR and issued to COMPANY as indicated below. These documents

and/or their supporting data bases shall describe in detail the scope of WORK in

terms of quantity and schedule. They shall be CONTRACTOR's principal control

tool, shall allow time for COMPANY review/approval and shall provide the basis

which it is specifically furnished or outside the extent of the agreed upon right of use.

for the day to day implementation of the WORK, as well as being the mechanism

for progress measurement.

Level IV Detailed Schedules and Control Documents shall be compatible with the

WBS and shall fully support the Level III Schedules. These documents shall

comprise as a minimum the following and include their supporting data bases:

(a) Design Drawing and Document Indexes.

(b) Schedule of Requisitions.

(c) Vendor Document Index.

(d) Equipment Delivery and Material Delivery Schedules (see paragraph 6

below).

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 12/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

(e) Subcontracts Schedule (see Paragraph 7 below).

(f) Third Party/Authority Interface Schedule.

(g) Prefabricated materials status reports.

(h) Detailed Construction Schedules.

(i) Detailed Testing Schedules – an example is provided in Attachment 4.

(j) Detailed System Completion Schedule.

(k) Interface Schedule.

(l) Water for Hydrotest and Flushing.

(m) Heavy Lift Schedule.

(n) Transport Schedule.

(o) Site Materials Received Reports.

(p) Manpower Reports.

(q) Loop checking Schedule - an example is provided in Attachment 5.

(r) Construction equipment report.

The format of the above shall be agreed with COMPANY following award of

CONTRACT. They shall be comprehensive. Planned, actual and forecast data

shall be detailed and reports provided both in full and on an exception basis.

Additional schedules and documents shall be provided by CONTRACTOR where

requested by COMPANY to demonstrate effective control of the WORK.

Level IV Schedules (a), (b), (c), (d), (e) and (f) above shall be issued to

COMPANY within thirty (30) calendar days of effective date of this Contract.

Level IV Schedules (h), (i), (j), (k), (l), (m), (n) and (q) above shall be issued to

COMPANY at least one hundred and twenty (120) calendar days prior to planned

commencement of these activities.

Items (g), (o), (p) and (r) shall be produced weekly throughout the relevant

periods of progress.

(6) Equipment Delivery Schedule

which it is specifically furnished or outside the extent of the agreed upon right of use.

CONTRACTOR shall prepare an Equipment Delivery Schedule which shall be a

summary presented in tabular format and shall demonstrate the procurement

plan. It shall show all tagged equipment items and critical, long lead and

specialist items and major equipment groups.

For each entry the following procurement steps shall clearly show:

• Issue of Enquiry (Request for Quotation).

• Receipt of Bids

• Issue of Technical Tabulation and Vendor Recommendation to COMPANY.

• Purchase Order.

• Receipt and Approval of Critical Vendor Documentation.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 13/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

• Vendors' Ex Works Delivery and FOB.

• Shipping Period.

• Customs Clearance

• Delivery to WORK Site.

A 'Required on Site' (ROS) date shall also be indicated.

The Equipment Delivery Schedule shall be issued for COMPANY approval within

forty-five (45) calendar days of effective date of Contract. It shall be consistent

with the Level II Overall Project Schedule and the Material Status Report and any

changes from month to month shall be identified to COMPANY. The Schedule

shall be updated weekly to show actual achievement against the plan. A forecast

shall indicate where a significant deviation from the Plan is anticipated.

(7) Subcontract Schedule

CONTRACTOR shall prepare a Subcontract Schedule in a tabular format and

provide details of Subcontracts including Vendor engineers to be undertaken. For

each entry the following details shall be shown:

• WORK items to be subcontracted.

• Enquiry Number/Requisition Number.

• Potential subcontractors bidding for the WORK.

• Bid dates:

• Issue

• Closing

• Received

• Pre-order submission package date.

• Selected Subcontractor name.

• Approval of Bid Summary recommendations by COMPANY prior to award of

subcontract.

• Issue date of letter of intent.

• Contract Award date.

• Start of mobilisation date.

• Commence work onsite date.

which it is specifically furnished or outside the extent of the agreed upon right of use.

4.3. Progress Planning

4.3.1. General

Throughout the duration of the WORK, CONTRACTOR shall develop, maintain,

update and report against a series of progress control curves and manpower

histograms. The baseline curves shall show the monthly planned vs. actual progress,

which shall be generated directly from the approved schedules and shall form the

basis of the physical progress control system. During the execution of the WORK the

actual monthly progress shall be compared with the planned. A forecast shall be

introduced if there is any negative deviation from the plan.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 14/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

4.3.2. Level I Progress Control Curve

The Level I Progress Control Curve shall be a summation of the Level II Progress

Control Curves for all of the Engineering, Procurement and Construction phases. The

progress figures for each phase and their respective weightings shall be shown, as

well as the overall WORK figures, either in tabular format below the curve or

separately as a progress table. The weightings will be based as much as possible on

contractual values

4.3.3. Level II Progress Control Curves

Individual Progress Control Curves shall be produced for Engineering, Procurement

and Construction.

(1) The Engineering curve shall be supported by a table of the weighting by

manhours and progress figures for all of the direct Engineering disciplines.

Engineering disciplines shall include all direct disciplines contributing to the

engineering, procurement and contract services. A separate table shall be

produced showing progress figures per discipline in accordance with the

WBS.

(2) Procurement curves shall be shown separately and overall for equipment

and bulk materials. They shall be generated from the relevant procurement

schedules whereby the weighting of equipment, bulk materials and

procurement steps are used to describe planned progress. The curves shall

be supported by a table of the weightings and progress figures for each

equipment group or bulk material category as appropriate. Additionally

curves shall also be produced showing 'Order Placement', 'Shipping' and

'Delivery to Site' separately for Equipment and Bulks.

(3) The Construction curve shall be fully supported by a table of the weightings and

progress figures for all of the direct Construction trades. Construction shall

include all prefabrication (both on and away from the work Site), vessel

dressing and sub-assembly, but exclude preliminaries. A separate table shall

be produced showing progress figures per trade in accordance with the WBS.

The approved planned Progress Control Curves shall provide the baseline of

which it is specifically furnished or outside the extent of the agreed upon right of use.

the WORK and shall be fixed for the duration of the WORK. All changes shall

be superimposed on the original curves to reflect any approved revision or

change.

4.3.4. Manpower Histograms

For each of the above Level II Progress Control Curves, with the exception of

Procurement, CONTRACTOR shall prepare compatible manpower histograms.

Additionally, histograms shall be prepared for both Home Engineering office and Site

Construction works showing management and indirect separately. The histograms for

each work location shall show the monthly planned manpower, and the assumed

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 15/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

manhours per man month shall be clearly indicated. A table detailing the breakdown

by discipline/trade shall be provided below the histogram or as a separate tabulation.

During the execution of the WORK, the actual manpower shall be compared with the

planned and a forecast shall be produced to support any progress curves as

necessary.

The working week for equivalent manpower calculation shall be based on:

• 40 hr/week Home Engineering Office

• 60 hr/week Site Works

4.3.5. Progress Measurement

The Level I and II Progress Control Curves identified in above sections shall be

updated with progress and issued in the monthly report. The method of progress

measurement shall be fully described in CONTRACTOR's procedures. As a minimum

requirement, the Progress measurement system shall satisfy the following criteria:

(1) Engineering progress, which shall include procurement and contract

services, is to be measured and aggregated from individual

deliverables/actions defined in the Level IV schedules and shall encompass

the complete engineering scope of work.

Progress shall be a measurement of work done and shall be an assessment of

the percentage completion against a series of predetermined production

verifiable steps for deliverables/actions from start to completion. The steps shall

be sequential to align the progress calculation with manhours expenditure,

keeping the interval between the steps as shorter as possible. Aggregation of

assigned weightings shall enable the calculation of percentage progress and

earned manhours to the summary levels of the WBS.

All deliverables which need to be issued for construction shall have their own

weighting within the progress measurement system, and the system shall be

able to declare separate planned and actual progress values for all types of

deliverables.

(2) Procurement progress shall include all equipment and direct bulk materials to

be procured for the WORK.

which it is specifically furnished or outside the extent of the agreed upon right of use.

Procurement progress shall be calculated by summing the results of the

following:

• Twenty percent (20%) of the quotient derived by dividing the number of

Purchase Requisitions issued for bid by the total number of purchase

requisitions.

• Forty percent (40%) of the quotient derived by dividing the number of

Purchase Orders placed by the total number of Purchase Orders.

• Forty percent (40%) of the quotient derived by dividing the number of

Purchase Orders for which all material has been delivered to the Work

Site by the total number of Purchase Orders.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 16/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

(3) Construction progress shall be determined by the measurement of the

physical quantity of work done. Measurement of each category of WORK,

e.g., cubic metres of concrete poured, number of piping spools fabricated

and installed etc, shall be for the complete scope of that category of WORK.

Each category of work shall be weighted by direct labour man hours.

A reference list as progress steps for construction progress calculation is

reported in Attachment 6 and will based on QC documents.(The principles to be

applied are also described in above paragraph).

The Level IV Construction Schedules shall provide the means of recording

progress. The earned manhours for each category of WORK shall be

aggregated to calculate the percentage completion to the summary levels of

the WBS.

Where quantities or manhours are forecast to significantly exceed the baselines

established for progress measurement and reporting, CONTRACTOR shall prepare,

following agreement of COMPANY, a recovery schedule of the remaining WORK.

COMPANY review and approval shall be required prior to implementation.

CONTRACTOR shall provide COMPANY with unlimited access to CONTRACTOR's

progress measurement data for the purpose of verification of physical progress.

4.3.6. Construction Productivity

CONTRACTOR shall keep up to date records and report to COMPANY each month on

the productivity of the work force.

The productivity factors, based on earned (or achieved) manhours divided by actual (or

expended) manhours, shall be used by CONTRACTOR to demonstrate the

performance of the WORK and to substantiate that adequate manning levels are being

provided to meet the WORK Schedule.

Additionally, during the Construction phase, CONTRACTOR shall report each month

both the productivity in terms of expended manhours per unit of each category of

WORK installed and the actual quantity achievement against the quantity planned for

each of the major categories of WORK, such as:

which it is specifically furnished or outside the extent of the agreed upon right of use.

1) Number of piles installed.

2) Cubic metres of concrete poured.

3) Square metres of paving completed.

4) Tonnage of structural steel fabricated and erected.

5) Equipment items installed.

6) Number/tonnage/metres of spools fabricated, installed, straight pipe installed,

field welds complete, split large bore and small bore, underground and above

ground.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 17/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

7) Electrical and instrument cable length installed and terminated, split main and

field cable.

8) Number and weld inches of welds, by material type, passed and failed.

9) Number of hydrostatic tests completed and accepted.

10) Number of instrument loops checked, tested and accepted.

11) Systems flushed and reinstated.

12) Systems painted and insulated.

13) Metres of insulation installed on pipe and square metres on equipment.

14) Metres of steam tracing installed.

4.4. Progress Reporting

4.4.1. General

CONTRACTOR shall prepare and issue Monthly Status Reports and Weekly Progress

Reports to inform COMPANY of the status of the WORK.

The reporting requirements shall not relieve CONTRACTOR of its obligations to

promptly report to COMPANY any matters that significantly affect the completion of the

WORK to COMPANY.

CONTRACTOR shall provide ad hoc reports and/or presentations as required by

COMPANY to focus on a specific subject, e.g., action plans to overcome potential

schedule problems or recover progress slippage.

4.4.2. Monthly Status Reports

The cut off date shall be the last Friday of each month the Report shall be issued 6

working days later. Formal monthly progress meetings shall be held as mutually

agreed between COMPANY and CONTRACTOR. The report shall be prepared in two

(2) sections:

which it is specifically furnished or outside the extent of the agreed upon right of use.

(1) Management Summary

The Management Summary shall include:

(a) Management foreword summarising the highlights of the period: Project

Milestones achieved, main meetings held, main decisions reached, main

problems solved, outstanding and/or new problems arising.

A WORK Schedule analysis, highlighting the slippage of activities or progress

shortfalls, which adversely affect the WORK Schedule, with particular

reference to the critical path and the impact to Project Milestones and WORK

completion.

A strategy and plan for the implementation and timing of recovery actions

shall be fully explained.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 18/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

(b) Safety summary reporting achievements in the reporting period, current

objectives, and safety performance together with incident/accident

statistics, results of investigations and remedial action/follow-up related to

the Contract.

(c) Summary progress table: actual versus planned/forecast (period and

cumulative).

(d) Level I Progress Control Curve: Actual versus planned/forecast (period

and cumulative).

(e) Summary Manpower histograms for Engineering and Construction, plus

Design Office(s) and WORK Site office management and indirect. The

number of planned and actual personnel to be shown in tabular format.

(f) Updated Level I Project Management Schedule.

(g) A summary status and progress curve for each Subcontract.

(h) A summary status of Contract changes.

(2) Detailed Report

The detailed Report section shall include, but not limited to:

(a) Detailed narrative highlighting the main events for each work area: status

of objectives planned for period ending, objectives for next period, areas of

concern and outstanding actions to be taken by COMPANY,

CONTRACTOR, Subcontractors and Vendors.

(b) Detailed Work Package Progress Tables showing period and cumulative

planned/actual progress figures for each discipline within each work

package/facility.

(c) Level II Progress Control Curves, for Engineering, Procurement and

Construction.

(d) Updated Level II Overall Project Schedule.

(e) 90 Day Look Ahead Schedule taken from Level III Network.

(f) Updated Manpower Histograms as specified in above sections

which it is specifically furnished or outside the extent of the agreed upon right of use.

(g) Updated Material Summaries and Material Status Report.

(h) Updated Equipment Delivery Schedule.

(i) Updated Drawing and Document Summaries and Drawing and Document

Index.

(j) Updated Subcontracts' Schedule.

(k) Updated status of materials and issued for construction (IFC) drawings

received on WORK Site.

(l) Updated Construction report(s) illustrating the status/quantity of installation

of the major construction work categories.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 19/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

(m) Updated Commissioning report(s) illustrating the status of System and

System group completion.

(n) Quality Management report as specified in Schedule “Q”.

(o) Invoice Status Report.

(p) Change Order and Claim Status Report.

(q) Change Order Schedule in network format.

(r) Photographs of WORK Site (see below section for details)

(s) 3D CADD pictures (see below section for details)

(t) Non-conformance report (NCR) status

(u) Statistics for detailed engineering (see Attachments)

(3) Photographs.

CONTRACTOR shall provide photographs in the Monthly Report indicating

construction progress, and key events. Photographs shall be taken during the

monthly construction period, as a minimum one at each location, with location

and direction marked up on an A3 sized Plot Plan(s).

In addition to construction photographs, additional subjects shall include: Model

Construction; Equipment Manufacture; Prefabrication; Hazards and Problems;

Equipment Off loading, Transportation and Heavy Lifts.

COMPANY shall be given the colour negatives of each photograph with the

Monthly Status Report. All photographs shall be stamped with the date the

photograph was taken.

CONTRACTOR shall apply for and obtain Photo Permits at WORK Site before

photography will be authorised, as described in Attachment 3 of this Procedure.

(4) 3D CADD Pictures

CONTRACTOR shall provide 3D CADD pictures depicting views of the plant

during the engineering development phase. These views shall be further used

which it is specifically furnished or outside the extent of the agreed upon right of use.

during the construction phase to demonstrate physical progress during

weekly/monthly meetings.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 20/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

4.4.3. Weekly Progress Reports

CONTRACTOR shall submit weekly progress reports. These shall be issued to the

COMPANY at least one (1) working day prior to each weekly meeting. The weekly

progress report shall contain the following information.

(1) For Engineering activities

(a) A statement of actual versus planned/forecast progress achieved overall

and per area Plant/Unit and discipline, both for the period and cumulative.

(b) A statement per Plant/Unit area and discipline of drawings and

documents issued, and planned but not issued.

(c) A statement of any critical Vendor drawings received and approved during

the period and those behind schedule.

which it is specifically furnished or outside the extent of the agreed upon right of use.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 21/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

(d) A narrative and supporting three (3) week bar chart, one (1) week past

and two (2) week look ahead, showing achievements in past week,

activities planned/forecast for the coming period, critical activities, and

problem areas. Consecutive reports shall show a logical flow. Where

activities are shown as planned for the coming week, the following week

these shall either be shown as achieved, or if not achieved, what the

current status is and any action being taken.

(e) Manpower statement by discipline for the week, actual versus planned,

and planned for the next week.

(2) For Procurement activities

(a) A statement of purchasing status of equipment and materials for the

week, actual versus planned/forecast.

(b) A narrative and supporting three (3) week bar chart, one (1) week past

and two (2) week look ahead, showing achievements in past week,

activities planned/forecast for the coming period, critical activities, and

problem areas. Consecutive reports shall show a logical flow. Where

activities are shown as planned for the coming week, the following week

these shall either be shown as achieved, or if not achieved, what the

current status is and any action being taken.

(3) For Construction activities

(a) A statement of progress achieved and quantities installed overall and per

area, actual versus planned, for the period and cumulative.

(b) A safety summary and statistics.

(c) A statement of materials and Issued for Construction drawings received.

(d) A narrative and supporting three (3) week bar chart, one (1) week past

and two (2) week look ahead, showing achievements in past week,

activities planned/forecast for the coming period, critical activities, and

problem areas. Consecutive reports shall show a logical flow. Where

activities are shown as planned for the coming week, the following week

these shall either be shown as achieved, or if not achieved, what the

which it is specifically furnished or outside the extent of the agreed upon right of use.

current status is and any action being taken.

(e) A statement of recovery actions to be taken for activities behind schedule.

(f) Manpower statement by area and trade for the week actual versus

planned, and planned for the next week.

(4) For Precommissioning activities

(a) A statement of progress achieved per Precommissioning system, actual

versus planned, for the period and cumulative.

(b) A statement in a tabular form, of punch list clearing by Precommissioning

system and category.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 22/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

(c) A narrative and supporting three (3) week barchart, one (1) week past

and two (2) weeks look ahead showing achievements in past week,

activities planned/forecast for the following period, critical activities and

problem areas. Consecutive reports shall show a logical flow. Where

activities are shown as planned for the coming week, the following week

these shall either be shown as achieved, or if not achieved, what the

current status is and any action being taken.

(5) For Quality Control/Assurance activities

(a) A statement of QA/QC activities achieved.

(b) Summary records of audit activities, non-conformities identified and

corrective actions undertaken.

(c) Statistical analysis of all areas of non-conformity and trends.

4.4.4. Daily Reporting (Construction Phase)

(1) CONTRACTOR shall maintain a daily field log sheet giving a brief description

of the WORK in progress and include reference to visits by non-project

personnel and lost time accidents.

(2) CONTRACTOR shall provide to COMPANY daily labour and equipment

sheets detailing both CONTRACTOR's, Subcontractors' and Vendors'

Manpower (direct and indirect shown separately) by trade and major

equipment being used on the WORK Site.

(3) Records shall be kept of weather conditions.

4.5. Progress Meetings

4.5.1. General

CONTRACTOR shall report to and discuss with COMPANY the status of the Contract

at Weekly Progress Meetings, Monthly Progress Meetings and Quarterly Review

Meetings.

which it is specifically furnished or outside the extent of the agreed upon right of use.

4.5.2. Weekly Progress Meetings

The main purpose of the Weekly Progress Meeting shall be to discuss the Weekly

Progress Report. Particular attention shall be directed towards any recovery actions

required, other topics may be introduced at the request of COMPANY or

CONTRACTOR. The location, timing, attendees and agenda shall be agreed with

COMPANY.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 23/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

4.5.3. Monthly Progress Meeting

The main purpose of the Monthly Progress Meeting shall be to discuss the Monthly

Status Report. Other topics may be introduced at the request of COMPANY or

CONTRACTOR. The location, timing, attendees and agenda shall be agreed with

COMPANY.

4.5.4. Quarterly Review Meetings

CONTRACTOR shall be required to make presentations of project status to

COMPANY's Executive Management covering typically:

• Overall project status.

• Engineering and Design status.

• Procurement status.

• Construction status.

• Precommissioning status.

Hard copies of the presentation material shall be provided one (1) week prior to the

meeting date. The presentations shall cover activities completed during the previous

quarter and activities planned for the next quarter.

Should there be any areas of concern, these shall be presented and discussed with

the aim of agreeing corrective action.

4.5.5. Subcontractors' and Vendors' Progress Meetings

COMPANY has the right to attend all progress meetings with Subcontractors' and

Vendors' and shall be notified of such meetings and receive a copy of the minutes

within four (4) working days of the meeting.

5. RECORDS

5.1. Records

which it is specifically furnished or outside the extent of the agreed upon right of use.

CONTRACTOR shall maintain records of all weekly and monthly progress report

statistics and supporting databases which shall be available to COMPANY.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 24/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

ATTACHMENT 1 - EPC packages composition and TYPICAL WORK BREAKDOWN

STRUCTURE for each package (WBS)

# EPC Package Definition EPC Package Composition

1 DISTILLATION AND CDU/VDU (011, 012), LP HSD (101, 102), HP HSD

HYDROTREATING UNITS (091/092), NHPT (111, 112), H2 (151, 152),

2 CONVERSION UNITS DHCK (041), MHCK (051), FCC (061), SRU & TGT

(221/2/3), Amine Regen (201, 202), SWS (211, 212),

Unsaturated Gas (171), LPG selective hydrogenation (031),

Alky (081), Sulphuric Acid Regeneration (181), Saturated

Gas (161), Fuel System (571)

3 AROMATICS UNITS Reformer (131), Paraxylene (301), Benzene extraction (141)

4 COKER UNITS Coker (021), LPG Merox (071)

5 PLANT UTILITIES, MAIN Utilities (501÷581), Flare (601), Effluent treatment system

PIPERACKS AND COORDINATION (651), Process and Utilities Interconnecting (691), Control

System (701) and Main Control Building, Truck Loading

(731), Main Electrical Substations and electrical system

6 REFINERY TANK FARM ISBL Tankage Facilities (661), Interconnecting internal to

storage areas, Metering system

7 PERMANENT INFRASTRUCTURE Buildings (721), Patrol Road, Permanent Fencing

8 PIPELINES AND OFF PLOT OSBL Pipelines (801), Coke Handling System (811), Coke

FACILITIES Loading (903), Liquid Sulphur Transportation and handling

(821)

9 PORT TANK FARM Port Facilities (831, 841, 851, 861, 871, 881), Port Tank

Farm (891), Port Operation Buildings (901), Loading

Facilities (902)

10 PERMANENT COMMUNICATIONS Telecommunication System (711)

11 SITE PREPARATION & ACCESS ISBL Site Preparation, Access Roads and Bridges

ROAD

12 DREDGING AND RECLAMATION Land Reclaiming, Landfill & Compaction, Dredging

WORKS

13 TEMPORARY FACILITIES Area Preparation and Utilities for Contractor’s Camps and

offices, company housing and temporary communications

which it is specifically furnished or outside the extent of the agreed upon right of use.

Note: Progress has to be reported for each Plant/Unit

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 25/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

ATTACHMENT 1 - EPC PACKAGES COMPOSITION AND TYPICAL WORK BREAKDOWN

STRUCTURE (WBS)

Engineering - Disciplines

Directs: Project Engineering Process

Piping Civil

Structural Buildings

Electrical Instruments

Equipment Others

Contract Services Procurement Services

Indirects: Project Management Engineering Management

Secretarial and Clerical Quality Assurance (QA)

Project Control Others

Construction – Trades

Directs: Piping Prefabrication Steelwork Prefabrication

Plate Prefabrication (Tanks) Others

Site Preparation Piling

Civil and Underground Buildings

Steelwork Erection Welding Piping Erection and Welding

Equipment Installation Electrical

Instrument Painting

Cable Pulling Insulation

Chemical Cleaning Others

Indirects: Construction Management Construction Supervision

Project Control Contracts Management

QA/QC Safety

Administration Others

Site Support Services

Precommissioning and Commissioning – Personnel

Directs: Mech Test Engineers Instrument Technicians

Electricians Others

Precommissioning Engineers

Indirects: Commissioning Management Documentation and Control

Procurement – Categories

which it is specifically furnished or outside the extent of the agreed upon right of use.

Equipment: Package Equipment Columns and Reactors

Heat Exchangers (excl Air Fins) Compressors

Heat Exchangers Air Fin Vessels

Heaters and Furnaces Pumps

Instrument Equipment Electrical Equipment

Others

Materials: Civil and Building Piping and Valves

Steelwork Tankage Plates

Electrical Bulks Electrical and Instrument

Instrument Bulks Cable

Others

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 26/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

ATTACHMENT 2 - PROJECT CONTROL DOCUMENTATION INDEX

Ref Description Issue for Issue for Frequency Comments

Review Approval

4.1.1 Project Control 3° calendar days May need to

Procedure after effective resubmit for

date of Contract. later phases

4.2.2 Work Breakdown Pre-award 30 calendar days

Structure WBS

4.2.2. (1) Project Milestone Pre-award 30 calendar days Monthly May need

Schedule Level I after effective revision if

date of Contract. Level II

changes

significantly

4.2.2. (2) Project Summary Pre-award 30 calendar days Monthly Will need

Schedule Level II after effective revision

date of Contract. following

issue of Level

III Schedules

4.2.2. (3) Mobilization Pre-award 10 calendar days Weekly Must be in

Schedule Level III after effective place for

date of Contract. initial period

only, until

formal Level

III in place.

4.2.2. (4) Detailed Network 30 calendar days Monthly Sample

Schedule Level III after effective Reports in Bid

date of Contract

4.2.2.(4) Detailed interface 90 calendar Monthly

and tie in schedule. days after

effective date of

contract.

4.2.2 (4) Systems List Tba Monthly System limits

to be marked

up on P and

ID

4.2.2.(5a) Detailed Schedules 30 calendar 45 calendar days Monthly Weekly

Level IV Drawing days after after effective Statistics and

and Document effective date of date of Contract Exception

Index Contract Reports

4.2.2(5b) Schedules of 30 calendar 45 calendar days Monthly

Requisitions days after after effective

effective date of date of Contract

Contract

4.2.2.(5c) Detailed Schedules 30 calendar 45 Monthly Weekly

Level IV Suppliers days after calendar days Statistics and

Drawing Index effective date of after effective Exception

Contract. date of Contract Reports

4.2.2.(5d) Detailed Schedules 30 calendar 45 Weekly Weekly

which it is specifically furnished or outside the extent of the agreed upon right of use.

Level IV days after calendar days Statistics and

Equipment Delivery effective date of after effective Exception

and Material Contract. date of Contract Reports

Delivery Schedules

4.2.2.(5e) Detailed Schedules 30 calendar 45 Monthly

Level IV days after calendar days

Subcontracts effective date of after effective

Schedule Contract. date of Contract

4.2.2.(5f) Third 30 calendar 45 Monthly

Party/Authority days after calendar days

Interface Schedule effective date of after effective

Contract. date of Contract

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 27/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

ATTACHMENT 2 - PROJECT CONTROL DOCUMENTATION INDEX

4.2.2.(5g) Detailed Schedules Tba Weekly

Level IV Statistics

Prefabrication

Status Reports

4.2.2.(5h) Detailed Schedules 120 calendar Weekly

Level IV Detailed days prior to Statistics

Construction planned

Schedules commencement

4.2.2.(5i) Detailed Schedules 120 calendar Weekly

Level IV Detailed days prior to Statistics

Testing Schedules planned

commencement

4.2.2.(5j) Detailed Schedules 6 months prior 120 calendar Weekly

Level IV Detailed to 1st system days prior to Statistics

System Completion available for pre- planned

Schedules commissioning commencement

4.2.2.(5k) Interface Schedule 120 calendar Monthly

days prior to

planned

commencement

4.2.2.(5l) Water 120 calendar Weekly

Management for days prior to

Hydrotesting and planned

flushing commencement

4.2.2.(5m) Heavy Lift 120 calendar

Schedule days prior to

planned

commencement

4.2.2.(5n) Transport 120 calendar

Schedule days prior to

planned

commencement

4.2.2.(5o) Site Materials Weekly

Received Reports

4.2.2.(5p) Manpower Reports Weekly

Statistics

4.2.2. (5q) Loop Checking 120 calendar Weekly

days prior to

planned

commencement

4.2.2.(r) Construction Weekly

Equipment Report Statistics

4.4.2 Monthly Status Monthly

Report

4.4.3 Weekly Progress Weekly

Report

which it is specifically furnished or outside the extent of the agreed upon right of use.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2271 AAA JSM 301 B 28/65

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

ATTACHMENT 3 - PHOTOGRAPHY LIMITATIONS

Unauthorised photography of any and all COMPANY’s installations and property is prohibited.

This includes but is not limited to:

(1) Onshore plants, communication facilities including antenna towers, aviation facilities,

computer centres, material yards, and restricted administration buildings.

(2) Offshore plants, platforms, sea islands, and pier.

(3) COMPANY aircraft.

All photography shall be in accordance with COMPANY and Saudi Arabia requirements.

Requests for authorisation by CONTRACTOR to photograph the FACILITIES, for advertising and

publicity purposes, shall be in accordance with the following:

Not less than fourteen (14) days prior to the requested photography, CONTRACTOR's General

Manager shall write to:

Manager, COMPANY Public Relations

……..

………, Saudi Arabia

with the following information:

a. Purpose of the photography.

b. Beginning and ending dates of the photography.

c. Subject and location to be photographed.

d. Particulars of the photography:

a) Name.

b) Passport Number and Nationality.

c) Sponsoring COMPANY Department.

e. Description of equipment to be used.

f. Copy to Company Representative.

After receipt of an approved COMPANY Photo Permit (Form …), photography of the FACILITY will

which it is specifically furnished or outside the extent of the agreed upon right of use.

be considered authorised.

All photographs and film shall be submitted to COMPANY Public Relations for review and

approval.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

which it is specifically furnished or outside the extent of the agreed upon right of use.

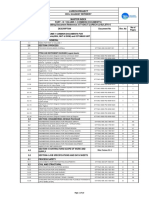

LSTK Contractor Line Check Aramco Line Check

No of Offer for Issue Cat'A' Offer Client Issue Cat'A' Flush Test Reinstate Testpack

Test Walk- Punch Items to Walk- Punch Items Complete

System packs down Constr Eng QC list Compl SA down list Compl

System 1 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20

System 2 35 15 15 15 15 15 12 12 11 11 8 7 7 6 4

System 3 5 0 0 0 0 0 0 0 0 0 0 0 0 0 0

System 4 20 15 14 13 13 12 9 8 7 6 4 4 4 3 1

System 5 20 15 13 13 12 12 11 9 8 7 5 5 4 3 3

System 6 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15

2271

Project N°

System 7 12 4 3 3 2 2 0 0 0 0 0 0 0 0 0

Unit

AAA

Total 127 84 80 79 77 76 67 64 61 59 52 51 50 47 43

JUBAIL EXPORT REFINERY PROJECT

ARAMCO OVERSEAS COMPANY AND TOTAL

JSM 301

Document Code

ATTACHMENT 4 – EXAMPLE OF DETAILED TESTING SCHEDULE

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Serial N°

B

Rev.

Page

29/65

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for