Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CRA All PDF

Caricato da

Rohan PanditDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CRA All PDF

Caricato da

Rohan PanditCopyright:

Formati disponibili

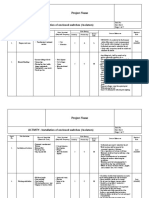

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

Calcium Chloride Building: 205 Room: 001

Manufacturer / Supplier Lab for Intended Use

AMC Building: 205 Room: 001

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

16/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Storage: Store in a cool, dry, well ventilated area, removed

(Including any storage or disposal requirements) from incompatible substances, heat or ignition sources and

foodstuffs. Ensure containers are adequately labelled,

protected from physical damage and sealed when not in

use.

Disposal: Ensure product is covered with moist soil to

prevent dust generation and dispose of to approved Council

landfill. Contact the manufacturer/supplier for additional

information (if required).

Concentration: 100 Quantity: 38 mg Duration 2 days Frequency twice

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

SECTION 3: HOW CAN EXPOSURE OCCUR?

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Who is potentially exposed? : Students, Lab Staff.

(e.g. Students, Lab Staff, Researchers, Others)

Worksheet Page 1 of 4 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

Worksheet Page 2 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

So the questions are: based on the above matrix:

What could be the consequences? Irritating to eyes, Breathing in the Dust

What is the likelihood of that happening? Possible

What is the risk rating? Low

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 3 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering

5. Administrative

6. PPE

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 4 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

Glucose Building: 205 Room:

Manufacturer / Supplier Lab for Intended Use

SIGMA-ALDRICH PTY. LTD. (AUS) Building: 205 Room: 001

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

18/04/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Storage: Store in a cool, dry, well ventilated area, removed

(Including any storage or disposal requirements) from incompatible substances and foodstuffs. Ensure

containers are adequately labelled and tightly closed when

not in use.

Disposal: Ensure product is covered with moist soil to

prevent dust generation and dispose of to approved Council

landfill. Contact the manufacturer/supplier for additional

information (if required).

Concentration: 100 Quantity: 2, 720 Duration 2 days Frequency twice

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

SECTION 3: HOW CAN EXPOSURE OCCUR?

Worksheet Page 1 of 4 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Who is potentially exposed? :

(e.g. Students, Lab Staff, Researchers, Others)

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

Worksheet Page 2 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

So the questions are: based on the above matrix:

What could be the consequences?

What is the likelihood of that happening?

What is the risk rating?

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 3 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering

5. Administrative

6. PPE

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 4 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

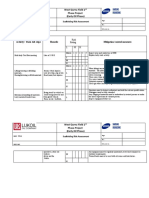

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

HYDROGEN PEROXIDE Building: 205 Room:

Manufacturer / Supplier Lab for Intended Use

ELITE SURFACE TECHNOLOGIES Building: 205 Room: 001

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

16/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Handling: Before use carefully read the product label. Use of

(Including any storage or disposal requirements) safe work practices are recommended to avoid eye or skin

contact and inhalation. Observe good personal hygiene,

including washing hands before eating. Prohibit eating,

drinking and smoking in contaminated areas.

Storage: Store in a cool, dry, well ventilated area, removed

from incompatible substances and foodstuffs. Ensure

containers are adequately labelled, protected from physical

damage and sealed when not in use. Large storage areas

should have appropriate ventilation systems. Store below

24°C.

Concentration: 100 Quantity: Duration 2 days Frequency twice

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

SECTION 3: HOW CAN EXPOSURE OCCUR?

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Worksheet Page 1 of 4 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Who is potentially exposed? : Students, Lab Staff

(e.g. Students, Lab Staff, Researchers, Others)

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

Worksheet Page 2 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

So the questions are: based on the above matrix:

What could be the consequences? Corrosive. This product has the potential to cause adverse

health effects. Use safe work practices to avoid eye or skin

contact and inhalation. Over exposure may result in severe

and permanent eye, skin and respiratory damage. Upon

dilution, the potential for corrosive effects may be reduced..

Eye Irritant - Corrosive. Contact may result in irritation,

lacrimation, pain, redness, corneal burns and possible

permanent damage.

Inhalation- Corrosive - toxic. Over exposure may result in

mucous membrane irritation of the respiratory tract, coughing

and possible burns. High level exposure may result in

ulceration of the respiratory tract, breathing difficulties,

chemical pneumonitis and pulmonary oedema.

Skin – Corrosive Irritant. Contact may result in irritation,

redness, pain, rash, dermatitis and possible burns.

Ingestion - Harmful. Ingestion of large quantities may result in

vomiting, acidosis, bloody diarrhoea and shock. In some

cases, necrosis and haemorrhage of the gastrointestinal tract,

liver damage and death may occur. Scarring of the

gastrointestinal tract may occur in non-fatal cases.

What is the likelihood of that happening? rare

What is the risk rating? high

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 3 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering Making sure the work is carried out in a well ventilated area

5. Administrative Making sure all safe practices are followed

6. PPE All PPE will be worn at all times.

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 4 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

MAGNESIUM SULFATE HEPTAHYDRATE Building: 205 Room:

Manufacturer / Supplier Lab for Intended Use

ASTRAL SCIENTIFIC PTY LTD Building: 205 Room: 001

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

16/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Handling: Before use carefully read the product label. Use of

(Including any storage or disposal requirements) safe work practices are recommended to avoid eye or skin

contact and inhalation. Observe good personal hygiene,

including washing hands before eating. Prohibit eating,

drinking and smoking in contaminated areas.

Storage: Store in a cool, dry, well ventilated area, removed

from incompatible substances and foodstuffs. Ensure

containers are adequately labelled, protected from physical

damage and sealed when not in use.

Disposal: Dispose of to an approved landfill or waste

processing site. Contact the manufacturer/supplier for

additional information (if required).

Concentration: 100 Quantity: 42 mg Duration 2 days Frequency twice

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

SECTION 3: HOW CAN EXPOSURE OCCUR?

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Worksheet Page 1 of 4 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Who is potentially exposed? :

(e.g. Students, Lab Staff, Researchers, Others)

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

Worksheet Page 2 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

So the questions are: based on the above matrix:

What could be the consequences?

What is the likelihood of that happening?

What is the risk rating?

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 3 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering

5. Administrative

6. PPE

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 4 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

Meat Extract Building: 205 Room:

Manufacturer / Supplier Lab for Intended Use

MERCK PTY LIMITED Building: 205 Room: 001

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

16/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Storage: No special requirements for the storage of this

(Including any storage or disposal requirements) product. Store between 15°C and 25°C.

Disposal: Reuse where possible. No special precautions are

normally required when handling this product.

Concentration: Quantity: 560 mg Duration 2 days Frequency twice

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

SECTION 3: HOW CAN EXPOSURE OCCUR?

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Who is potentially exposed? :

(e.g. Students, Lab Staff, Researchers, Others)

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Worksheet Page 1 of 3 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

So the questions are: based on the above matrix:

What could be the consequences?

What is the likelihood of that happening?

What is the risk rating?

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 2 of 3 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering

5. Administrative

6. PPE

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 3 of 3 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

0 - 5% CARBON DIOXIDE IN NITROGEN Building: 205 Room:

Manufacturer / Supplier Lab for Intended Use

AIR LIQUIDE AUSTRALIA Building: 205 Room: 001

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

16/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Handling: Use of safe work practices are recommended to

(Including any storage or disposal requirements) avoid inhalation. Do not drag, drop, slide or roll cylinders.

The uncontrolled release of a gas under pressure may

cause physical harm. Use a suitable hand truck for cylinder

movement.

Storage: Do not store near incompatible materials. Cylinders

should be stored below 45°C in a secure area, upright and

restrained to prevent cylinders from falling. Cylinders should

also be stored in a dry, well ventilated area constructed of

non-combustible material with firm level floor (preferably

concrete), away from areas of heavy traffic and emergency

exits.

Concentration: 100 Quantity: Duration 2 days Frequency twice

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

SECTION 3: HOW CAN EXPOSURE OCCUR?

Worksheet Page 1 of 4 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Who is potentially exposed? : Students, Lab Staff

(e.g. Students, Lab Staff, Researchers, Others)

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

Worksheet Page 2 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

So the questions are: based on the above matrix:

What could be the consequences? Based on available data, the classification criteria are not met.

Low concentrations of carbon dioxide cause increased

respiration and headache.

Asphyxiant. Effects are proportional to oxygen displacement.

Over exposure may result in dizziness,drowsiness, weakness,

fatigue, breathing difficulties and unconsciousness.

Likelihood Level: Not expected but the event may occur at

some time

Consequence Level: Injury or illness requiring First Aid

treatment No lost time injury days

What is the likelihood of that happening? rare

What is the risk rating? low

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 3 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering

5. Administrative

6. PPE

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 4 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

BACTERIOLOGICAL PEPTONE Building: 205 Room:

Manufacturer / Supplier Lab for Intended Use

AMYL MEDIA PTY LTD Building: Room:

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

18/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Storage: Store in a cool, dry, well ventilated area, removed

(Including any storage or disposal requirements) from incompatible substances and foodstuffs. Ensure

containers are adequately labelled and tightly closed when

not in use. Store below 25°C.

Waste disposal: Ensure product is covered with moist soil to

prevent dust generation and dispose of to approved Council

landfill. Contact the manufacturer/supplier for additional

information (if required).

Legislation: Dispose of in accordance with relevant local

legislation.

Concentration: 100 Quantity: 800 mg/L Duration 2 days Frequency Once

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

SECTION 3: HOW CAN EXPOSURE OCCUR?

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Worksheet Page 1 of 4 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Who is potentially exposed? :

(e.g. Students, Lab Staff, Researchers, Others)

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

Worksheet Page 2 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

So the questions are: based on the above matrix:

What could be the consequences?

What is the likelihood of that happening?

What is the risk rating?

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 3 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering

5. Administrative

6. PPE

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 4 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

DBL POTASSIUM DI-HYDROGEN PHOSPHATE Building: 205 Room:

FOR INJECTION

Manufacturer / Supplier Lab for Intended Use

HOSPIRA AUSTRALIA PTY LTD Building: 205 Room: 001

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

16/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Handling: Before use carefully read the product label. Use of

(Including any storage or disposal requirements) safe work practices are recommended to avoid eye or skin

contact and inhalation. Observe good personal hygiene,

including washing hands before eating. Prohibit eating,

drinking and smoking in contaminated areas.

Storage: Store in a cool, dry, well ventilated area, removed

from incompatible substances and foodstuffs. Ensure

containers are adequately labelled, protected from physical

damage and sealed when not in use.

Disposal: For small amounts, absorb with sand or similar

and dispose of to an approved landfill site. Contact the

manufacturer/supplier for additional information (if required).

Ensure that appropriate personal protective equipment is

used during disposal.

Concentration: 100 Quantity: 60 mg Duration 2 days Frequency twice

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

Worksheet Page 1 of 4 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

SECTION 3: HOW CAN EXPOSURE OCCUR?

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Who is potentially exposed? :

(e.g. Students, Lab Staff, Researchers, Others)

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

Worksheet Page 2 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

So the questions are: based on the above matrix:

What could be the consequences?

What is the likelihood of that happening?

What is the risk rating?

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 3 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering

5. Administrative

6. PPE

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 4 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

Sodium Bicarbonate Building: 203 Room: 001

Manufacturer / Supplier Lab for Intended Use

NYRSTAR HOBART Building: 203 Room: 001

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

16/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Storage: Store in a cool, dry, well ventilated area, removed

(Including any storage or disposal requirements) from incompatible substances and foodstuffs. Ensure

containers are adequately

labelled, protected from physical damage and sealed when

not in use.

Disposal: For small amounts, absorb with sand or similar

and dispose of to an approved landfill site. Contact the

manufacturer/supplier for additional information (if required).

Ensure that appropriate personal protective equipment is

used during disposal.

Concentration: Quantity: Duration Frequency

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

SECTION 3: HOW CAN EXPOSURE OCCUR?

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Who is potentially exposed? :

(e.g. Students, Lab Staff, Researchers, Others)

Worksheet Page 1 of 3 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

So the questions are: based on the above matrix:

What could be the consequences?

What is the likelihood of that happening?

What is the risk rating?

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 2 of 3 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering

5. Administrative

6. PPE

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 3 of 3 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

0 - 5% CARBON DIOXIDE IN NITROGEN Building: 205 Room:

Manufacturer / Supplier Lab for Intended Use

AIR LIQUIDE AUSTRALIA Building: 205 Room: 001

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

16/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE

Task Description: Handling: Use of safe work practices are recommended to

(Including any storage or disposal requirements) avoid inhalation. Do not drag, drop, slide or roll cylinders.

The uncontrolled release of a gas under pressure may

cause physical harm. Use a suitable hand truck for cylinder

movement.

Storage: Do not store near incompatible materials. Cylinders

should be stored below 45°C in a secure area, upright and

restrained to prevent cylinders from falling. Cylinders should

also be stored in a dry, well ventilated area constructed of

non-combustible material with firm level floor (preferably

concrete), away from areas of heavy traffic and emergency

exits.

Concentration: 100 Quantity: Duration 2 days Frequency twice

(%) (including units) of Use: of Use:

Note: Substances that are not classified as a Hazardous Substance or Dangerous Good require

no further assessment (i.e. you do not need to compete the remaining sections).

SECTION 3: HOW CAN EXPOSURE OCCUR?

Worksheet Page 1 of 4 Health and Safety

Chemical Risk Assessment Form Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Dermal (Skin): Eyes: Inhalation: Ingestion: Injection:

Solid Dust Vapour Dust Pressure

Aerosol Aerosol Aerosols Aerosols Sharp objects

Liquid Liquid Gas Liquid Open wounds

Dust Hygiene

Who is potentially exposed? : Students, Lab Staff

(e.g. Students, Lab Staff, Researchers, Others)

SECTION 4: POTENTIAL HEALTH EFFECTS

Acute (Immediate) Effects Chronic (Delayed) Effects

Eye and skin Irritant / Corrosion Sensitising Agent (Skin/Inhalation)

Central Nervous System Carcinogenic

Asphyxiant (Inhalation) Liver/Kidney Disease

Respiratory Tract Irritant Brain/Nerve Disease

Toxic by Skin Exposure Respiratory Disease

Toxic by Ingestion Reproductive System Disease

Other (Specify): Other (Specify):

SECTION 5: RISK RANKING WITH EXISTING CONTROLS IN PLACE

Risk Matrix

LIKELIHOOD DESCRIPTION

The event may Not expected The event The event will The event is expected

LIKELIHOOD occur only in but the event could occur probably occur to occur or has

exceptional may occur at at some time in most occurred and is

circumstances some time circumstances continuing to impact

IMPACTS Likelihood Level

Health and Safety Rare Unlikely Possible Likely Almost Certain

Fatality

Critical

Permanent Total Extreme

Disability

CONSEQUENCE DESCRIPTION

Significant/extensive

injury or illness.

Major

Permanent Partial

High

Consequence Level

Disability

Serious injury or

illness.

Moderate

Lost time injury >10

Medium

days

Injury or illness

requiring medical

treatment Minor

Low

Lost time injury <10

days

Injury or illness

requiring First Aid

treatment Insignificant

No lost time injury

days

Worksheet Page 2 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

So the questions are: based on the above matrix:

What could be the consequences? Based on available data, the classification criteria are not met.

Low concentrations of carbon dioxide cause increased

respiration and headache.

Asphyxiant. Effects are proportional to oxygen displacement.

Over exposure may result in dizziness,drowsiness, weakness,

fatigue, breathing difficulties and unconsciousness.

Likelihood Level: Not expected but the event may occur at

some time

Consequence Level: Injury or illness requiring First Aid

treatment No lost time injury days

What is the likelihood of that happening? rare

What is the risk rating? low

Note: If the rating is above LOW,

Risk Management action is required.

Worksheet Page 3 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Risk Management Action

Risk Level Response

Immediate action required to reduce exposure. A detailed mitigation plan must be developed,

Extreme implemented and monitored by senior management to reduce the risk to as low as reasonably

practicable.

A mitigation plan shall be developed and authorised by area manager or supervisor to reduce the

High risk to as low as reasonably practicable. The effectiveness of risk control strategies shall be

monitored and reported to management and relevant committee.

A mitigation plan shall be developed. Control strategies are implemented and periodically

Medium

monitored.

Manage by documented routine processes and procedures. Monitor periodically to determine

Low

situation changes which may affect the risk.

SECTION 6: REQUIRED CONTROL MEASURES TO REDUCE RISK

Control Example Intention to apply

1. Elimination Eliminate materials or elements of the process that carry

significant risk.

2. Substitution Substitute a safer chemical or safer process.

3. Isolation Barriers, enclosures, remote operation.

4. Engineering Local exhaust ventilation, dilution ventilation.

5. Administrative Supervision, use of safe work procedures, housekeeping,

organisation of work to limit contact, standards, training,

signage.

6. PPE Face shields, safety glasses, goggles, gloves, aprons.

SECTION 7: SPECIFIC ACTIONS TO REDUCE RISK

List specific actions that will be carried out for each of the controls you nominated in Section 6.

Control Action

1. Elimination

2. Substitution

3. Isolation

4. Engineering

5. Administrative

6. PPE

Note: If after the implementation of all of the controls above, the risks of using the assessed

chemical remain MODERATE or higher (based on the Risk Matrix in Section 5); expert

advice must be obtained so as to reduce risk before proceeding.

The Occupational Health and Safety Regulations (1996) require that Risk Assessments are retained.

Risk Assessments must be revised if procedures change and are to be reviewed every 5 years. Save a

copy of this Risk Assessment, to be retained in your area. Give it a unique name (eg CRA + product

name + your name). Send a copy to Health and Safety. Any queries should be directed to the Curtin

Health and Safety Ext. 4900.

Worksheet Page 4 of 4 Health and Safety

Chemical Risk Assessment Rev 2.0 issued: 21 April 2016

Uncontrolled document when printed Review: 13 February 2015

Chemical Risk Assessment

Worksheet

INTRODUCTION

The questions in this Worksheet are designed to prompt you to think about the risks you face when

using chemicals and whether you believe the current controls will adequately protect you. You should

not proceed with the use of a product if you believe it is unsafe.

There are two elements to the Risk Assessment: You will need a Safety Data Sheet (SDS) for the

product (obtained from Chem Alert or from the supplier); and you will need to consider circumstances

of use in your area. Complete the Risk Assessment in consultation with your supervisor.

SECTION 1: SUMMARY (from SDS)

Chemical / Product Name Storage Location

FERROUS SULFATE HEPTAHYDRATE Building: 205 Room:

Manufacturer / Supplier Lab for Intended Use

IXOM OPERATIONS PTY LTD (FORMERLY Building: 205 Room: 001

ORICA CHEMICALS)

Safety Data Sheet Hazardous and Dangerous Goods

Is a current SDS Available? (You must obtain it) Is the chemical classified as Hazardous?

Yes No Yes No

Assessment Date: Is the chemical classified as Dangerous Goods?

16/4/2016 Yes No (if applicable)

Class: Sub Class:

Assessor Supervisor

Rohan Pandit Dr Tushar Sen

SECTION 2: USE