Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BB BB: Code and Specifications

Caricato da

andersonTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BB BB: Code and Specifications

Caricato da

andersonCopyright:

Formati disponibili

1 2 3 4

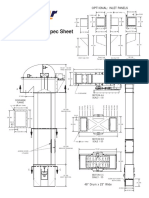

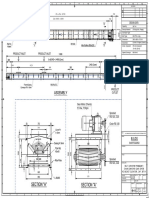

CODE AND SPECIFICATIONS

CODE: ASME, SECT.VIII, DIV.1, ED.2015. TEMA NINTH EDITION

TEMA CLASS: "R", TYPE BEU

115 in [2921,00 mm] STAMPED: TUBE BUNDLE, YES "U"PART

406 11/16 in [10329,93 mm] USER'S DESIGN REQUIREMENTS: UDR-16002-PC-HT

101 in [2565,15 mm]

INSPECTED BY: AUTHORIZED INSPECTOR (HSBCT)

393 3/16 in [9987,03 mm]

DESIGN DATA (TUBE BUNDLE)

390 1/4 in [9912,35 mm]

N3 N3 N3 MAXIMUM ALLOWABLE WORKING PRESSURE 151 psig

126 1/8 in [3203,58 mm] 126 1/8 in [3203,58 mm] MAXIMUM DESIGN TEMPERATURE 151 °F

WORKING PRESSURE 20.01 psig

WORKING TEMPERATURE 127.22 °F

CORROSION ALLOWANCE 0.0

MINIMAL DESIGN METAL TEMPERATURE 32 °F @ 151 psig

HYDROSTATIC PRESSURE TEST 196,3 psig

BB BB IMPACT TEST YES, ONLY TUBESHEET TO -40 °F PER UHA (a)

HEAT TREATMENT NO

SERVICE CONSIDERATION NO LETHAL

FLUID CIRCULATED (TUBE SIDE) WATER

106 5/8 in [2708,28 mm]

107 7/8 in [2740,03 mm]

TUBE TO TUBESHEET JOINT WELDED AND EXPANDED

NO. PASS PER SHELL 2

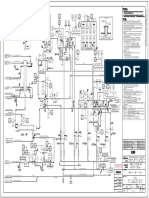

N2 N1 NDE: (FOR BUNDLE)

172 15/16 in [4392,61 mm]

JOINT EFFICIENCY: N/A

GAS RADIOGRAPH EXAM: N/A

N2 N1

FLOW MATERIALS

U TUBES SA-789-S32750

TUBESHEET SA-182-F60-S32750

104 7/8 in [2663,83 mm]

BAFFLES AND SUPPORT PLATE SA-240-TP 316L

SEALING STRIP SA-240-TP 316L

IMPINGEMENT PLATE SA-240-S32205

TIE ROD SA-479-S32205

SPACER SA-789-S32750

IMPINGEMENT ROD SA-479-S32205

SLIDING PLATE SA-479-S32205

A PIN GUIDE SA-479-S32205 A

NUTS SA-194-S32205

N4 N4 N4

WEIGHT

LIFT WEIGHT xxxx

42 13/16 in [1087,44 mm]

PAINTING AND SURFACE PREPARATIONS

7 in [177,80 mm] 7 in [177,80 mm] 399 3/8 in [10144,89 mm] SYSTEM APPLY FOR SURFACE PRIMER MID COAT TOP COAT DFT MILS

N/A N/A N/A N/A N/A N/A N/A

31 1/8 in [791,16 mm]

84 in [2133,59 mm] GENERAL NOTES

13

1.- ALL DIMENSIONS ARE IN INCHES [MILIMETERS] UNLESS OTHERWISE IS INDICATED.

14 2.- ANY MACHINING OPERATIONS BURRS SHALL BE REMOVED AND GIVEN A WORKMANLIKE FINISH.

12

3.- TOLERANCES FOR TUBE HOLES IN TUBESHEET: ±0.002 in [±0.05 mm]

9

7 8 4.- THE SURFACE FINISH FOR TUBE HOLES WILL BE [RESEARSCH]

61 1/2 in [1561,82 mm]

24) B 2-A 22) 5.- THE LOCATION OF DRILLING OPERATIONS IN TUBESHEET AND BAFFLES IS REFERRED FROM THE

4

23) 22) 2-B 21) CENTERLINE OF PIECES, MEASURES MUST HAVE TOLERANCES 0.005 in [0.127 mm].

4 21)

22) 2-B 20)

20) 4

21) 2-B 19)

4

6.- TOLERANCE FOR TUBESHEET EXTERNAL DIAMETER: `

1

6 20) 19) 2-B 18) 16 in [±1,5875 mm].

18) 4

19) 2-B 17)

4 17)

18) 2-B 16)

4 7.- TOLERANCES FOR TUBESHEET INTERNAL DIAMETERS: ±1/32"[±0.8]

17) 16) 2-B 15)

5 4 15)

16) 2-B 14)

14) 4 8.- TOLERANCES FOR GROOVES:

15) 2-B 13)

11 4 13) DEPTH: +0"[+0], -1/32"[-0.8]

14) 2-B 12)

4 WIDTH: ±1/16"[±1.6]

13) 12) 2-B 11)

4 11)

12) 2-B 10)

10) 4

11) 2-B 9) 9.- TOLERANCE +0"[+0], -1/32"[-0.8] WHERE INDICATED.

47 15/16 in [1217,61 mm]

61 1/2 in [1561,82 mm]

4

10) 9) 2-B 8)

8) 4

9) 2-B 7) 10.- TOLERANCE ±1/16"[±1.6] WHERE INDICATED.

4 7)

8) 2-B 6)

4

7) 6) 2-B 5)

4 11.- NOMINAL LENGTH FOR U-TUBES IS THE STRAIGHT LENGTH FROM END OF TUBE TO BEND TANGENT.

6) 5) 2-B 4)

4) 4

5) 1-B 3)

3 12.- EXPAND TUBES AFTER WELDING.

4) 3) 1-B 2)

2) 3

3) A 1-A 1)

2) 1) 13.- FOR BILL OF MATERIALS SEE DGW 16002-PC-HT-GEN-002.

1)

14.-TOLERANCE FROM TUBESHEET TO LAST BAFFLE: ±1/8 [±3.20].

BL

GAS FLOW 15.-TOLERANCE FROM BAFFLE TO BAFFLE: ±1/8 [±3.20].

9 3/16 in [233,09 mm] 16.-STAMPING TO BE LOCATED ON TUBESHEET OD.

18 11/16 in [474,93 mm] 17.-FOR STAMPING THE MINIMUM HIGH OF LETTERS IS 5/16".

o4 in [101,60 mm] 18.-STAMPING MARK SHALL BE PERFORMED AS FOLLOWING:

SECTION BB-BB

SCALE 1/30

4 in [101,60 mm]

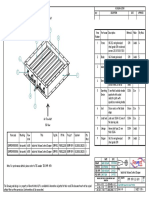

BILL OF MATERIAL

ITEM QTY PART DESCRIPTION MATERIAL

1 72 STRAIGHT SMLS FINNED TUBE 2 in [50,8 mm] OD, 0.135 in [3,429 mm] M.W. SA-213 Gr.T22

DETAIL BL 2 456 STRAIGHT SMLS FINNED TUBE 2 in [50,8 mm] OD, 0.135 in [3,429 mm] M.W. SA-192

3 48 180° RETURN BEND 2 in [50,8 mm] OD, 0.135 in [3,429 mm] M.W. SA-234 Gr. WP22 S58

SCALE 1 / 15 4 456 180° RETURN BEND 2 in [50,8 mm] OD, 0.135 in [3,429 mm] M.W. SA-234 Gr. WPB S58

10 BN 5 2 BUTT WELD TEE REDUCCION NPS 8X6, SCH80 SA-234 WPB

BK 6 4 SMLS PIPE NPS 8, SCH 80, LONG 40. 3/4 in [1035,05 mm] SA-106 Gr. B

7 4 BUTT WELD CAP NPS 8, SCH80 SA-234 WPB

X1 F X2 8 4 SMLS PIPE NPS 1. 1/2, SCH 80, LONG 6. 1/16 in [154 mm] SA-106 Gr. B

9 4 WN FLANGE NPS 1. 1/2, RF, CL 600, SCH 80 SA-105

B

BE 10 2 SMLS PIPE NPS 6, SCH 80, LONG 7 in [117,8 mm] SA-106 Gr. B B

1

BH 11 2 WN FLANGE NPS 6, RF, CL 600, SCH 80 SA-105

BODY ASTM A105, RF FLANGED CLASS 600, TRIM

12 14 GATE VALVE BOLTED BONNET SA-105

BJ 8

DETAIL BM 13 4 BLIND FLAGE NPS 1. 1/2, RE, CL 600 SA-105

L

SCALE 1 / 5

DETAIL BG

SCALE 1 / 8 TABLE

GS-1-1-G-1 ITEM L F X1 X2

GS-5-1-G-7 A 404. 5/8 in [10277,475 mm] 386. 1/4 [9810,75 mm] 3. 3/8 in [85,725 mm] 9. 5/8 in 244,475 mm]

60° ±5° 5/32" 60,0° `5° GS-1-1-G-1 B 393 in [9982,2 mm] 386. 1/4 [9810,75 mm] 3. 3/8 in [85,725 mm] 3. 3/8 in [85,725 mm]

38~

GS-1-1-G-1

GS-5-5-G-6 T22

7/16"x3/8"

5/32" 3/16

+0

- 1/16 [

in 5,29 + ,0

- 1,6

mm

]

38~

GS-5-1-G-7 ENGINEERING DEPARTMENT QA/QC DEPARTMENT

1/8" 3/8"

60°~

APPROVED:_____ DATE____ APPROVED:_____ DATE____

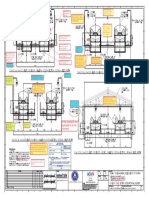

GENERAL ARRANGEMENT 16003-PS-CRF-MEC-GEN-001 TAG No: SERIAL No: JOB NUMBER (OT):

tc:1/4

+0

- 1/8 [

in 6,39 + ,0

- 3,2

mm

] 1/8 in [3,18 mm]

DETAIL BN DWG N~

GS

1/8 `1/16 in [3,18 `1,6 mm] REFERENCES 03S306/07/08 V-111002/3/4 16003-PS-CRF

TITLE:

TABLE OF NOZZLES INTERNAL DETAILS

SCALE 1 / 2 PROJECTION CARTRIDGE FILTER

MARK QTY SERVICE NPS CLASS TYPE SCH

TO C.L/R.L 03S306/07/08 GLOBAL SUPPLY

DETAIL BJ DETAIL BK

DETAIL BE DETAIL BH N1 1 FEEDWATER INLET 6 600 Lb WN RF 80 INDICATE

DWG: REVISED: APPROVED: P.: 1

SCALE 1 / 2 SCALE 1 / 2

N2 1 FEEDWATER OUTLET 6 150 Lb WN RF 80 INDICATE A.R J.L A.R. OF: 1

SCALE 1 SCALE 1 / 2 N3 2 VET 1. 1/2 -- WN RF 80 INDICATE 0 10-10-18 FIRST ISSUED A.R J.L A.R. DATE: DWG N°: SCALE: REV:

N4 2 DRAIN 1. 1/2 -- WN RF 80 INDICATE REV DATE: REVISIONS DWG. REV. APP. 10-10-18 16003-PS-CRF-MEC-DET-001 S/E 0

SIZE A1 1 2 3 4

Potrebbero piacerti anche

- Faisal Awad - January 2012Documento42 pagineFaisal Awad - January 2012eng_far0% (1)

- Gear Pump Design SheetDocumento3 pagineGear Pump Design SheetpartoNessuna valutazione finora

- (O) - 1 Bored PileDocumento16 pagine(O) - 1 Bored Pileautienhai100% (4)

- Mean Metal TempsDocumento1 paginaMean Metal TempsThiruppathi RajanNessuna valutazione finora

- GA-150027-1 (003) Ffetbigbore1750 PDFDocumento1 paginaGA-150027-1 (003) Ffetbigbore1750 PDFriinNessuna valutazione finora

- Chipper Knives For The Wood IndustryDocumento5 pagineChipper Knives For The Wood IndustryX800XLNessuna valutazione finora

- Compressed Air Piping Design Data (Pressure Drop Tables For SCH 40 Steel, Type K & Type L, Fitting Equivalent Length & Required SCFM)Documento52 pagineCompressed Air Piping Design Data (Pressure Drop Tables For SCH 40 Steel, Type K & Type L, Fitting Equivalent Length & Required SCFM)rahulrampNessuna valutazione finora

- Plan Elevation: Job No. ClientDocumento1 paginaPlan Elevation: Job No. Clientriz2010Nessuna valutazione finora

- Sop Pressure TestDocumento5 pagineSop Pressure TestRichard Adolf100% (1)

- Sample Seal Pot DWGDocumento1 paginaSample Seal Pot DWGsandesh sadvilkarNessuna valutazione finora

- ANSI B16.9 ElbowDocumento3 pagineANSI B16.9 ElbowMahmoud Reda ElSherifNessuna valutazione finora

- Advanced Isometric Configuration in AutoCADPlant3DDocumento49 pagineAdvanced Isometric Configuration in AutoCADPlant3DRoobens SC Lara100% (1)

- 9736 1 3 - Im-Clm1,2,3-En-10 03Documento87 pagine9736 1 3 - Im-Clm1,2,3-En-10 03Jeremy ShaneNessuna valutazione finora

- Technical and Financial Proposal Mep With Revit Auto CadDocumento10 pagineTechnical and Financial Proposal Mep With Revit Auto CadHaymanot BaynesagnNessuna valutazione finora

- 050 0160 A (Main Frame Assembly)Documento3 pagine050 0160 A (Main Frame Assembly)Miltongrimi GrimilNessuna valutazione finora

- Note 1: Design Code: Pd5500 Cat Ii 2015Documento1 paginaNote 1: Design Code: Pd5500 Cat Ii 2015Edo FaiZal CandraWinataNessuna valutazione finora

- LMTD CalculatorDocumento2 pagineLMTD CalculatorSATISH PAWARNessuna valutazione finora

- Sae Insert S1yt3232 DWG 0Documento1 paginaSae Insert S1yt3232 DWG 0kaliya12Nessuna valutazione finora

- m0043 016 2 PDFDocumento1 paginam0043 016 2 PDFajarekarga ajarekarNessuna valutazione finora

- 185-170-5-300-M44-0055 RevBDocumento1 pagina185-170-5-300-M44-0055 RevBVashish RamrechaNessuna valutazione finora

- 320-R-101 (Gasifier Quench Ring)Documento2 pagine320-R-101 (Gasifier Quench Ring)idilfitriNessuna valutazione finora

- DOD-MST-INS-002, MST For Installation of Field Instruments.-Rev-1Documento15 pagineDOD-MST-INS-002, MST For Installation of Field Instruments.-Rev-1BharathiNessuna valutazione finora

- North: East Elevation View SCALE 1/100Documento16 pagineNorth: East Elevation View SCALE 1/100Potential SupportNessuna valutazione finora

- All About PipingDocumento46 pagineAll About PipingRakesh RanjanNessuna valutazione finora

- PS Mec Gen 001Documento1 paginaPS Mec Gen 001Anderson RodriguezNessuna valutazione finora

- Power Powders: The inDocumento6 paginePower Powders: The insalkan_rahmanovic810Nessuna valutazione finora

- 3147 Hoist r3Documento1 pagina3147 Hoist r3Ade Y SaputraNessuna valutazione finora

- Be 4800 Spec Sheet 2Documento1 paginaBe 4800 Spec Sheet 2Nhero DulatreNessuna valutazione finora

- Wreckoning 161.1 Exploded ViewDocumento2 pagineWreckoning 161.1 Exploded ViewAnonymous xlbj4Lm5aUNessuna valutazione finora

- Design Calculation S: Item: Tag No.: Serial No.: Project Name: Customer: Job No: DesignerDocumento23 pagineDesign Calculation S: Item: Tag No.: Serial No.: Project Name: Customer: Job No: DesignerandersonNessuna valutazione finora

- Kennedy Valve: 3"-12" Oil Cushion Check Valve AssemblyDocumento1 paginaKennedy Valve: 3"-12" Oil Cushion Check Valve AssemblySamuel Lopez BenitesNessuna valutazione finora

- 20100PE-DW02-0006 Rev1 11-SD-2122Documento1 pagina20100PE-DW02-0006 Rev1 11-SD-2122Jovit BeaNessuna valutazione finora

- Co2 Damper6Documento4 pagineCo2 Damper6sabir hussainNessuna valutazione finora

- Sheet 1 of 1: All Dimensions Are in MMDocumento1 paginaSheet 1 of 1: All Dimensions Are in MMPRASHANTHNessuna valutazione finora

- Bill of Material - 3105538: QTY Description Part No. ItemDocumento3 pagineBill of Material - 3105538: QTY Description Part No. ItemluisNessuna valutazione finora

- Conveyor Cross Section at Each Typical Segment r0 - c3Documento1 paginaConveyor Cross Section at Each Typical Segment r0 - c3Harish KumarNessuna valutazione finora

- Ba 204302 001Documento1 paginaBa 204302 001Muhammad ArshadNessuna valutazione finora

- SEMA AH Hook Block Assly. Sheet 2 3Documento1 paginaSEMA AH Hook Block Assly. Sheet 2 3Ade Y SaputraNessuna valutazione finora

- Assembly: Section "A"Documento2 pagineAssembly: Section "A"mrmp bbiNessuna valutazione finora

- C 84524 PS KK1 CAL ST 3K 0020 - R0A Pipeline Buoyancy Control AnalysisDocumento6 pagineC 84524 PS KK1 CAL ST 3K 0020 - R0A Pipeline Buoyancy Control AnalysisbonnicoNessuna valutazione finora

- Ingenieria-Cema 300-Screw Conveyor Standard PDFDocumento33 pagineIngenieria-Cema 300-Screw Conveyor Standard PDFsaulomonNessuna valutazione finora

- 05 Microtunneling Machines 22Documento13 pagine05 Microtunneling Machines 22Madalina Nitu100% (1)

- Confidential Information: Fire Water Tanks TAG NO. 62-T-1001A/B 51.2 M. DIA. X 17 M. HT. (CR)Documento1 paginaConfidential Information: Fire Water Tanks TAG NO. 62-T-1001A/B 51.2 M. DIA. X 17 M. HT. (CR)shravan.office11Nessuna valutazione finora

- Sliding Elastomeric Bearing - 301 MTDocumento1 paginaSliding Elastomeric Bearing - 301 MTAnusha KishoreNessuna valutazione finora

- 11-2756-b Elevator Boot Assy 28SIDocumento1 pagina11-2756-b Elevator Boot Assy 28SIBoanerges BritoNessuna valutazione finora

- Machine Afzar Shams: Bearing HousingDocumento8 pagineMachine Afzar Shams: Bearing HousingmasoodkamaliNessuna valutazione finora

- V-8120 DWG CommentsDocumento1 paginaV-8120 DWG CommentsSulist N WahyudieNessuna valutazione finora

- Preliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingDocumento1 paginaPreliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingbarrosojmsNessuna valutazione finora

- PPD 0600-00 2DRT2 2018-EN 4367.076.00M Rev.1Documento1 paginaPPD 0600-00 2DRT2 2018-EN 4367.076.00M Rev.1Mujahidin AhmadNessuna valutazione finora

- Weld Map Control RoomDocumento12 pagineWeld Map Control RoomAry Cipta KusumaNessuna valutazione finora

- Test Fixture Optical MountDocumento1 paginaTest Fixture Optical Mounti50229Nessuna valutazione finora

- 0740 19a PDFDocumento1 pagina0740 19a PDFDavid SarccoNessuna valutazione finora

- A554 y 730 HV DWG Hva 300Documento1 paginaA554 y 730 HV DWG Hva 300josephNessuna valutazione finora

- Notes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512Documento2 pagineNotes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512antoine131Nessuna valutazione finora

- Drawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMDocumento1 paginaDrawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMjonodo89Nessuna valutazione finora

- Belt Conveyor 600x12000 (k2) - Belt Conveyor TataDocumento1 paginaBelt Conveyor 600x12000 (k2) - Belt Conveyor TataAde SNessuna valutazione finora

- Peract Pi Q23 DW 0004 PDFDocumento5 paginePeract Pi Q23 DW 0004 PDFGNessuna valutazione finora

- Part 1 - Trolley WheelDocumento1 paginaPart 1 - Trolley WheellexatrinNessuna valutazione finora

- Wip Rev-E 25-Jun-19Documento2 pagineWip Rev-E 25-Jun-19QuyetNessuna valutazione finora

- 1714010223-Vent Ext Fima - RDocumento1 pagina1714010223-Vent Ext Fima - RMilton IngaNessuna valutazione finora

- 50 Cu Yd (Heaped) Aggregate Bin 225 BBL (MAX) Cement I Bin: Rear ViewDocumento1 pagina50 Cu Yd (Heaped) Aggregate Bin 225 BBL (MAX) Cement I Bin: Rear ViewDavid SarccoNessuna valutazione finora

- Manual Da Deslintadeira-200 SerrasDocumento56 pagineManual Da Deslintadeira-200 SerrasAilson Silva AlvesNessuna valutazione finora

- Acrobat Document PDFDocumento1 paginaAcrobat Document PDFKhepa BabaNessuna valutazione finora

- Ls Bearing Positioning Ls Bearing Positioning: Section View Reducer Jumborex Jc62Documento1 paginaLs Bearing Positioning Ls Bearing Positioning: Section View Reducer Jumborex Jc62Luu Thanh CongNessuna valutazione finora

- App1002413340030-03 Piping Drawing Miscellaneous Piping Ass Rev.ADocumento11 pagineApp1002413340030-03 Piping Drawing Miscellaneous Piping Ass Rev.AAswindana Ibnu SenaNessuna valutazione finora

- 06) 5333-106-D - General Arrangement Drawing CN7065 Screw ConveyorDocumento1 pagina06) 5333-106-D - General Arrangement Drawing CN7065 Screw ConveyorluisleojossewNessuna valutazione finora

- Rotary Valve Engine AssyDocumento1 paginaRotary Valve Engine AssyMaria Cristina DijmarescuNessuna valutazione finora

- Foundation Loading Data of Skid For Pipe Supports of Amine Circulation Pumps (Skid 1)Documento6 pagineFoundation Loading Data of Skid For Pipe Supports of Amine Circulation Pumps (Skid 1)Aisha SajidNessuna valutazione finora

- Nozzle Table: K-K Foundation Detail TypDocumento1 paginaNozzle Table: K-K Foundation Detail TypVishal KandNessuna valutazione finora

- Rotary Valves Airlocks Rotolok UsaDocumento6 pagineRotary Valves Airlocks Rotolok UsagallowdrNessuna valutazione finora

- Chain Appron Conveyor R1a01-BushingDocumento1 paginaChain Appron Conveyor R1a01-Bushinger_winwibowoNessuna valutazione finora

- Sprocket PT Petrodrill Manufacture IndonesiaDocumento1 paginaSprocket PT Petrodrill Manufacture Indonesiaer_winwibowoNessuna valutazione finora

- Skid 1 - Foundation Load Table: Dead Weight (LB) Wind Load (120 MPH) Load (LBF) Load (LBF) S 0.825gDocumento3 pagineSkid 1 - Foundation Load Table: Dead Weight (LB) Wind Load (120 MPH) Load (LBF) Load (LBF) S 0.825gomarNessuna valutazione finora

- DN Nagar Mandala: Viaduct Layout Plan For Pier No. P1 To P18Documento1 paginaDN Nagar Mandala: Viaduct Layout Plan For Pier No. P1 To P18naba1577Nessuna valutazione finora

- Pressure Ecualizer DeviceDocumento27 paginePressure Ecualizer DeviceandersonNessuna valutazione finora

- Pressure Ecualizer DeviceDocumento27 paginePressure Ecualizer DeviceandersonNessuna valutazione finora

- 2700 Catalog SectionDocumento37 pagine2700 Catalog SectionIebe SeventynineNessuna valutazione finora

- BHCN 2700 TS 20249C 1020 EnglishDocumento40 pagineBHCN 2700 TS 20249C 1020 EnglishandersonNessuna valutazione finora

- Ambient Heat Loss From A VesselDocumento2 pagineAmbient Heat Loss From A VesselandersonNessuna valutazione finora

- Api 617 ErtaDocumento1 paginaApi 617 ErtaandersonNessuna valutazione finora

- Ambient Heat Loss From A VesselDocumento2 pagineAmbient Heat Loss From A VesselandersonNessuna valutazione finora

- Carbon Filter HeadDocumento1 paginaCarbon Filter HeadandersonNessuna valutazione finora

- Ferroli Gázszelep SIT 825 NOVADocumento8 pagineFerroli Gázszelep SIT 825 NOVAkerandibNessuna valutazione finora

- Hdpe NICDocumento57 pagineHdpe NICsaravananNessuna valutazione finora

- Wasco Brochure 2012Documento31 pagineWasco Brochure 2012Amir Asyraf SuhailiNessuna valutazione finora

- Floorsinks PDFDocumento27 pagineFloorsinks PDFiranomaasNessuna valutazione finora

- Tangit PVC U Can 500gDocumento7 pagineTangit PVC U Can 500gSaravanan SekarNessuna valutazione finora

- Magnatech Tubesheet OrbitalDocumento4 pagineMagnatech Tubesheet OrbitalmartinNessuna valutazione finora

- 7251 08 103 Pipe Outfall PDFDocumento1 pagina7251 08 103 Pipe Outfall PDFKBNessuna valutazione finora

- H Im pcs1Documento42 pagineH Im pcs1Maria DazaNessuna valutazione finora

- Cida Bullein of Construction Statistics October 2020Documento28 pagineCida Bullein of Construction Statistics October 2020Niruban ThaventhiranNessuna valutazione finora

- Hydronic Heat-Distributing Units and RadiatorsDocumento6 pagineHydronic Heat-Distributing Units and RadiatorsLejinNessuna valutazione finora

- Tyfo® Fibrwrap® Systems: Blast Mitigation & Penstock RehabilitationDocumento45 pagineTyfo® Fibrwrap® Systems: Blast Mitigation & Penstock RehabilitationBob AlaNessuna valutazione finora

- Preparation Guide: Orbit Sprinkler System DesignerDocumento6 paginePreparation Guide: Orbit Sprinkler System DesignerPera ZderaNessuna valutazione finora

- 2019-03 (Corrosion Monitoring - Uniflow Cyclones)Documento88 pagine2019-03 (Corrosion Monitoring - Uniflow Cyclones)nicacio_89507470Nessuna valutazione finora

- r050212102 Mechanics of FluidsDocumento8 paginer050212102 Mechanics of FluidsSrinivasa Rao GNessuna valutazione finora

- Oil Water Separators Manual TV3xnZFDocumento44 pagineOil Water Separators Manual TV3xnZFabcdeNessuna valutazione finora

- Static Cartridge Cleaning StationDocumento10 pagineStatic Cartridge Cleaning StationsergeyNessuna valutazione finora

- Scope of Works, Technical Specifications AND Bill of MaterialsDocumento16 pagineScope of Works, Technical Specifications AND Bill of MaterialsRoi KimssiNessuna valutazione finora

- TEC-033000.2-MET-DoR - (Method Statement For Constructions of Pile Caps, Lift Pit, Pipe Encasement Below Raft) (A)Documento16 pagineTEC-033000.2-MET-DoR - (Method Statement For Constructions of Pile Caps, Lift Pit, Pipe Encasement Below Raft) (A)Haymanot BaynesagnNessuna valutazione finora

- ABB Flujómetro HygienicMaster 630 PDFDocumento152 pagineABB Flujómetro HygienicMaster 630 PDFAlejandro GuerraNessuna valutazione finora