Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Plastics Innovation Towards Zero Waste PDF

Caricato da

Jack PadiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Plastics Innovation Towards Zero Waste PDF

Caricato da

Jack PadiCopyright:

Formati disponibili

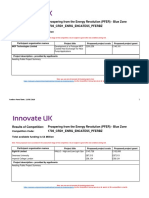

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

ZUVASYNTHA LIMITED Optimisation and scale-up of a £603,504 £422,453

novel bioprocess for commercial

production of (R)-1,3-Butanediol

TDELTAS LIMITED £14,966 £10,476

University of Kent £245,211 £245,211

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 1

Project description - provided by applicants

The future sustainable production of chemicals and fuels from non-petrochemical resources and the reduction of greenhouse gas emissions

are two of the greatest challenges facing society. To date, research to address this need has often focused on using microbial cell factories

(bacteria and yeasts) to ferment the sugar derived from plants, often targeting the production of key high volume, lower value commodity

products. However, the price of sugar, a commodity in its own right, is very often inconsistent with the constrained techno-economics

associated with biological commodity chemical production. In addition, utilising sugar for high volume chemical synthesis has raised concerns

regarding competition with the use of sugar as a foodstuff. Unfortunately, sourcing sugar from the far more desirable non-food lignocellulosic

plants, has also proved economically challenging due to the resistance of these plants to deconstruction. These economic hurdles have

constrained the development of many new, sustainable, chemical production technologies which are required to drive the growth of

bioprocessing in the UK. An alternative strategy is to target small but high value, meaningful markets to pioneer novel biotechnologies from

sugar, while co developing the use of cheap (C1) waste derived non-sugar feedstocks, for application to the much bigger and environmentally

more impactful, but cost sensitive, commodity markets. This project seeks to develop a novel bioprocess for commercial production of 1,3-

BDO, a highly desirable chemical with diverse applications, initially for application as a speciality chemical.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 2

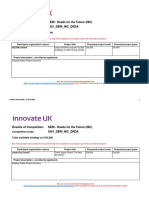

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

RECYCLING TECHNOLOGIES LTD Recovering value from £570,902 £399,631

contaminated plastic wastes

TOMRA SORTING LIMITED £145,900 £72,950

University of Bath £172,151 £172,151

WESSEX WATER ENTERPRISES LIMITED £17,280 £0

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 3

Project description - provided by applicants

Recycling Technologies' process is capable of chemically recycling plastic waste. We are determined to reduce the amount of plastic that is

either landfilled or incinerated. More than a quarter of the UK's 3.2MT (Million Tonnes) of plastic waste is landfilled because of its

contamination with organic material or other plastics. The challenge is to find a way and recover the plastic from this waste stream and reduce

the ever-increasing plastic pollution. This project aims to take on this challenge!

Our technology, RT7000 is capable of processing the recovered plastic via thermal cracking into an ultra low sulphur hydrocarbon product

branded as Plaxx. Plaxx is a synthetic equivalent of crude oil. It can be used as a low sulphur fuel or chemical feedstock (naphtha) to make

new plastics.

Municipal waste at Material Recovery Facilities (MRF), food contaminated plastic packaging waste from Anaerobic Digestion (AD) plants and

Recovered Plastic Litter (RPL) in water treatment facilities are some of the largest sources of plastic waste.

We can use smart optical sorting techniques to pick up and separate the plastic from streams of waste from a MRF. In doing so, we can divert

the plastic away from incineration and reduce its CO2 impact.

Enzyme-based biological cleaning system can be used on AD and RPL waste to break down the organic contamination. In addition to its

green and sustainable credentials, enzymatic degradation is relatively cheap and it releases soluble and fermentable sugars that can be re-

cycled for other processes.

The technologies (optical and enzyme) can be combined together to give RT the ability to accept a wide variety of contaminated waste into its

core technology. Once the contamination is processed using a pre-treatment module, the separated plastic waste can be processed using the

RT7000\. This combined approach will allow UK to reduce landfilling, increase its recycling rates and develop innovative technologies to

handle contaminated plastic waste.

Furthermore, the diversion of each tonne of plastic waste away from Energy from Waste (EfW) plants and converted into Plaxx fuel creates

up to 2.5 TCO2e savings. This saving for 7000 tonnes of plastic waste is equivalent to the emissions of more than 3,500 cars every year!!!!!

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 4

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

SKIPPING ROCKS LAB LIMITED Reducing single use plastic- £188,685 £84,908

aluminium packaging for <50ml

sachets through development and

scale up of the Ooho seaweed

sachet

JUST EAT.CO.UK LTD £46,898 £11,724

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 5

Project description - provided by applicants

**AMBITION:** Our aim is to reduce and replace the use of unsustainable, environmentally harmful packaging for sauces and gel sachets

through the development, scale up and roll-out of our natural, fully biodegradable plastic alternative technology Ooho - a unique,, seaweed-

derived membrane material.

**FOCUS**: Having perfected the strength, structure and shelf-life of our membrane technology in 2017, we now need to develop the

advanced production hardware and machinery to manufacture and fill single-use sachets on an industrial scale in order to meet demand --

replacing current laminated aluminium and plastic packaging for condiments (sauces, salad dressings), gels (energy gels) and cosmetics

(shampoo, conditioner) up to 50mL.

Our alginate material cheaper than plastic and aluminium as input material however difficulties in the manufacturing process, requiring

significant human intervention, restrict our maximum production capacity to meaning that despite strong commercial interest, we are unable to

meet the volume demanded by restaurants, take aways and retailers in a cost-competitive manner.

As part of our long-term growth strategy, our goal is to develop an method (hardware and production process) to manufacture Oohos,

packaging range of single-use liquids on an industrial scale, in a consistent, high quality, low cost manner required.

**APPROACH:** Working with development partner, Just Eat the project focuses on overcoming the technical difficulties associated with

designing and developing a unique, automated, machine to manufacture and fill 3000 Oohos sachets/day with a variety of

condiments/sauces, without compromising structural integrity or consistence of the packaging membrane.

Our alginate packaging is naturally sourced, biodegradable, robust (thanks to the previous IUK project) and is even edible. The only issue

holding back its adoption is our ability manufacture and fill the membrane on an industrial scale.

**SIGNIFICANCE:** The UK throws away over 300m plastic and aluminium single-use sachets (2ml-50ml) each year (Unilever;2017), with

less than 9% ever recycled (National Geographic;2017). due to their disposable nature and plastic-aluminium composition.

In line with UK GOVs 'Plastic Pact' 2025 commitment, by developing manufacturing at scale capability, seaweed membrane will be cost-

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 6

competitive with that of plastic/aluminium sachets and packaging, enabling retailers to adopt out technology for single-use liquid items. This in

turn will save considerable CO2 in waste, reduced transport costs, plastic production and enable us to take advantage of global interest in the

technology, spearheading the use of natural, plastic alternatives.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 7

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

GR8 ENGINEERING LIMITED Development of a technology to £99,034 £69,324

produce clear rigid food packaging

pots for high temperature

applications using Recycled

Polyethylene Terephthalate (rPET)

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 8

Project description - provided by applicants

GR8 Engineering Limited (GR8) is a UK based SME with in-depth experience and knowledge in the production of high quality plastic food

packaging.

Through our discussions with the market influencers, development partners and early adopters, we have identified a market opportunity for a

technology 'rPET-tech' which will enable the use of recycled Polyethylene Terephthalate (rPET) to manufacture packaging for the high

temperature food grade applications. We request Innovate UK funding support in order to prove our concept of developing a two-stage

injection compression/stretch blow moulding process which will be able to process rPET with Intrinsic Viscosity of 1.15 to produce clear rigid

food packaging pot which will maintain their thermo-mechanical performance at temperatures as high as 160degC (suitable for Microwave

use). As a result of project success, we will drive growth and innovation into a greener food packaging sector through circular economy and

reduce materials wastage, increase production rates; and improve design flexibility.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 9

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

IN-CYCLE LTD Closed loop innovation for fused £90,220 £63,154

filament fabrication (CLIFFF)

EXPRESS GROUP LIMITED £101,230 £60,738

HSSMI LIMITED £58,117 £58,117

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 10

Project description - provided by applicants

The Closed Loop Innovation in Fused Filament Fabrication (CLIFFF) project will enable industry and academic 3D print service bureaus to

reprocess discarded 3D prints back into high value new 3D printing filaments creating a fully circular business model for the Additive

manufacturing (AM) sector.

AM and 3D printing is a rapidly growing industrial sector, however, there are environmental concerns around this fast-growing sector. Unlike

other plastic products, there is currently no established End-Of-Life (EoL) processing system for 3D printed polymer parts, so the vast majority

of discarded prints ultimately end up in landfill.

The CLIFFF project will therefore take a proactive approach whilst the industry is still maturing. Main objectives are to create a material

identification system for EoL and failed 3D prints using a novel NIR based approach, create new reverse logistics business models and

develop a lab-scale processing facility. The facility will shred and extrude the failed prints back into high quality 3D printer filament that will be

comprehensively tested on a range of commercial 3D printers. End-user engagement and feedback will help ensure the long term

sustainability of the approach. As opposed to a traditional large scale centralized recycling systems, the proposed system would be deployed

regionally to reduce transportation costs and associated environmental impacts.

The project team consists three organisations. GoPrint3D, a 30-year-old printing company, HSSMI a manufacturing RTO and In-Cycle a

materials recycling technology SME and will run for 12 months.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 11

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

IMPACT LABORATORIES LIMITED Efficient plastic size reduction £99,947 £69,963

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 12

Project description - provided by applicants

CryoCut has been created in order to solve the largest cost in plastic recycling -- size reduction. The process requires huge amounts of

energy to drive large metal rotors to tear the plastic apart. Many plastics have been designed and manufactured though to be resilient

materials, and instead of shattering as other materials do (for example copper), they slowly are torn into smaller pieces.

Plastic is also abrasive, causing damage to the metal rotors, and requiring constant replacement of knives and blades, causing operational

cost and downtime on capitally expensive material.

CryoCut will not just reduce electrical usage and wear on rotors, but also massively increase throughput by up to 10 times. The CryoCut

technology therefore has the potential to be a disruptive technology in the plastic recycling market.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 13

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

LUCIDEON LIMITED Inorganic Sustainable Alternatives £90,810 £54,486

to Plastic Microbeads

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 14

Project description - provided by applicants

Plastic microbeads are widely used in the Cosmetics industry either in rinse-off products such as shampoos and toothpaste or in leave-on

formulations such as lipsticks and sun-creams. For example, up to 100,000 plastic microbeads are released from a single shower. A study

conducted by Niva in collaboration with the University of Manchester counted more than 75,000 particles/kg of riverbed sediments in the

Manchester river network alone. Although plastics have several benefits, the size of these additives is such that the waste water treatment

plants cannot retain them efficiently and they are released into the environment. Once released, they enter the food chain either though

plankton or worms with negative effects on the environment. Microplastics have now been banned from rinse-off products in the UK and the

industry has been voluntarily working on replacing them since 2015\. Although microplastics have almost disappeared from rinse-off products,

alternatives for leave-on are lacking due to poor performance, safety issues or high costs. This feasibility study aims at finding an alternative

to microplastics for the cosmetic industry, and especially for leave-on products. The target is to achieve spherical beads, smaller than 20?m

and at a cost lower than £15/kg based on the metrics given by the industry. We will explore two approaches: one based on silica using

Lucideon's iCRT (inorganic controlled release technology) material and the second one based on a clay geopolymer chemistry. Both will

make use of emulsion processing to achieve small spheres. Lucideon has developed a geopolymer formulation called MIDAR, mostly used

for the nuclear and construction industries but also as a matrix to encapsulate active ingredients for the pharmaceutical industry. The MIDAR

approach would cover the low cost bulk product range while the silica approach would suit premium products, both having the ability to

introduce additional functionality. In this project we will aim to produce microbeads with the required characteristics at the laboratory and

demonstration scale and the deliverable will include cost analysis and scaleability. Current solutions involving silica are either at the right

price, but obtained through an energy intensive process and with limited functionalisation opportunities or too expensive. Geopolymers have

been turned into spherical beads but usually for applications requiring larger sizes. We believe that the properties of our iCRT and MIDAR

technologies have the potential to fill the gaps above and provide a green processed material to replace microplastics in leave-on cosmetics

products.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 15

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

REED THERMOFORMED PACKAGING LTD. Project ENVPac £316,772 £221,740

AVONDALE FOODS (CRAIGAVON) LIMITED £26,254 £13,127

CENTRE FOR PROCESS INNOVATION £158,705 £158,705

LIMITED

CRANSWICK COUNTRY FOODS PLC £27,362 £13,681

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 16

Project description - provided by applicants

The issue of increasing ocean plastics pollution over recent years has created an increasing focus on biodegradable alternatives to traditional

fossil-based polymers. Plastics have demonstrated many positive benefits e.g. reducing food waste, enabling globalised distribution of goods

boosting economic growth, and providing highly recyclable packaging options. However, mismanagement of waste streams has resulted in a

growing call for packaging options which will naturally bio-degrade.

Project Partners (IPAC, Avondale, Cranswick Plc, together with their customers including major UK retailers) are collaborating as a complete

value-chain (supply, manufacturing, retail), with World-Class Polymer-Chemistry Research/Materials Capability (CPI). Developing new

product materials for food packaging (e.g. meats/salads) that are comparable to existing plastic packaging but also environmentally

compatible, and can be consumed by nature like any other organic polymer on earth.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 17

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

INTERFACE POLYMERS LTD Polarfin-Blue: compatibilization of £844,721 £591,305

polymers to enable recycling

PRESEAL LIMITED £67,155 £47,008

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 18

Project description - provided by applicants

Interface Polymers Ltd will develop the use of Polarfin material to address the global problem of recycling multi-layer flexible plastic packaging

back into high value uses.

The approach is totally disruptive, unlike existing adhesion promoters, Polarfin chemistry can be finetuned, making polar and polyolefin block

chains of any size, enabling the combination of a wide range of currently incompatible thermoplastics into new polymer alloys which offer

unique properties.

Being able to produce high-value polymer alloys from recycled packaging will eliminate the need for high-cost/complex/hazardous recycling

infrastructure needed to separate multi-layered films and enable new global markets

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 19

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

Ichthion Ltd Remora Cobalt - A turbomachinery £498,702 £349,091

system to collect micro and macro

plastics to clean up rivers and

oceans

Imperial College London £119,083 £119,083

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 20

Project description - provided by applicants

Ocean plastic pollution is one of the most critical global environmental issues. It is estimated that five trillion pieces of plastic debris are in the

oceans already. An additional 17.5 million tonnes of plastic is forecast to enter the oceans annually by 2025, with 80% of this coming from just

10 major rivers. The effects of plastic pollution on tourism and wildlife cost £13 billion a year globally and leads to the premature death of

millions of animals, including marine mammals, seabirds and fish.

Despite the urgency and scale of the problem, current approaches to collect plastic from rivers and oceans is ineffective. In rivers, manual

plastic removal using nets remains the mainstay, but is inefficient (<1% collected) and not economically viable in the developed world. Trash-

Wheels as seen in Baltimore, are considered state-of-the-art for removal of plastics in river environments, however they are unable to collect

microplastics -- the main cause of premature death for marine wildlife. Efforts to collect plastic from ocean environments are a poor use of

resources, with studies showing it is 30x more effective to collect plastic before it has reached deep-water environments.

Remora Marine seek to overcome the limitations of current solutions to deliver the first truly scalable technology to reduce the flow of plastics

into the world's oceans by developing a novel, versatile turbo machinery system, 'Cobalt', that can unobtrusively attach to a range of static

and dynamic fluvial infrastructures to filter and collect approximately 15% of macro and micro plastics passing downstream. Through the

collaboration with the Dyson School of Design Engineering at Imperial College London, the approach offers: \[1\] Filters capable of retrieving

microplastics down to 1mm in length. \[2\] A revolutionary self-cleaning mechanism to sustain maximum efficiency using the mechanical force

supplied by the river flow. \[3\] Versatile axle design allowing Cobalt to be attached to a variety of static rivers infrastructures. \[4\] Additional

output of electricity, with the generative power of Cobalt more than that required for collecting the plastics.

With Innovate-UK support, a 24-month programme of R&D is required to deliver a prototype validated both in the laboratory and simulated

environment. If successful, Cobalt will truly revolutionise the ocean plastic pollution problem -- with the potential to collect 10% of the plastic

entering the world's oceans through rivers by 2025\. Cobalt can be exploited globally, with the project delivering significant export led growth,

substantial RoI and taxpayer value.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 21

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

COLOUR TONE MASTERBATCH LIMITED Recycling up to 376,000 tonnes of £155,342 £93,205

waste per annum that would

otherwise have gone to

landfill/incineration through a new

sustainable multi-life NIR sortable

polymer pigment and recycling

system

LUXUS LIMITED £283,676 £170,206

RPC GROUP PLC £47,414 £23,707

THE TECHNOLOGY RESEARCH CENTRE £186,750 £130,725

LIMITED

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 22

Project description - provided by applicants

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 23

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

BLUE CASTLE BUSINESS SERVICES LTD A new method of recycling PVC; £89,999 £62,999

bolstering the circular economy

through producing both a purer

REACH compliant R-PVC and

other new high-value outputs

MATRIX RECYCLING SYSTEMS LTD £84,999 £59,499

University of York £74,969 £74,969

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 24

Project description - provided by applicants

The UK and EU are striving for a circular economy where our precious resources are reused, recycled and repurposed instead of being

disposed of. Plastics are an increasingly consumed commodity and Western Europe are amongst the world's highest consumers (WRAP,

2006) - approximately 25.8Mt of plastic waste is generated across Europe annually (EC 2018); therefore ensuring sustainable plastics

recycling is paramount to achieving a circular economy for plastics. Polyvinyl chloride (PVC) is amongst the world's most widely used

polymers, accounting for 20% of all plastic manufacture (BPF, 2018) but with less than 30% (96kt) of the UK's PVC use being recycled in

2014 (WRAP, 2016) there is much progress needed to achieve the European PVC industry target of 800kt/year recycled by 2020 (VinylPlus,

2010).

PVC often contains additives, some of which are considered to be substances of very high concern and are undergoing REACH authorisation

which bans their use in new PVC materials, including recycled PVCs (R-PVC). This is leading to limitations on the PVC recycling industry and

has already caused the closure of one PVC recycling plant.

Our innovation looks to respond to this market need and provide the first method to recycle PVC containing banned additives through

removing and re-purposing into new, valuable polymers which can be used in a range of applications, including coatings and composite

materials for construction - benefitting the environment and the UK economy through reduced imports of materials and exports of plastics

waste and increased revenue generation.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 25

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

PVOH POLYMERS LIMITED Self Removing Polymer Packaging £144,706 £101,294

with Active Function

BRILLIANT BASICS CONSULTANCY £37,250 £26,075

LIMITED

SOLUPAK LIMITED £157,534 £110,274

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 26

Project description - provided by applicants

Our vision is to develop self removing packaging to perform a secondary cleaning function during its removal from the traditional waste

stream thus encouraging customer engagement of this technology.

This project is aimed at the detergent sector, multilayer barrier films are currently used to protect highly sensitive water soluble films, these

multilayer barrier films contain mixed polymers therefore these are difficult to recycle being recycling class 7 "other".

Polyvinyl Alcohol (PVOH) is a water soluble nontoxic biodegradable polymer which conforms to CEN 13432\. In its film and injection moulded

format it is predominantly used for detergent and Agrichemical dosing, where the polymer dissolves in water to release the active

components.

Being Hygroscopic it is susceptible to atmospheric moisture uptake in conditions over 50RH. Therefore, expensive protective packaging is

required to maintain its physical properties, this is important to maintain child safety regulations when caustic detergents are encapsulated.

Our first key objective is to to design and develop a new detergent format which eliminates the requirement for secondary barrier packaging

by the substitution of cast PVOH film with a new less hygroscopic PVOH formulation suitable for injection moulding. Formulation will need to

be developed surrounding capsule strength for child safety and product release with no residue observed during a short eco wash cycle and

be resistant to atmospheric moisture.

Our second key innovative objective is to develop secondary packaging to protect the primary packaged product against atmospheric

moisture in the form of a water soluble container to be dissolved when empty in a dishwasher. This container will contain a cleaning agent to

be released during dissolution, adding function to the polymer which will either be encapsulated in the polymer or in a self contained tamper

proof compartment within the packaging.

Polymer products entering water courses has been recently highlighted by Sir David Attenborough (Blue Planet and A Plastic Ocean). PVOH

is quickly biodegraded in the natural environment and will not form microbeads or plastic residue causing hazards to wildlife.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 27

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

CRALEY GROUP LIMITED PROMOTE - Advanced pipe £356,053 £249,237

relining technology manufactured

from plastic waste recyclates

IMPACT RECYCLING LIMITED £124,755 £87,328

London South Bank University £139,875 £139,875

RADIUS SYSTEMS LIMITED £195,619 £97,810

TWI LIMITED £145,171 £145,171

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 28

Project description - provided by applicants

The problem of persistent plastic waste and lack of adequate recycling solutions poses a significant challenge to current and future

generations. As the amount of plastic placed on market (POM) continues to increase, the amount we recycle is failing to make tangible

inroads into curbing the amount of end-of-life plastic POM being disposed (landfill, incineration, lost to the environment) e.g. 62% of plastic

packaging (1.3m tonnes per year) annually never gets recycled. Although there is not one main cause or solution to this problem, there are

insufficient market applications in the UK suitable for lower grade plastic recyclates.

The PROMOTE project will take advantage of lower grade waste plastic as part of a world's first solution capable of exploiting a significant

global opportunity: the rehabilitation of deteriorated underground piping and drainage infrastructure, a market worth in excess £7.71billion.

Our solution will achieve step-change performance over CIPP (Cure in Place Polymer), the market's current leading solution.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 29

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

AXION RECYCLING LTD. ReCLAIM: Recovery of polymers £536,602 £268,301

Containing Legacy Additives in

MEP

CROMPTON MOULDINGS LIMITED £109,034 £76,324

TROJAN SERVICES LIMITED £93,659 £56,195

University of Birmingham £208,685 £208,685

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 30

Project description - provided by applicants

The move to a circular economy is vital for the development of industry and the protection of the environment. One material constantly in the

spotlight is plastics. Plastic is a highly engineered, indispensable material used over a wide range of applications. One of the strengths of

thermoplastics is the potential ability to recycle the same material many times and make use of it in a circular economy.

However, there is still a significant volume of plastic that is not recycled currently, and is destined for landfill or incineration. This material is

the residual Mixed Engineering Plastics (MEP), which contains a wide range of less-common polymer types and importantly a significant

proportion of legacy additives which are a concern when recycling the material.

Within the ReCLAIM project, Axion Recycling, Trojan Services, Crompton Mouldings, and University of Birmingham will address these

problems by: developing new processes for greater recovery of polymer fractions from MEP; creating chemical and physical methods for

making BFRs biologically unavailable in the recycled polymers and verifying their efficacy; and proving that the polymer is suitable for real end

markets.

The results from ReCLAIM will boost competitiveness of the partner organisations by adding to their product lines, increasing revenue, and

reducing operating costs. The benefits to the UK will be increased economic activity, new jobs, a reduction in waste incinerated or sent to

landfill, and significant CO2 savings.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 31

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

POLYMATERIA LIMITED A novel additive-based technology £412,058 £288,441

to biotransform polypropylene

packaging to be compostable

CHEMEX ENVIRONMENTAL £188,093 £131,665

INTERNATIONAL LIMITED

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 32

Project description - provided by applicants

A throwaway society has spread plastic packaging waste worldwide, polluting every corner of our planet. Each year \>200M tonnes of plastic

is produced for 'single-use' with 35% of that sent to recycling rejected due to 'contamination' by remnants of unconsumed food or liquid.

Astonishingly, less than 10% of plastic ends up being recycled.

Public awareness of on-the-go food packaging waste has increased significantly following the recent "Latte Levy" promoting scientific

research/interest into compostable plastic. A key focus of this research has been on additive-based compostable plastic which seeks to retain

physical characteristics of conventional plastic throughout its useful life whilst offering accelerated composting under industrial composting

conditions, transforming entirely to CO2, water and biomass. This provides alternative capture carbon, as food contamination is inevitable,

protecting the environment from accumulating plastic waste.

However, current compostable plastic solutions are predominantly biobased/hydro-biodegradable plastics which increase land

competition(limited feedstock), are \>6x more expensive and require different manufacturing infrastructure compared to petroleum-based

plastics. Current best-in-class additives for polyolefins (polyethylene(PE), polypropylene(PP)) which offer accelerated biodegradation in the

open environment require a minimum of 2-years with no solution available to achieve the same within 6-months under industrial composting

conditions -- and therefore marketed as compostable.

Addressing this gap, Polymateria aim to develop a portfolio of advanced drop-in additive formulations for the manufacture of compostable,

biodegradable, cost-effective plastics. In collaboration with ecotoxicology testing experts at Chemex, this project aims to develop the first

additive-based biotransforming technology for compostable PP packaging, which will be tested and certified at Chemex's facilities, as the first

UK SME with capabilities to meet EN13432 Standard. This will offer a breakthrough technology for the plastic packaging sector,

simultaneously providing unique expertise to the UK in compostability testing.

Both partners are well placed to exploit this opportunity: Polymateria has already commercialised bespoke biotransforming formulations for

PP&PE in the open environment, and Chemex have state-of-the-art testing equipment and experts in terrestrial & aquatic ecotoxicology

testing.

With InnovateUK support, a 2-year programme of industrial research is required to design and test formulations for physiochemical polymer

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 33

properties and compostability. Project success will support a co-development deal with PP Converters with commercialisation by 2022, to

establish:

- Polymateria at the forefront of compostable additives for a plastics market, poised for significant growth and

- Chemex as the only UK testing laboratory capable of specific accredited composting testing, alongside their entire ecotoxology testing suite,

plus terrestrial and aquatic biodegradation testing.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 34

Results of Competition: Plastics Innovation: Towards Zero Waste

Competition Code: 1806_ISCF_MM_PLASTICS

Total available funding is £3million

Note: These proposals have succeeded in the assessment stage of this competition. All are subject to grant offer and conditions being met.

Participant organisation names Project title Proposed project costs Proposed project grant

HARLEQUIN MANUFACTURING LIMITED ROTOCYCLE - Novel use of hard £115,290 £69,174

to recycle plastics in rotomoulded

applications

IMPACT LABORATORIES LIMITED £156,311 £109,418

IMPACT RECYCLING LIMITED £100,889 £70,622

Queen's University of Belfast £155,614 £155,614

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 35

Project description - provided by applicants

Although rotomoulding is a well-established processing technique for the manufacture of products from polymers such as polyethylene, the

use of post-consumer waste polyethylene is rare due to the problems associated with achieving good interfacial interaction between the base

polymer and post-consumer waste polyethylene resulting in products that having poor mechanical properties. These low carbon footprint

fillers could however be used to replace a high proportion of the virgin polymer in rotomoulded articles to enable good quality, eco-friendly

commercially viable products to be manufactured reducing the the industries reliance on virgin polymers.

Enabling post-consumer waste polyethylene materials to be used in rotomoulding would increase the variety of materials that are available to

Rotomoulders, demonstrating their effectiveness and open up a new and potentially massive market for recyclers to sell their recyclate into,

absorbing the growing supply of post consumer waste plastics.

Our project will look to develop a full recycler to manufacturer supply chain for the rotomoulding industry, developing; recyclate grade

polymers, the manufacturing processes to use them and confirming through industry standard tests they are suitable for sale into the market.

Note: you can see all Innovate UK-funded projects here https://www.gov.uk/government/publications/innovate-uk-funded-projects

Use the Competition Code given above to search for this competition’s results

Funders Panel Date: 21/09/2018 36

Potrebbero piacerti anche

- A Checklist For Editors, Reviewers, and Authors Checklist PDFDocumento4 pagineA Checklist For Editors, Reviewers, and Authors Checklist PDFJack PadiNessuna valutazione finora

- Results of Competition: November 2017 Sector Competition Strand 1: Materials and Manufacturing - Up To 12 Months 1711 - MM - INFRA - R4 - ST1 - 12MDocumento44 pagineResults of Competition: November 2017 Sector Competition Strand 1: Materials and Manufacturing - Up To 12 Months 1711 - MM - INFRA - R4 - ST1 - 12MJack PadiNessuna valutazione finora

- Open Round 2 - Competition Results PDFDocumento156 pagineOpen Round 2 - Competition Results PDFJack PadiNessuna valutazione finora

- Results of Competition: November 2017 Sector Competition Strand 2: Infrastructure Systems - 3 To 12 Months 1711 - MM - INFRA - R4 - ST2 - 12MDocumento32 pagineResults of Competition: November 2017 Sector Competition Strand 2: Infrastructure Systems - 3 To 12 Months 1711 - MM - INFRA - R4 - ST2 - 12MJack PadiNessuna valutazione finora

- Open Round 1 2018-19 - Competition Results PDFDocumento126 pagineOpen Round 1 2018-19 - Competition Results PDFJack PadiNessuna valutazione finora

- Checklist of Review Criteria For Research Manuscripts PDFDocumento3 pagineChecklist of Review Criteria For Research Manuscripts PDFJack PadiNessuna valutazione finora

- Open Round 5 March 2018 - Competition Results PDFDocumento133 pagineOpen Round 5 March 2018 - Competition Results PDFJack PadiNessuna valutazione finora

- Results of Competition: Innovation in Health and Life Sciences Round 3 - Up To 12 Months 1710 - HLS - R3 - 12MDocumento56 pagineResults of Competition: Innovation in Health and Life Sciences Round 3 - Up To 12 Months 1710 - HLS - R3 - 12MJack PadiNessuna valutazione finora

- Results of Competition: Electric Vehicle Charging For Public Spaces: Feasibility Studies Competition Code: 1807 - FS - OLEV - ELEC - ST1Documento45 pagineResults of Competition: Electric Vehicle Charging For Public Spaces: Feasibility Studies Competition Code: 1807 - FS - OLEV - ELEC - ST1Jack PadiNessuna valutazione finora

- Results of Competition: Robotics and AI in Extreme Environments 1806 - ROB - AIDocumento1 paginaResults of Competition: Robotics and AI in Extreme Environments 1806 - ROB - AIJack PadiNessuna valutazione finora

- Results of Competition: Increase Productivity, Performance and Quality in UK Construction Competition Code: 1807 - ISCF - IPPQUKCDocumento52 pagineResults of Competition: Increase Productivity, Performance and Quality in UK Construction Competition Code: 1807 - ISCF - IPPQUKCJack PadiNessuna valutazione finora

- Results of Competition: Support For Smes To Evaluate Innovative Medical Technologies 1801 - CRD - Ols - SmeimtDocumento15 pagineResults of Competition: Support For Smes To Evaluate Innovative Medical Technologies 1801 - CRD - Ols - SmeimtJack PadiNessuna valutazione finora

- Results of Competition: First of A Kind: Demonstrating Tomorrow's Trains Today 1710 - SBRI - FOAK - RAILDocumento17 pagineResults of Competition: First of A Kind: Demonstrating Tomorrow's Trains Today 1710 - SBRI - FOAK - RAILJack PadiNessuna valutazione finora

- Results of Competition: Prospering From The Energy Revolution (PFER) - Blue Zone 1703 - CRD1 - ENRG - ENCATES5 - PFERBZDocumento22 pagineResults of Competition: Prospering From The Energy Revolution (PFER) - Blue Zone 1703 - CRD1 - ENRG - ENCATES5 - PFERBZJack PadiNessuna valutazione finora

- December 2017 Sector Competition - Open - Competition Results 13 - To - 24 - Months PDFDocumento46 pagineDecember 2017 Sector Competition - Open - Competition Results 13 - To - 24 - Months PDFJack PadiNessuna valutazione finora

- Results of Competition: SBRI: Protecting Nuclear Decommissioning Operators Competition Code: 1804 - SBRI - SELLAFIELDDocumento26 pagineResults of Competition: SBRI: Protecting Nuclear Decommissioning Operators Competition Code: 1804 - SBRI - SELLAFIELDJack PadiNessuna valutazione finora

- Competition Results - SBRI First of A Kind 2 - Demonstrating Tomorrow S PDFDocumento20 pagineCompetition Results - SBRI First of A Kind 2 - Demonstrating Tomorrow S PDFJack PadiNessuna valutazione finora

- Results of Competition: SBRI: Antimicrobial Resistance (AMR) in Humans Competition Code: 1807 - SBRI - ANTIMICROBIALDocumento26 pagineResults of Competition: SBRI: Antimicrobial Resistance (AMR) in Humans Competition Code: 1807 - SBRI - ANTIMICROBIALJack PadiNessuna valutazione finora

- Results of Competition: Sustainable Urbanisation Global Initiative (SUGI) 1612 - EU - ERANET - URBANDocumento7 pagineResults of Competition: Sustainable Urbanisation Global Initiative (SUGI) 1612 - EU - ERANET - URBANJack PadiNessuna valutazione finora

- Competition Results - SBRI Rail First of A Kind Round 3 - Resilience Freight Noise Environment PDFDocumento48 pagineCompetition Results - SBRI Rail First of A Kind Round 3 - Resilience Freight Noise Environment PDFJack PadiNessuna valutazione finora

- Results of Competition: Newton - UK-China Agri Tech Challenge 2017 Competition Code: 1706 - CRD1 - NEWTON - CHNBBSRCDocumento19 pagineResults of Competition: Newton - UK-China Agri Tech Challenge 2017 Competition Code: 1706 - CRD1 - NEWTON - CHNBBSRCJack PadiNessuna valutazione finora

- Wireless Electric Vehicle Charging For Commercial Users - FS - Competition Results PDFDocumento19 pagineWireless Electric Vehicle Charging For Commercial Users - FS - Competition Results PDFJack PadiNessuna valutazione finora

- Design Foundations Round 1 2018 - Competition Results PDFDocumento74 pagineDesign Foundations Round 1 2018 - Competition Results PDFJack PadiNessuna valutazione finora

- Results of Competition: Young Innovators' Awards Batch 1 1802 - CRD - YOUNG - INNOV - 1Documento24 pagineResults of Competition: Young Innovators' Awards Batch 1 1802 - CRD - YOUNG - INNOV - 1Jack PadiNessuna valutazione finora

- Results of Competition: Newton Fund - China - Guangdong Province 1707 - CRD1 - NEWTON - CHNGDSTDocumento10 pagineResults of Competition: Newton Fund - China - Guangdong Province 1707 - CRD1 - NEWTON - CHNGDSTJack PadiNessuna valutazione finora

- Results of Competition: Newton - UK-India Industrial Biotechnology (BBSRC) 1706 - Crd1 - Newton - IndbbsrcDocumento8 pagineResults of Competition: Newton - UK-India Industrial Biotechnology (BBSRC) 1706 - Crd1 - Newton - IndbbsrcJack PadiNessuna valutazione finora

- Results of Competition: SBRI - Roads For The Future (NIC) 1801 - SBRI - NIC - DRDADocumento5 pagineResults of Competition: SBRI - Roads For The Future (NIC) 1801 - SBRI - NIC - DRDAJack PadiNessuna valutazione finora

- Results of Competition: Precision Medicine Technologies: Shaping The Future Competition Code: 1805 - CRD - ASHN - PREC - MEDDocumento39 pagineResults of Competition: Precision Medicine Technologies: Shaping The Future Competition Code: 1805 - CRD - ASHN - PREC - MEDJack PadiNessuna valutazione finora

- January 2018 Sector Competition - Strand 1 Health and Life Sciences - Competition Results PDFDocumento63 pagineJanuary 2018 Sector Competition - Strand 1 Health and Life Sciences - Competition Results PDFJack PadiNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Amobonye (2020) Plastic Biodegradation - Frontline Microbes and Their EnzymesDocumento59 pagineAmobonye (2020) Plastic Biodegradation - Frontline Microbes and Their EnzymesV LjNessuna valutazione finora

- Biodegradable Synthetic Polymers For Tissue EngineeringDocumento16 pagineBiodegradable Synthetic Polymers For Tissue Engineeringcallisto69Nessuna valutazione finora

- ASTM 5864 Mar Report BioHyd Biodegradable TestDocumento2 pagineASTM 5864 Mar Report BioHyd Biodegradable TestTudor RatiuNessuna valutazione finora

- Aerosol Formulation Considerations: - Robert D. GeerDocumento53 pagineAerosol Formulation Considerations: - Robert D. GeerVenu Gopal NNessuna valutazione finora

- SYM Sustainability BroschuereDocumento5 pagineSYM Sustainability BroschuereSyed SaleemNessuna valutazione finora

- Project Report Final TNGDocumento21 pagineProject Report Final TNGTanmay GosaviNessuna valutazione finora

- Padhle - Manufacturing Industries - PYQDocumento6 paginePadhle - Manufacturing Industries - PYQkaursapinderbadaliNessuna valutazione finora

- 74-Household Tumbling Composter 9.26Documento8 pagine74-Household Tumbling Composter 9.26John Michael TingsonNessuna valutazione finora

- Karakteristik Bioplastik Dari Pati Buah Lindur : Bruguiera GymnorrizhaDocumento11 pagineKarakteristik Bioplastik Dari Pati Buah Lindur : Bruguiera GymnorrizhaFetty GhaessaniNessuna valutazione finora

- Environmental Applications of Immobilized Microbial Cells A PDFDocumento23 pagineEnvironmental Applications of Immobilized Microbial Cells A PDFCamelia TincuNessuna valutazione finora

- Astm-D5338 - 2021Documento6 pagineAstm-D5338 - 2021Denis Rho100% (1)

- Sanitation MOOC Slides Week 3Documento159 pagineSanitation MOOC Slides Week 3M.Srushanth ReddyNessuna valutazione finora

- MsdsDocumento5 pagineMsdsLukman Nul HakimNessuna valutazione finora

- Pesticide Biodegradation: Mechanisms, Genetics and Strategies To Enhance The ProcessDocumento39 paginePesticide Biodegradation: Mechanisms, Genetics and Strategies To Enhance The ProcessLia MaldivesNessuna valutazione finora

- Koe00006 002 PDFDocumento42 pagineKoe00006 002 PDFZuriel AzametiNessuna valutazione finora

- Residual Lifetime Assessment of Pe Pipelines: White PaperDocumento4 pagineResidual Lifetime Assessment of Pe Pipelines: White PaperNurhadi SiswantoroNessuna valutazione finora

- Study On The Use of Banana Peels For Oil Spill RemovalDocumento8 pagineStudy On The Use of Banana Peels For Oil Spill RemovalKilsys AlvaradoNessuna valutazione finora

- The Use of Chinese Taro (Xanthosoma Sagittifolium) As Source of BioplasticDocumento24 pagineThe Use of Chinese Taro (Xanthosoma Sagittifolium) As Source of Bioplasticfantastic ladyNessuna valutazione finora

- Biocomposites Carbon FootprintDocumento10 pagineBiocomposites Carbon FootprintJuan Pablo CorreaNessuna valutazione finora

- Bioplastics As Better Alternative To PetroplasticsDocumento9 pagineBioplastics As Better Alternative To PetroplasticsAngelo ErminoNessuna valutazione finora

- Upgrading Plant List 2014Documento29 pagineUpgrading Plant List 2014olliehortonNessuna valutazione finora

- Group 1 SIP Final PaperDocumento27 pagineGroup 1 SIP Final Papervino mercadojr100% (1)

- Solid Waste Management Detailed Project ReportDocumento6 pagineSolid Waste Management Detailed Project ReportPem DromaNessuna valutazione finora

- Ansell 8thEditionChemicalResistanceGuideDocumento8 pagineAnsell 8thEditionChemicalResistanceGuideAndry De Jesus GraulauNessuna valutazione finora

- Accuracy of Furanic Compound Analysis in Determining The Ageing of Power TransformersDocumento4 pagineAccuracy of Furanic Compound Analysis in Determining The Ageing of Power TransformersLucas BrasileiroNessuna valutazione finora

- ADM Fuels and Industrials CatalogDocumento24 pagineADM Fuels and Industrials CatalogjumpupdnbdjNessuna valutazione finora

- 6min PlasticDocumento5 pagine6min PlasticBila TranNessuna valutazione finora

- Locally Mna Debi Ores in 2016Documento5 pagineLocally Mna Debi Ores in 2016C1Muhammad Iqbal FarozinNessuna valutazione finora

- Synthesis of Bacterial Cellulose by Acetobacter Xylinum Sp. Using Pineapple Pith For Biocomposite ApplicationDocumento26 pagineSynthesis of Bacterial Cellulose by Acetobacter Xylinum Sp. Using Pineapple Pith For Biocomposite ApplicationMike AndersonNessuna valutazione finora