Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Standards and Approvals For Valves: American Petroleum Institute (API

Caricato da

milton1987100%(1)Il 100% ha trovato utile questo documento (1 voto)

120 visualizzazioni3 pagineThis document lists numerous standards and approval organizations that regulate valves used in industrial processes. It outlines specifications from the American Petroleum Institute (API), American Society of Mechanical Engineers (ASME), European Committee for Standardization (CEN), Instrument Society of America (ISA), International Electrotechnical Commission (IEC), International Standards Organization (ISO), Manufacturers Standardization Society (MSS), and NACE International that cover materials, dimensions, testing procedures, and other requirements for valves. Compliance with these standards helps ensure valves are suitable for their intended applications and processes.

Descrizione originale:

Standards

Titolo originale

Standards

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document lists numerous standards and approval organizations that regulate valves used in industrial processes. It outlines specifications from the American Petroleum Institute (API), American Society of Mechanical Engineers (ASME), European Committee for Standardization (CEN), Instrument Society of America (ISA), International Electrotechnical Commission (IEC), International Standards Organization (ISO), Manufacturers Standardization Society (MSS), and NACE International that cover materials, dimensions, testing procedures, and other requirements for valves. Compliance with these standards helps ensure valves are suitable for their intended applications and processes.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

120 visualizzazioni3 pagineStandards and Approvals For Valves: American Petroleum Institute (API

Caricato da

milton1987This document lists numerous standards and approval organizations that regulate valves used in industrial processes. It outlines specifications from the American Petroleum Institute (API), American Society of Mechanical Engineers (ASME), European Committee for Standardization (CEN), Instrument Society of America (ISA), International Electrotechnical Commission (IEC), International Standards Organization (ISO), Manufacturers Standardization Society (MSS), and NACE International that cover materials, dimensions, testing procedures, and other requirements for valves. Compliance with these standards helps ensure valves are suitable for their intended applications and processes.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

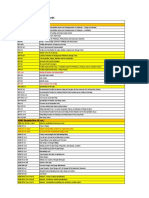

Standards and Approvals for Valves

American Petroleum Institute (API)

Spec 6D, Specification for Pipeline Valves (Gate, Plug, Ball, and Check Valves)

598, Valve Inspection and Testing

607, Fire Test for Soft-Seated Quarter-Turn Valves

609, Lug- and Wafer-Type Butterfly Valve

American Society of Mechanical Engineers (ASME)

B16.1, Cast Iron Pipe Flanges and Flanged Fittings

B16.4, Gray Iron Threaded Fittings

B16.5, Pipe Flanges and Flanged Fittings (for steel, nickel-based alloys,and other alloys)

B16.10, Face-to-Face and End-to-End Dimensions of Valves (see ISA standards for

dimensions for most control valves)

B16.24, Cast Copper Alloy Pipe Flanges and Flanged Fittings

B16.25, Buttwelding Ends

B16.34, Valves - Flanged, Threaded, and Welding End

B16.42, Ductile Iron Pipe Flanges and Flanged Fittings

B16.47, Large Diameter Steel Flanges (NPS 26 through NPS 60)

European Committee for Standardization (CEN)

European Industrial Valve Standards

EN 19, Marking

EN 558-1, Face-to-Face and Centre-to-Face Dimensions of Metal Valves for Use in

Flanged Pipe Systems - Part 1: PN-Designated Valves

EN 558-2, Face-to-Face and Centre-to-Face Dimensions of Metal Valves for Use in

Flanged Pipe Systems - Part 2: Class-Designated Valves

EN 593, Butterfly valves

EN 736-1, Terminology - Part 1: Definition of types of valves

EN 736-2, Terminology - Part 2: Definition of components of valves

EN 736-3 Terminology - Part 3: Definition of terms (in preparation)

EN 1349, Industrial Process Control Valves (in preparation)

EN 12266-1,Testing of valves - Part 1: Tests, test procedures and acceptance criteria (in

preparation)

EN 12516-1, Shell design strength - Part 1: Tabulation method for steel valves (in

preparation)

EN 12516-2, Shell design strength - Part 2: Calculation method for steel valves (in

preparation)

EN 12516-3, Shell design strength - Part 3: Experimental method (in preparation)

EN 12627, Butt weld end design (in preparation)

EN 12760, Socket weld end design (in preparation)

EN 12982, End to end dimensions for butt welding end valves (in preparation)

European Material Standards

EN 10213-1, Technical conditions of delivery of steel castings for pressure purposes -

Part 1: General

EN 10213-2, Technical conditions of delivery of steel castings for pressure purposes -

Part 2: Steel grades for use at room temperature and elevated temperatures

EN 10213-3, Technical conditions of delivery of steel castings for pressure purposes -

Part 3: Steel grades for use at low temperatures

EN 10213-4, Technical conditions of delivery of steel castings for pressure purposes -

Part 4: Austenitic and austeno-ferritic steel grades

EN 10222-2, Technical conditions of delivery of steel forgings for pressure purposes -

Part 2: Ferritic and martensitic steels for use at elevated temperatures

EN 10222-3, Technical conditions of delivery of steel forgings for pressure purposes -

Part 3: Nickel steel for low temperature

EN 10222-4, Technical conditions of delivery of steel forgings for pressure purposes -

Part 4: Fine grain steel

EN 10222-5, Technical conditions of delivery of steel forgings for pressure purposes -

Part 5: Austenitic martensitic and austeno-ferritic stainless steel

European Flange Standards

EN 1092-1, Part 1: Steel flanges PN designated

EN 1092-2 (September 1997), Part 2: Cast iron flanges PN designated

EN 1759-1, Part 1: Steel flanges Class designated (in preparation)

Fluid Controls Institute (FCI)

70-2-1991, Control Valve Seat Leakage

Instrument Society of America (ISA)

S51.1, Process Instrumentation Terminology

S75.01, Flow Equations for Sizing Control Valves

S75.02, Control Valve Capacity Test Procedures

S75.03, Face-to-Face Dimensions for Flanged Globe-Style Control Valve Bodies

(Classes 125, 150, 250, 300, and 600)

S75.04, Face-to-Face Dimensions for Flangeless Control Valves (Classes 150, 300, and

600)

S75.05, Terminology

S75.07, Laboratory Measurement of Aerodynamic Noise Generated by Control Valves

S75.08, Installed Face-to-Face Dimensions for Flanged Clamp or Pinch Valves

S75.11, Inherent Flow Characteristic and Rangeability of Control Valves

S75.12, Face-to-Face Dimensions for Socket Weld-End and Screwed-End Globe-Style

Control Valves (Classes 150, 300, 600, 900, 1500, and 2500)

S75.13, Method of Evaluating the Performance of Positioners with Analog Input Signals

S75.14, Face-to-Face Dimensions for Buttweld-End Globe-Style Control Valves (Class

4500)

S75.15, Face-to-Face Dimensions for Buttweld-End Globe-Style Control Valves (Classes

150, 300, 600, 900,1500, and 2500)

S75.16, Face-to-Face Dimensions for Flanged Globe-Style Control Valve Bodies

(Classes 900, 1500, and 2500)

S75.17, Control Valve Aerodynamic Noise Prediction

S75.19, Hydrostatic Testing of Control Valves

S75.20, Face-to-Face Dimensions for Separable Flanged Globe-Style Control Valves

(Classes 150, 300,and 600)

S75.22, Face-to-Centerline Dimensions for Flanged Globe-Style Angle Control Valve

Bodies (Classes 150, 300, and 600)

RP75.23, Considerations for Evaluating Control Valve Cavitation

International Electrotechnical Commission (IEC) (60534 series)

60534-1, Part 1: Control valve terminology and general considerations

60534-2-1, Part 2: Flow capacity -Section One: Sizing equations for incompressible fluid

flow under installed conditions (based on ISA S75.01)

60534-2-3, Part 2: Flow capacity -Section Three: Test procedures (based on ISA

S75.02)

60534-2-4, Part 2: Flow capacity -Section Four: Inherent flow characteristics and

rangeability (based on ISA S75.11)

60534-4, Part 4: Inspection and routine testing

60534-5, Part 5: Marking

60534-6-1, Part 6: Mounting details for attachment of positioners to control valve

actuators - Section One:Positioner mounting on linear actuators

60534-6-2, Part 6: Mounting details for attachment of positioners to control valve

actuators - Section Two:Positioner mounting on rotary actuators

60534-7, Part 7: Control valve data sheet

60534-8-1, Part 8: Noise considerations - Section One:Laboratory measurement of

noise generated by aerodynamic flow through control valves (based on ISA S75.07)

60534-8-2, Part 8: Noise considerations - Section Two: Laboratory measurement of

noise generated by hydrodynamic flow through control valves

60534-8-3, Part 8: Noise considerations - Section Three: Control valve aerodynamic

noise prediction method (based on ISA S75.17)

60534-8-4, Part 8: Noise considerations - Section Four:Prediction of noise generated by

hydrodynamic flow

International Standards Organization (ISO)

5752, Metal valves for use in flanged pipe systems - Face-to-face and centre-to-face

dimensions

7005-1, Metallic flanges - Part 1: Steel flanges

7005-2, Metallic flanges - Part 2: Cast iron flanges

7005-3, Metallic flanges - Part 3: Copper alloy and composite flanges

Manufacturers Standardization Society (MSS)

SP-6, Standard Finishes for Contact Faces of Pipe Flanges and Connecting-End

Flanges of Valves and Fittings

SP-25, Standard Marking System for Valves, Fittings, Flanges and Unions

SP-44, Steel Pipe Line Flanges

SP-67, Butterfly Valves

SP-68, High Pressure Butterfly Valves with Offset Design

NACE International

NACE MR0175/ISO 15156, Petroleum and Natural Gas Industries − Materials for Use in

H2S-Containing Environments in Oil and Gas Production

NACE MR0175-2002, Sulfide Stress Corrosion Cracking Resistant Metallic Materials for

Oil Field Equipment

NACE MR0103, Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum

Refining Envoronments

Potrebbero piacerti anche

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationDa EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNessuna valutazione finora

- Pages From Cvh99Documento16 paginePages From Cvh99Paraschiv AlexandruNessuna valutazione finora

- Standard and Approval: European Industrial Valve StandardDocumento2 pagineStandard and Approval: European Industrial Valve StandardprasadNessuna valutazione finora

- MssDocumento8 pagineMssGuillermo Gonzales AmayaNessuna valutazione finora

- Valve StandardsDocumento22 pagineValve StandardsKlubowoloya110% (1)

- Valve StandardsDocumento5 pagineValve StandardsSingaravel GanesanNessuna valutazione finora

- Valve & StandardsDocumento3 pagineValve & Standardsbanan maintechNessuna valutazione finora

- List of StandardsDocumento3 pagineList of Standardssumant.c.singh1694Nessuna valutazione finora

- Valve StandardsDocumento2 pagineValve Standardsengrmalik100% (1)

- ANSI Valve StandardDocumento5 pagineANSI Valve StandardsandystaysNessuna valutazione finora

- Regulatory Standards For Gate ValvesDocumento1 paginaRegulatory Standards For Gate ValvesRohin Venu100% (1)

- Code and Standards List - 2014Documento42 pagineCode and Standards List - 2014amirrulasyraf100% (2)

- Standards Norms Used For Industrial ValvesDocumento3 pagineStandards Norms Used For Industrial ValvesLuis PereiraNessuna valutazione finora

- Standards and Specifications: ANSI (American National Standards Institute)Documento5 pagineStandards and Specifications: ANSI (American National Standards Institute)norhazarudinNessuna valutazione finora

- Normas Mas Comunes Usadas en ProyectosDocumento11 pagineNormas Mas Comunes Usadas en ProyectosAlvaro Gutiérrez TrocheNessuna valutazione finora

- Valve Standards ANSI ASMEDocumento0 pagineValve Standards ANSI ASMELuis Alberto Chable GarciaNessuna valutazione finora

- PROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01Documento7 paginePROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01mihahudeaNessuna valutazione finora

- Metal Valves StandardsDocumento5 pagineMetal Valves StandardsheitorgmsNessuna valutazione finora

- Applicable Valve StandardsDocumento21 pagineApplicable Valve StandardsMatthew KuttikadNessuna valutazione finora

- Valve StandardDocumento5 pagineValve StandardKukuh Priambodo100% (1)

- TK0000.2021 Valve - StandardDocumento5 pagineTK0000.2021 Valve - StandardCleiton BernardoNessuna valutazione finora

- Piping Standard and Specification For Piping Material PresentationDocumento62 paginePiping Standard and Specification For Piping Material PresentationDuy Hiệp LâmNessuna valutazione finora

- Terminology of Valves Used PDFDocumento11 pagineTerminology of Valves Used PDFglazetmNessuna valutazione finora

- StandardsDocumento4 pagineStandardsrania hammamiNessuna valutazione finora

- Normas Aplicables A Las Válvulas de GloboDocumento11 pagineNormas Aplicables A Las Válvulas de GloboHumbertoOtaloraNessuna valutazione finora

- Codes and Standards: ASME B31 Piping CodesDocumento44 pagineCodes and Standards: ASME B31 Piping CodesMuthukumar ThangaiahNessuna valutazione finora

- 1.06 A Piping Codes & StandardsDocumento31 pagine1.06 A Piping Codes & StandardsSumedh Singh100% (2)

- ASPE - 45 - Siphonic Drainage PDFDocumento49 pagineASPE - 45 - Siphonic Drainage PDFsaftirikNessuna valutazione finora

- ASME ListadoDocumento2 pagineASME Listadojuma1987Nessuna valutazione finora

- Piping Codes and StandardsDocumento21 paginePiping Codes and StandardsZa Yon100% (1)

- List of International Standards: API Standards Block (25 Nos.)Documento4 pagineList of International Standards: API Standards Block (25 Nos.)Siva baalan100% (1)

- Abreviaciones ComevalDocumento3 pagineAbreviaciones ComevalEly Za BethNessuna valutazione finora

- Piping Material Specification 2010014 00 l0 Gs 001Documento215 paginePiping Material Specification 2010014 00 l0 Gs 001Wilson Xavier Orbea Bracho100% (1)

- Documents Plc150Documento7 pagineDocuments Plc150Anonymous cuOIjrLINessuna valutazione finora

- ASTM A790-2001 Standard Specification For Seamless & Welded Ferritic Austentic SS PipeDocumento6 pagineASTM A790-2001 Standard Specification For Seamless & Welded Ferritic Austentic SS PipeHyundianto AgNessuna valutazione finora

- Ball Valve CatalogueDocumento48 pagineBall Valve CataloguePlutesto100% (1)

- StandardsDocumento23 pagineStandardskrixot33% (3)

- Valve Standards ANSI BS APIDocumento6 pagineValve Standards ANSI BS APInaveenbaskaran1989Nessuna valutazione finora

- Piping Codes and Standards - The Piping Engineering BlogDocumento5 paginePiping Codes and Standards - The Piping Engineering BlogSalman KhanNessuna valutazione finora

- Valve Stds AllDocumento11 pagineValve Stds AllGohilakrishnan ThiagarajanNessuna valutazione finora

- Valve Standards ISO API ASMEDocumento1 paginaValve Standards ISO API ASMEGohilakrishnan ThiagarajanNessuna valutazione finora

- L&T GateGlobe&CheckValves-API 600Documento31 pagineL&T GateGlobe&CheckValves-API 600vsvineesh100% (1)

- DR Engp I 1.1 R.11Documento1.093 pagineDR Engp I 1.1 R.11HEFTOS P-55100% (1)

- Valve Standards From API - The American Petroleum InstituteDocumento3 pagineValve Standards From API - The American Petroleum InstituteErwinsyah FauziNessuna valutazione finora

- Valve StandardsDocumento20 pagineValve StandardsCosimoNessuna valutazione finora

- Asme Standards ListDocumento6 pagineAsme Standards ListCorjan TerblancheNessuna valutazione finora

- AWWA M11 - 4th Edition - Steel Pipe - A Guide For Design and Installation (PREVIEW)Documento17 pagineAWWA M11 - 4th Edition - Steel Pipe - A Guide For Design and Installation (PREVIEW)vuong17% (12)

- Standards For RefineryDocumento11 pagineStandards For RefinerykknanduriNessuna valutazione finora

- An Overview of The American Petroleum Institute - API - Valve StandardsDocumento48 pagineAn Overview of The American Petroleum Institute - API - Valve StandardsazitaggNessuna valutazione finora

- Course Material - Standards Pertaining To ValvesDocumento11 pagineCourse Material - Standards Pertaining To ValvesAhmed Abd El RahmanNessuna valutazione finora

- List Shell Dep & Mesc SpeDocumento9 pagineList Shell Dep & Mesc Spewawan80% (5)

- AWWA M11ed4Documento16 pagineAWWA M11ed4авдей александр33% (3)

- Valve Standards ANSI ASME PDFDocumento6 pagineValve Standards ANSI ASME PDFChi JoyNessuna valutazione finora

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationDa EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationValutazione: 4.5 su 5 stelle4.5/5 (21)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Structural Analysis and Design of Process EquipmentDa EverandStructural Analysis and Design of Process EquipmentNessuna valutazione finora

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- G-INST-004.231-A Checklist For Displacement Type Level InstrumentDocumento6 pagineG-INST-004.231-A Checklist For Displacement Type Level Instrumentmilton1987Nessuna valutazione finora

- Pa Dpi 7883Documento2 paginePa Dpi 7883milton1987Nessuna valutazione finora

- Pa at 7776Documento2 paginePa at 7776milton1987Nessuna valutazione finora

- G-INST-004.220-A Checklist For Orifice PlateDocumento5 pagineG-INST-004.220-A Checklist For Orifice Platemilton1987Nessuna valutazione finora

- G-INST-004.232-A Checklist For Capacitance Type Level InstrumentDocumento5 pagineG-INST-004.232-A Checklist For Capacitance Type Level Instrumentmilton1987Nessuna valutazione finora

- G-INST-004.233-A Checklist For Ultrasonic Level TransmitterDocumento6 pagineG-INST-004.233-A Checklist For Ultrasonic Level Transmittermilton1987Nessuna valutazione finora

- G-INST-004.221-A Checklist For Ultrasonic Flow MeterDocumento5 pagineG-INST-004.221-A Checklist For Ultrasonic Flow Metermilton1987Nessuna valutazione finora

- Checklist For Desuperheater StationDocumento7 pagineChecklist For Desuperheater Stationmilton1987Nessuna valutazione finora

- Pa TT 7041Documento2 paginePa TT 7041milton1987Nessuna valutazione finora

- Checklist For On-Off ValvesDocumento5 pagineChecklist For On-Off Valvesmilton1987Nessuna valutazione finora

- Checklist For Rupture DiscDocumento5 pagineChecklist For Rupture Discmilton1987Nessuna valutazione finora

- Check List Analyzer and Analyzer SystemDocumento6 pagineCheck List Analyzer and Analyzer Systemmilton1987Nessuna valutazione finora

- Checklist For CablesDocumento4 pagineChecklist For Cablesmilton1987Nessuna valutazione finora

- Training Module: AnalysersDocumento28 pagineTraining Module: Analysersmilton1987Nessuna valutazione finora

- GeneralDocumento6 pagineGeneralmilton1987Nessuna valutazione finora

- Training Manuals-Instruments: Preparation of Installation TenderDocumento9 pagineTraining Manuals-Instruments: Preparation of Installation Tendermilton1987Nessuna valutazione finora

- Installation TenderDocumento5 pagineInstallation Tendermilton1987Nessuna valutazione finora

- Training Module: AnalysersDocumento28 pagineTraining Module: Analysersmilton1987Nessuna valutazione finora

- How To Commissioning Job,! and What Is The Procedure of CommissioningDocumento3 pagineHow To Commissioning Job,! and What Is The Procedure of Commissioningmilton1987Nessuna valutazione finora

- CV 4Documento6 pagineCV 4milton1987Nessuna valutazione finora

- Valve Sizing TablesDocumento5 pagineValve Sizing Tablesmilton1987Nessuna valutazione finora

- PCVDocumento6 paginePCVmilton1987Nessuna valutazione finora

- Workover Kill Fluid Density CalculationDocumento3 pagineWorkover Kill Fluid Density CalculationSanny Astari100% (1)

- ORF Issue Brief 309 SpaceLawDocumento12 pagineORF Issue Brief 309 SpaceLawNitish KumarNessuna valutazione finora

- Mobile Robots and Autonomous VehiclesDocumento2 pagineMobile Robots and Autonomous VehiclesAbel Varghese DavidNessuna valutazione finora

- Sanjay ProjectDocumento41 pagineSanjay ProjectPrynka RawatNessuna valutazione finora

- Technology and Culture - ReadingDocumento3 pagineTechnology and Culture - ReadingBraulio Pezantes100% (1)

- Halo Lighting Product Catalog 1974Documento68 pagineHalo Lighting Product Catalog 1974Alan Masters100% (1)

- Ice Plant TrainerDocumento1 paginaIce Plant TrainerVirender RanaNessuna valutazione finora

- Waste Management in Selected Hotels in GoaDocumento11 pagineWaste Management in Selected Hotels in GoaSyna SoaresNessuna valutazione finora

- Ellis Patents Cable Cleats Complete CatalogueDocumento28 pagineEllis Patents Cable Cleats Complete CataloguefndprojectNessuna valutazione finora

- 14 Bernardo Soustruhy deDocumento40 pagine14 Bernardo Soustruhy deTanase Constantin0% (1)

- Wire CodeDocumento7 pagineWire CodeAryans Kumar0% (1)

- Payment InstructionDocumento2 paginePayment InstructionNeel PatelNessuna valutazione finora

- Revised Runway Length Discussion (20171206) - 201712211212022318Documento3 pagineRevised Runway Length Discussion (20171206) - 201712211212022318Ilham RaffiNessuna valutazione finora

- Arco Solar Inc.: Case Analysis OnDocumento12 pagineArco Solar Inc.: Case Analysis OnAnish RajNessuna valutazione finora

- Ef3602 9Documento2 pagineEf3602 9AwanNessuna valutazione finora

- NFC Reader LibrarayDocumento63 pagineNFC Reader Libraraysekhar479Nessuna valutazione finora

- CATALOGO DE VALVULAS OsvatDocumento218 pagineCATALOGO DE VALVULAS OsvatGabriel Piñon Conde67% (3)

- Biochemical Oxygen DemandDocumento18 pagineBiochemical Oxygen DemandUnputdownable Bishwarup100% (1)

- Sand Reclamation - Standard Devices: Shake Out MachinesDocumento2 pagineSand Reclamation - Standard Devices: Shake Out MachinesKaarthicNatarajanNessuna valutazione finora

- Case Study Analysis of Apex Corporation PDFDocumento2 pagineCase Study Analysis of Apex Corporation PDFAJNessuna valutazione finora

- TEX20-NV: Technical and Maintenance ManualDocumento110 pagineTEX20-NV: Technical and Maintenance Manualvasilikot50% (2)

- Product Presentation PPT NeerajDocumento8 pagineProduct Presentation PPT NeerajNeeraj UdiniyaNessuna valutazione finora

- Simple Free-Energy InformationDocumento11 pagineSimple Free-Energy InformationDrago MelovNessuna valutazione finora

- Hydraulic Cartridge SystemsDocumento14 pagineHydraulic Cartridge SystemsJas SumNessuna valutazione finora

- Solucionario Libro Infotech 4th EditionDocumento32 pagineSolucionario Libro Infotech 4th EditionGisella Espinoza BarberenaNessuna valutazione finora

- GitHub - Shenwei356 - Datakit - CSV - TSV File Manipulation and More. Please Use My Another Tool - CSVTK, Https - Github - Com - Shenwei356 - CSVTKDocumento4 pagineGitHub - Shenwei356 - Datakit - CSV - TSV File Manipulation and More. Please Use My Another Tool - CSVTK, Https - Github - Com - Shenwei356 - CSVTKtabani_shaikNessuna valutazione finora

- Mason Melito: EducationDocumento2 pagineMason Melito: Educationapi-568517799Nessuna valutazione finora

- Collaborative Filtering and Inference Rules For Context-Aware Learning Object RecommendationDocumento11 pagineCollaborative Filtering and Inference Rules For Context-Aware Learning Object RecommendationDaniel LemireNessuna valutazione finora

- Set 2 Unit 2 PDF FreeDocumento13 pagineSet 2 Unit 2 PDF FreeASHWATH G (RA2111018010045)Nessuna valutazione finora

- The Relevance of YS/UTS RatioDocumento21 pagineThe Relevance of YS/UTS RatiocarrespmNessuna valutazione finora