Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pdvsa: Engineering Design Manual

Caricato da

wdavid81Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pdvsa: Engineering Design Manual

Caricato da

wdavid81Copyright:

Formati disponibili

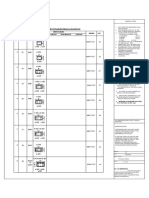

PDVSA

ENGINEERING DESIGN MANUAL

VOLUME 21

ENGINEERING SPECIFICATION

PDVSA N° TITLE

A2.701 VESSELS TOLERANCES

(VERTICAL AND HORIZONTAL)

1 DEC.98 GENERAL REVISION 2 Y.K. A.A. J.E.R.

0 MAR.92 ORIGINAL 1 J.S. E.S.

REV. DATE DESCRIPTION PAG. REV. APPD. APPD.

APPD.BY Alexis Arévalo DATE DEC.98 APPD.BY Jesús E. Rojas DATE DEC.98

E PDVSA, 1983 SPECIALISTS

ENGINEERING DESIGN MANUAL PDVSA A2.701

PDVSA

REVISION FECHA

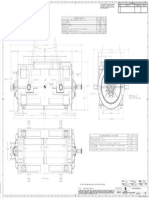

VESSEL TOLERANCES

(VERTICAL AND HORIZONTAL) 1 DEC.98

Página 1

.Menú Principal Indice manual Indice volumen Indice norma

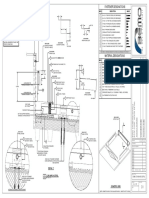

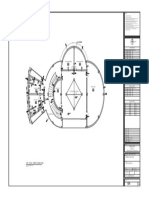

2 VESSEL; TOLERANCES

(ELEVATION)

16

15

1. HEIGHT FROM BASE LINE TO FACE OF TOP NOZZLE

± 1/4” OR 1/64” PER FOOT OF HEIGT 3/4” MAX.

17 2. NOZZLES FOR AGITATOR MOUNTING SHALL HAVE

5 FLANGE FACE ALIGNED WITHIN 1/4” OF SPECIFIED

14 PLANE PLUS REQUIREMENTS OF NOTE 28.

18

3. DISTANCE FROM BOTTOM TO TOP OF TRAY SUPPORTS ± 1/8”

29

4. WEIR HEIGHT± 1/16” MEASURED AT HIGH POINT OF WEIR.

3

5. VERTICAL CLEARANCE UNDER DOWNFLOW PLATE FOR

INSTALLED TRAYS ± 1/16”.

6. FACE OF NOZZLE TO CENTERLINE OF VESSEL..... ± 1/8”

4

19 7. ALIGNMENT OF FLANGE FACE OF NOZZLE SHALL BE

WITHIN 1/2” OF SPECIFIED PLANE.

8. LOCATION OF SHELL NOZZLES FROM BASE LINE SHALL

BE ± 1/4” FOR SHOP FABRICATED VESSELS OR SUB–

6 ASSEMBLIES: AND ± 1/2” FOR FIELD ASSEMBLED

1 VESSELS. WHEN LOCATION IS SPECIFIED FROM OTHER

20 REFERENCE POINTS, TOLERANCE SHALL BE ... ± 1/8”

9. ALIGNMENT OF FLANGE FACE OF MANWAY SHALL BE

WITHIN 1° OF SPECIFIED PLANE.

10. FACE OF MANWAY TO CENTERLINE OF VESSEL ...± 1/2”

7 21 11. LOCATION OF MANWAYS FROM BASE LINE SHALL BE

± 1/2” FOR SHOP FABRICATED VESSEL AND SUB

ASSEMBLIES AND + 1” FOR FIELD ASSEMBLED VESSELS

12. BOTTOM OF VESSEL SUPPORT TO BASE LINE + 0”,–1/32

10 PER FOOT OF VESSEL DIAMETER , 1/2” MAX.

9 22 13. FOR SUPPORTS LOCATED ABOVE BASELINE, TOLERANCES

SHALL BE + 0”,–1/32” PER FOOT OF VESSEL DIAMETER, 1/2”MAX.

26 14. ALIGMENT OF CYLINDRICAL SHELL SECTIONS SHALL BE

8

TRUE AND STRAIGHT WITHIN 0.01” PER FOOT OF HEIGHT

FROM BASE LINE BUT SHALL NOT EXCEED...3/4”

22 15. HIGH–POINT TO LOW–POINT OF INSTALLED TRAY LEVEL

AND PLANE WITHIN THE FOLLOWING.

26

VESSEL ID *CLASS A *CLASS B

11 < 60” 1/8” 3/16”

23

>60” TO <120” 3/16” 1/4”

13 23 >120” 1/4” 3/8”

16. FAR SIDE OF TOWER TO PLATE ....±1/8”

17. WEIRS SHALL BE LEVEL WITHIN ± 1/16” FROM A LEVEL

25

PLANE AT THE MIDPOINT OF THE WEIR.

18. TRAY SPACING ± 1/8”

26

19. LOCATION OF TRAY PLATES FROM BASE LINE ...+1/8”

24

12

28 27

26

26

* CLASS A AND CLASS B TOLERANCES WILL BE GOVERNED

BY THE TYPE OF TRAY SPECIFIED. THIS INFORMATION

WILL BE PER THE TRAY SPECIFICATION SHEET/HYDRAULICS.

THESE TOLERANCES APPLY TO VERTICAL & HORIZONTAL

VESSELS EXCEPT AS OTHERWISE NOTED ON VESSEL

DRAWING/DATA SHEET RELATING TO SPECIFIC VESSELS

ENGINEERING DESIGN MANUAL PDVSA A2.701

PDVSA

REVISION FECHA

VESSEL TOLERANCES

(VERTICAL AND HORIZONTAL) 1 DEC.98

Página 2

.Menú Principal Indice manual Indice volumen Indice norma

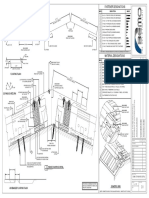

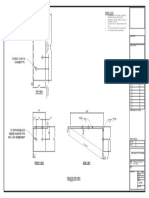

20. DEVIATION FROM AVERAGE I.D. (AS DETERMINED BY

STRAPPING) FROM NOMINAL I.D.: ±1/4” A.S.M.E CODE

VESSEL; TOLERANCES SECTION VIII TO APPLY TO OUT–OF–ROUNNES EXCEPT

(ORIENTATION) WHEN NOTED OTHERWISE

21. PIPE OR WALKWAY SUPPORTS AND STRUCTURAL

ATTACHMENTS TO: VESSEL CENTERLINE.... ±1/8”:

BASE LINE ....± 1/4”

ORIENTATION LINE 22. LOCATION OF HORIZONTAL VESSEL SUPPORT FROM

(REFERENCE) VESSEL CENTERLINES.... +0 –1/8”

23. LOCATION OF HORIZONTAL VESSEL SUPPORTS FROM

BASE LINE....+1/4” SUPPORTS LOCATED FROM

OTHER REFERENCE POINTS.... +1/8”

2 24. LOCATION OF BOTTOM NOZZLE FLNAGE FACE FROM

3 BASE LINE SHALL BE ...+1/4”

25. LIGHT CENTER PUNCH MARK (WITH A ROUND NOSE

STAMP) THE PRINCIPAL CENTER LINES SHOWN ON

ORIENTATION PLAN. CIRCLE PUNCH MARKS WITH

4 PAINT TO DESIGNATE LOCATION.

1 CLIP 26. SUPPORTS OUT OF LEVEL OVER ANY DIAMETER THE

GREATER OF + 1/8” OR +0.02” PER FOOT OF

NOZZLE VESSEL DIAMETER, 3/8” MAX.

27. BOLT HOLES WITHIN 1/8” OF SPECIFIED LOCATION

28. IF BOTTOM FLANGE IS USED AS FOOT BEARING

MOUNT AND WITH AGITATOR MOUNTIHG FLANGE

HORIZONTAL, A PLUMB BOB DROPPED FROM CNTR.

OF TOP FLANGE SHALL FALL WITHIN 0.025” PER FOOT

(OF DIST. BETWEEN FLG. FACES) OF CENTER OF BTM.

FLG., AND BTM. FLG. SHALL BE NOT MORE THAN 1/4”

OFF HORIZONTAL.

29. HORIZONTAL CLEARRANCE BETWEEN DOWNFLOW PLATE

AND TOP OF INLET WEIR + 1/16”

30. FOR POST SUPPORTED TRAYS, CLEARANCE BETWEEN

TRAY COLLAR AND SHELL 0.015” MAX. OVER 90% OF

CIRCUMFERENCE,+ 1/16” MAX. OVER REMAINING 10%

SADDLE MANWAY

ORIENTATION LINE VERTICAL

VESSELS IS BASED ON A DIRECTIONAL

CENTERLINE (EX. NORTH. SOUTH ETC..)

5 VESSELS IS BASED ON THE HORINZONTAL

CENTERLINE

FLANGE C

L BOLT CIRCLE

1. LOCATION OF SADDLE FROM ORIENTATION SHALL BE +3/16”

2. LOCATION OF CLIPS FROM ORIENTATION LINE SHALL BE + 1/4”

3. LOCATION OF NOZZLES FROM ORIENTATION LINE SHALL BE + 3/16

4. LOCATION OF MANWAYS FROM ORIENTATION LINE SHALL BE + 1”

5. ALLWABLE TOLERANCE ON NOZZLE BOLT HOLE ORIENTAATION + 1/16”

THESE TOLERANCES APPLY TO VERTICAL & HORIZONTAL VESSELS EXCEPT AS

OTHERWISE NOTED ON VESSEL DRAWINGS/DATA SHEETS RELATING TO SPECIFIC VESSELS

v–tol

Potrebbero piacerti anche

- API 611, General-Purpose Steam TurbinesDocumento6 pagineAPI 611, General-Purpose Steam TurbinesMReza100% (1)

- IEEE PES - Tutorial Course On Power System Stabilization Via Excitation ControlDocumento74 pagineIEEE PES - Tutorial Course On Power System Stabilization Via Excitation Controlsulemankhalid100% (2)

- VacconPartsManual PDFDocumento383 pagineVacconPartsManual PDFJhon Sanabria100% (2)

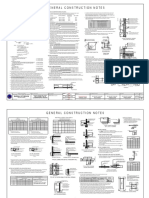

- General Construction Notes: Bureau of DesignDocumento15 pagineGeneral Construction Notes: Bureau of DesignRicoyan YanNessuna valutazione finora

- Your Payment Receipt - Christmas 2019Documento1 paginaYour Payment Receipt - Christmas 2019wdavid81100% (1)

- WPSDocumento2 pagineWPSJuli Agus50% (2)

- Process Industry Practices Fabrication/Installation Details Vessel Toleran (Elevation)Documento1 paginaProcess Industry Practices Fabrication/Installation Details Vessel Toleran (Elevation)Federico GonzálezNessuna valutazione finora

- 32 Roof Curb - Apron DetailDocumento1 pagina32 Roof Curb - Apron DetailAhmed Saber NassarNessuna valutazione finora

- Arch Plans v2 (Approved)Documento12 pagineArch Plans v2 (Approved)rabbetmrNessuna valutazione finora

- Standard Sidewalk Replacement/Installation DetailDocumento19 pagineStandard Sidewalk Replacement/Installation DetailJuan Carlos ZordanNessuna valutazione finora

- Basis of DesignDocumento1 paginaBasis of DesignRajaImranNessuna valutazione finora

- 31 Roof Curb - Sidepan DetailsDocumento1 pagina31 Roof Curb - Sidepan DetailsAhmed Saber NassarNessuna valutazione finora

- General Construction NotesDocumento1 paginaGeneral Construction NotesCarlo M. FloresNessuna valutazione finora

- General Construction NotesDocumento1 paginaGeneral Construction NoteschrisNessuna valutazione finora

- 23 Ridge-Hip (Floating) DetailDocumento1 pagina23 Ridge-Hip (Floating) DetailAhmed Saber NassarNessuna valutazione finora

- 37 Valley DetailDocumento1 pagina37 Valley DetailAhmed Saber NassarNessuna valutazione finora

- 33 70 00-7 Generator Pad Detail PDFDocumento1 pagina33 70 00-7 Generator Pad Detail PDFNadom MutlibNessuna valutazione finora

- Simple Drip IrrigationDocumento2 pagineSimple Drip IrrigationHarry JouleNessuna valutazione finora

- SAS-18 Jack and Bore - 202104191007448529Documento2 pagineSAS-18 Jack and Bore - 202104191007448529Sumantra ChattopadhyayNessuna valutazione finora

- 33 Roof Curb - Backpan DetailDocumento1 pagina33 Roof Curb - Backpan DetailAhmed Saber NassarNessuna valutazione finora

- 3.5xRC 21.5'X46.5' - Structural Drawing - R00Documento31 pagine3.5xRC 21.5'X46.5' - Structural Drawing - R00Moe Oo HtunNessuna valutazione finora

- FL DS 1023Documento1 paginaFL DS 1023basemapNessuna valutazione finora

- Structurals 2Documento1 paginaStructurals 2seulipark2629Nessuna valutazione finora

- Revised Structural PlansDocumento46 pagineRevised Structural Plansangelandlucifergabriel009Nessuna valutazione finora

- Column SheduleDocumento1 paginaColumn SheduleAK DESIGN DESTINYNessuna valutazione finora

- StructuralDocumento15 pagineStructuralMark James MateoNessuna valutazione finora

- Structural 2storeyDocumento11 pagineStructural 2storeyMark James Mateo100% (1)

- Plan 20ld0130 - Part 3Documento11 paginePlan 20ld0130 - Part 3MarjanNessuna valutazione finora

- 24 Ridge (Fixed) DetailDocumento1 pagina24 Ridge (Fixed) DetailAhmed Saber NassarNessuna valutazione finora

- 09 High Uplift DetailDocumento1 pagina09 High Uplift DetailAhmed Saber NassarNessuna valutazione finora

- FMT18 Conventional Room DrawingDocumento2 pagineFMT18 Conventional Room DrawingMr. AlegríaNessuna valutazione finora

- Automatic Vent Station For Pipeline 8" Section B-B 1:50 Manual Vent Station For Pipeline 8" Section B-B 1:50Documento1 paginaAutomatic Vent Station For Pipeline 8" Section B-B 1:50 Manual Vent Station For Pipeline 8" Section B-B 1:50nawajhaNessuna valutazione finora

- 38 3/16" Max Width: Released For ProductionDocumento2 pagine38 3/16" Max Width: Released For ProductionJeisson David Velandia MendivelsoNessuna valutazione finora

- O.H.W.T As Built DrawingsDocumento9 pagineO.H.W.T As Built DrawingsyasirjurabaNessuna valutazione finora

- Diagrama Electrico SplitDocumento20 pagineDiagrama Electrico SplitDanielNessuna valutazione finora

- Wa0000.Documento4 pagineWa0000.سلطان السواعيرNessuna valutazione finora

- A Title: First Floor Plan: FWC FWCDocumento1 paginaA Title: First Floor Plan: FWC FWCCHEEKOTI VIVEKNessuna valutazione finora

- Am14u4 MK688Documento2 pagineAm14u4 MK688victor moacoNessuna valutazione finora

- Especificación de Sistema de Anclaje en EstructuraDocumento1 paginaEspecificación de Sistema de Anclaje en EstructuraEnmanuel BrachoNessuna valutazione finora

- Steel Bracket For StaircaseDocumento1 paginaSteel Bracket For StaircaseAS V KameshNessuna valutazione finora

- .!!iifi!iii!fi! (I.i"!:: Lunar Module Systems HandbookDocumento13 pagine.!!iifi!iii!fi! (I.i"!:: Lunar Module Systems HandbookRick MendelezNessuna valutazione finora

- Plumbing IllustrationsDocumento8 paginePlumbing Illustrationsmnt6176Nessuna valutazione finora

- TCX 1100 AbvDocumento1 paginaTCX 1100 AbvMarcoNessuna valutazione finora

- Detail 02 Thrust BlockDocumento1 paginaDetail 02 Thrust Blockengr_haseeb07100% (1)

- Contract Srvice Req-4044280954 W.O # 50102453 04-02Documento1 paginaContract Srvice Req-4044280954 W.O # 50102453 04-02Akram ShaikhNessuna valutazione finora

- Ances LN Rev.3Documento7 pagineAnces LN Rev.3ManuelGarciaNessuna valutazione finora

- ABSto BrakeDocumento3 pagineABSto BrakeManuel MoralesNessuna valutazione finora

- Inside Drop ManholeDocumento1 paginaInside Drop ManholeAtef MohamedenNessuna valutazione finora

- Basement Electrical Floor Plan: Main EntryDocumento1 paginaBasement Electrical Floor Plan: Main EntryAngela ClarkNessuna valutazione finora

- IDT DAtasheetDocumento18 pagineIDT DAtasheetbalajiiconNessuna valutazione finora

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedDocumento1 paginaThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110Nessuna valutazione finora

- Slab Expansion Joint - Type ADocumento4 pagineSlab Expansion Joint - Type AnvnagarajuNessuna valutazione finora

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocumento1 paginaSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNessuna valutazione finora

- 39 Roof Panel Penetration DetailDocumento1 pagina39 Roof Panel Penetration DetailAhmed Saber NassarNessuna valutazione finora

- 23kk0043 Set BDocumento30 pagine23kk0043 Set BcemirasmpcNessuna valutazione finora

- Transportation Idaho Department: NotesDocumento1 paginaTransportation Idaho Department: NotesBikash SigdelNessuna valutazione finora

- Service Manual: "Korinto"Documento41 pagineService Manual: "Korinto"nubercard6111Nessuna valutazione finora

- Product Drawing: Power Entry 13 1/2" WIDE X 7" HIGHDocumento1 paginaProduct Drawing: Power Entry 13 1/2" WIDE X 7" HIGHsamersibaniNessuna valutazione finora

- 1250 GPM DieselDocumento1 pagina1250 GPM DieselProyectos e Ingeniería - Inprofuego, C.A.Nessuna valutazione finora

- Released For Production: Tong SpecificationDocumento1 paginaReleased For Production: Tong SpecificationFerney FonsecaNessuna valutazione finora

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocumento1 paginaGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNessuna valutazione finora

- 25 Vented Ridge DetailDocumento1 pagina25 Vented Ridge DetailAhmed Saber NassarNessuna valutazione finora

- Adnan - Lined Nipple DrawingDocumento1 paginaAdnan - Lined Nipple Drawingwdavid81Nessuna valutazione finora

- JOF (18-20-Dec) PDFDocumento1 paginaJOF (18-20-Dec) PDFwdavid81Nessuna valutazione finora

- Piping Isometric Drawing (PW Line) : Project TitleDocumento8 paginePiping Isometric Drawing (PW Line) : Project Titlewdavid81Nessuna valutazione finora

- UKA Runbritain COVID19 v1Documento13 pagineUKA Runbritain COVID19 v1wdavid81Nessuna valutazione finora

- Thesis 2007 LiDocumento235 pagineThesis 2007 Liwdavid81Nessuna valutazione finora

- Test: Penetrant Test 100% (Weldment and Body/Pipe) : Sri Takada Industries (Malaysia) Sdn. BHDDocumento1 paginaTest: Penetrant Test 100% (Weldment and Body/Pipe) : Sri Takada Industries (Malaysia) Sdn. BHDwdavid81Nessuna valutazione finora

- MOS Pickling and Passivation (David Comment, 29-11-19)Documento4 pagineMOS Pickling and Passivation (David Comment, 29-11-19)wdavid81Nessuna valutazione finora

- Info GraphicDocumento29 pagineInfo Graphicwdavid81Nessuna valutazione finora

- Mul Points Calculation: TH TH TH TH TH TH TH RD ND STDocumento2 pagineMul Points Calculation: TH TH TH TH TH TH TH RD ND STwdavid81Nessuna valutazione finora

- Nickel WeldingDocumento87 pagineNickel Weldingwdavid810% (1)

- Tank Inspection (DRAFT) Rev.2Documento1 paginaTank Inspection (DRAFT) Rev.2wdavid81Nessuna valutazione finora

- DTank Inspection (DRAFT) Rev.2Documento1 paginaDTank Inspection (DRAFT) Rev.2wdavid81Nessuna valutazione finora

- A. Dimension Inspection of Support Saddle Orientation and AnchoringDocumento7 pagineA. Dimension Inspection of Support Saddle Orientation and Anchoringwdavid81Nessuna valutazione finora

- ATank Inspection (DRAFT) Rev.2Documento1 paginaATank Inspection (DRAFT) Rev.2wdavid81Nessuna valutazione finora

- BTank Inspection (DRAFT) Rev.2Documento1 paginaBTank Inspection (DRAFT) Rev.2wdavid81Nessuna valutazione finora

- Nickel 200 201 PDFDocumento20 pagineNickel 200 201 PDFwdavid81Nessuna valutazione finora

- Press: StatementDocumento26 paginePress: Statementwdavid81Nessuna valutazione finora

- CV Agung Pramuriyanto Update-1 - Agung PramDocumento2 pagineCV Agung Pramuriyanto Update-1 - Agung Pramimammaul7Nessuna valutazione finora

- 2018 G 1.0 MPI KAPPA Schematic Diagrams Brake System Anti-Lock Brake System (ABS) Schematic DiagramsDocumento1 pagina2018 G 1.0 MPI KAPPA Schematic Diagrams Brake System Anti-Lock Brake System (ABS) Schematic DiagramsHuy Trần QuốcNessuna valutazione finora

- UAES 473F Engine Electronic Fuel Injection Section PDFDocumento81 pagineUAES 473F Engine Electronic Fuel Injection Section PDFjardenNessuna valutazione finora

- L14 15 ABCD and S ParametersDocumento15 pagineL14 15 ABCD and S ParametersAmeya KadamNessuna valutazione finora

- Bus Switching Scheme PDFDocumento6 pagineBus Switching Scheme PDFJAYKUMAR SINGHNessuna valutazione finora

- Kroeplin - Katalog 2019 ENDocumento24 pagineKroeplin - Katalog 2019 END.T.Nessuna valutazione finora

- 13bentonit SlurryDocumento24 pagine13bentonit SlurrykesharinareshNessuna valutazione finora

- DX79TO ProductGuide01 EnglishDocumento86 pagineDX79TO ProductGuide01 EnglishqwarztNessuna valutazione finora

- Catalogue TD InsulatorsDocumento26 pagineCatalogue TD InsulatorsBery HamidNessuna valutazione finora

- Conpress: Moidinafsan - Cv15@Rvce - Edu.InDocumento3 pagineConpress: Moidinafsan - Cv15@Rvce - Edu.InMoidin AfsanNessuna valutazione finora

- Unit 1: Configuration Layout and LoftDocumento45 pagineUnit 1: Configuration Layout and LoftDaxit LodaliyaNessuna valutazione finora

- SECTION 307-01: Automatic Transaxle/Transmission - 6R80 2012 F-150 Workshop Manual General ProceduresDocumento3 pagineSECTION 307-01: Automatic Transaxle/Transmission - 6R80 2012 F-150 Workshop Manual General ProceduresPriscilla Kelly Freitas dos SantosNessuna valutazione finora

- Brosur SikaDocumento7 pagineBrosur SikachaerulNessuna valutazione finora

- Concrete Paver Size Test (RECTANGULAR 80mm) : 80.29 MM Averagre of PaversDocumento2 pagineConcrete Paver Size Test (RECTANGULAR 80mm) : 80.29 MM Averagre of PaversNaveed Ul Qamar MughalNessuna valutazione finora

- 2.1 System Requirement SpecificationDocumento30 pagine2.1 System Requirement SpecificationAtif NiazNessuna valutazione finora

- Cloudera Administrator Training Slides PDFDocumento601 pagineCloudera Administrator Training Slides PDFeabernsteinNessuna valutazione finora

- Normas Iec - AstmDocumento3 pagineNormas Iec - AstmGregorio Mendoza PolaresNessuna valutazione finora

- Measurement of Small DistancesDocumento3 pagineMeasurement of Small DistancesJacie TupasNessuna valutazione finora

- Jenbacher: 1. Ignition System: - 1Documento2 pagineJenbacher: 1. Ignition System: - 1ArîfNessuna valutazione finora

- Evaco 2 FDocumento5 pagineEvaco 2 FjnmanivannanNessuna valutazione finora

- SW 2.7 ReadmeDocumento4 pagineSW 2.7 Readmene0botNessuna valutazione finora

- Experiment / Assignment / Tutorial No. 1 Grade: Aa / Ab / BB / BC / CC / CD /DD Signature of The Faculty In-Charge With DateDocumento10 pagineExperiment / Assignment / Tutorial No. 1 Grade: Aa / Ab / BB / BC / CC / CD /DD Signature of The Faculty In-Charge With DateSourabhNessuna valutazione finora

- CDB2043 - CH 03 - StoichiometryDocumento36 pagineCDB2043 - CH 03 - StoichiometryAqilah HanimNessuna valutazione finora

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Documento15 pagineAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)HyungTae JangNessuna valutazione finora

- History of Information Technology: PremechanicalDocumento5 pagineHistory of Information Technology: PremechanicalMichael RamogaNessuna valutazione finora

- Buzzer WT1205Documento1 paginaBuzzer WT1205Tiago Alves Dos SantosNessuna valutazione finora

- Ep-15 CCTV, Telephone Fdas Riser DiagramDocumento1 paginaEp-15 CCTV, Telephone Fdas Riser DiagramNyel ArmstrongNessuna valutazione finora

- Primary CellDocumento4 paginePrimary CellganeshpreetamNessuna valutazione finora