Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Refra Energía

Caricato da

Ricardor123Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Refra Energía

Caricato da

Ricardor123Copyright:

Formati disponibili

REFRAWIRE®

Technology for prefabricated components

in highly stressed application areas.

REFRAWIRE®

A new technology for prefabricated components

As a systems supplier, we develop This enables us to implement com- Prefabricated REFRAWIRE® com-

refractory concepts for specific plex geometries with accurate fits ponents were developed specifi-

process technologies that always and optimum material properties cally to protect equipment linings

ensure optimum plant efficiency. that are precisely matched to the from thermal shocks and mechani-

specific tasks. cal influences.

We have developed optimized

solutions for a wide range of spe- In applications subjected to fast Already during its production, the

cialized requirements and prefabri- temperature variations, severe modular structure of REFRAWIRE®

cated components for all industrial abrasion, and high mechani- – steel fiber matrix plus casting

sectors. Based on our decades of cal loads, standard castables or slurry – ensures perfect adapta-

experience in the manufacture of refractory bricks are not always tion to the individual application

high-grade prefabricated compo- able to withstand these loads. conditions.

nents, new ways were found in the Now, REFRAWIRE®, the latest

fields of drying, firing, and com- generation of our prefabricated REFRAWIRE® components are suit-

paction technology. components is the ideal solution. able for a wide range of applica-

tion areas, e.g. in the iron & steel,

aluminium, refuse incineration,

and cement industries.

Advantages at a glance

• High abrasion resistance

• High thermal shock resistance

• High tensile strength

• Individual design

• Individual formulation

• High resistance to mechanical impacts

• Outstanding thermal strength

From production ...

Steel fiber matrix Addition of the slurry

©Refratechnik Steel GmbH 2

REFRAWIRE®

The advantages in detail

Abrasion resistance

REFRAWIRE® F-60 AR/R H-30 versus low-cement products

with a comparable raw material basis:

Material Raw density Abrasion Test conditions:

(t/m3) (cm3) Preheating: 1000 °C / 5 h

Low-cement casting 2.55 <5 Method: DIN EN 993-20

Low-cement jetcrete 2.40 <6

REFRAWIRE® F-60 AR/R H-30 2.96 <4

The REFRAWIRE® product exhibits extremely high abrasion resistance.

Thermal shock resistance

60

50

Cold modulus of rupture

40

[MPa]

30

Cold modulus of rupture

20 after 5 cycles [MPa]

10

0

Low-cement Low-cement REFRAWIRE® Testing method:

casting jetcrete F-60 AR/R H-30 DIN EN 993-11, B

The thermal shock resistance of REFRAWIRE®

is 6 times higher than that of a low-cement compound.

... to the application

REFRAWIRE® prefabricated components in an electric arc furnace

©Refratechnik Steel GmbH 3

REFRAWIRE®

A complete product range

REFRAWIRE® consists of two Both components are individually The prefabricated REFRAWIRE®

components: A self-flowing combinable. This leads to a com- components are manufactured

c astable and high-quality stainless plete product range that ensures in our highly specialized factory

steel fibers. utmost individuality. in Dülmen, Germany.

Stainless steel fiber types

Typ C: „Low carbon“ Stainless steel fibers for max. operating temperatures up to 1000 °C, not CO-resistant

Typ H: Stainless steel fibers for max. operating temperatures up to 1500 °C, CO-resistant

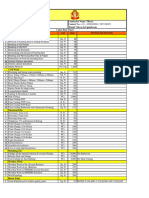

REFRAWIRE® product range (selection)

Quality* Raw material basis Application

REFRAWIRE® F-60 R Firebrick 60 For most reactors/furnaces up to max. 1500 °C

REFRAWIRE® F-60 AR/R Firebrick 60 + SiC For iron & steel casting applications

REFRAWIRE® A-60 TS Andalusite For environments with high temperature changes

REFRAWIRE® A-60 AR/R Andalusite + SiC For environments with high temperature changes

and severe abrasion

REFRAWIRE® B-85 Bauxite Applications for medium and high temperatures

REFRAWIRE® T-95 R Tabular alumina High temperatures and corrosive environments

REFRAWIRE® T-95 SP/R Tabular alumina + spinel High temperatures and corrosive environments

REFRAWIRE® T-90 AL Tabular alumina + anti-wetting Specifically for the aluminium industry

*plus description of the stainless steel fiber

REFRAWIRE® application examples

Edge components Blocks for the upper part of

for casting ladle an aluminium smelting furnace

REFRAWIRE® A-60 TS H-30 REFRAWIRE® T-90 AL H-30

©Refratechnik Steel GmbH 4

Let's talk about your goals.

We will find the right way.

Refratechnik Steel GmbH is a

member of the Refratechnik Group.

Based on a solid foundation of

more than 60 years experience,

Refratechnik Steel GmbH focuses

on solutions for iron & steel found-

ries as well as the non-ferrous and

aluminium industries, which con-

sequently involves environmental,

energy, and chemical aspects.

Since 2002, Refratechnik Steel demands on technology, product

has been manufacturing pre- range, production capacities, and

fabricated, flow control, and gas environmental compatibility in a

purging pro-ducts in their own fac- sustainable manner.

tory. The rapid increase of these

applications forced Refratechnik to Apart from the practically fully

expand their production capacity automated production, innovative

in this field: functional components – also as

The new factory in Dülmen/Germa- customized one-off parts – are

ny was inaugurated in September manufactured with consistent high

2011, and meets today' increased quality.

The Refratechnik Group is certified according to:

ISO 9001 – Quality management systems, and

ISO 14001 – Environmental management systems.

©Refratechnik Steel GmbH 5

Refratechnik Steel GmbH

Schiessstrasse 58

40549 Düsseldorf

Germany

St 1-044-09/2018

Phone +49 211 5858 0

Fax +49 211 5858 49

steel@refra.com

www.refra.com

Potrebbero piacerti anche

- PDF Ce Refractory Concrete e 2 2014Documento10 paginePDF Ce Refractory Concrete e 2 2014cristian villegasNessuna valutazione finora

- PDF ST PrimarAlu e 9 2014.en.32Documento6 paginePDF ST PrimarAlu e 9 2014.en.32Argenis Emmanuel Rodriguez MarianoNessuna valutazione finora

- Gouda Refractories Brochure WEbDocumento16 pagineGouda Refractories Brochure WEbjsszep jNessuna valutazione finora

- Hepha Vibes For Maghreb Middle East (2023)Documento10 pagineHepha Vibes For Maghreb Middle East (2023)engr kazamNessuna valutazione finora

- Wall Colmonoy LTD - Surfacing Alloys Brochure - ENG - August2019Documento8 pagineWall Colmonoy LTD - Surfacing Alloys Brochure - ENG - August2019pranav kariaNessuna valutazione finora

- Chemical 20 26 20hydrocarbon 20processing 20PDF, Templateid Default, Property DataDocumento34 pagineChemical 20 26 20hydrocarbon 20processing 20PDF, Templateid Default, Property Datagems_gce074325Nessuna valutazione finora

- Super Duplex Stainless Steel: Excellent Engineering SolutionsDocumento3 pagineSuper Duplex Stainless Steel: Excellent Engineering SolutionsshyamNessuna valutazione finora

- 1 Refractory Minerals Line Card EmailDocumento2 pagine1 Refractory Minerals Line Card EmailMuhammad victoryan nadezulNessuna valutazione finora

- Thermal Spray WiresDocumento4 pagineThermal Spray WiresSHUBH Engeeniaring worksNessuna valutazione finora

- Steel Ladle Calderys Brochure A4Documento22 pagineSteel Ladle Calderys Brochure A4Mitone Diaz100% (1)

- Material Product Data Sheet Chromium Carbide - 20 % Nickel Chromium PowdersDocumento4 pagineMaterial Product Data Sheet Chromium Carbide - 20 % Nickel Chromium PowdersJesus D. Gutierrez G.Nessuna valutazione finora

- Wear Plate PDFDocumento19 pagineWear Plate PDFNorma SalazarNessuna valutazione finora

- THE Tri-Con SeriesDocumento6 pagineTHE Tri-Con Seriespablopasqualini18Nessuna valutazione finora

- Special Steels, Superalloys, Aluminum and Titanium Alloys For The Space IndustryDocumento6 pagineSpecial Steels, Superalloys, Aluminum and Titanium Alloys For The Space Industrychetan_thakur4278Nessuna valutazione finora

- PDF Ce Feuerbetone e 8 2017.en.7Documento10 paginePDF Ce Feuerbetone e 8 2017.en.7Henry SunarkoNessuna valutazione finora

- Spiral Heat ExchangersDocumento8 pagineSpiral Heat ExchangersHolayilNessuna valutazione finora

- LR-C-VentureClad Catalogue 01Documento16 pagineLR-C-VentureClad Catalogue 01himanshu desaiNessuna valutazione finora

- PSP 108 Alloy409Documento2 paginePSP 108 Alloy409Alexis A. Illarramendi G.Nessuna valutazione finora

- O - Alloy 59: Nicrofer 5923 HDocumento12 pagineO - Alloy 59: Nicrofer 5923 HIniyan Thiruselvam Navaladi KarthikeyanNessuna valutazione finora

- BW Grade+91 EN 2021 GL 135 Preview+Documento20 pagineBW Grade+91 EN 2021 GL 135 Preview+attaullaNessuna valutazione finora

- High Performance: Properties & General DataDocumento4 pagineHigh Performance: Properties & General DataRaghNessuna valutazione finora

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Select Arc Brochure On Ni Alloy Welding ProductsDocumento6 pagineSelect Arc Brochure On Ni Alloy Welding Productsharan2000Nessuna valutazione finora

- Raj Rubber ProductsDocumento35 pagineRaj Rubber Productsnaveenraj mNessuna valutazione finora

- MCM AllDocumento7 pagineMCM AllPalanisamy RajaNessuna valutazione finora

- Material Programme: For Corrosive, Abrasive and Hot MediaDocumento18 pagineMaterial Programme: For Corrosive, Abrasive and Hot Mediarohitshukla23Nessuna valutazione finora

- Parker TechSeal Packer Elements TSD 5430Documento4 pagineParker TechSeal Packer Elements TSD 5430Vendro MunajadNessuna valutazione finora

- High Strength Steels For Naval ApplicationsDocumento19 pagineHigh Strength Steels For Naval ApplicationsRaju NagendraNessuna valutazione finora

- Greene Tweed Energy at A GlanceDocumento8 pagineGreene Tweed Energy at A GlanceYang WangNessuna valutazione finora

- BOHLER WELDING GHID EN-GL-UTP - Cement - WEBDocumento36 pagineBOHLER WELDING GHID EN-GL-UTP - Cement - WEBcristian popescuNessuna valutazione finora

- Refractories 151013152522 Lva1 App6892Documento19 pagineRefractories 151013152522 Lva1 App6892Taha KhanNessuna valutazione finora

- DSM-0310.0 WC10Co4Cr SintCrushDocumento3 pagineDSM-0310.0 WC10Co4Cr SintCrushNabil SalimNessuna valutazione finora

- Brands You Trust.: Industrial Diaphragm ValvesDocumento20 pagineBrands You Trust.: Industrial Diaphragm ValvesShayan Hasan KhanNessuna valutazione finora

- Bradken Fixed Plant BrochureDocumento29 pagineBradken Fixed Plant BrochurepinkypachoNessuna valutazione finora

- Floating Seals: Your Seal of QualityDocumento12 pagineFloating Seals: Your Seal of QualityMahendra Tyre Works RaigarhNessuna valutazione finora

- Presentation On Refractories By: Haleem Haider Farrukh Shahzad Muzammil JavedDocumento23 paginePresentation On Refractories By: Haleem Haider Farrukh Shahzad Muzammil JavedwatcharpNessuna valutazione finora

- Heresite Product SheetDocumento1 paginaHeresite Product SheetHardiman ArbiNessuna valutazione finora

- Material Product Data Sheet Iron Chromium Aluminum Yttrium (Fecraly) Thermal Spray PowderDocumento3 pagineMaterial Product Data Sheet Iron Chromium Aluminum Yttrium (Fecraly) Thermal Spray PowderfrdnNessuna valutazione finora

- 25CR20NIDocumento2 pagine25CR20NIShariq KhanNessuna valutazione finora

- Stainless Steels For Springs and Other Demanding Applications (S 3411 ENG - Sept.2002)Documento14 pagineStainless Steels For Springs and Other Demanding Applications (S 3411 ENG - Sept.2002)DanielNessuna valutazione finora

- Etatron Chemical Resistance Chart UploadedDocumento35 pagineEtatron Chemical Resistance Chart Uploadedatiq124Nessuna valutazione finora

- WaterfordDocumento12 pagineWaterfordCamilo MorenoNessuna valutazione finora

- Lubricants Technology For Steel IndustryDocumento54 pagineLubricants Technology For Steel Industrysalah.a.abdelazimNessuna valutazione finora

- CALDE Iron Casthouse V2 112015-CompressedDocumento12 pagineCALDE Iron Casthouse V2 112015-CompressedChristian PurbaNessuna valutazione finora

- Extintores Amerex Product CatalogDocumento20 pagineExtintores Amerex Product CatalogGilberto GarciaNessuna valutazione finora

- Aspac Royalloy enDocumento7 pagineAspac Royalloy enNugroho Faris SudrajatNessuna valutazione finora

- Giunzione e ManutenzioneDocumento29 pagineGiunzione e Manutenzionerenhat parulian sitorusNessuna valutazione finora

- High Quality Products For Welding and CladdingDocumento25 pagineHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- Corrosion Resistant AlloysDocumento40 pagineCorrosion Resistant Alloysmiker100Nessuna valutazione finora

- Fabrication of Hastelloy Corrosion-Resistant AlloysDocumento40 pagineFabrication of Hastelloy Corrosion-Resistant AlloysAli VarmazyarNessuna valutazione finora

- CP Eg Saundersidvsml Bu en A2!06!2013 12 Sml1Documento20 pagineCP Eg Saundersidvsml Bu en A2!06!2013 12 Sml1Matt TremoglieNessuna valutazione finora

- Stainless Steels For High Service Temperatures: Outokumpu Therma RangeDocumento12 pagineStainless Steels For High Service Temperatures: Outokumpu Therma RangeAngel MendozaNessuna valutazione finora

- MP RDC Profile English VersionDocumento39 pagineMP RDC Profile English VersionNP METALPROTECTIONNessuna valutazione finora

- Properties of Refractory Material: IntroductionDocumento13 pagineProperties of Refractory Material: Introductionpratiksha nagargojeNessuna valutazione finora

- RA SiC T CM EC PDFDocumento2 pagineRA SiC T CM EC PDFDaniel RicartNessuna valutazione finora

- PEP Session Industrial RefractoriesDocumento64 paginePEP Session Industrial RefractoriesNowsherwan MazariNessuna valutazione finora

- FloatingDocumento12 pagineFloatingrobson2015Nessuna valutazione finora

- Wall-Colmonoy-Ltd Fusewelder-Brochure ENG November2021smlDocumento4 pagineWall-Colmonoy-Ltd Fusewelder-Brochure ENG November2021smlpranav kariaNessuna valutazione finora

- Pipeclad Product Brochure Sherwin Williams EnglishDocumento12 paginePipeclad Product Brochure Sherwin Williams EnglishCésarNessuna valutazione finora

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- Uk Pigs Hillary BookletDocumento7 pagineUk Pigs Hillary BookletNiken SusantiNessuna valutazione finora

- Paes 310Documento9 paginePaes 310Jemina Jean Dorado SensanoNessuna valutazione finora

- Aquastore Brochure WaterstorageDocumento4 pagineAquastore Brochure WaterstoragePraveenNessuna valutazione finora

- DJF21012 Sand Casting 1006Documento15 pagineDJF21012 Sand Casting 1006Sakinah KamalNessuna valutazione finora

- Mechanical Behavior and Microstructural Development in Phosphate Modified High Alumina CementDocumento9 pagineMechanical Behavior and Microstructural Development in Phosphate Modified High Alumina CementAndhy Arya EkaputraNessuna valutazione finora

- NABERS Waste: List of Waste StreamsDocumento8 pagineNABERS Waste: List of Waste StreamsChrina MalolotNessuna valutazione finora

- Enhanced Oxidation of The 9%Cr Steel P91 in Water Vapour Containing EnvironmentsDocumento27 pagineEnhanced Oxidation of The 9%Cr Steel P91 in Water Vapour Containing EnvironmentsAleš NagodeNessuna valutazione finora

- Formulation Guide Household 2018Documento28 pagineFormulation Guide Household 2018adelaide university100% (1)

- ASTM B466 (2009) - Standard Specification For Seamless Copper-Nickel Pipe and TubeDocumento6 pagineASTM B466 (2009) - Standard Specification For Seamless Copper-Nickel Pipe and Tubeanoop100% (1)

- Filtration of Iron and Steel Castings PDFDocumento24 pagineFiltration of Iron and Steel Castings PDFbvphimanshu100% (1)

- Essar Petrol Pump ListDocumento21 pagineEssar Petrol Pump ListRajesh PramanikNessuna valutazione finora

- Chemistry - Higher Level: Pre-Leaving Certiϐicate Examination, 2019 Triailscrúdú Na Hardteistiméireachta, 2019Documento12 pagineChemistry - Higher Level: Pre-Leaving Certiϐicate Examination, 2019 Triailscrúdú Na Hardteistiméireachta, 2019Diaa SaberNessuna valutazione finora

- Cement Consistency and Setting Time PDFDocumento5 pagineCement Consistency and Setting Time PDFvelmurug_balaNessuna valutazione finora

- Dimensional Stone Mining and EnvironmentDocumento42 pagineDimensional Stone Mining and EnvironmentZlatanMasic100% (5)

- Methodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering CorporationDocumento10 pagineMethodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering Corporationvenkateswara rao PothinaNessuna valutazione finora

- Corrosion and Protection of Transmission Steel Structure TowerDocumento5 pagineCorrosion and Protection of Transmission Steel Structure Towerabhi120783Nessuna valutazione finora

- Stoichiometry IGCSE Chemistry STB Grade 10 PDFDocumento6 pagineStoichiometry IGCSE Chemistry STB Grade 10 PDFRudyWahyudiNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Jul-18 WeldDocumento2 pagineSaudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Jul-18 WeldjahaanNessuna valutazione finora

- API 577 Closed Books Questions AnswersDocumento3 pagineAPI 577 Closed Books Questions Answersnikafiq100% (5)

- Sylobloc® 44 - GraceDocumento2 pagineSylobloc® 44 - Gracewhatever39100% (1)

- Fundamentals of Mobile Heavy EquipmentDocumento9 pagineFundamentals of Mobile Heavy Equipmentwin min soeNessuna valutazione finora

- Camarines Sur Polytechnic Colleges: Republic of The Philippines Nabua, Camarines Sur A.Y. 2020-2021 2 SemesterDocumento5 pagineCamarines Sur Polytechnic Colleges: Republic of The Philippines Nabua, Camarines Sur A.Y. 2020-2021 2 SemesterMarvin CarcidoNessuna valutazione finora

- Chemical Reactions MinDocumento2 pagineChemical Reactions MinrachmajuwitaNessuna valutazione finora

- Krishna Apra Saffaire 1Documento1 paginaKrishna Apra Saffaire 1Ishu BansalNessuna valutazione finora

- Ebook Chemistry Atoms First 2Nd Edition Burdge Solutions Manual Full Chapter PDFDocumento67 pagineEbook Chemistry Atoms First 2Nd Edition Burdge Solutions Manual Full Chapter PDFMrNicolasGuerraJrnsadz100% (11)

- Galfan eDocumento1 paginaGalfan ePCX2491100% (1)

- Allah Ditta: ObjectiveDocumento2 pagineAllah Ditta: ObjectiveSam RanaNessuna valutazione finora

- Accepted Manuscript: Process Safety and Environment ProtectionDocumento75 pagineAccepted Manuscript: Process Safety and Environment ProtectionDiego TorresNessuna valutazione finora

- Packaging Fruit PracticesDocumento18 paginePackaging Fruit PracticesVikrant JaryanNessuna valutazione finora

- TJ-Design Calculation PDFDocumento336 pagineTJ-Design Calculation PDFaldeto71Nessuna valutazione finora