Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Base Slab Design - Ramp

Caricato da

Suresh MahalingamCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Base Slab Design - Ramp

Caricato da

Suresh MahalingamCopyright:

Formati disponibili

E.P.C.

FOR THE FAO

PUMPING STATION AL FAW

– BASRAH, IRAQ Project

No. : A34501

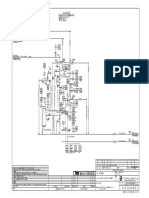

Ramp Base Slab Design - Flexure ( Max Mx Ultimate )

Data:-

Design ultimate bending moment = M = 203.4 kN.m

Design service moment = Ms = 126.9 kN.m

Breadth of Cross-section = b = 1000.0 mm

Overall depth = h = 400.0 mm

Grade of concrete = fcu = 30.0 N/mm2

Grade of main steel = fy = 420.0 N/mm2

Clear cover = c = 50.0 mm

Elastic modulus of steel = Es = 2.10E+05 N/mm2

Elastic modulus of concrete = Ec = 2.46E+04 N/mm2

Solution:-

Effective depth = d = h-C -bar dia/2

= 342.0 mm

The ratio = k = M / bd2fcu

= 0.058

Lever arm = {Min of 0.95d & d[0.5+SQRT(0.25-k/0.9 ]} = z

= 318.3 mm

Area of steel required = (As)req. = M / 0.95fyz

= 1601.6 mm2

Minimum area of steel = (As)Min. = 0.13% bD

= 520.0 mm2

Maximum area of steel = (As)Max. = 4% bD

= 16000 mm2

T 16 @ 125

OKAY

Area of steel provided = (As)Prov. = 1608 mm 2

C/C spacing of the bottom most main bar = 125.0 mm

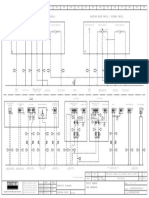

b ec fc s

0.5 fc b x " "

x

h d NEUTRAL AXIS acr Dia

c

As es fs A s

e1 fs

Section Strain Stresses / forces

Ramp Base slab design

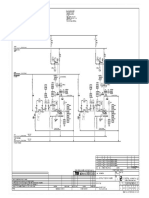

Ramp Base Slab Design - Flexure ( Max Mx Service )

CRACK WIDTH CALCULATIONS - FLEXURE

Service Moment (Crack Width Calculations to BS8110: 1997/ BS

INPUT

fcu=

fy=

Area of reinforcement " As " =

b=

h=

d=

Minimum cover to tension reinforcement " CO " =

Maxmum bar spacing " S " =

Bar dia " DIA " =

" acr " =(((S/2)^2+(CO+DIA/2)^2)^(1/2)-DIA/2) as default or enter other value =

"acr " is distance from the point considered to the surface of the nearest longitudinal b

Applied service moment " Ms "=

CALCULATIONS

moduli of elasticity of concrete " Ec" = (1)*(20+0.2*fcu)*0.5 =

moduli of elasticity of steel " Es " =

Modular ratio " a " = (Es/Ec) =

" r " = As/bd =

depth to neutral axis, "x" = (-a.r +((a.r)2 + 2.a.r)0.5.d =

" Z " = d-(x/3) =

Reinforcement stress " fs " = Ms/(As*Z) =

Concrete stress " fc " = (fs*As)/(0.5*b*x) =

Strain at soffit of concrete beam/slab " e1 " = (fs/Es)*(h-x)/(d-x) =

Strain due to stiffening effect of concrete between cracks " e2 " =

e 2 = b.(h-x)2/(3.Es.As.(d-x)) for crack widths of 0.2 mm

e 2 = 1.5.b.(h-x)2/(3.Es.As.(d-x)) for crack widths of 0.1 mm

Ramp Base Slab Design

e2 =

Average strain for calculation of crack width " e m "= e 1-e 2 =

Calculated crack width, " w " = 3.acr.em/(1+2.(acr-c)/(h-x))

CALCULATED CRACK WIDTH, 'w' =

Allowable Crack Width for Water retaining structures = 0.2 mm

Allowable Crack Width for normal structures = 0.3 mm

Ramp Base Slab Design

E.P.C. FOR THE FAO

PUMPING STATION AL FAW

– BASRAH, IRAQ

Project No. : A34501

o BS8110: 1997/ BS8007:1987)

30 N/mm2

420 N/mm2

1608 mm2

1000 mm

400 mm

342 mm

50 mm

125 mm

16 mm

77.27 mm

arest longitudinal bar

126.9 KNm

13.0 KN/mm2

210.0 KN/mm2

16.15

0.005

110 mm

305

258 N/mm2

7.57 N/mm2

0.001538

Used

n/a

Ramp Base Slab Design

0.000358

0.001180

0.23 mm

< 0.3mm OK

Ramp Base Slab Design

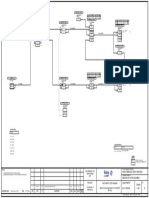

E.P.C. FOR THE FAO

PUMPING STATION AL FAW

– BASRAH, IRAQ Project

No. : A34501

Ramp Base Slab Design - Flexure ( Max My Ultimate )

Data:-

Design ultimate bending moment = M = 107.3 kN.m

Design service moment = Ms = 67.9 kN.m

Breadth of Cross-section = b = 1000.0 mm

Overall depth = h = 400.0 mm

Grade of concrete = fcu = 30.0 N/mm2

Grade of main steel = fy = 420.0 N/mm2

Clear cover = c = 50.0 mm

Elastic modulus of steel = Es = 2.10E+05 N/mm2

Elastic modulus of concrete = Ec = 2.46E+04 N/mm2

Solution:-

Effective depth = d = h-C -bar dia -bar dia/2

= 326.0 mm

The ratio = k = M / bd2fcu

= 0.034

Lever arm = {Min of 0.95d & d[0.5+SQRT(0.25-k/0.9 ]} = z

= 309.7 mm

Area of steel required = (As)req. = M / 0.95fyz

= 868.6 mm2

Minimum area of steel = (As)Min. = 0.13% bD

= 520.0 mm2

Maximum area of steel = (As)Max. = 4% bD

= 16000 mm2

T 16 @ 150

OKAY

Area of steel provided = (As)Prov. = 1340 mm 2

C/C spacing of the bottom most main bar = 150.0 mm

b ec fc s

0.5 fc b x " "

x

h d NEUTRAL AXIS acr Dia

c

As es fs A s

e1 fs

Section Strain Stresses / forces

Ramp Base slab design

Potrebbero piacerti anche

- Column Base Plate DesignDocumento1 paginaColumn Base Plate DesignBunkun15Nessuna valutazione finora

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDocumento1 paginaChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNessuna valutazione finora

- 2 Piles Cap Design ExampleDocumento3 pagine2 Piles Cap Design ExampleSilvanus ChepkocheiNessuna valutazione finora

- Design Calculations For Primary Beam Connections As Welded Connections R2Documento6 pagineDesign Calculations For Primary Beam Connections As Welded Connections R2Rajesh PoreNessuna valutazione finora

- Splice 03Documento15 pagineSplice 03LexNessuna valutazione finora

- Slab PedestalDocumento5 pagineSlab PedestalnhulugallaNessuna valutazione finora

- Check For Requirement of Boundary ElementDocumento9 pagineCheck For Requirement of Boundary ElementJai ThakkarNessuna valutazione finora

- Repport Steel Structure PDFDocumento111 pagineRepport Steel Structure PDFAnonymous fxqnhfKNessuna valutazione finora

- Base Plate BiaxilDocumento26 pagineBase Plate BiaxilvijaystructuralNessuna valutazione finora

- Base Plate Design BS CodeDocumento3 pagineBase Plate Design BS CodeFodor ZoltanNessuna valutazione finora

- PAEC2017 - Slab On Grade InvestigationDocumento2 paginePAEC2017 - Slab On Grade InvestigationSayavi Nicole Sayavi NickNessuna valutazione finora

- Hollow Core Slab DesignDocumento3 pagineHollow Core Slab DesignNaveen Nunna0% (1)

- Column Design With ExcelDocumento47 pagineColumn Design With ExcelMatiur Rahman BasumNessuna valutazione finora

- RCC92 Ribbed Slabs (Tables)Documento8 pagineRCC92 Ribbed Slabs (Tables)lucianduNessuna valutazione finora

- Anchor Bolt DesignDocumento1 paginaAnchor Bolt DesignpawanNessuna valutazione finora

- Design of Purlin & Runner-Ro-Final-Rev-0Documento8 pagineDesign of Purlin & Runner-Ro-Final-Rev-0Sabrina ImloulNessuna valutazione finora

- Case 1 Positive Moment: Geometrical Properties Material PropertiesDocumento3 pagineCase 1 Positive Moment: Geometrical Properties Material Propertiessidiq7Nessuna valutazione finora

- Beam DesignDocumento7 pagineBeam DesignKasi ViswanathanNessuna valutazione finora

- Sachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Documento5 pagineSachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Costas SachpazisNessuna valutazione finora

- Beam - Capacity Check - SumanDocumento4 pagineBeam - Capacity Check - Sumansuman_civilNessuna valutazione finora

- Canopy - Final Design PDFDocumento4 pagineCanopy - Final Design PDFDhina karanNessuna valutazione finora

- Design of SlabDocumento3 pagineDesign of SlabKetan Dhameliya100% (2)

- Pinned Base As Per AISC-Detail-A-R0Documento5 paginePinned Base As Per AISC-Detail-A-R0Sunil Pulikkal100% (1)

- Base Plate DesignDocumento1 paginaBase Plate DesignOlusegun S. AjibolaNessuna valutazione finora

- Punching Stress AciDocumento20 paginePunching Stress AcijhdmssNessuna valutazione finora

- Anchor Bolt Design For Portal and Connecting BridgeDocumento2 pagineAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNessuna valutazione finora

- Cable Trench Desiign Report 26.04.2020 PDFDocumento50 pagineCable Trench Desiign Report 26.04.2020 PDFkkgcNessuna valutazione finora

- Strip Footing Load Analysis For Rajendra Prasad Kharel: Grid 1-1Documento3 pagineStrip Footing Load Analysis For Rajendra Prasad Kharel: Grid 1-1Er Saroj PaudelNessuna valutazione finora

- Design of Strap Footing PDFDocumento3 pagineDesign of Strap Footing PDFVasanthakumarNessuna valutazione finora

- 2.column Base Plate (Fixed Type)Documento15 pagine2.column Base Plate (Fixed Type)ZevanyaRolandTualakaNessuna valutazione finora

- EC3 - Fin Plate Connection Design ChecksDocumento5 pagineEC3 - Fin Plate Connection Design Checkssuman_civilNessuna valutazione finora

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Documento5 pagineEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNessuna valutazione finora

- Design of SunshadeDocumento19 pagineDesign of SunshadeNitesh SinghNessuna valutazione finora

- RCC Mat Foundation 4 PedestalDocumento173 pagineRCC Mat Foundation 4 PedestalKutty Mansoor50% (2)

- Grid Slab WITH BBSDocumento11 pagineGrid Slab WITH BBSJyoti PatilNessuna valutazione finora

- Foundation Design of Lamp PostDocumento1 paginaFoundation Design of Lamp PostMayank Agrawal100% (1)

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Documento14 pagineSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNessuna valutazione finora

- Pile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterDocumento22 paginePile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterShuvam SarkarNessuna valutazione finora

- SHS and RHSDocumento16 pagineSHS and RHSOuseppachan AmbookenNessuna valutazione finora

- Etabs Steel Column Design Compair EtabsDocumento10 pagineEtabs Steel Column Design Compair EtabsSumedha MayadunnaNessuna valutazione finora

- Open Foundation With Eccentric Loading and Moments-FinalDocumento6 pagineOpen Foundation With Eccentric Loading and Moments-FinalMahadev Sastry100% (1)

- Cantilever BeamDocumento4 pagineCantilever BeamWaheed AhmadNessuna valutazione finora

- Busunju - Site (3141) - Structural Analysis Report 1 of 2 - Version 1Documento26 pagineBusunju - Site (3141) - Structural Analysis Report 1 of 2 - Version 1Emmanuel MusaasiziNessuna valutazione finora

- SteelDocumento80 pagineSteelAnonymous HJ7hmihhNessuna valutazione finora

- Slab Manual DesignDocumento1 paginaSlab Manual DesignAtul ShrivastavaNessuna valutazione finora

- Design Parameters For Longitudinal Bars (Beams - BS 8110)Documento4 pagineDesign Parameters For Longitudinal Bars (Beams - BS 8110)Lavanyan Satchithananthan100% (1)

- Aci318-08 Moment Shear Torsion DesignDocumento7 pagineAci318-08 Moment Shear Torsion DesignMohammed HanafiNessuna valutazione finora

- Fencing Oman With Block Footing - 03072013Documento20 pagineFencing Oman With Block Footing - 03072013RAJENDRA PRASADNessuna valutazione finora

- ANCHOR - REINFORCEMENT (Metric)Documento10 pagineANCHOR - REINFORCEMENT (Metric)Tarek AbulailNessuna valutazione finora

- Base Plate Design (Fixed Base)Documento3 pagineBase Plate Design (Fixed Base)Saravana NNessuna valutazione finora

- Pad Foundation With Two Columns ExampleDocumento10 paginePad Foundation With Two Columns ExampleakankwasaNessuna valutazione finora

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDocumento56 pagineSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNessuna valutazione finora

- Annexure-B - Pile Cap DesignDocumento32 pagineAnnexure-B - Pile Cap Designnikhil lokhandeNessuna valutazione finora

- Check SCDocumento22 pagineCheck SCNhuVan NguyenNessuna valutazione finora

- Base Slab Design - CulvertDocumento6 pagineBase Slab Design - CulvertSuresh MahalingamNessuna valutazione finora

- Wall Design - CulvertDocumento5 pagineWall Design - CulvertSuresh Mahalingam100% (1)

- Corner Wall Design - RampDocumento5 pagineCorner Wall Design - RampSuresh MahalingamNessuna valutazione finora

- Corner Wall Design - CulvertDocumento5 pagineCorner Wall Design - CulvertSuresh MahalingamNessuna valutazione finora

- Calculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK DataDocumento3 pagineCalculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK Dataasif billalNessuna valutazione finora

- Valve Pit DesignDocumento3 pagineValve Pit DesignersivarajNessuna valutazione finora

- MUK-62-MGT-AIC-09011 Rev A Filter Press Erec. & Install. Proc. 110314Documento12 pagineMUK-62-MGT-AIC-09011 Rev A Filter Press Erec. & Install. Proc. 110314Suresh MahalingamNessuna valutazione finora

- GPM OverviewDocumento158 pagineGPM OverviewSuresh MahalingamNessuna valutazione finora

- MUK-62-MGT-AIC-09010 Rev A Lime & Soa Ash Erec. and Install. Proced. 110314Documento28 pagineMUK-62-MGT-AIC-09010 Rev A Lime & Soa Ash Erec. and Install. Proced. 110314Suresh MahalingamNessuna valutazione finora

- MUK-61-2-0658-ERC-2004 Rev 1Documento1 paginaMUK-61-2-0658-ERC-2004 Rev 1Suresh MahalingamNessuna valutazione finora

- TRX 2011 2555Documento78 pagineTRX 2011 2555Suresh MahalingamNessuna valutazione finora

- TRX 2011 2555Documento78 pagineTRX 2011 2555Suresh MahalingamNessuna valutazione finora

- TRX 2011 2555Documento78 pagineTRX 2011 2555Suresh MahalingamNessuna valutazione finora

- Corner Wall Design - CulvertDocumento5 pagineCorner Wall Design - CulvertSuresh MahalingamNessuna valutazione finora

- Design Input and OutputDocumento3 pagineDesign Input and OutputSuresh MahalingamNessuna valutazione finora

- Base Slab Design - CulvertDocumento6 pagineBase Slab Design - CulvertSuresh MahalingamNessuna valutazione finora

- Corner Wall Design - RampDocumento5 pagineCorner Wall Design - RampSuresh MahalingamNessuna valutazione finora

- Braking Distance CalculationDocumento4 pagineBraking Distance CalculationSuresh MahalingamNessuna valutazione finora

- MUK 61-1-0175 001 9B4 1 Crude Product Pipeline Pumps 101228Documento1 paginaMUK 61-1-0175 001 9B4 1 Crude Product Pipeline Pumps 101228Suresh MahalingamNessuna valutazione finora

- Wall Design - CulvertDocumento5 pagineWall Design - CulvertSuresh Mahalingam100% (1)

- MUK-61!1!0542-002-9B4-1 Crude Product Pipeline Pump 20101228Documento1 paginaMUK-61!1!0542-002-9B4-1 Crude Product Pipeline Pump 20101228Suresh MahalingamNessuna valutazione finora

- MUK-61-5-1472-007-9B4-1 Rev 0 110510 PDFDocumento1 paginaMUK-61-5-1472-007-9B4-1 Rev 0 110510 PDFSuresh MahalingamNessuna valutazione finora

- MUK-61-1-0541-002-9B4-1 Crude Product Booster Pump 20101228Documento1 paginaMUK-61-1-0541-002-9B4-1 Crude Product Booster Pump 20101228Suresh MahalingamNessuna valutazione finora

- MUK-61!1!0542-001-9B4-1 Crude Product Pipeline Pump 20101228Documento1 paginaMUK-61!1!0542-001-9B4-1 Crude Product Pipeline Pump 20101228Suresh MahalingamNessuna valutazione finora

- MUK-61!1!0542-002-9B4-1 Crude Product Pipeline Pump 20101228Documento1 paginaMUK-61!1!0542-002-9B4-1 Crude Product Pipeline Pump 20101228Suresh MahalingamNessuna valutazione finora

- MUK-61-5-1472-023-9B4-1 Rev 0 110621 PDFDocumento1 paginaMUK-61-5-1472-023-9B4-1 Rev 0 110621 PDFSuresh MahalingamNessuna valutazione finora

- Displacement Check 1Documento3 pagineDisplacement Check 1Suresh MahalingamNessuna valutazione finora

- MUK-61-5-1472-007-9B4-1 Rev 0 110510 PDFDocumento1 paginaMUK-61-5-1472-007-9B4-1 Rev 0 110510 PDFSuresh MahalingamNessuna valutazione finora

- BoP System List With Marked-Up PnID (Issued 12feb12)Documento160 pagineBoP System List With Marked-Up PnID (Issued 12feb12)Suresh MahalingamNessuna valutazione finora

- Iqwq KD WPWRK D7 1109 - 0Documento76 pagineIqwq KD WPWRK D7 1109 - 0Suresh MahalingamNessuna valutazione finora

- MUK-61-2-0574-001-9B4 Rev 1 110606Documento1 paginaMUK-61-2-0574-001-9B4 Rev 1 110606Suresh MahalingamNessuna valutazione finora

- Reactions 1223Documento2 pagineReactions 1223Suresh MahalingamNessuna valutazione finora

- MUK-61-2-0570-001-9B4 Rev 2 110621 PDFDocumento1 paginaMUK-61-2-0570-001-9B4 Rev 2 110621 PDFSuresh MahalingamNessuna valutazione finora

- MUK-61-2-0573-001-9B4 Rev 1 110606 PDFDocumento1 paginaMUK-61-2-0573-001-9B4 Rev 1 110606 PDFSuresh MahalingamNessuna valutazione finora

- UAE Ramadan Kareem Catalogue 2016Documento48 pagineUAE Ramadan Kareem Catalogue 2016Suresh MahalingamNessuna valutazione finora

- Standards of MeasurementDocumento12 pagineStandards of MeasurementShubham KheraNessuna valutazione finora

- Quest CCS ProjectDocumento10 pagineQuest CCS ProjecttruehemingwayNessuna valutazione finora

- Reason Key CommandsDocumento6 pagineReason Key CommandsVijay KumarNessuna valutazione finora

- Kuokuang Petrochemicals Executive SummaryDocumento40 pagineKuokuang Petrochemicals Executive SummaryKhoh Kai ShengNessuna valutazione finora

- "Part - I - General Central Services Group B'Documento13 pagine"Part - I - General Central Services Group B'NarayanaNessuna valutazione finora

- Physics 02-07 Centripetal Force and Banked CurvesDocumento2 paginePhysics 02-07 Centripetal Force and Banked CurveslatteNessuna valutazione finora

- Asida Distance Relay Adr-239aDocumento27 pagineAsida Distance Relay Adr-239aRitesh JaiswalNessuna valutazione finora

- ICE Annex A Methodologies For RecyclingDocumento17 pagineICE Annex A Methodologies For RecyclingChai Lin NyokNessuna valutazione finora

- Resistor DatasheetDocumento10 pagineResistor DatasheetEndradno KurniaNessuna valutazione finora

- Brilliance - 64 - (ct101) - Site - Guidefor TrailerDocumento19 pagineBrilliance - 64 - (ct101) - Site - Guidefor Trailerbody2030Nessuna valutazione finora

- ReadmeDocumento9 pagineReadmewatzzupNessuna valutazione finora

- Nauticus 3D BeamDocumento114 pagineNauticus 3D BeamMinca AndreiNessuna valutazione finora

- Bolts TheoryDocumento30 pagineBolts TheoryIbrahim Mesfin100% (1)

- How To Draw and Read Line Diagrams Onboard Ships?: ShareDocumento9 pagineHow To Draw and Read Line Diagrams Onboard Ships?: ShareShaif uddin rifatNessuna valutazione finora

- STK412 150 Sanyo PDFDocumento4 pagineSTK412 150 Sanyo PDFroger.Nessuna valutazione finora

- Steering Wheel Slip - Check: Pruebas y AjustesDocumento2 pagineSteering Wheel Slip - Check: Pruebas y AjustesLENIN JHAIR VALDERRAMA SEGURANessuna valutazione finora

- AA Holtz & Kovacs - An Introduction To Geotechnical Engineering PDFDocumento746 pagineAA Holtz & Kovacs - An Introduction To Geotechnical Engineering PDFPeterNessuna valutazione finora

- Module 3 Density Altitude ExperimentDocumento3 pagineModule 3 Density Altitude ExperimentIvan100% (1)

- Corrosion of Stainless SteelsDocumento5 pagineCorrosion of Stainless Steelsparasite0167% (3)

- Nirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVDocumento2 pagineNirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVKartik aminNessuna valutazione finora

- Chapter5 Memory ManagementDocumento78 pagineChapter5 Memory ManagementJackYuan JinFengNessuna valutazione finora

- Cost BreakdownDocumento241 pagineCost Breakdownbilisuma sebokaNessuna valutazione finora

- Sandvik: 11/2019 PME F Additional Comments For Hydrabolt Option & HH200Documento1 paginaSandvik: 11/2019 PME F Additional Comments For Hydrabolt Option & HH200Elber Luis Chavez BarriosNessuna valutazione finora

- Scope: Ferritic Heat-Resistant Steel TK 1.4762Documento5 pagineScope: Ferritic Heat-Resistant Steel TK 1.4762Siis IngenieriaNessuna valutazione finora

- Ghorbani - AlfalfaDocumento7 pagineGhorbani - AlfalfaarizalNessuna valutazione finora

- WaterproofingDocumento29 pagineWaterproofingAakansha DNessuna valutazione finora

- FM Approvals CN 1613Documento0 pagineFM Approvals CN 1613Marcelo PeixotoNessuna valutazione finora

- E4-E5 CM (3G Operational Issues)Documento42 pagineE4-E5 CM (3G Operational Issues)VIKAS NIGAMNessuna valutazione finora

- Business Plan On Plastic Recycling & ManufacturingDocumento19 pagineBusiness Plan On Plastic Recycling & ManufacturingSah Sanjiv KumarNessuna valutazione finora

- TN 1473Documento63 pagineTN 1473Meisam TabrizNessuna valutazione finora