Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Maharashtra State Board of Technical Education

Caricato da

Pramod Dhaigude0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

12 visualizzazioni3 pagineThis document contains a teaching plan for a course on Advanced Manufacturing Processes (AMP) covering 5 chapters over 48 hours. The plan lists the topics to be covered in each chapter, the allocated time, the teaching methods to be used including lectures, demonstrations, assignments, and the dates of commencement and completion for each chapter. References for the course include textbooks on workshop technology, production technology and manufacturing processes. Other references include instructor notes, YouTube videos, and online resources.

Descrizione originale:

79

Titolo originale

TP AMP

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document contains a teaching plan for a course on Advanced Manufacturing Processes (AMP) covering 5 chapters over 48 hours. The plan lists the topics to be covered in each chapter, the allocated time, the teaching methods to be used including lectures, demonstrations, assignments, and the dates of commencement and completion for each chapter. References for the course include textbooks on workshop technology, production technology and manufacturing processes. Other references include instructor notes, YouTube videos, and online resources.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

12 visualizzazioni3 pagineMaharashtra State Board of Technical Education

Caricato da

Pramod DhaigudeThis document contains a teaching plan for a course on Advanced Manufacturing Processes (AMP) covering 5 chapters over 48 hours. The plan lists the topics to be covered in each chapter, the allocated time, the teaching methods to be used including lectures, demonstrations, assignments, and the dates of commencement and completion for each chapter. References for the course include textbooks on workshop technology, production technology and manufacturing processes. Other references include instructor notes, YouTube videos, and online resources.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

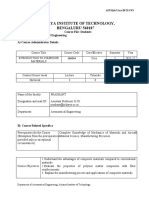

Maharashtra State Board of Technical Education D–1

TEACHING PLAN (TP)

Institute Code :0038 Probable Hrs. : 48

Course and Code : AE4E Academic Year : 2012-2013 Subject Code: AMP (12100)

Semester : Fourth Name of Faculty : Dhaigude.P.B.

Chapter No. Allocated Hrs Date of Commencing Date of Completion Teaching Method/

Title/Details Remarks

(Total Hrs.) In Curriculum Of Topic of Topic Media

Chalk, Blackboard,

1.1 Forgeable materials and Forgeability. 60 min Conventional, chalk

1.2 Advantages and limitations of forging 150 min and board, Answering

process. questions, feedback,

1(06) 1.3 Classification of forging processes. 19/12/12 28/12/12

OHP, LCD Video cd’s

1.4 Hand tools 60 min Reference books,

1.5 Forging sequences for connecting rods, 60 min giving assignments etc.

crankshafts, camshafts, spanners and gears. 60 min

Chalk, Blackboard,

2.1 Materials used in press work. 180min Conventional, chalk

2.2 Classifications of presses. 03 hr and board, Answering

2.3 Parts of standard die set. 180min questions, feedback,

2.4 Die accessories- Pilots, Stops, Strippers, 03 hr OHP, LCD Video cd’s

2(12) Pressure pads & Knock outs

02/01/13 23/01/13

Reference books,

2.5 Types and construction of dies—Simple, 180min giving assignments

progressive, compound and combination die.

2.6 Press operations with sketches 03 hr

2.7 Press components used in automobiles. 180min

Chalk, Blackboard,

3.1 Classification of welding process. 60 min Conventional, chalk

3.2 Working principle of Gas welding and 60min and board, Answering

types of flames. questions, feedback,

3(08) 3.3 Arc welding process like metal arc, TIG 120min

06/03/13 15/03/13

OHP, LCD Video cd’s

3.4 Resistance welding (spot, projection, seam 60min Reference books,

3.5 Brazing and soldering. 60min giving assignments etc.

Chalk, Blackboard,

4.1 Introduction 60 min Conventional, chalk

4.2 Surface cleaning process (acid, alkaline, 60min and board, Answering

electrolytic cleaning, blasting and tumbling. questions, feedback,

4(04) 4.3 Metallic surface coating(Electroplating, 120min 20/3/13 22/03/13 OHP, LCD Video cd’s

Galvanizing and metal spraying) Reference books, etc.

4.4 Selection and use of finishing process. 60min

4.5 Surface finishing processes (Lapping, 60min

honing, super finishing, buffing, burnishing.)

Chalk, Blackboard,

5.1 NC, CNC and DNC machines. 07 hr Conventional, chalk

5.2 Classifications of CNC machines. 60 min and board, Answering

5.3 Advantages and disadvantages of CNC 60 min questions, feedback,

5.4 Co-ordinate system- Absolute and 150min OHP, LCD Video cd’s

Incremental Reference books,

5(18) 5.5 Axes identification- X, Y and Z axes. 150 min 23/02/13 06/03/12 giving assignments etc.

5.6 Procedure for developing the Part pro. 05 hr

5.7 ISO Codes used in programming. 150min

5.8 Structure (Format) – Block and part pro 150 min

5.9 Simple Part programming as per ISO codes 150 min

on CNC &VMC for operations like turning,

drilling and milling

( Name & signature of HOD ) ( Name & signature of Faculty )

Shaha. S.R. Dhaigude. P.B.

REFERENCES:

Sr. No Author Title Publisher & Address

S. K. Hajra Choudhury. Elements of Workshop Media Promoters &

1

A. K. Hajra Choudhury Technology Vol. - I & II Publishers

2 H. S. Bawa Workshop Technology Vol. - I & II. Tata McGraw-Hill Publishing

3 R. K. Jain Production technology Khanna Publishers.Delhi.

Workshop Technology ELBS & Edward Arnold

4 Dr. W. A. J. Chapman

Part- I, II & III ( Publishers ) Ltd., London

B. H. Amstead, Phillip

5 Manufacturing Processes John Wiley & Sons

Ostwald, Myronl Begeman.

6 H.M.T. Production Technology H.M.T.

7 B.S.Raghuwanshi Workshop Technology Vol. - I & II. Dhanpat Rai & Co.

OTHER REFERENCES:

REFERENCES 1: Self Notes

REFERENCES 2: Youtube.com

REFERENCES 2: Internet

Potrebbero piacerti anche

- Institute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Documento3 pagineInstitute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Pramod DhaigudeNessuna valutazione finora

- Ae404eDocumento7 pagineAe404eVijay KumbharNessuna valutazione finora

- EDGLTPDocumento4 pagineEDGLTPpramod dhaigudeNessuna valutazione finora

- Introduction To Digital Audio ProcessingDocumento8 pagineIntroduction To Digital Audio ProcessingVictor BaezaNessuna valutazione finora

- Cert AUTOCADDocumento1 paginaCert AUTOCADviplove6708Nessuna valutazione finora

- 8D Report of Urea Tank For Pump Welding Leakage IssueDocumento122 pagine8D Report of Urea Tank For Pump Welding Leakage IssueAvinash NikamNessuna valutazione finora

- Pilani Campus: Practice, EDD, BITS PilaniDocumento3 paginePilani Campus: Practice, EDD, BITS PilaniRitik GuptaNessuna valutazione finora

- Pujo DeliverablesDocumento3 paginePujo Deliverablesvermar6875Nessuna valutazione finora

- Metal CuttingDocumento131 pagineMetal CuttingFRANCIS THOMASNessuna valutazione finora

- FurnaceSeminar4 PDFDocumento2 pagineFurnaceSeminar4 PDFframon.chem35Nessuna valutazione finora

- Radiant Coil (2) Emissions Round Table Discussions: Linde AGDocumento2 pagineRadiant Coil (2) Emissions Round Table Discussions: Linde AGframon.chem35Nessuna valutazione finora

- Technical University of ChemnitzDocumento4 pagineTechnical University of ChemnitzMohd Rashid JaafarNessuna valutazione finora

- SR AO Building PDFDocumento11 pagineSR AO Building PDFAmit Kumar PandeyNessuna valutazione finora

- Introduction To Open Hole LoggingDocumento277 pagineIntroduction To Open Hole LoggingKean PerezNessuna valutazione finora

- Split Up Practical For S2-JrDocumento7 pagineSplit Up Practical For S2-JrDijesh PunathilNessuna valutazione finora

- Basic Boiler Engineering Drawing Schedule & Topics (Paper-03)Documento2 pagineBasic Boiler Engineering Drawing Schedule & Topics (Paper-03)LamheNessuna valutazione finora

- 2023 CSC ExaminationDocumento44 pagine2023 CSC ExaminationalegbeesiNessuna valutazione finora

- Dental Lab - TechnicanDocumento6 pagineDental Lab - Technicangaurav chauhanNessuna valutazione finora

- BITSF110 Course HandoutDocumento3 pagineBITSF110 Course HandoutultimateNessuna valutazione finora

- MPR-1 2Documento7 pagineMPR-1 2pradipd4271Nessuna valutazione finora

- A Microphone Array System For Speech Source Localization, Denoising, and DereverberationDocumento163 pagineA Microphone Array System For Speech Source Localization, Denoising, and DereverberationDr. Rizwan UllahNessuna valutazione finora

- Toc ADocumento4 pagineToc AIndrajit SonawaneNessuna valutazione finora

- متطلبات تخصص الصيانة الكهروميكانيكة العامةDocumento68 pagineمتطلبات تخصص الصيانة الكهروميكانيكة العامةibraheemNessuna valutazione finora

- Sri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 6Documento6 pagineSri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 6Ʀoʛeʀ Ɩeo ƖɩbɩŋNessuna valutazione finora

- 2ND RRLDocumento7 pagine2ND RRLTristan Tabago ConsolacionNessuna valutazione finora

- Metal Cutting TrainingDocumento13 pagineMetal Cutting Trainingநளின் கான்Nessuna valutazione finora

- PMC ModuleDocumento91 paginePMC ModuleAbdi ZerihunNessuna valutazione finora

- Coconut Oil As Cutting FluidDocumento6 pagineCoconut Oil As Cutting FluidYusuf Aliyu UNessuna valutazione finora

- Metal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyDocumento4 pagineMetal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyFikadu EshetuNessuna valutazione finora

- Course HandoutDocumento3 pagineCourse HandoutDharaniChintaNessuna valutazione finora

- Project Timeline: Phase 1: Preparation Phase 2: StudyingDocumento2 pagineProject Timeline: Phase 1: Preparation Phase 2: StudyingGazzara WorldNessuna valutazione finora

- Non Conventional PDFDocumento5 pagineNon Conventional PDFRavichandran GNessuna valutazione finora

- Algorythm Analysis1Documento2 pagineAlgorythm Analysis1Rubiya KhadkaNessuna valutazione finora

- Course File - Introduction To Composite MaterialsDocumento9 pagineCourse File - Introduction To Composite MaterialsAmarNessuna valutazione finora

- Tatyasaheb Kore Institute of Engineering and Technology, Warananagar. Quality Manual - Level IIIDocumento2 pagineTatyasaheb Kore Institute of Engineering and Technology, Warananagar. Quality Manual - Level IIIpallavimamNessuna valutazione finora

- MCE 538 enDocumento1 paginaMCE 538 enاحمدالاغبريNessuna valutazione finora

- Thesis - An Acoustic Foundation For A Fully-Coupled Aeroelastic and Aeroacoustic Phonation Model Using OpenFOAMDocumento116 pagineThesis - An Acoustic Foundation For A Fully-Coupled Aeroelastic and Aeroacoustic Phonation Model Using OpenFOAMFurkan KesimNessuna valutazione finora

- 15EI403J-image-processing Lab-Manual PDFDocumento58 pagine15EI403J-image-processing Lab-Manual PDFHimanka Sekhar MondalNessuna valutazione finora

- BTU-B520-QMP-PR-025 Coating & Repair Coating For Welding Area (Outside) of Steel Box GirderDocumento15 pagineBTU-B520-QMP-PR-025 Coating & Repair Coating For Welding Area (Outside) of Steel Box GirderramdhaniNessuna valutazione finora

- 1.10 Practice ProblemsDocumento5 pagine1.10 Practice ProblemsBen GuhmanNessuna valutazione finora

- Production TechniquesDocumento2 pagineProduction TechniquesVELUGUBANTLA AALAPNessuna valutazione finora

- CHAPTER III (Peping)Documento8 pagineCHAPTER III (Peping)Jhon Ciryl M. CalayNessuna valutazione finora

- Drum Machine VSTDocumento51 pagineDrum Machine VSTIstok JugNessuna valutazione finora

- Manufacturing ProcessDocumento3 pagineManufacturing ProcessSatyam PatelNessuna valutazione finora

- 2 0 Paper - 1246 MADMDocumento16 pagine2 0 Paper - 1246 MADMputtaNessuna valutazione finora

- Mini ProjectDocumento16 pagineMini Projecthemalatha balasubramanianNessuna valutazione finora

- Carpenter 3 Month 2Documento17 pagineCarpenter 3 Month 2Kishore Kumar100% (1)

- Prestressed Concrete Naaman PDFDocumento1.108 paginePrestressed Concrete Naaman PDFCamille G67% (12)

- Xenakis' Psappha: V Ictor Ad AnDocumento53 pagineXenakis' Psappha: V Ictor Ad Anpili catenaNessuna valutazione finora

- Headbands FlammabilityDocumento2 pagineHeadbands FlammabilitymanitsiNessuna valutazione finora

- Automata Theory: José Anastacio Hernández SaldañaDocumento4 pagineAutomata Theory: José Anastacio Hernández SaldañaMilton Alfonso Gomez GonzalezNessuna valutazione finora

- Satin User GuideDocumento55 pagineSatin User GuideAaron SmithNessuna valutazione finora

- Spin Plan & Report by Group 3 - 20231110 - 112237 - 0000Documento15 pagineSpin Plan & Report by Group 3 - 20231110 - 112237 - 0000Zea LiselaNessuna valutazione finora

- Donner Company: Professor Ganesh JanakiramanDocumento36 pagineDonner Company: Professor Ganesh JanakiramanHarshaVardhan Reddy MNessuna valutazione finora

- Basics of Printing ProcessessDocumento4 pagineBasics of Printing ProcessessSarath SachuNessuna valutazione finora

- CS425 Audio and Speech Processing - Hodgkinson - 2012Documento106 pagineCS425 Audio and Speech Processing - Hodgkinson - 2012Dương QuáNessuna valutazione finora

- Project FINALDocumento3 pagineProject FINALMary Hazel Sarto, V.Nessuna valutazione finora

- SESG3024 T05 Casting PDFDocumento28 pagineSESG3024 T05 Casting PDF3220355Nessuna valutazione finora

- MX-6500N, MX-7500N Technical Handy GuideDocumento68 pagineMX-6500N, MX-7500N Technical Handy GuideDoicho AndonovNessuna valutazione finora

- Chapter-1: Savitribai Phule Pune UniversityDocumento68 pagineChapter-1: Savitribai Phule Pune UniversityPramod DhaigudeNessuna valutazione finora

- Naresh SynopsisDocumento8 pagineNaresh SynopsisPramod DhaigudeNessuna valutazione finora

- Total Marks Out of (10 X No - of Expt.) PA Marks of Practical Converted According To T.E. Scheme (Max. Marks.)Documento22 pagineTotal Marks Out of (10 X No - of Expt.) PA Marks of Practical Converted According To T.E. Scheme (Max. Marks.)Pramod DhaigudeNessuna valutazione finora

- SDGSDGDocumento34 pagineSDGSDGPramod DhaigudeNessuna valutazione finora

- WefDocumento60 pagineWefPramod DhaigudeNessuna valutazione finora

- D3a Ae4iDocumento1 paginaD3a Ae4iPramod DhaigudeNessuna valutazione finora

- Acknowledgement: Prof. (DR.) S. S. Patil, Head, Department of Mechanical Engineering, SVPM's CollegeDocumento8 pagineAcknowledgement: Prof. (DR.) S. S. Patil, Head, Department of Mechanical Engineering, SVPM's CollegePramod DhaigudeNessuna valutazione finora

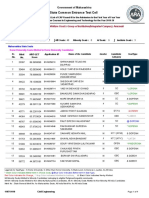

- State Common Entrance Test Cell: 1101 Shri Sant Gajanan Maharaj College of Engineering, ShegaonDocumento28 pagineState Common Entrance Test Cell: 1101 Shri Sant Gajanan Maharaj College of Engineering, ShegaonPramod DhaigudeNessuna valutazione finora

- "Design Analysis and Weight Optimization of Gudgeon Pin": College of Engineering, Malegaon (BK.)Documento3 pagine"Design Analysis and Weight Optimization of Gudgeon Pin": College of Engineering, Malegaon (BK.)Pramod DhaigudeNessuna valutazione finora

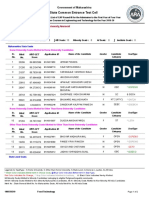

- State Common Entrance Test Cell: 1105 Prof. Ram Meghe Institute of Technology & Research, AmravatiDocumento60 pagineState Common Entrance Test Cell: 1105 Prof. Ram Meghe Institute of Technology & Research, AmravatiPramod DhaigudeNessuna valutazione finora

- State Common Entrance Test Cell: 1101 Shri Sant Gajanan Maharaj College of Engineering, ShegaonDocumento28 pagineState Common Entrance Test Cell: 1101 Shri Sant Gajanan Maharaj College of Engineering, ShegaonPramod DhaigudeNessuna valutazione finora

- 52 EfsdfDocumento34 pagine52 EfsdfPramod DhaigudeNessuna valutazione finora

- State Common Entrance Test Cell: 1005 Sant Gadge Baba Amravati University, AmravatiDocumento16 pagineState Common Entrance Test Cell: 1005 Sant Gadge Baba Amravati University, AmravatiPramod DhaigudeNessuna valutazione finora

- Capr-Iii En1002 PDFDocumento39 pagineCapr-Iii En1002 PDFPramod DhaigudeNessuna valutazione finora

- Lva1 App6891 PDFDocumento94 pagineLva1 App6891 PDFPramod DhaigudeNessuna valutazione finora

- State Common Entrance Test Cell: 1005 Sant Gadge Baba Amravati University, AmravatiDocumento16 pagineState Common Entrance Test Cell: 1005 Sant Gadge Baba Amravati University, AmravatiPramod DhaigudeNessuna valutazione finora

- State Common Entrance Test Cell: 1002 Government College of Engineering, AmravatiDocumento40 pagineState Common Entrance Test Cell: 1002 Government College of Engineering, AmravatiPramod DhaigudeNessuna valutazione finora

- QweDocumento40 pagineQwePramod DhaigudeNessuna valutazione finora

- Automobile Drag CoefficientsDocumento5 pagineAutomobile Drag CoefficientsPramod DhaigudeNessuna valutazione finora

- RWDocumento29 pagineRWPramod DhaigudeNessuna valutazione finora

- 8.1 Influence Coefficient Method: Are Static Forces On Discs 1, 2,, N Respectively, and X, X Are TheDocumento4 pagine8.1 Influence Coefficient Method: Are Static Forces On Discs 1, 2,, N Respectively, and X, X Are ThePramod DhaigudeNessuna valutazione finora

- State Common Entrance Test CellDocumento35 pagineState Common Entrance Test CellPramod DhaigudeNessuna valutazione finora

- An Overview of Buckling Analysis of Cylinder Subjected To Axially Compressive LoadDocumento5 pagineAn Overview of Buckling Analysis of Cylinder Subjected To Axially Compressive LoadPramod DhaigudeNessuna valutazione finora

- Advantages of FFT Spectrum Analyzer TechnologyDocumento2 pagineAdvantages of FFT Spectrum Analyzer TechnologyPramod DhaigudeNessuna valutazione finora

- In Situ BalancingDocumento1 paginaIn Situ BalancingPramod DhaigudeNessuna valutazione finora

- Cross Power Spectral Density: Z T Which Is Sum of Two Real Jointly WSS Random ProcessesDocumento8 pagineCross Power Spectral Density: Z T Which Is Sum of Two Real Jointly WSS Random ProcessesPramod DhaigudeNessuna valutazione finora

- Types of Drag On AircraftDocumento20 pagineTypes of Drag On AircraftPramod DhaigudeNessuna valutazione finora

- Difference Between Wideband Frequency Modulation and Narrowband Frequency ModulationDocumento1 paginaDifference Between Wideband Frequency Modulation and Narrowband Frequency ModulationPramod DhaigudeNessuna valutazione finora

- Difference Between Wideband Frequency Modulation and Narrowband Frequency ModulationDocumento1 paginaDifference Between Wideband Frequency Modulation and Narrowband Frequency ModulationPramod DhaigudeNessuna valutazione finora

- RWDocumento57 pagineRWPramod DhaigudeNessuna valutazione finora

- 02 Chapter 2 - Corporate Governance MechanismDocumento19 pagine02 Chapter 2 - Corporate Governance MechanismHanis ZahiraNessuna valutazione finora

- Nyamango Site Meeting 9 ReportDocumento18 pagineNyamango Site Meeting 9 ReportMbayo David GodfreyNessuna valutazione finora

- Bustax Midtem Quiz 1 Answer Key Problem SolvingDocumento2 pagineBustax Midtem Quiz 1 Answer Key Problem Solvingralph anthony macahiligNessuna valutazione finora

- VerificationManual en PDFDocumento621 pagineVerificationManual en PDFurdanetanpNessuna valutazione finora

- Instruction Manual 115cx ENGLISHDocumento72 pagineInstruction Manual 115cx ENGLISHRomanPiscraftMosqueteerNessuna valutazione finora

- Dash 3000/4000 Patient Monitor: Service ManualDocumento292 pagineDash 3000/4000 Patient Monitor: Service ManualYair CarreraNessuna valutazione finora

- Vintage Airplane - May 1982Documento24 pagineVintage Airplane - May 1982Aviation/Space History LibraryNessuna valutazione finora

- Comparitive Study of Fifty Cases of Open Pyelolithotomy and Ureterolithotomy With or Without Double J Stent InsertionDocumento4 pagineComparitive Study of Fifty Cases of Open Pyelolithotomy and Ureterolithotomy With or Without Double J Stent InsertionSuril VithalaniNessuna valutazione finora

- Physico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegDocumento9 paginePhysico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegZyuha AiniiNessuna valutazione finora

- Cocaine in Blood of Coca ChewersDocumento10 pagineCocaine in Blood of Coca ChewersKarl-GeorgNessuna valutazione finora

- Dept & Sem: Subject Name: Course Code: Unit: Prepared byDocumento75 pagineDept & Sem: Subject Name: Course Code: Unit: Prepared by474 likithkumarreddy1Nessuna valutazione finora

- Chapter 24 - The Solar SystemDocumento36 pagineChapter 24 - The Solar SystemHeather Blackwell100% (1)

- Pautas Anatómicas para La Inserción de Minitornillos: Sitios PalatinosDocumento11 paginePautas Anatómicas para La Inserción de Minitornillos: Sitios PalatinosValery V JaureguiNessuna valutazione finora

- Needle BasicsDocumento31 pagineNeedle BasicsARYAN RATHORENessuna valutazione finora

- 2001 Ford F150 ManualDocumento296 pagine2001 Ford F150 Manualerjenkins1100% (2)

- Mangement of Shipping CompaniesDocumento20 pagineMangement of Shipping CompaniesSatyam MishraNessuna valutazione finora

- Beamng DxdiagDocumento22 pagineBeamng Dxdiagsilvioluismoraes1Nessuna valutazione finora

- Slides - SARSDocumento191 pagineSlides - SARSCedric PoolNessuna valutazione finora

- Chapter 1 4Documento76 pagineChapter 1 4Sean Suing100% (1)

- Hydraulics and PneumaticsDocumento6 pagineHydraulics and PneumaticsRyo TevezNessuna valutazione finora

- Bathinda - Wikipedia, The Free EncyclopediaDocumento4 pagineBathinda - Wikipedia, The Free EncyclopediaBhuwan GargNessuna valutazione finora

- Zambia National FormularlyDocumento188 pagineZambia National FormularlyAngetile Kasanga100% (1)

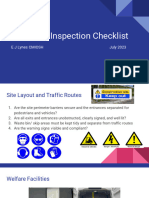

- Work Site Inspection Checklist 1Documento13 pagineWork Site Inspection Checklist 1syed hassanNessuna valutazione finora

- Durability of Prestressed Concrete StructuresDocumento12 pagineDurability of Prestressed Concrete StructuresMadura JobsNessuna valutazione finora

- EDB Postgres Failover Manager Guide v2.1Documento86 pagineEDB Postgres Failover Manager Guide v2.1Anggia MauritianaNessuna valutazione finora

- Report-Smaw Group 12,13,14Documento115 pagineReport-Smaw Group 12,13,14Yingying MimayNessuna valutazione finora

- Marieb ch3dDocumento20 pagineMarieb ch3dapi-229554503Nessuna valutazione finora

- Assessment 4 PDFDocumento10 pagineAssessment 4 PDFAboud Hawrechz MacalilayNessuna valutazione finora

- Furnace Temperature & PCE ConesDocumento3 pagineFurnace Temperature & PCE ConesAbdullrahman Alzahrani100% (1)

- Icici PrudentialDocumento52 pagineIcici PrudentialDeepak DevaniNessuna valutazione finora