Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fix-Z-A4 Stainless Steel Design Guide

Caricato da

dineshCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fix-Z-A4 Stainless Steel Design Guide

Caricato da

dineshCopyright:

Formati disponibili

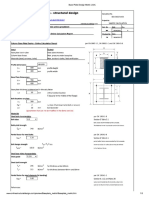

Fix Z - A4

Stainless Steel 1/4

¬ Torque controlled expansion anchor, made of

stainless steel for use in cracked and non cracked

European Technical Approval concrete

ETA Option 1

n° 04/0010 Technical data

SPIT

FIX Z A4 Minimum anchor depth Maximum anchor depth

Min. Depth Max thick Drilling. Min thick Max. Depth Max thick Driling Min thick Ø Ø drill Ø clear Total Max Eurocode

Letter marking

a nchor before of part to Depth of base anchor before of part to Depth of base thread bit ance anchor tighten

depth e xpans be fixed material depth expans be fixed material length torque

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm)

hef,min hnom tfix ho hmin hef,max hnom tfix ho hmin d dO df L Tinst

M6x55/15* - 25,6 35 15 41 100 35 45 5 51 100 6 6 8 55 10 054270

M8x55/5 - 5 - 55 050441

M8x70/20-7 C 35 42 20 52 100 48 55 7 65 100 8 8 9 70 20 054610

M8x90/40-27 E 40 27 90 055343

M8x130/80-67 H 80 67 130 050367

M10x65/5 - 5 - 65 050466

M10x75/15 C 42 50 15 62 100 58 66 - 78 100 10 10 12 75 35 054630

Pre-assembled anchor M10x95/35-20 E 35 20 95 054640

M10x120/60-45 G 60 45 120 050442

M12x80/5 - 5 - 80 055344

Applications M12x100/25-6 E 50 60 25 75 100 70 80 6 95 140 12 12 14 100 50 055345

M12x115/40-21 G 40 21 115 055346

¬ Steel and timber framework M12x140/65-46 I 65 46 140 054680

and beams M16x125/30-8 G 30 8 125 050443

¬ Lift guide rails M16x150/55-33 I 64 70 55 95 128 86 100 33 117 172 16 16 18 150 100 054700

M16x170/75-53 K 75 53 170 050444

¬ Industrial doors and gates

¬ Brickwork support angles * Does not conform to ETA

¬ Storage systems

Anchor mechanical properties

Material

M6 M8 M10 M12 M16

¬ Bolt M8-M16: Cross-section above cone

Steel n°1.4404 (A4), 1.4578, fuk (N/mm2) Min. tensile strength 900 900 900 900 880

NF EN 10088.3 fyk(N/mm2) Yield strength 780 780 780 780 750

¬ Sleeve: Steel n°1.4404 cold As (mm2) Stressed cross-section 24,6 41,9 58,1 107,5

laminated, NF EN 10088.3 Threaded part

¬ Washer: Stainless Steel A4, fuk (N/mm2) Min. tensile strength 620 620 620 620 580

NF EN 20898 fyk(N/mm2) Yield strength 420 420 420 420 330

As (mm2) Stressed cross-section 20,1 36,6 58 84,3 157

¬ Hexagonal nut: Stainless Steel Wel (mm3) Elastic section modulus 12,71 31,23 62,3 109,17 277,47

A4-80, NF EN 20898-2 M0Rk,s (Nm) Characteristic bending moment 9,45 23 46 81 193

M (Nm) Recommended bending moment 3,7 9,4 18,8 33,1 78,8

Installation

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Fix Z - A4

Stainless Steel 2/4

The loads specified on this page are derived from internal test results. For results derived from CC Methodology, please see overleaf.

The data given in the pages “CC - Method” have to be applied.

Ultimate (NRu,m, VRu,m) / characteristic loads (NRk, VRk) in kN

Mean Ultimate loads are derived from test results in admissible service conditions, and characteristic loads are statistically determined.

TENSILE SHEAR

Anchor size M6 M8 M10 M12 M16 Anchor size M6 M8 M10 M12 M16

Non cracked concrete Cracked and non-cracked concrete

hef,min 25,6 35 42 50 64 VRu,m 7,4 18,2 29,2 43,2 69,1

NRu,m 6,0 12,5 13,3 20,1 33,1 VRk 6,2 17,3 25 36,1 51,3

NRk 4,5 8,0 9,9 13,6 24,1

hef,max 35 48 58 70 86

NRu,m 9,4 22,0 23,0 26,3 53,6

NRk 7,0 17,2 19,2 25,1 44,1

Cracked concrete

hef,min - 35 42 50 64

NRu,m - 12,5 13,1 18,6 29,6

NRk - 7,5 9,1 14,2 24,8

hef,max - 48 58 70 86

NRu,m - 15,9 20,3 29,2 54,2

NRk - 14,7 18,8 27,0 49,5

Design Loads (NRd, VRd) for one anchor without edge or spacing influence in kN

N Rk * VRk *

N Rd = VRd =

γ Mc γ Ms

*Derived from test results

TENSILE SHEAR

Anchor size M6 M8 M10 M12 M16 Anchor size M6 M8 M10 M12 M16

Non cracked concrete Cracked and non-cracked concrete

hef,min 25,6 35 42 50 64 VRd 4,1 11,5 16,7 24,1 28,5

NRd 2,5 5,3 6,6 9,1 16,1 γMs = 1,5 for M8 to M12 and γMs = 1,8 for M16

hef,max 35 48 58 70 86

NRd 3,8 11,5 12,8 14,3 29,4

Cracked concrete

hef,min - 35 42 50 64

NRd - 5,0 6,1 9,5 16,5

hef,max - 48 58 70 86

NRd - 9,8 12,5 18,0 33,0

γMc = 1,5

Recommended loads (Nrec, Vrec) for one anchor without edge or spacing influence in kN

N Rk * VRk *

N Rec = VRec =

γ Mγ F γ M .γ F

*Derived from test results

TENSILE SHEAR

Anchor size M6 M8 M10 M12 M16 Anchor size M6 M8 M10 M12 M16

Non cracked concrete Cracked and non-cracked concrete

hef,min 25,6 35 42 50 64 VRec 2,9 8,2 11,9 17,2 20,4

NRec 1,7 3,8 4,7 6,5 11,5 γMs = 1,5 for M8 to M12 and γMs = 1,8 for M16

hef,max 35 48 58 70 86

NRec 2,7 8,2 9,1 10,2 21,0

Cracked concrete

hef,min - 35 42 50 64

NRec - 3,6 4,3 6,8 11,8

hef,max - 48 58 70 86

NRec - 7,0 9,0 12,8 23,6

γF = 1,4 ; γMc = 1,5

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Fix Z - A4

Stainless Steel 3/4

SPIT CC - Method (values issued from ETA)

TENSILE in kN SHEAR in kN

¬ Pull-out resistance ¬ Concrete edge resistance

VRd,c = VRd

O

,c .fb .fβ ,V .ΨS − C ,V

N Rd,p = N ORd , p .fb

V0Rd,c Design concrete edge resistance

at minimum edge distance (Cmin)

N0Rd,p Design pull-out resistance Anchor size M8 M10 M12 M16

Anchor size M8 M10 M12 M16

Minimum anchorage depth

hef,min 35 42 50 64 hef 35 42 50 64

hef,max 48 58 70 86 Cmin 60 65 100 100

Non cracked concrete (C20/25) Smin 60 75 170 150

N0Rd,p (hef,min) 6,0 6,0 8,0 13,3 V0Rd,c (C20/25) 3,3 4,1 8,7 10,1

N0Rd,p (hef,max) 8,0 10,7 10,7 20,0 Maximum anchorage depth

Cracked concrete (C20/25) hef 48 58 70 86

N0Rd,p (hef,min) 2,0 4,0 5,0 8,0 Cmin 60 65 90 105

N0Rd,p (hef,max) 2,7 5,0 6,0 10,7 Smin 50 55 75 90

γMc = 1,5 V0Rd,c (C20/25) 3,7 4,4 8,2 11,8

γMc = 1,5

¬ Concrete cone resistance

N Rd,c = N ORd ,c .fb .Ψs .Ψc, N ¬ Pryout failure

0

VRd,cp = VRd ,cp .fb .Ψs .Ψc, N

N0Rd,c Design cone resistance V0Rd,cp Design pryout resistance

Anchor size M8 M10 M12 M16 Anchor size M8 M10 M12 M16

hef,min 35 42 50 64 Non cracked concrete

hef,max 48 58 70 86 hef min 35 42 50 64

Non cracked concrete (C20/25) V0Rd,cp (C20/25) 7,0 9,1 11,9 34,4

N0Rd,c (hef,min) 7,0 9,1 11,9 17,2 hef max 48 58 70 86

N0Rd,c (hef,max) 11,2 14,8 19,7 26,8 V0Rd,cp (C20/25) 11,2 14,8 39,4 53,6

Cracked concrete (C20/25) Cracked concrete

N0Rd,c (hef,min) 5,0 6,5 8,5 12,3 hef min 35 42 50 64

N0Rd,c (hef,max) 8,0 10,6 14,1 19,1 V0Rd,cp (C20/25) 5,0 6,5 8,5 24,6

γMc = 1,5 hef max 48 58 70 86

V0Rd,cp (C20/25) 8,0 10,6 28,1 38,3

γMcp = 1,5

¬ Steel resistance

¬ Steel resistance

NRd,s Design steel tensile resistance VRd,s Design steel shear resistance

Anchor size M8 M10 M12 M16 Anchor size M8 M10 M12 M16

NRd,s 8,5 14,4 20,0 29,7 Minimum anchorage depth

γMs = 1,8 for M8 to M12 and γMs = 2,1 for M16 VRd,s 7,5 12,0 17,4 25,3

γMs = 1,5 for M8 to M12 and γMs = 1,8 for M16

NRd = min(NRd,p ; NRd,c ; NRd,s) VRd = min(VRd,c ; VRd,cp ; VRd,s)

βN = NSd / NRd ≤ 1 βV = VSd / VRd ≤ 1

βN + βV ≤ 1.2

fB Influence of Concrete fβ,V Influence of Shear Loading Direction

Concrete class fB Concrete class fB Angle β [°] fβ,V

C25/30 1,1 C40/50 1,41 0 to 55 1

C30/37 1,22 C45/55 1,48 60 1.1

C35/45 1,34 C50/60 1,55 70 1.2

80 1.5

90 to 180 2

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Fix Z - A4

Stainless Steel 4/4

SPIT CC - Method (values issued from ETA)

Ψs Influence of spacing for concrete cone resistance in tensile load

spacing S Factor Ψs spacing S Factor Ψs

Minimum anchorage depth Maximum anchorage depth

M8 M10 M12 M16 M8 M10 M12 M16

60 0,78 50 0,67

75 0,86 0,80 55 0,69 0,66

100 0,98 0,90 0,83 0,76 75 0,76 0,72 0,68

105 1,00 0,92 0,85 0,77 90 0,81 0,76 0,71 0,67

s

ΨS = 0, 5 + 110 0,94 0,87 0,79 110 0,88 0,82 0,76 0,71

6.hef 125 1,00 0,92 0,83 130 0,95 0,87 0,81 0,75

150 1,00 0,89 145 1,00 0,92 0,85 0,78

Smin < S < Scr,N 170 0,94 155 0,95 0,87 0,80

Scr,N = 3.hef

192 1,00 175 1,00 0,92 0,84

ΨS must be used for each spacing

influenced the anchors group. 205 0,99 0,90

210 1,00 0,91

258 1,00

Ψc,N Influence of edge for concrete cone resistance in tensile load

EDGE C Factor Ψc,N EDGE C Factor Ψc,N

Minimum anchorage depth Maximum anchorage depth

M8 M10 M12 M16 M8 M10 M12 M16

60 1,00 60 0,91

65 1,00 65 0,95 0,91

100 1,00 72 1,00 0,96

100 1,00 80 1,00

90 0,94

105 1,00 0,90

Cmin < C < Ccr,N

130 1,00

Ccr,N = 1,5.hef

Ψc,N must be used for each distance

influenced the anchors group.

Ψs-c,V Influence of spacing and edge distance for concrete edge resistance in shear load

¬

For single anchor fastening Factor Ψs-c,V

Non-cracked concrete

C 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2

Cmin

Ψs-c,V 1,00 1,31 1,66 2,02 2,41 2,83 3,26 3,72 4,19 4,69 5,20 5,72

Ψs − c,V c c

¬ For 2 anchors Factor Ψs-c,V

= . Non-cracked concrete

cmin cmin C

Cmin

S

1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2

Cmin

1,0 0,67 0,84 1,03 1,22 1,43 1,65 1,88 2,12 2,36 2,62 2,89 3,16

1,5 0,75 0,93 1,12 1,33 1,54 1,77 2,00 2,25 2,50 2,76 3,03 3,31

2,0 0,83 1,02 1,22 1,43 1,65 1,89 2,12 2,38 2,63 2,90 3,18 3,46

2,5 0,92 1,11 1,32 1,54 1,77 2,00 2,25 2,50 2,77 3,04 3,32 3,61

3,0 1,00 1,20 1,42 1,64 1,88 2,12 2,37 2,63 2,90 3,18 3,46 3,76

Ψs − c,V 3.c + s c 3,5 1,30 1,52 1,75 1,99 2,24 2,50 2,76 3,04 3,32 3,61 3,91

= .

6.cmin cmin

4,0

4,5

1,62 1,86 2,10

1,96 2,21

2,36

2,47

2,62

2,74

2,89

3,02

3,17

3,31

3,46

3,60

3,75

3,90

4,05

4,20

5,0 2,33 2,59 2,87 3,15 3,44 3,74 4,04 4,35

5,5 2,71 2,99 3,28 3,71 4,02 4,33 4,65

6,0 2,83 3,11 3,41 3,71 4,02 4,33 4,65

¬ For 3 anchors or more

3.c + s1 + s2 + s3 + ... + sn −1 c

Ψs − c,V = .

3nc c

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Potrebbero piacerti anche

- SPIT Fix-II Zinc CoatedDocumento4 pagineSPIT Fix-II Zinc CoatedAhmed SakrNessuna valutazione finora

- m2 and m2-C ThroughboltDocumento7 paginem2 and m2-C ThroughboltAmir ElkassasNessuna valutazione finora

- S.S. A4 m1tr Throughbolt TDS - MungoDocumento7 pagineS.S. A4 m1tr Throughbolt TDS - MungoMohammed AnwarNessuna valutazione finora

- Spit Epomax: Zinc Coated Steel (Standard Anchorage)Documento12 pagineSpit Epomax: Zinc Coated Steel (Standard Anchorage)Sudhakar KrishnamurthyNessuna valutazione finora

- Torque Controlled Expansion Anchor, For Use in Cracked and Non-Cracked ConcreteDocumento6 pagineTorque Controlled Expansion Anchor, For Use in Cracked and Non-Cracked ConcreteEsraa HarazNessuna valutazione finora

- Dynabolt Zinc Coated Steel Design Guide PDFDocumento4 pagineDynabolt Zinc Coated Steel Design Guide PDFShadin Asari ArabaniNessuna valutazione finora

- Tyre Coupling With Spacer UNEFLEX SD SeriesDocumento3 pagineTyre Coupling With Spacer UNEFLEX SD SeriesGabriel MoreiraNessuna valutazione finora

- Mechanical Anchoring TruBoltDocumento3 pagineMechanical Anchoring TruBoltwokeoooNessuna valutazione finora

- EJOT-pds-sw-8-rt-4-8-EN SURUB CU CALOTA PENTRU ACOPERIS CU PROFIL TRAPEZOIDALDocumento2 pagineEJOT-pds-sw-8-rt-4-8-EN SURUB CU CALOTA PENTRU ACOPERIS CU PROFIL TRAPEZOIDALproteor_srlNessuna valutazione finora

- Rawlbolt: Shield Anchor Loose BoltDocumento2 pagineRawlbolt: Shield Anchor Loose BoltBappy IslamNessuna valutazione finora

- HILTI HST Catalogue PageDocumento2 pagineHILTI HST Catalogue PageGoutam HotaNessuna valutazione finora

- Iso7005 FlangesDocumento7 pagineIso7005 FlangesHaris StavrouNessuna valutazione finora

- DIN Flange ClassesDocumento7 pagineDIN Flange ClassesSebastián Alexander Flores OroscoNessuna valutazione finora

- Spit Multi-Max Metacrylato para Uso en Concreto No FisuradoDocumento7 pagineSpit Multi-Max Metacrylato para Uso en Concreto No FisuradoduraeduNessuna valutazione finora

- m1tr SS Anchor BoltDocumento1 paginam1tr SS Anchor BoltLeo SerasingheNessuna valutazione finora

- DIN Flange ClassesDocumento7 pagineDIN Flange ClassesAugustinNavarreteNessuna valutazione finora

- INKOMA - Shaft-Hub Connections - Polygonaxlar Enligt DIN 32711 Och DIN 32712Documento18 pagineINKOMA - Shaft-Hub Connections - Polygonaxlar Enligt DIN 32711 Och DIN 32712kristoffer_mossheden100% (1)

- TWF TozenDocumento6 pagineTWF TozenAri WibowoNessuna valutazione finora

- P14 CX Hydr NippelsDocumento11 pagineP14 CX Hydr NippelsasdfNessuna valutazione finora

- Stainless StudsDocumento4 pagineStainless StudsNestramiNessuna valutazione finora

- Installation Note: Valid For: DN Part NumberDocumento4 pagineInstallation Note: Valid For: DN Part NumberJhonny Mayo RodriguezNessuna valutazione finora

- LUKAS Compact CylindersDocumento5 pagineLUKAS Compact CylindersMilan BanovicNessuna valutazione finora

- Color Hole - Fasten Enterprises (Pte) LTD - SingaporeDocumento2 pagineColor Hole - Fasten Enterprises (Pte) LTD - SingaporeTran BdsNessuna valutazione finora

- I Ec Quick Reference Dimensional ChartDocumento2 pagineI Ec Quick Reference Dimensional ChartGamma RohkmatullohNessuna valutazione finora

- 13.-En NT Bolts UtilcellDocumento3 pagine13.-En NT Bolts Utilcellnu.arabiaNessuna valutazione finora

- Engineer's Handbook General Part: Torque Specification For Bolted ConnectionsDocumento2 pagineEngineer's Handbook General Part: Torque Specification For Bolted ConnectionsenzobvNessuna valutazione finora

- A4 - 70 Stainless Steel Hexagon Head BoltDocumento1 paginaA4 - 70 Stainless Steel Hexagon Head Boltwelding inspectorNessuna valutazione finora

- Pro 787426Documento5 paginePro 787426Mohamed ElmakkyNessuna valutazione finora

- A16 A17 CylinderDocumento7 pagineA16 A17 CylinderkarthikNessuna valutazione finora

- Disc Pack Coupling LP2Documento4 pagineDisc Pack Coupling LP2Rakesh B BalehosurNessuna valutazione finora

- Copper Tubes, Coils & Solder Fittings (Inch & Metric)Documento43 pagineCopper Tubes, Coils & Solder Fittings (Inch & Metric)dffgfdg dfgdgNessuna valutazione finora

- Wedge AnchorDocumento10 pagineWedge AnchorDoreen PohNessuna valutazione finora

- Mechanical Anchoring BoltDocumento6 pagineMechanical Anchoring BoltMani MaranNessuna valutazione finora

- Hilti Hvu HasDocumento12 pagineHilti Hvu HasAMCRUZ77Nessuna valutazione finora

- Hra Panel SpecDocumento4 pagineHra Panel SpecMuhammad Arslan Khurshid BhattiNessuna valutazione finora

- ISO Pump 50Hz Technical Data Metric UnitsDocumento29 pagineISO Pump 50Hz Technical Data Metric UnitsTimothy PopeNessuna valutazione finora

- SD II PDF - OCRDocumento18 pagineSD II PDF - OCRSuraj KumarNessuna valutazione finora

- R-KER Vinylester Resin + Steel Rods 5.8 M8 - M30: Technical Data SheetDocumento7 pagineR-KER Vinylester Resin + Steel Rods 5.8 M8 - M30: Technical Data SheetChristian LazzariniNessuna valutazione finora

- Spit Dynabolt PDFDocumento4 pagineSpit Dynabolt PDFAchmad Zaki ZulkarnainNessuna valutazione finora

- Block Roller 2Documento1 paginaBlock Roller 2Juan Ismael Grave LolNessuna valutazione finora

- Inova Ball Joints JBDocumento2 pagineInova Ball Joints JBSympatyagaNessuna valutazione finora

- Ezydek 44 Profile - DimensionsDocumento2 pagineEzydek 44 Profile - DimensionsAnirban BhattacharjeeNessuna valutazione finora

- FCU&FANSDocumento50 pagineFCU&FANSmohamad.damerly.zaidg.kaigNessuna valutazione finora

- Mhda Hollow Ceiling AnchorDocumento1 paginaMhda Hollow Ceiling AnchorMohammed AnwarNessuna valutazione finora

- A16 A17 CylinderDocumento7 pagineA16 A17 Cylinderjaneesh RNessuna valutazione finora

- Avk Butterfly Valve - Installation Instruction 820Documento5 pagineAvk Butterfly Valve - Installation Instruction 820DjapaNessuna valutazione finora

- Fixing Sytems Products-176 - INKADocumento105 pagineFixing Sytems Products-176 - INKAKhaled AbdelhamidNessuna valutazione finora

- Industry Guidelines: Metal Backing Flanges For Use With Polyethylene (Pe) Pipe Flange AdaptorsDocumento17 pagineIndustry Guidelines: Metal Backing Flanges For Use With Polyethylene (Pe) Pipe Flange AdaptorsAnthonyNessuna valutazione finora

- ChevroletDocumento22 pagineChevroletsmhaltinNessuna valutazione finora

- Fabor Fastener Wel NutDocumento4 pagineFabor Fastener Wel NutRidhwan MohamedNessuna valutazione finora

- Linde Service GuideDocumento3 pagineLinde Service GuideMário AndradeNessuna valutazione finora

- Design Guide: Unicon Qwikfoot and Qwikfix Threaded InsertsDocumento30 pagineDesign Guide: Unicon Qwikfoot and Qwikfix Threaded InsertsCora XuNessuna valutazione finora

- Belt Data Sheet - PhoenixDocumento2 pagineBelt Data Sheet - PhoenixSeshuNessuna valutazione finora

- Mooring Spare PartsDocumento1 paginaMooring Spare PartsCosmin IulianNessuna valutazione finora

- Shield Anchor Hex Bolt: Steel Yellow Zinc PlatedDocumento1 paginaShield Anchor Hex Bolt: Steel Yellow Zinc PlatedMarko KavaricNessuna valutazione finora

- HAS-E Threaded Anchor RodDocumento2 pagineHAS-E Threaded Anchor RodConifer YuNessuna valutazione finora

- Profile Products Associates Exhibitions Enquiry Contact UsDocumento1 paginaProfile Products Associates Exhibitions Enquiry Contact UsENGR 414Nessuna valutazione finora

- Parker Fitting AssemblyDocumento16 pagineParker Fitting AssemblyMechanical2022Nessuna valutazione finora

- Design of Foundation For 220 KV ElectricalDocumento7 pagineDesign of Foundation For 220 KV ElectricaldineshNessuna valutazione finora

- HDPEDocumento4 pagineHDPEdineshNessuna valutazione finora

- Edoc - Pub - Transformer Foundation DesignDocumento26 pagineEdoc - Pub - Transformer Foundation DesigndineshNessuna valutazione finora

- Redundancy of Structural Systems in The Context of Structural SafetyDocumento7 pagineRedundancy of Structural Systems in The Context of Structural SafetyNishan GajurelNessuna valutazione finora

- On The Correlation of Seismic Intensity Scale WithDocumento25 pagineOn The Correlation of Seismic Intensity Scale WithdineshNessuna valutazione finora

- 8448-Article Text-27459-1-10-20211115Documento17 pagine8448-Article Text-27459-1-10-20211115dineshNessuna valutazione finora

- Geodesy and GeodynamicsDocumento20 pagineGeodesy and GeodynamicsJoan Vega EspinozaNessuna valutazione finora

- Comparison of Seismic Risk Assessment Based On Macroseismic Intensity and S (Ectrum Approaches Using SeisVARADocumento15 pagineComparison of Seismic Risk Assessment Based On Macroseismic Intensity and S (Ectrum Approaches Using SeisVARAdharmNessuna valutazione finora

- Calculation of Seismic Protective Qualities of Dampefer and AbsorterDocumento4 pagineCalculation of Seismic Protective Qualities of Dampefer and AbsorterdineshNessuna valutazione finora

- Seismic Risk Mapping For UzbekistanDocumento20 pagineSeismic Risk Mapping For UzbekistandineshNessuna valutazione finora

- Seismic Risk Assessment of Built Environment in PakistanDocumento10 pagineSeismic Risk Assessment of Built Environment in PakistandineshNessuna valutazione finora

- Nuclear CodesDocumento4 pagineNuclear CodesdineshNessuna valutazione finora

- UNit Transformer GA DrawingDocumento3 pagineUNit Transformer GA DrawingdineshNessuna valutazione finora

- Probabilistic Seismic Hazard Analysis For YemenDocumento16 pagineProbabilistic Seismic Hazard Analysis For YemendineshNessuna valutazione finora

- Aisc Asd ParametersDocumento9 pagineAisc Asd ParametersdineshNessuna valutazione finora

- Base Plate Design Metric UnitsDocumento3 pagineBase Plate Design Metric UnitsdineshNessuna valutazione finora

- RAM Connection Standalone CE Report - 11Documento2 pagineRAM Connection Standalone CE Report - 11dineshNessuna valutazione finora

- Annexure-6 FOSROC - Lokfix & Nitobond Technical DataDocumento10 pagineAnnexure-6 FOSROC - Lokfix & Nitobond Technical DatadineshNessuna valutazione finora

- Schedule 80 Mild Steel Pipe Sizes - Dimensions - Weight and PriceDocumento10 pagineSchedule 80 Mild Steel Pipe Sizes - Dimensions - Weight and PricedineshNessuna valutazione finora

- Design Parameter EC3Documento20 pagineDesign Parameter EC3dineshNessuna valutazione finora

- Comparative Study of Diagrid Structures With and Without Corner ColumnsDocumento6 pagineComparative Study of Diagrid Structures With and Without Corner ColumnsdineshNessuna valutazione finora

- METSEC Purlins SystemsDocumento84 pagineMETSEC Purlins SystemsIvan KlyuchkaNessuna valutazione finora

- Seismic Code Developments For Steel & Composite StructuresDocumento23 pagineSeismic Code Developments For Steel & Composite StructuresdineshNessuna valutazione finora

- MSP 2018-2023 Final AdoptedDocumento28 pagineMSP 2018-2023 Final AdopteddineshNessuna valutazione finora

- BS en ISO 12944-1 2017 Paints and Varnishes-Corrosion Pro. Steel - General IntroductionDocumento18 pagineBS en ISO 12944-1 2017 Paints and Varnishes-Corrosion Pro. Steel - General Introductionssebastian8177100% (7)

- Nitobond EP2Documento4 pagineNitobond EP2Sanjeev KumarNessuna valutazione finora

- Irc 112-2019 - 06-03-2019Documento240 pagineIrc 112-2019 - 06-03-2019Varun Verma85% (20)

- Bored CIP Piles - Capacity Calculation - International Practice - Updated-1Documento13 pagineBored CIP Piles - Capacity Calculation - International Practice - Updated-1dineshNessuna valutazione finora

- Steel Design Parameter - EuroDocumento11 pagineSteel Design Parameter - EurodineshNessuna valutazione finora

- Cross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3Documento12 pagineCross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3dineshNessuna valutazione finora

- Glossary of Terms Used in Galvanizing of SteelDocumento11 pagineGlossary of Terms Used in Galvanizing of SteelMaria Ines CastelluccioNessuna valutazione finora

- Potasium Dichromate TitrationDocumento4 paginePotasium Dichromate TitrationChandran100% (1)

- Silver BrightDocumento2 pagineSilver BrightBRIGHT TECH INDUSTRIALS INDIA PVT LTDNessuna valutazione finora

- Parker O-Ring Material Guide-2008Documento72 pagineParker O-Ring Material Guide-2008Ian Pillay50% (2)

- NF LCF12 E01Documento2 pagineNF LCF12 E01Cy RamosNessuna valutazione finora

- BKC4543 Environmental EngineeringDocumento16 pagineBKC4543 Environmental EngineeringHarshini SivanganamNessuna valutazione finora

- Reviews: Chemical Recycling of Waste Plastics For New Materials ProductionDocumento11 pagineReviews: Chemical Recycling of Waste Plastics For New Materials ProductionbrianNessuna valutazione finora

- Condensate Stabilization Unit 1Documento23 pagineCondensate Stabilization Unit 1Vraja KisoriNessuna valutazione finora

- Cussons Boiler Instructon ManualDocumento32 pagineCussons Boiler Instructon Manualjakakolenk100% (1)

- SteelBook PlateDocumento9 pagineSteelBook PlatePageduesca RouelNessuna valutazione finora

- ROTOFLEXI Couplings: Operating Instruction Valid For Type G and GNDocumento8 pagineROTOFLEXI Couplings: Operating Instruction Valid For Type G and GNIzzi Al-AkbarNessuna valutazione finora

- Checklist - FFS Inlet HeaderDocumento3 pagineChecklist - FFS Inlet HeaderRamalingam PrabhakaranNessuna valutazione finora

- Buenasher Learning Academy IncDocumento4 pagineBuenasher Learning Academy IncEl CruzNessuna valutazione finora

- 2.1 (131 Marks) : MarkschemeDocumento48 pagine2.1 (131 Marks) : MarkschemeSemwezi EnockNessuna valutazione finora

- Partial Acid Number in Unsaturated Polyester Resin According To EN ISO 2114Documento2 paginePartial Acid Number in Unsaturated Polyester Resin According To EN ISO 2114Mamoon ShahidNessuna valutazione finora

- Zinc Sulfate 35 Maxi Granular Spec Sheet CCIDocumento1 paginaZinc Sulfate 35 Maxi Granular Spec Sheet CCIricko4001Nessuna valutazione finora

- Chemistry Project On Study of Diffusion of Solids in LiquidsDocumento3 pagineChemistry Project On Study of Diffusion of Solids in LiquidsAbhijith TharunNessuna valutazione finora

- 324-Chapter 1 Rock Bit Interactions PDFDocumento42 pagine324-Chapter 1 Rock Bit Interactions PDFBilge KaanNessuna valutazione finora

- Chemistry Practical Manual 2021Documento50 pagineChemistry Practical Manual 2021Jagdish PrajapatiNessuna valutazione finora

- European Steel and Alloy GradesDocumento2 pagineEuropean Steel and Alloy Gradesfarshid KarpasandNessuna valutazione finora

- 2nd Summative Test Earth and LifeDocumento3 pagine2nd Summative Test Earth and LifeJarven SaguinNessuna valutazione finora

- 212-Chpt 4Documento6 pagine212-Chpt 4zainabcomNessuna valutazione finora

- Zisman-Contact AngleDocumento51 pagineZisman-Contact AnglethuronNessuna valutazione finora

- Multiple Choice Questions emDocumento21 pagineMultiple Choice Questions emvaibhavmn100% (2)

- Boiler Boilout by RentechDocumento4 pagineBoiler Boilout by RentechRonald MesinaNessuna valutazione finora

- PlasticsDocumento21 paginePlasticsJaypee MontealegreNessuna valutazione finora

- Algerian CondensateDocumento3 pagineAlgerian CondensateibrankNessuna valutazione finora

- Class-XII Chemistry: S No Unit Portion To Be ReducedDocumento3 pagineClass-XII Chemistry: S No Unit Portion To Be ReducedShivanshu JainNessuna valutazione finora

- Questioned: Document ExaminationDocumento4 pagineQuestioned: Document ExaminationApple AsneNessuna valutazione finora