Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Customizable Table Saw Station Plans: by John Gerard From Our Home From Scratch

Caricato da

MinhTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Customizable Table Saw Station Plans: by John Gerard From Our Home From Scratch

Caricato da

MinhCopyright:

Formati disponibili

Customizable Table Saw Station Plans

by

John Gerard

from

Our Home from Scratch

Our Home from Scratch LLC Page 1

www.OurHomefromScratch.com

Disclaimer

Our Home from Scratch LLC and its legal owners cannot be held responsible for

any loss, damage, injury or death resulting from following the procedures or

techniques described in these plans. Our Home from Scratch LLC and its legal

owners assume no risk and cannot be held responsible for any misuse of these

plans either directly or indirectly. They make no statements as to the weight or

strength capacity of the item described in these plans.

These plans may contain errors and Our Home from Scratch LLC and its legal

owners cannot be held responsible for any error. No guarantee is made as to the

quality of any product that is described herein.

Always use appropriate Personal Protection Equipment when working with tools

and exercise caution if taking any action associated with these plans.

Attempt at your own risk. Some woodworking skills are required.

This procedure contains affiliate links.

Distribution Policy

By downloading these plans you consent to this distribution policy. These plans

are not to be distributed in anyway without the express consent of Our Home

from Scratch LLC or its legal owners. The individual pictures or procedures

contained herein are also not to be copied or shared.

Our Home from Scratch LLC Page 2

www.OurHomefromScratch.com

Introduction

For a lot of DIYers, spending thousands of dollars for one professional-

quality power tool is not an option. Most of us have limited budgets and there

are a lot of tools that we need to buy. The high-end table and miter saws are well

over a thousand dollar. While we can get by just fine with some of the lower

priced models, the higher end tools tend to come with some pretty sweet

features. I built this table saw station to capture some of those sought after

features of the more expensive models.

This table saw station is designed to accept a smaller, portable contractor

grade saw. Contractor grade table saws are significantly lower priced, but nearly

all of them have very small work surfaces, which makes cutting larger pieces of

wood a challenge. This station will give you a much larger work area.

Another improvement to note is the fence. Although you’ll either have to

buy a separate unit or build your own, having a larger, more accurate fence will

give you better results on your projects and will be easier to use.

These plans are designed to be fully customizable. You’ll just need to take

three quick measurements of your table saw, plug them into the form and the

parts list will adapt to the appropriate dimensions to accommodate your saw.

If you get stuck on any particular part of these woodworking plans, feel free

to email me at John@ourhomefromscratch.com with any questions you may

have.

I hope you enjoy the challenge of building this project and get as much use

out of this table saw station as I have.

R,

John

Our Home from Scratch LLC Page 3

www.OurHomefromScratch.com

Getting Started

These woodworking plans will take you step by step through the build of

the table saw station. The first thing you should do is read through these

procedures to familiarize yourself with the materials, tools and skill requirements

necessary to complete them.

Please not that due to the wide variety of table saw dimensions, a cut sheet

for this project was not practical.

Tools

See a complete list of all the tools I used for my project on my new Project

Tools page.

Our Home from Scratch LLC Page 4

www.OurHomefromScratch.com

Table Saw Dimensions

Before we begin, you’ll need to take three basic measurements: the length,

width and height of your existing table saw. These dimensions should NOT

include the fence or the stand. You can include any side or rear extensions. Refer

to Figure 1 for further guidance.

Figure 1: Table Saw Dimensions

Our Home from Scratch LLC Page 5

www.OurHomefromScratch.com

Type in the values of the measurements in the boxes below. The

dimensions must be in inches in order for the calculator to work.

Length: 31.75

Width: 23.5

Height: 11.25

Our Home from Scratch LLC Page 6

www.OurHomefromScratch.com

Material:

Table 1 is a list of all the lumber and hardware you’ll need to build the

table saw station. All of this lumber should be available at your local large

hardware store (Lowe’s, Home Depot, Manard’s, True Value, etc.). You will need

to cut out each of the individual parts out from this list. The individual parts are

listed in later sections. In addition to the material listed below, you’ll also need 1-

1/4” long coarse pocket screws, 1-1/2” long wood screws, wood glue and a brad

nailer (optional).

TABLE 1: Material Shopping List

Item Description Width Length Qty

1 3/4" Thick Birch Plywood 3/4" 96" 1

2 3/4" Thick Melamine or Other 3/4" 96" 1

3 Caster Wheels 4

Our Home from Scratch LLC Page 7

www.OurHomefromScratch.com

Part 1: The Outer Frame

To make this project easier to build, we’re going to construct it in three

different sections. The first is the outer frame, which consists of the legs, back

brace, side braces and feet. This part of the project does not change dimensions

from one table saw to the next.

Table 2 has a list of all the parts required for the outer frame.

TABLE 2: Outer Frame Parts List

Item Description Length Width Thickness Qty

1 Legs 27.5" 3.5" 3/4" 8

2 Back Brace 42.5" 3.5" 3/4" 1

3 Side Braces 37.5" 3.5" 3/4" 2

4 Feet 4.25" 3.5" 3/4" 8

1. Start construction on the outer frame by drilling three pocket screw holes into

the sides of one of the leg boards. Attach it to a non-drilled leg board using

pocket screws and wood glue. The finished leg piece can be seen in Figure 2.

Repeat for the other three legs as in Figure 3.

Figure 2: Legs

Our Home from Scratch LLC Page 8

www.OurHomefromScratch.com

Figure 3: Four Assembled Legs

Our Home from Scratch LLC Page 9

www.OurHomefromScratch.com

2. Drill two pocket screw holes onto each end of the Back Brace and the Side

Braces. Using pocket screws, fasten the Back Brace between two Legs. Fasten

the Side Braces to each side of the Back Brace-Legs assembly. Fasten the open

end of the Side Braces to a Leg. See Figure 4.

Figure 4: Back and Side Braces Attached to Legs

Our Home from Scratch LLC Page 10

www.OurHomefromScratch.com

3. To assemble the Feet, glue and brad nail one Foot board to another and then

attach to the bottom of each set of Legs. You can attach the Feet to the Legs by

using pocket screws from the Legs into the Feet. This step completes the

assembly of the Outer Frame.

Figure 5: Feet Fastened to the Legs

Our Home from Scratch LLC Page 11

www.OurHomefromScratch.com

Part 2: The Lower Structure

The Lower Structure will support the weight of the table saw. Its height

from the top of the Feet is critical to ensure the table saw is flush with the top of

the table. The Lower Braces Prop Sticks can be cut from a piece of scrap 2x4 and

can be used to ensure the height of the Lower Structure is set properly.

TABLE 3: Lower Structure Parts List

Item Description Length Width Thickness Qty.

1 Lower Front and Back Braces 48" 3.5" 3/4" 2

2 Lower Braces Prop Stick 12 " 1.5" 1.5" 2

3 Lower Side Braces 45" 3.5" 3/4" 2

4 Lower Middle Brace 46.5" 3.5" 3/4" 1

5 Small Side Brace 22-7/8" 3.5" 3/4" 1

6 Table Saw Supports 24-3/8" 3.5" 3/4" 2

4. Start the assembly of the Lower Structure by resting the Lower Braces Prop

Sticks on the two rear Feet. The Lower Back Brace board can then be rested on

the Prop Stick and fastened to the Legs using wood glue and wood screws.

Repeat for the Lower Front Brace. See Figure 6.

Figure 6: Lower Front and Back Braces Installed

Our Home from Scratch LLC Page 12

www.OurHomefromScratch.com

5. Repeat Step 4 for the Lower Side Braces. See Figure 7. Discard the Prop Sticks.

Figure 7: Lower Side Braces

6. Install the Lower Middle Brace by marking the middle of the Lower Side Braces

on each side and installing it with either pocket screws or wood screws. See

Figure 8.

Figure 8: Lower Middle Brace

Our Home from Scratch LLC Page 13

www.OurHomefromScratch.com

7. Now install the Small Side Brace by measuring X” from the left side of the

32.25 ”. Mark the Lower Front

lower frame, where for your table saw X = ____

Brace and the Lower Middle Brace with a pencil at that measurement. The

Small Side Brace’s left edge should align with that pencil mark. See Figure 9.

Figure 9: Small Side Brace

Our Home from Scratch LLC Page 14

www.OurHomefromScratch.com

8. The Table Saw Supports can now be installed. Both boards will lay over the

Lower Braces as depicted in Figure 10. It’s best to use your table saw to

determine the exact location for these boards. Make sure there is a sufficient

space beneath the center of your table saw for a dust collection bag or

connection.

Figure 10: Table Saw Support Boards

Our Home from Scratch LLC Page 15

www.OurHomefromScratch.com

Part 2: The Upper Structure

The Upper Structure consists of two small, separate frames that support

the weight of the work surface, the Rear Frame and the Front Frame. Their exact

dimensions depend on the size of your table saw.

TABLE 4: Upper Structure Parts List

Item Description Length Width Thickness Qty.

1 Vertical Supports 8.5 " 3.5" 3/4" 2

2 Rear Top Frame Joists 48" 2.75" 3/4" 2

3 Rear Top Frame Ribs 21 " 2.75" 3/4" 3

4 Front Top Frame Joists 24 " 2.75" 3/4" 2

5 Front Top Frame Sides 14.25 " 2.75" 3/4" 2

6 Front Cover 11.5 " 3.5" 3/4" 1

7 Melamine Top 48" 46.5" 3/4" 1

9. We’ll start the Upper Structure by installing the Vertical Supports. Drill two or

three pocket screws into the side of one of the Vertical Support boards and fasten

it to the other Vertical Support Board exactly like you did with the Legs in Step 1

using glue and pocket screws.

10. Install the Vertical Support boards to the corner of the Lower Front Support

and the Side Support with glue and pocket screws. See Figure 11.

Our Home from Scratch LLC Page 16

www.OurHomefromScratch.com

Figure 11: Vertical Support Boards Installed

11. Now we can start installing the Rear Top Frame. Begin by screwing one of the

Rear Top Frame Joists into the Back Brace. Use glue and wood screws. Make sure

the Rear Top Frame Joist is ¾” below the top of the table. It should also be flush

against the bottom of the Back Brace. See Figure 12.

Figure 12: Rear Top Frame Joists

Our Home from Scratch LLC Page 17

www.OurHomefromScratch.com

12. Next, install the 3 Rear Frame Ribs. Two of the Ribs will be glued and screwed

into the Side Braces. The remaining Rib can be secured to the middle of the Rear

Frame Joist using glue and pocket screws. See Figure 13.

Figure 13: Rear Top Frame Ribs

Our Home from Scratch LLC Page 18

www.OurHomefromScratch.com

13. Now install the remaining Rear Frame Joist to the 3 Rear Frame Ribs using

glue, pocket screws and/or wood screws. See Figure 14. This completes assembly

of the Rear Frame.

Figure 13: Rear Top Frame Assembled

14. Now we’ll build the Front Frame. Start by installing one of the Top Frame

Joists by using wood screws and glue. See Figure 14.

Our Home from Scratch LLC Page 19

www.OurHomefromScratch.com

Figure 14: Top Frame Joist

15. Using glue, pocket screws and/or wood screws install the Top Frame Ribs.

The Ribs should be attached to the Rear Frame Joist, the Vertical Supports and the

Legs. See Figure 15.

Figure 15: Top Frame Joist

Our Home from Scratch LLC Page 20

www.OurHomefromScratch.com

16. With the Ribs installed, you can attach the second Front Frame Joist using

wood screws and glue. Se Figure 16.

Figure 16: Front Frame Assembled

Our Home from Scratch LLC Page 21

www.OurHomefromScratch.com

17. For the last piece of the frame, attach the Front Cover piece to the front

frame so its edge is flush with the top of the front right Leg. Use glue and wood

screws. See Figure 17. That completes the assembly of the structure.

Figure 17: Front Cover Added

Our Home from Scratch LLC Page 22

www.OurHomefromScratch.com

18. Now for the work surface. I used a large piece of melamine for this project,

but you are welcome to use whatever material you prefer. Other options include

MDF or birch plywood. To install the custom sized work surface, simply cut out a

large piece of the material you picked to the dimensions listed in Table 4. Drop

the cut out work surface onto the table. See Figure 18.

Figure 18: Work Surface Pre-Cut

Our Home from Scratch LLC Page 23

www.OurHomefromScratch.com

19. Using a pencil, trace out the outline of the table saw opening from below.

Use a circular saw to cut along the outline. Make sure the table saw fits into the

opening before installing the work surface permanently using glue and pocket

screws from below. See Figure 19.

Figure 19: Completed Table Saw Station

20. The last thing you’ll need to do is add the caster wheels and install your table

saw. You can use washers to shim the table saw up if required. Don’t forget, you

still need a fence. Also consider building an outfeed table to the same height as

this table saw station using our Workbench Plans (available on our plans page).

Our Home from Scratch LLC Page 24

www.OurHomefromScratch.com

Resources

This project appeared on our blog, Our Home from Scratch, over a series of

blog posts. The design has undergone significant revisions compared to what

appeared on the blog. The version featured in these plans is easier to build than

the version described in the blog posts.

You are welcome to refer to those blog posts for reference if you wish, but

keep in mind that these plans are the ultimate authority for the design and

dimensions.

Post 1: Setting Up Shop: Table Saw Upgrade #1

Post 2: Setting Up Shop: Table Saw Upgrade #2

Post 3: Setting Up Shop: Table Saw Upgrade #3

That’s it. If you find any errors, have any suggestions for improvement or

any questions, drop me a line at John@ourhomefromscratch.com

Thanks!!

Our Home from Scratch LLC Page 25

www.OurHomefromScratch.com

Potrebbero piacerti anche

- Family Handyman Ultimate 1 Day ProjectsDa EverandFamily Handyman Ultimate 1 Day ProjectsValutazione: 5 su 5 stelle5/5 (1)

- Traditional Workbench - Jeff Greef WoodworkingDocumento14 pagineTraditional Workbench - Jeff Greef Woodworkingtantiaglaia100% (1)

- The Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerDa EverandThe Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerValutazione: 4 su 5 stelle4/5 (1)

- Worm Harvester 212011Documento0 pagineWorm Harvester 212011mattpac3Nessuna valutazione finora

- Kreg Multipurpose Work CenterDocumento14 pagineKreg Multipurpose Work CenterMiguel Angel Garcia de la Rosa100% (1)

- Oriental Box of Drawers PDFDocumento10 pagineOriental Box of Drawers PDFAleksandar Nikolic100% (2)

- Cama InfantilDocumento12 pagineCama InfantilBaltzazarNessuna valutazione finora

- Building Wooden Vises - en PDFDocumento39 pagineBuilding Wooden Vises - en PDFJhonas Carvalho100% (3)

- RouterTable Bob PlansDocumento24 pagineRouterTable Bob Plansiacob_gilberto6473100% (2)

- Cutting Board TrioDocumento12 pagineCutting Board Triokcc2012100% (1)

- Tools Required For The DIY Workbench ProjectDocumento26 pagineTools Required For The DIY Workbench Projectjose.figueroa@foseco.comNessuna valutazione finora

- DIY Guide - Squat Rack 8.5x11Documento44 pagineDIY Guide - Squat Rack 8.5x11Alex ascanioNessuna valutazione finora

- Folding Workbench PlansDocumento11 pagineFolding Workbench Plansbwatkins6Nessuna valutazione finora

- Marce Nari ADocumento3 pagineMarce Nari AEdriano SantosNessuna valutazione finora

- Furniture Plans How To Build A Rocking ChairDocumento10 pagineFurniture Plans How To Build A Rocking ChairAntónio SousaNessuna valutazione finora

- 2x4 BenchDocumento4 pagine2x4 BenchBobby Cardona100% (1)

- Complete Table Saw Book, Revised Edition: Step-by-Step Illustrated Guide to Essential Table Saw Skills, Techniques, Tools and TipsDa EverandComplete Table Saw Book, Revised Edition: Step-by-Step Illustrated Guide to Essential Table Saw Skills, Techniques, Tools and TipsValutazione: 3.5 su 5 stelle3.5/5 (2)

- Table Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!Documento8 pagineTable Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!LinNessuna valutazione finora

- DIY Miter Saw Station PDFDocumento6 pagineDIY Miter Saw Station PDFNana Obiri Yeboa DarkoNessuna valutazione finora

- DP571 Victorian QueenDocumento24 pagineDP571 Victorian QueenAntonio GatoNessuna valutazione finora

- Stand AssemblyDocumento6 pagineStand AssemblyAredaNessuna valutazione finora

- Bandsaw Circle JigDocumento3 pagineBandsaw Circle Jigphilipisaia100% (1)

- Banco Escalera PDFDocumento3 pagineBanco Escalera PDFluanbagonNessuna valutazione finora

- DIY Cornhole Boards PlanDocumento6 pagineDIY Cornhole Boards Plantribb94Nessuna valutazione finora

- Project Plans: Tool Storage CenterDocumento14 pagineProject Plans: Tool Storage CenterJayme LealNessuna valutazione finora

- Quilt Block Genius, Expanded Second Edition: Over 300 Pieced Quilt Blocks to Make 1001 Blocks with No Math ChartsDa EverandQuilt Block Genius, Expanded Second Edition: Over 300 Pieced Quilt Blocks to Make 1001 Blocks with No Math ChartsNessuna valutazione finora

- Building A 5 String BanjoDocumento8 pagineBuilding A 5 String BanjoDimitris BasiotisNessuna valutazione finora

- Folding Work Bench: Beginner Level ProjectDocumento12 pagineFolding Work Bench: Beginner Level ProjectB. Ionut100% (1)

- Building Blocks Sampler Quilt: a Quilting for Beginners Quilt Pattern & TutorialDa EverandBuilding Blocks Sampler Quilt: a Quilting for Beginners Quilt Pattern & TutorialNessuna valutazione finora

- YW Daytripper ChairDocumento8 pagineYW Daytripper ChairEric HubbardNessuna valutazione finora

- Precision Crosscuts LedDocumento10 paginePrecision Crosscuts LedMauro Regis100% (1)

- DIY Fidget Spinners How to Make Fidget Spinner ButtonsDa EverandDIY Fidget Spinners How to Make Fidget Spinner ButtonsNessuna valutazione finora

- DoubleChairBench DIYPETE PDFDocumento20 pagineDoubleChairBench DIYPETE PDFRostocanieNessuna valutazione finora

- How To Build A Toddler Kitchen Helper Stool For $30: InstructablesDocumento8 pagineHow To Build A Toddler Kitchen Helper Stool For $30: InstructablesalphyshorNessuna valutazione finora

- Build Your Own Drafting Table - That Should Hold!Documento18 pagineBuild Your Own Drafting Table - That Should Hold!KarogelRamiterreNessuna valutazione finora

- Mobile WorkbenchDocumento5 pagineMobile Workbenchcfh666100% (3)

- How To Build A TreehouseDocumento9 pagineHow To Build A TreehousehsgdafudysghvfdsoyNessuna valutazione finora

- 6Ft Home BarDocumento27 pagine6Ft Home BarMileta SindjelicNessuna valutazione finora

- Adirondack Chair Plans 10pagesDocumento10 pagineAdirondack Chair Plans 10pagesNilton100% (2)

- WJ140 Hoosier Step StoolDocumento7 pagineWJ140 Hoosier Step Stoolmtejadacoll100% (1)

- Holographic Audio Visualizer With Motion ControlDocumento10 pagineHolographic Audio Visualizer With Motion ControlLuelsonCordovaDeclaradorNessuna valutazione finora

- Hank Ou: Get More From Your Table SawDocumento12 pagineHank Ou: Get More From Your Table Sawrefsocrd1Nessuna valutazione finora

- Silla MaderaDocumento12 pagineSilla Maderagmo2189Nessuna valutazione finora

- How To Build A Wild Bird Feeder PDFDocumento17 pagineHow To Build A Wild Bird Feeder PDFmihaly61Nessuna valutazione finora

- DaybedDocumento15 pagineDaybedAdnan HasanovicNessuna valutazione finora

- Woodcademy Dining Table PlansDocumento39 pagineWoodcademy Dining Table PlansRaul Ambrosetti100% (1)

- Bellows Construction: A Basic Tutorial Detailing The Design and Construction of Your Own Large Format Camera BellowsDocumento39 pagineBellows Construction: A Basic Tutorial Detailing The Design and Construction of Your Own Large Format Camera BellowsBrad Alan SelfNessuna valutazione finora

- #P203 - Candy HoldersDocumento10 pagine#P203 - Candy HoldersgabrielmorosanuNessuna valutazione finora

- How To Build Modern Barstools Like A ProDocumento17 pagineHow To Build Modern Barstools Like A Progerman100% (1)

- Craft & HobbyDocumento14 pagineCraft & HobbyDjordje TasicNessuna valutazione finora

- Folding Workbench PlansDocumento13 pagineFolding Workbench PlansChris Couch100% (2)

- Queen Size Platform BedDocumento20 pagineQueen Size Platform BedPerry100% (1)

- Dowel Maker InstructionDocumento12 pagineDowel Maker InstructionKeanu ReavesNessuna valutazione finora

- How To Build An Adirondack Lawn Chair and Table: Simple DIY Woodworking ProjectDocumento7 pagineHow To Build An Adirondack Lawn Chair and Table: Simple DIY Woodworking Projectnevadablue67% (3)

- Chiefsshop PirateschestDocumento12 pagineChiefsshop PirateschestdonguieNessuna valutazione finora

- Materials, Supplies, & Cutting Diagram No. 152: Futon Sofa BedDocumento1 paginaMaterials, Supplies, & Cutting Diagram No. 152: Futon Sofa BedMinhNessuna valutazione finora

- Sling GunDocumento7 pagineSling GunMinh100% (1)

- Sparrow: Designed by Jo NakashimaDocumento3 pagineSparrow: Designed by Jo NakashimaMinhNessuna valutazione finora

- Beginner 4 Book - Teacher CardDocumento1 paginaBeginner 4 Book - Teacher CardMinhNessuna valutazione finora

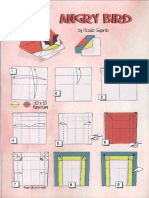

- Angry Bird PDFDocumento4 pagineAngry Bird PDFMinhNessuna valutazione finora

- List of Songs For KidsDocumento2 pagineList of Songs For KidsMinhNessuna valutazione finora

- Beginner 4 Book - ColorDocumento7 pagineBeginner 4 Book - ColorMinhNessuna valutazione finora

- Cat Pop Up Box Paper Craft Templates PDFDocumento3 pagineCat Pop Up Box Paper Craft Templates PDFMinhNessuna valutazione finora

- A. Understood A. Stopped A. Were C. Hadn't Said A. Spoke A Kept C. Had Caught C. Had Seen C. Hadn't Gone A. Went A. LivedDocumento2 pagineA. Understood A. Stopped A. Were C. Hadn't Said A. Spoke A Kept C. Had Caught C. Had Seen C. Hadn't Gone A. Went A. LivedMinhNessuna valutazione finora

- Starters ReadingWriting With KeyDocumento8 pagineStarters ReadingWriting With KeyMinhNessuna valutazione finora

- Movers Vocabulary List: Cambridge Young LearnersDocumento62 pagineMovers Vocabulary List: Cambridge Young LearnersMinhNessuna valutazione finora

- 721585cb1620fd3 - TCVN 7364-4 2004Documento8 pagine721585cb1620fd3 - TCVN 7364-4 2004MinhNessuna valutazione finora

- Future TensesDocumento2 pagineFuture TensesMinhNessuna valutazione finora

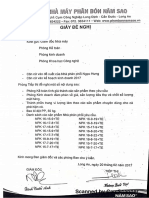

- New Doc 37Documento1 paginaNew Doc 37MinhNessuna valutazione finora

- 715 Animal Riddles 2 MediumDocumento3 pagine715 Animal Riddles 2 MediumMinhNessuna valutazione finora

- Present TensesDocumento2 paginePresent TensesMinhNessuna valutazione finora

- Borrechel (English Metric) LowRez RefDocumento8 pagineBorrechel (English Metric) LowRez RefMinhNessuna valutazione finora

- Fastener IdentificationDocumento30 pagineFastener Identificationti_pit100% (4)

- Compact Excavator Attachments Parts Manual 918180BDocumento40 pagineCompact Excavator Attachments Parts Manual 918180BPhilNessuna valutazione finora

- Dfn-Distal Femoral NailDocumento27 pagineDfn-Distal Femoral Nailradha satiNessuna valutazione finora

- Innoair 400 TDSDocumento1 paginaInnoair 400 TDSsapientsoftNessuna valutazione finora

- Appendix I - Specification For Doors & WindowsDocumento13 pagineAppendix I - Specification For Doors & WindowsSantoshkumar GurmeNessuna valutazione finora

- 95T - Service ManualDocumento168 pagine95T - Service ManualLupuNessuna valutazione finora

- Duplo 660p Maintenance ManualDocumento51 pagineDuplo 660p Maintenance ManualXLPNessuna valutazione finora

- Parts Reference List: Home Embroidery MachineDocumento39 pagineParts Reference List: Home Embroidery MachinePhilip EgyNessuna valutazione finora

- Type-FT-H Riser SystemDocumento201 pagineType-FT-H Riser Systemadnan0307Nessuna valutazione finora

- Dv2.1246 Ispl Book For Dv12 Engine For Power Generation For ExportDocumento125 pagineDv2.1246 Ispl Book For Dv12 Engine For Power Generation For ExportMECHO STORENessuna valutazione finora

- Porsche Cayenne Repair Manual 2003-2006Documento6.024 paginePorsche Cayenne Repair Manual 2003-2006Ly Fotoestudio Digitalca100% (3)

- Owner's Manual & Safety InstructionsDocumento16 pagineOwner's Manual & Safety InstructionsBryanNessuna valutazione finora

- EX-2000 X-Caliber Installation REV071911Documento28 pagineEX-2000 X-Caliber Installation REV071911Manuel Vivero Diéguez100% (1)

- Makita Products Catalog - Buy DirectDocumento122 pagineMakita Products Catalog - Buy DirectShopHomeOnline100% (1)

- Pca - IomDocumento15 paginePca - IomwavehayiathNessuna valutazione finora

- Supracadd ESby SK AnDocumento9 pagineSupracadd ESby SK AnEfraim JacobNessuna valutazione finora

- 2 Ton DumperDocumento56 pagine2 Ton DumpersengottaiyanNessuna valutazione finora

- Asme B18.18-2017Documento22 pagineAsme B18.18-2017sravan kumar100% (1)

- Maryland Metrics KeensertsDocumento60 pagineMaryland Metrics KeensertsThor InternationalNessuna valutazione finora

- And Owner'S Manual: Operating InstructionsDocumento24 pagineAnd Owner'S Manual: Operating InstructionsMohd Shahrul NizamNessuna valutazione finora

- Body-Solid: Owner'S ManualDocumento90 pagineBody-Solid: Owner'S ManualGesadyrNessuna valutazione finora

- 149200-1 Manipulador ManualDocumento95 pagine149200-1 Manipulador ManualOscar SaucedoNessuna valutazione finora

- LCR - Iq Masterload - Iq Product Manual 03sep2019 LoresDocumento180 pagineLCR - Iq Masterload - Iq Product Manual 03sep2019 Loresnormal tigaNessuna valutazione finora

- TM 9-1240-413-12P - M68 - Sight - Reflex - 2004Documento176 pagineTM 9-1240-413-12P - M68 - Sight - Reflex - 2004Wurzel1946100% (2)

- Geh 5305 PDFDocumento18 pagineGeh 5305 PDFleidy vidalNessuna valutazione finora

- Parts Manual 622B TimberiteDocumento18 pagineParts Manual 622B TimberitemiguelNessuna valutazione finora

- SJ-20151105160120-004-ZXMW NR8250 (V2.04.02) Hardware Installation GuideDocumento186 pagineSJ-20151105160120-004-ZXMW NR8250 (V2.04.02) Hardware Installation GuideIng Abraham J Tiberio LNessuna valutazione finora

- Understanding - Unbrako Fasteners (Technical Brochure)Documento48 pagineUnderstanding - Unbrako Fasteners (Technical Brochure)pavan_jssatebNessuna valutazione finora

- PRM Owners HandbookDocumento22 paginePRM Owners HandbookOS-CARS LTDA100% (1)

- HondaRevo110NEW PDFDocumento13 pagineHondaRevo110NEW PDFmahendrachmandaNessuna valutazione finora