Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LAB 075 Stability and Trial Testing Procedure Sample

Caricato da

sppCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LAB 075 Stability and Trial Testing Procedure Sample

Caricato da

sppCopyright:

Formati disponibili

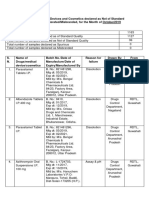

Standard Operating Procedure

Title: Stability & Trial Testing Procedure

______________________________________________________________________________________

o Discard remaining samples from Fridge/Stability room.

2. General Sampling

2.1. Sampling of products for Stability testing is initiated by the Laboratory staff. Each week ,the

Production Schedules are examined to determine which batches are required. The decision

on which batches and which tests are required are based on Stability Programs.

2.2. Samples must be set down within 30 calendar days from the date of packaging.

2.3. Sufficient samples for chemical, physical and microbiological testing plus an overage for

repeat testing are to be set down. The quantity of samples to be taken for Stability testing is

given in SOP MAN-125.

2.4. All samples are to be stored at the temperatures specified in the Stability Protocol.

2.5. All products tested are to be stored in their usual containers, closures and packaging.

2.6. The frequency of testing points is recorded on the Stability & Trial cards. Samples for testing

are sourced from the Stability Rooms or refrigerators.

2.7. Samples are stored in the fridge at 2-8°C and in the Stability rooms at the designated

temperatures/humidity.

Ensure that all cartons are MARKED with BATCH NUMBER and EXPIRY DATE.

2.8. The temperature and humidity of the Stability rooms is monitored by the Plant Monitoring

System.

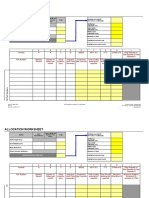

2.9. When a batch is to be set down for Stability testing, the following details are filled in on the

Stability/Trial card:

Product name and strength,

Container size and type

Product code

Batch number,

Date of manufacture

Storage temperature

Quantity required from production

Any relevant comments

The card is then sent to Production and warehouse office.

2.10. The Stability card then comes back to the Laboratory with the required samples. The

Laboratory Technician in charge of Stability then completes the card with the following:

The product Expiry date

The Team

Stability Specification no.(From Technical Service Master File, see SOP QMS-030)

Sequence

Tests to be performed

Relevant testing points

Container details (back of card)

Any other comments

Release results.

2.10.1. The Stability tests required are found by referring the Stability Specification folder.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 3 of 8

Standard Operating Procedure

Title: Stability & Trial Testing Procedure

______________________________________________________________________________________

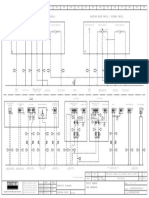

* Initial results may be taken as the results of the batch release testing only if the release method is

identical to the Stability method.

L – Long term study

I – Intermediate study

A – Short term study

25°C/60%RH Long term storage to support marketing in Climatic Zone I & II.

25°C/40%RH Long term storage to support semi-permeable containers

30°C/35%RH Long term storage to support semi-permeable containers

30°C/60%RH Accelerated storage conditions to replace 40°C/75%RH where allowed by

guidelines or with flammable products.

40°C/25%RH Accelerated storage conditions to support semi-permeable containers

6.5. Where a lower temperature long term storage condition in necessary (product instability), the

six month accelerated condition should be performed.

7. Special Studies Stability (Trials)

7.1. When a permanent change is made and approved by the authorities, e.g. Method of

Manufacture, Manufacture off site, or primary packaging material, which may affect the

Stability, the first three (3) batches produced after the change must be included in the

programme.

7.2. If a single batch is subject to any significant deviation during production, e.g. concerning

formula, method of manufacture, or primary packaging material and this change is likely to

affect the product stability, this batch must be included in the programme to give further

Stability data.

7.3. The following modifications are typical of situations, which may require additional Stability

studies.

Changes in the manufacturing process of the bulk product

Changes in the manufacturing site of the bulk product

Changes in the formulation of the product

New composition addition of the product

Changes in the manufacturing process of the product

Changes in the manufacturing site of the product

Changes in the batch size of product

Changes to the closure/container system (e.g. materials, size, configuration)

Reprocessing of the drug product.

7.4. Special Studies Arising from Manufacturing Changes

7.4.1. The need for special studies, to support registration of specific manufacturing

changes, shall be determined by a project team consisting of at least Technical,

Regulatory, Production and Sourcing and Supply personnel.

7.4.2. An integrated Stability protocol or protocol is to be created.

7.4.3. The Project team will appoint a person responsible for responsible for coordinating

all activities required to manufacture and pack the product and transport samples to

the commercial Stability site.

7.4.4. The QA Manager of the site wishing to instigate a study shall agree the need for a

study with other relevant sites (e.g. packaging or commercial Stability site).

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 6 of 8

Potrebbero piacerti anche

- ECDD 37th Report FINAL PrelayoutDocumento45 pagineECDD 37th Report FINAL PrelayoutsppNessuna valutazione finora

- DPS 2012 3 2 300 304Documento5 pagineDPS 2012 3 2 300 304sppNessuna valutazione finora

- Guideline For Stability StudiesDocumento44 pagineGuideline For Stability StudiesboddarambabuNessuna valutazione finora

- Zhang Asu 0010E 15975Documento148 pagineZhang Asu 0010E 15975sppNessuna valutazione finora

- US8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentsDocumento10 pagineUS8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentssppNessuna valutazione finora

- Formulation 2Documento38 pagineFormulation 2sppNessuna valutazione finora

- CN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentsDocumento3 pagineCN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentssppNessuna valutazione finora

- Agilent ASMS 2019 ThP762 PosterDocumento4 pagineAgilent ASMS 2019 ThP762 PostersppNessuna valutazione finora

- Guidance Documents APIDocumento83 pagineGuidance Documents APIAmit NagareNessuna valutazione finora

- Dareoct 19Documento6 pagineDareoct 19sppNessuna valutazione finora

- KB003Documento4 pagineKB003sppNessuna valutazione finora

- PERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFDocumento5 paginePERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFsppNessuna valutazione finora

- Rapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductsDocumento12 pagineRapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductssppNessuna valutazione finora

- CN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentsDocumento3 pagineCN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentssppNessuna valutazione finora

- Optimization and Use of Talc in Direct Compression Tablet FormulaDocumento307 pagineOptimization and Use of Talc in Direct Compression Tablet FormulasppNessuna valutazione finora

- Supplier Qualification...Documento5 pagineSupplier Qualification...elmiraNessuna valutazione finora

- Risk Assessments and Sourcing Strategies For Excipients and ApisDocumento2 pagineRisk Assessments and Sourcing Strategies For Excipients and ApissppNessuna valutazione finora

- List of Units Indore SEZ PithampurDocumento4 pagineList of Units Indore SEZ PithampursppNessuna valutazione finora

- PIC/S Assessment & Joint Reassessment ProgrammeDocumento15 paginePIC/S Assessment & Joint Reassessment ProgrammesppNessuna valutazione finora

- Dpco Price List April 2015Documento82 pagineDpco Price List April 2015sppNessuna valutazione finora

- Composition of A Dossier To Register A Drug: The ContraindicationsDocumento2 pagineComposition of A Dossier To Register A Drug: The ContraindicationssppNessuna valutazione finora

- ASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFDocumento3 pagineASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFAnuradha yadavNessuna valutazione finora

- Levofloxacin: The International PharmacopoeiaDocumento7 pagineLevofloxacin: The International PharmacopoeiasppNessuna valutazione finora

- Mapping Storage Areas Final Sign Off ADocumento25 pagineMapping Storage Areas Final Sign Off Ahandayani100% (2)

- QA PharmaceuticalDocumento413 pagineQA Pharmaceuticalalhalili100% (9)

- AQL For PGL F&PDocumento1 paginaAQL For PGL F&PsppNessuna valutazione finora

- MICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological LaboratoryDocumento11 pagineMICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological Laboratoryspp100% (1)

- Validation of BetalactamDocumento18 pagineValidation of BetalactamsppNessuna valutazione finora

- ECA PQG GDP Guideline Chapter 3 Appendix 2 Temp Map Report Template Feb2016Documento13 pagineECA PQG GDP Guideline Chapter 3 Appendix 2 Temp Map Report Template Feb2016RICHARD FABIAN DURAN100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- SOM One Linear PDFDocumento88 pagineSOM One Linear PDFDinuSkyNessuna valutazione finora

- Patrol Box PlansDocumento6 paginePatrol Box PlansPePe ProjectsNessuna valutazione finora

- Data Structures NotesDocumento9 pagineData Structures NotesMohammed JeelanNessuna valutazione finora

- Dual Draw/Dual Return Fuel System TroubleshootingDocumento4 pagineDual Draw/Dual Return Fuel System Troubleshootinginformer techNessuna valutazione finora

- Architecture Concerns of TST and NATO TST ToolDocumento9 pagineArchitecture Concerns of TST and NATO TST Tooldorupara718747Nessuna valutazione finora

- BoyapatyDocumento5 pagineBoyapatylalalallalalaaluuuNessuna valutazione finora

- TDG11Documento100 pagineTDG11Splycho GoranNessuna valutazione finora

- Torsion MEDocumento24 pagineTorsion MEmohamed.hassan031Nessuna valutazione finora

- DHLDocumento3 pagineDHLfmartinNessuna valutazione finora

- Business Plan On Plastic Recycling & ManufacturingDocumento19 pagineBusiness Plan On Plastic Recycling & ManufacturingSah Sanjiv KumarNessuna valutazione finora

- Supplier Run Rate CalculatorDocumento9 pagineSupplier Run Rate CalculatordcevipinNessuna valutazione finora

- TSM SmokeDocumento2 pagineTSM SmokeSudin AmatyaNessuna valutazione finora

- Sandvik: 11/2019 PME F Additional Comments For Hydrabolt Option & HH200Documento1 paginaSandvik: 11/2019 PME F Additional Comments For Hydrabolt Option & HH200Elber Luis Chavez BarriosNessuna valutazione finora

- STK412 150 Sanyo PDFDocumento4 pagineSTK412 150 Sanyo PDFroger.Nessuna valutazione finora

- Dynamic Arrays With The Arraylist Class Chapter Xii TopicsDocumento38 pagineDynamic Arrays With The Arraylist Class Chapter Xii TopicsRocket FireNessuna valutazione finora

- Noise and VibrationDocumento14 pagineNoise and VibrationABHISHEK V GOWDANessuna valutazione finora

- SG-05 Safety Guideline For Illumination at WorkplaceDocumento5 pagineSG-05 Safety Guideline For Illumination at WorkplacebsrchandruNessuna valutazione finora

- LiftingLugStress Rev 1.5Documento17 pagineLiftingLugStress Rev 1.5mohdshakir bahariNessuna valutazione finora

- Roofing SafetyDocumento38 pagineRoofing SafetyDhârâñî KûmârNessuna valutazione finora

- Pravin Yesubon.Y: and Social Responsibility (PSSR) and Personal Survival Techniques (PST)Documento2 paginePravin Yesubon.Y: and Social Responsibility (PSSR) and Personal Survival Techniques (PST)shaNessuna valutazione finora

- SAES-A-102 Ambient Air Quality and Source Emissions StandardsDocumento21 pagineSAES-A-102 Ambient Air Quality and Source Emissions StandardsFlorante NoblezaNessuna valutazione finora

- ASTM Data and ControlDocumento141 pagineASTM Data and ControlYohanes Ronny100% (1)

- Pedestrian Design Guidelines PDFDocumento50 paginePedestrian Design Guidelines PDFIvan AndradeNessuna valutazione finora

- Lab 2Documento8 pagineLab 2Hamid SaeedNessuna valutazione finora

- Hydrocracking Reactor Temperature Control For Increased Safety, Reliability and PerformanceDocumento8 pagineHydrocracking Reactor Temperature Control For Increased Safety, Reliability and Performancekirandevi1981Nessuna valutazione finora

- Body of Knowledge PDFDocumento1 paginaBody of Knowledge PDFAda RamirezNessuna valutazione finora

- Bomet CountyDocumento1 paginaBomet CountyPrince AliNessuna valutazione finora

- Environmental AuditDocumento22 pagineEnvironmental AuditungkumariamNessuna valutazione finora

- 92 - Summary of Items Discussed in 4 - 2021 ADF On 13.8.2021Documento20 pagine92 - Summary of Items Discussed in 4 - 2021 ADF On 13.8.2021trickyggNessuna valutazione finora

- Apollo Experience Report Electronic Systems Test Program Accomplishments and ResultsDocumento70 pagineApollo Experience Report Electronic Systems Test Program Accomplishments and ResultsBob AndrepontNessuna valutazione finora