Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

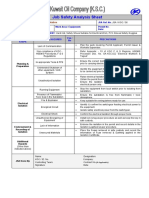

Arc Flash Hazard Checklist

Caricato da

Sajid HussainCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Arc Flash Hazard Checklist

Caricato da

Sajid HussainCopyright:

Formati disponibili

Arc Flash Hazard

Design, Maintenance and Operation Process Checklist

Don’t

Yes No

Know

1-1 DESIGN

1-1.1 Arc Flash 1-1.1.1 Has a design review been conducted to identify potential areas to reduce

Design Review hazards including fault levels, exposure times, remote operations, remote T T T

racking, and system grounding?

1-1.1.2 Have protective devices been tested/checked to verify performance per

study? T T T

1-1.1.3 Is there a procedure in place to assure studies are updated and testing is

performed when system or utility supply changes are made? T T T

1-1.2 Documentation 1-1.2.1 Is your Arc Flash Hazard plan documented? Does the documentation include

the results of the arc flash analysis, updated single-line diagrams, signs and

labels on equipment and at hazardous areas? Do all labels include the type,

T T T

name/ID, incident energy at working distances, flash protection boundary,

hazard/risk category, and arc flash training?

1-1.2.2 Are all single-line diagrams up-to-date reflecting any modification or

T T T

expansions to your electrical distribution system or any changes in the electric

utility system?

1-1.2.3 Do you have a documented method for maintaining required Personal

Protective Equipment? T T T

2-1 OPERATIONS

T T T

2-1.1 Safety 2-1.1.1 Does your safety program include a certified training program including

awareness of electrical hazards?

2-1.1.2 Does your safety program identify hazard / risk evaluation procedures,

T T T

electrically safe work procedures, tools and PPE, and electrical safety

principles?

2-1.1.3 Do you have appropriate safety procedures in place to minimize dangers

where exposure cannot be avoided? T T T

2-1.1.4 Do you have a formal record keeping process for documenting accidents and

near misses? T T T

2-1.1.5 Is there a process in place that ensures actions will be taken to update

T T T

procedures or take other corrective action when an accident or near miss

occurs?

T T T

2-1.1.6 Do workers comply with manual procedures?

2-1.1.7 Is there a periodic audit of workers to confirm compliance with safety manual

procedures? T T T

2-1.2 Training 2-1.2.1 Do you have an effective arc flash training program? Does it provide workers

T T T

the knowledge and understanding of the existence, nature, causes, and

methods to prevent electrical hazards?

2-1.2.2 Does your arc flash training program include training on arc flash awareness,

standards and codes, understanding of arc flash quantities, selection and use

of appropriate PPE, reading and following warning signs and labels, methods

T T T

to reduce risk while working on live exposed parts, and arc flash hazard

assessment?

©2004 Electrical Reliability Services, Inc. 1

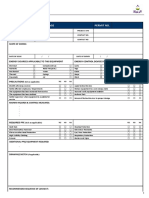

Arc Flash Hazard

Design, Maintenance and Operation Process Checklist

Don’t

Yes No

Know

2-1 Operations

2-1.2 Training 2-1.2.3 Is there a process in place that ensures the training program is periodically

reviewed to identify needed changes? T T T

2-1.2.4 Have all personnel working on or near energized equipment undergone

T T T

specific training in the hazards of working on energized equipment, and the

use and proper application of PPE?

T T T

2-1.2.5 Do training records exist?

2-1.3 Labeling 2-1.3.1 Does all electrical equipment that may remain energized during maintenance

T T T

or repair post a warning label in compliance with the National Electrical Code

110.16?

2-1.4 Personal 2-1.4.1 Do you have a personal protective equipment plan?

Protective

T T T

Equipment

T T T

2-1.4.2 Does the plan address all OSHA standards regarding PPE?

2-1.4.3 Does the plan cover how PPE should be worn, maintained, and disposed of

after the equipment life has expired? T T T

2-1.4.4 Is there a process in place to ensure PPE requirements are updated when

system or utility supply changes are made? T T T

2-1.5 Regulatory 2-1.5.1 Does your arc flash hazard program address all regulatory requirements

Compliance imposed by NFPA 70E 2004, The National Electrical Code 110.16, IEEE 1584

and OSHA 1910.132(d), and 1926.28(a)? T T T

2-1.5.2 Do you have an established process for updating Arc Flash Hazard programs

as new information becomes available? T T T

3-1 MAINTENANCE

3-1.1 Electrical 3-1.1.1 Does your preventive maintenance program specifically address arc flash

Preventive hazards?

T T T

Maintenance

Program

T T T

3-1.1.2 Is the program being followed rigorously?

3-1.1.3 Is there a procedure in place that updates the program based on changes to

plant equipment or processes? T T T

©2004 Electrical Reliability Services, Inc. 2

Potrebbero piacerti anche

- El32 Safe Isolation 2017Documento182 pagineEl32 Safe Isolation 2017sriramNessuna valutazione finora

- Arc Flash Hazard Analysis and Mitigation PaperDocumento20 pagineArc Flash Hazard Analysis and Mitigation PapergjanitoNessuna valutazione finora

- Arc Flash-ABBDocumento2 pagineArc Flash-ABBsemsem1972Nessuna valutazione finora

- Commissioning Tests For HV Underground Cables (Up To 33Kv) SWPDocumento13 pagineCommissioning Tests For HV Underground Cables (Up To 33Kv) SWPCharles Robiansyah100% (1)

- EL31 SEC Distribution Safety Rules v3Documento68 pagineEL31 SEC Distribution Safety Rules v3sriramNessuna valutazione finora

- Keeping Electrical Switchgear Safe: HSE BooksDocumento50 pagineKeeping Electrical Switchgear Safe: HSE BooksDESPOINA1Nessuna valutazione finora

- Electricity Supply Board Safety Rules - 2006Documento36 pagineElectricity Supply Board Safety Rules - 2006bdiaconu20048672Nessuna valutazione finora

- 18 SOP CBL Trench DiggingDocumento10 pagine18 SOP CBL Trench DiggingMd Gulam SafiNessuna valutazione finora

- Electricity at Work HSG85Documento24 pagineElectricity at Work HSG85Pradeep NairNessuna valutazione finora

- Document 2 PDFDocumento5 pagineDocument 2 PDFLuis Miguel Esquivel SequeiraNessuna valutazione finora

- MT Standard Safety Sign Checklist For 132kV SSDocumento18 pagineMT Standard Safety Sign Checklist For 132kV SSJeffy100% (1)

- OSHA Machine Guarding2Documento63 pagineOSHA Machine Guarding2hoan thanhNessuna valutazione finora

- HIRA No. 22-Installation & Use of Temp Electrical Supplies SBDDocumento2 pagineHIRA No. 22-Installation & Use of Temp Electrical Supplies SBDVenkadesh Periathambi75% (4)

- Checklist For Internal Safety Audit - OISD-145Documento4 pagineChecklist For Internal Safety Audit - OISD-145jai-shriram100% (1)

- Electric Powerlines Working Near Swms 10590-3Documento12 pagineElectric Powerlines Working Near Swms 10590-3JamesNessuna valutazione finora

- Electrical IsolationDocumento8 pagineElectrical IsolationABDUL GHAFOORNessuna valutazione finora

- Lightning Protection DesignDocumento6 pagineLightning Protection DesignPiyakarn BeeNessuna valutazione finora

- 125 kVA Exception Jim PhillipsDocumento2 pagine125 kVA Exception Jim PhillipsSellappan MuthusamyNessuna valutazione finora

- Electrical Safety Work Practices Plan - Michigan Technological UniversityDocumento7 pagineElectrical Safety Work Practices Plan - Michigan Technological UniversityBurak KucukkelesNessuna valutazione finora

- Caterpillar - Class of Insulation and Temprature Rise - Online CommunityDocumento3 pagineCaterpillar - Class of Insulation and Temprature Rise - Online Communitylbk50Nessuna valutazione finora

- Job Safety Analysis (Jsa) : Title of Activity / Work: DG OperationDocumento2 pagineJob Safety Analysis (Jsa) : Title of Activity / Work: DG Operationba ratnaparkheNessuna valutazione finora

- Srd960 Srd991 Sil enDocumento16 pagineSrd960 Srd991 Sil enryg1360Nessuna valutazione finora

- Arc Flash Calculations by ElizaldeDocumento55 pagineArc Flash Calculations by ElizaldeLazzaro DanieleNessuna valutazione finora

- Procedure For Assessment of Protection Relay Testing Engineers DCRPDocumento8 pagineProcedure For Assessment of Protection Relay Testing Engineers DCRPMohamed Wahid100% (1)

- Confined SpaceDocumento33 pagineConfined SpaceDesta WidayatNessuna valutazione finora

- Nfpa 780Documento30 pagineNfpa 780Anonymous V005epmNessuna valutazione finora

- QRG-DC-004 Regulation For Consolidated Permit To Work For DC Common Areas (CPW) - FinalDocumento56 pagineQRG-DC-004 Regulation For Consolidated Permit To Work For DC Common Areas (CPW) - FinalAJITSINGH100% (2)

- Portsaid Tunnels Project: Lock Out / Tag Out PermitDocumento2 paginePortsaid Tunnels Project: Lock Out / Tag Out PermitAhmed IbrahimNessuna valutazione finora

- Selection, Installation & Maintenance of Electrical EquipmentDocumento20 pagineSelection, Installation & Maintenance of Electrical EquipmentsandystaysNessuna valutazione finora

- Battery Room Design Review Checklist 2014Documento3 pagineBattery Room Design Review Checklist 2014candratrikusuma100% (1)

- Electrical Standards and Approved Codes of Practice - Electrical Safety at WorkDocumento6 pagineElectrical Standards and Approved Codes of Practice - Electrical Safety at WorkAngelo FranklinNessuna valutazione finora

- LOTO Policy and ProceduresDocumento11 pagineLOTO Policy and ProcedurestintucinbNessuna valutazione finora

- White Paper Arc Flash Compliance PDFDocumento15 pagineWhite Paper Arc Flash Compliance PDFAlexander WijesooriyaNessuna valutazione finora

- Surge Protection Over Voltage DevicesDocumento24 pagineSurge Protection Over Voltage Devicesnooruddinkhan1Nessuna valutazione finora

- While You're Here: P Lease Turn-Off Your Cell Phone, or Place On Mute / VibrateDocumento50 pagineWhile You're Here: P Lease Turn-Off Your Cell Phone, or Place On Mute / VibrateFabogadie Scaffolding100% (2)

- AdvertDocumento9 pagineAdvertjoseph katongoNessuna valutazione finora

- Paladin® Designbase™: Ac & DC Arc Flash Evaluation ManualDocumento81 paginePaladin® Designbase™: Ac & DC Arc Flash Evaluation ManualJulio Perez Rodriguez100% (1)

- Arc Flash Calculation Example1 PDFDocumento25 pagineArc Flash Calculation Example1 PDFcpuerto33Nessuna valutazione finora

- Ergon MSDS Transformer OilDocumento4 pagineErgon MSDS Transformer Oilbpd21Nessuna valutazione finora

- Abb MVDocumento66 pagineAbb MVHansika RajapakshaNessuna valutazione finora

- Certificate of Calibration and Conformance: OmicronDocumento1 paginaCertificate of Calibration and Conformance: OmicronNadiaNessuna valutazione finora

- Training Pack On Electrical Safety & PI For MTT July 25Documento52 pagineTraining Pack On Electrical Safety & PI For MTT July 25madhulika100% (1)

- Arc Flash Hazards and Electrical Safety Program ImplementationDocumento5 pagineArc Flash Hazards and Electrical Safety Program Implementationgirish19Nessuna valutazione finora

- JSA - Electrical IsolationDocumento1 paginaJSA - Electrical IsolationRaju KhalifaNessuna valutazione finora

- Electrical Safety Audit Why When How Ilovepdf CompressedDocumento22 pagineElectrical Safety Audit Why When How Ilovepdf CompressedGolam Samdanee TaneemNessuna valutazione finora

- 8BK88PLUSDocumento8 pagine8BK88PLUSSwapnil PatilNessuna valutazione finora

- Safety Clearence For Electrical Panel PDFDocumento11 pagineSafety Clearence For Electrical Panel PDFFarekh100% (1)

- Isolation Permit/ High Voltage Permit NoDocumento2 pagineIsolation Permit/ High Voltage Permit NoMohammed KadhimNessuna valutazione finora

- SC100 and SC110 NRJED313570EN-V6-2Documento70 pagineSC100 and SC110 NRJED313570EN-V6-2msiantexNessuna valutazione finora

- Ringmaster Nov07 SE6251 PDFDocumento92 pagineRingmaster Nov07 SE6251 PDFosmpot100% (1)

- Hi POT Test BasicsDocumento6 pagineHi POT Test BasicsdeepakNessuna valutazione finora

- Arc FlashDocumento7 pagineArc FlashGhulam MustaqeemNessuna valutazione finora

- Effects of Arc Flash Hazard AnalysisDocumento66 pagineEffects of Arc Flash Hazard Analysismelbien gacayanNessuna valutazione finora

- F-Ehs-045 PSSRDocumento4 pagineF-Ehs-045 PSSRyogiNessuna valutazione finora

- Tangos National Highschool Budget of Work Computer System Servicing Grade 8 Learning Competencies LC Number No. of Days CodeDocumento1 paginaTangos National Highschool Budget of Work Computer System Servicing Grade 8 Learning Competencies LC Number No. of Days CodeHenry De los Reyes100% (1)

- EN VEGACAP 65 Relay (DPDT)Documento44 pagineEN VEGACAP 65 Relay (DPDT)rajatNessuna valutazione finora

- Inspection and Testing of Electrical Installations Below 1000 VoltsDocumento14 pagineInspection and Testing of Electrical Installations Below 1000 VoltsGeri AlselaNessuna valutazione finora

- Annexure1 PSSR CheklistDocumento12 pagineAnnexure1 PSSR Cheklistanjna100% (1)

- Advanced Event Analysis Tutorial: Part 1: QuestionsDocumento5 pagineAdvanced Event Analysis Tutorial: Part 1: QuestionsDanilo Poma MuñozNessuna valutazione finora

- Project Hazard Analysis (HARC)Documento1 paginaProject Hazard Analysis (HARC)Sajid HussainNessuna valutazione finora

- Saes B 055 PDFDocumento33 pagineSaes B 055 PDFSajid HussainNessuna valutazione finora

- Walkbehined Wet Saw/Cutter Daily Checklist: Inspected By: Position: ID/Badge #: Location: Equip. #: DateDocumento1 paginaWalkbehined Wet Saw/Cutter Daily Checklist: Inspected By: Position: ID/Badge #: Location: Equip. #: DateSajid HussainNessuna valutazione finora

- DEKS Flashings For Metal Roofs CatalogDocumento3 pagineDEKS Flashings For Metal Roofs CatalogSajid HussainNessuna valutazione finora

- Cure and Liquid SurfacesDocumento4 pagineCure and Liquid SurfacesSajid HussainNessuna valutazione finora

- Equipment Inspection Checklist: Inspection List (Check One) Pass Fail CommentsDocumento2 pagineEquipment Inspection Checklist: Inspection List (Check One) Pass Fail CommentsSajid HussainNessuna valutazione finora

- Sa 9613Documento1 paginaSa 9613Sajid HussainNessuna valutazione finora

- HSE Alert 07-16 Damage To Drilling Mast IncidentDocumento1 paginaHSE Alert 07-16 Damage To Drilling Mast IncidentSajid HussainNessuna valutazione finora

- Backhoe ChecklistDocumento1 paginaBackhoe ChecklistSajid Hussain100% (1)

- Portable Space Heater Safety: 1 MeterDocumento1 paginaPortable Space Heater Safety: 1 MeterSajid HussainNessuna valutazione finora

- Work Permit Q&ADocumento3 pagineWork Permit Q&ASajid Hussain100% (1)

- Schedule B - Attachment 01Documento1 paginaSchedule B - Attachment 01Sajid HussainNessuna valutazione finora

- Car Parking PDFDocumento2 pagineCar Parking PDFSajid HussainNessuna valutazione finora

- Health and Safety Induction: For Smaller Construction CompaniesDocumento63 pagineHealth and Safety Induction: For Smaller Construction CompaniesSean ShamsNessuna valutazione finora

- GI 2.718, Contractor Site Allotment ProcedureDocumento12 pagineGI 2.718, Contractor Site Allotment ProcedureSajid Hussain100% (1)

- Centre For The Improvement of Working Conditions & Environment (CIWCE), Lahore - PakistanDocumento19 pagineCentre For The Improvement of Working Conditions & Environment (CIWCE), Lahore - PakistanSajid HussainNessuna valutazione finora

- 2018 Operational Calendar PDFDocumento1 pagina2018 Operational Calendar PDFSajid HussainNessuna valutazione finora

- Driver Evaluation Road Test FormDocumento2 pagineDriver Evaluation Road Test FormSajid Hussain100% (3)

- The Engraver's ManualDocumento117 pagineThe Engraver's ManualLamontCranston09100% (7)

- Gaurav Jain ResumeDocumento2 pagineGaurav Jain ResumeGaurav JainNessuna valutazione finora

- Asme B18.5.2.1M 1996Documento8 pagineAsme B18.5.2.1M 1996Jesse ChenNessuna valutazione finora

- IATF Top Management RequirementsDocumento6 pagineIATF Top Management RequirementsManu SharmaNessuna valutazione finora

- Ferrous Processing & Trading Co. Company OverviewDocumento5 pagineFerrous Processing & Trading Co. Company OverviewfptscrapNessuna valutazione finora

- Aircraft Design: T/WDocumento47 pagineAircraft Design: T/WYakNessuna valutazione finora

- Connaect Third Edition 2009Documento92 pagineConnaect Third Edition 2009Alin GiumancaNessuna valutazione finora

- Review On Edg PDFDocumento8 pagineReview On Edg PDFBibekanand PadhiNessuna valutazione finora

- Oracle ADF Developer GuideDocumento1.296 pagineOracle ADF Developer Guideapi-26825735Nessuna valutazione finora

- American Welding SocietyDocumento56 pagineAmerican Welding SocietyJUAN RAMOSNessuna valutazione finora

- Clean Steel Practices in The Melt ShopDocumento3 pagineClean Steel Practices in The Melt Shopmp87_ingNessuna valutazione finora

- Cardan Case Study1Documento2 pagineCardan Case Study1JJNessuna valutazione finora

- Introduction To Production and Operations ManagementDocumento17 pagineIntroduction To Production and Operations ManagementSyed M. Fakharullah KazmiNessuna valutazione finora

- SGRAO Aircraft Operator Requirements V3.1Documento287 pagineSGRAO Aircraft Operator Requirements V3.1smr767Nessuna valutazione finora

- m1100 s08 v1.1f en - Safety - ProductsDocumento4 paginem1100 s08 v1.1f en - Safety - Productsdzul fiqarNessuna valutazione finora

- UPU CatalogueStandardsCatalogueOfUpuStandardsEnDocumento28 pagineUPU CatalogueStandardsCatalogueOfUpuStandardsEntrujillo66@yahooNessuna valutazione finora

- MEP + Specialty Systems Design Standards (FOUR SEASONS)Documento304 pagineMEP + Specialty Systems Design Standards (FOUR SEASONS)Omar Sharawi92% (12)

- Intro To Lean ManufacturingDocumento46 pagineIntro To Lean ManufacturingSharonz Muthuveeran100% (3)

- GDST 1241 ManualDocumento24 pagineGDST 1241 ManualLida PerezNessuna valutazione finora

- MINERA IRL Project Gold OllacheaDocumento230 pagineMINERA IRL Project Gold OllacheaJhonCordovaCruz100% (1)

- List Applicable WPS StructureDocumento7 pagineList Applicable WPS StructureFerdie OSNessuna valutazione finora

- Is 3601.2006Documento21 pagineIs 3601.2006kprasad_56900Nessuna valutazione finora

- Eaton Fuller Heavy-Duty Transmissions TRDR0400: Driver InstructionsDocumento24 pagineEaton Fuller Heavy-Duty Transmissions TRDR0400: Driver InstructionsGeorge BuitragoNessuna valutazione finora

- Assignment 3 - OMDocumento2 pagineAssignment 3 - OMRushil RamroepNessuna valutazione finora

- Cat 20 23 Minibloc6 Rom GBDocumento16 pagineCat 20 23 Minibloc6 Rom GBarteorNessuna valutazione finora

- MSC - Nastran Rotor Dynamics: Simulating The Effects of Rotating Components For Design and AnalysisDocumento2 pagineMSC - Nastran Rotor Dynamics: Simulating The Effects of Rotating Components For Design and Analysischandra sekharNessuna valutazione finora

- Quiz QuestionsDocumento8 pagineQuiz QuestionsSai NathNessuna valutazione finora

- Manufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczDocumento2 pagineManufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczJosephMarkowiczNessuna valutazione finora

- Application of Lean in Caterpillar IncDocumento6 pagineApplication of Lean in Caterpillar IncAyush GautamNessuna valutazione finora

- Job Description For QA Automation EngineerDocumento1 paginaJob Description For QA Automation EngineerRam RaiNessuna valutazione finora