Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

4 KL Reactor Data Sheet

Caricato da

pankil patelTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

4 KL Reactor Data Sheet

Caricato da

pankil patelCopyright:

Formati disponibili

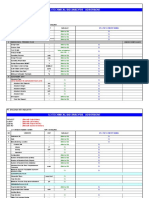

TECHNICAL SPECIFICATION SHEET

SHEET

CAP_4.0 KL SS316_REACTOR with

SR.NO. SPECIFICATION Mild Steel Jacket without Insulation

Qty. One No.

Tag no. CTC

Vertical cylindrical with Top & Bottom dish

Type ends.(Anchor Agitator )

MOC SS316 /MS

A GENERAL DATA

1 DESIGN CODE ASME SEC. VIII, DIV-Latest

2 TYPE /POSITION Cylindrical / Vertical top & bottom

dish end type

3 WORKING VOLUME 4000 Ltrs.

4 GEOMETRIC VOLUME 4838 Ltrs.

5 AREA CLASSIFICATION NON GMP, NON HAZARDOUS

6 SUPPORT TYPE 04 nos, Lugs Support

B SERVICE DETAILS

7 Material to be handled

8 Specific Gravity

9 Viscosity, Cp

10 Solid Content, mm

11 Particle size/type

12 Residue formation, if any

C DESIGN DATA (SHELL/JACKET)

13 DESIGN PRESS (kg/cm² g) 4.5/ 4.5 kgs/cm2

14 OPT. PRESS (kg/cm² g) 3.0/ 3.0 kgs/cm2

15 DESIGN TEMP. (°C) 10 To 150 deg. C/.10 To 150 deg. C

16 OPT. TEMP. (°C) 15 To 130 deg. C/15 To 135 deg. C

17 Hydro test Pressure (kg/cm² g) 6.75 / 6.75 kgs/cm2

18 CORROSION ALLOWANCE, SHELL Nil

19 JOINT EFFICIENCY 0.85

20 RADIOGRAPHY (SHELL + DISH) SPOT + FULL

D Vessel Technical Data

21 Shell Dia/ Ht/ Thickness 1500mm I.D/ 2250mm Ht. / 8mm

Thk. - SS 316

22 Top Dish dia / Thickness 1500mm I.D / 10mm Thk. ( 10%

Torispherical ) - SS 316

23 Bottom Dish dia / Thickness 1500mm I.D / 10mm Thk. ( 10%

Torispherical ) - SS 316

24 Bearings Standard - 2 Nos. ( 32214 & 32215 )-

SKF

25 VFD BY CLIENT

26 Jacket ID x Ht. ID Dia. 1616 x 2000 mm

27 Jacket Thickness 6.0 mm Shell & 8.0 mm dish end.

28 Jacket MOC Mild Steel

29 Insulation Cladding dia / Ht /

Thickness

30 Insulation Cladding Dish

Dia/Thickness

31 Insulation Cladding Closers

32 Stiffener Rings

33 Shaft Dia Ø80 mm two piece type - SS 316

34 Agitator Anchor Type

35 Agitator Rpm 35 RPM

36 Anchor Blades 80 mm width, 10mm Thk. Blades -

SS 316

37 Baffle 2250mm Lg. 100 mm width, 10mm

Thk., 4 Nos. - SS 316

450 NB, 200 mm Ht, 8mm Thk. Neck. Flange &

38 Manhole Cover 20mm Thk. - MS

WITH SS316 Lining

Ø400mm ID, 450mm Ht., 8mm Thk. Shell.,

39 Drive Stools 500mm OD,400 ID , 25mm

Thk. Flanges -Mild steel

40 Agitator pad 32mm Thk. MS WITH SS 316

Bushing

41 Motor 7.5HP / 1440 RPM Flange Mounted,

Make - C.G.-FLP

42 Gear Box Make - ELECON (7.5HP )Out Put

RPM 35, Worm Reduction type, Foot Mounted

Gear Box.

43 Shaft Seal STUFFING BOX / Single Mechanical Seal as per

requirement.

44 Bearing Housing MS / CI

45 Shell Nozzle Seamless Pipes, SCH40. - SS 316

46 Shell Nozzle Flanges ASA150# Sorf ANSI B 16.5 Flanges -

SS 316 As per Standard

47 Jacket Nozzle Seamless Pipes, Mild Steel

48 Jacket Nozzle Flanges ASA150# Sorf ANSIB16.5 Flanges –

As per standard

49 Lifting hooks 2 Nos. -mild steel with SS 316 pad

plate

50 Supports 4 Nos. Legs Type –mild steel with SS

316 Pad Plate

51 Earthing Boss SS 304-02 No

52 Nut & Bolts SS 316 /MS

53 Gasket CHAMPION TEFLON WRAPPED

54 Dual Insulation N/A

55 Insulation thickness N/A

56 Finishing ss surface - acid pickling and passivation. Mild steel surafes - Two coats of epoxy primer

E NOZZLE SCHEDULE As Per requirement. We considered Following Nozzles

56 N1 450/100 (Manhole/View glass)

57 N2 100 MM Light Glass

58 N3 100 mm Sight Glass

59 N4 50 NB – 02 Nos.

60 N5 40 NB – 03 Nos.

61 N6 25 NB – 02 Nos.

NOTES :

1) All bolt holes straddle to principal centerline of the vessel.

2) 40 NB and below nozzles to be provided with two stiffeners at 90 degree apart.

3) Outside projection of nozzles shall be 150mm.

4)50 NB and Above nozzles will be Provided with R.F Pad

01 OF 01

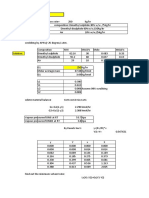

CAP_4.0 KL SS316_REACTOR with

Mild Steel Jacket without Insulation

One No.

CTC

Vertical cylindrical with Top & Bottom dish ends.(2

Bladde PBT, 2

Stage )

SS316 /MS

ASME SEC. VIII, DIV-Latest

Cylindrical / Vertical top & bottom

dish end type

4000 Ltrs.

4838 Ltrs.

NON GMP, NON HAZARDOUS

04 nos, Lugs Support

4.5/ 4.5 kgs/cm2

3.0/ 3.0 kgs/cm2

10 To 150 deg. C/.10 To 150 deg. C

15 To 130 deg. C/15 To 135 deg. C

6.75 / 6.75 kgs/cm2

Nil

0.85

SPOT + FULL

1500mm I.D/ 2250mm Ht. / 8mm

Thk. - SS 316

1500mm I.D / 10mm Thk. ( 10%

Torispherical ) - SS 316

1500mm I.D / 10mm Thk. ( 10%

Torispherical ) - SS 316

Standard - 2 Nos. ( 32214 & 32215 )-

SKF

BY CLIENT

ID Dia. 1616 x 2000 mm

6.0 mm Shell & 8.0 mm dish end.

Mild Steel

Ø80 mm two piece type - SS 316

3 Blade PBT, 2 Stage

90 RPM

80 mm width, 10mm Thk. Blades - SS

316

2250mm Lg. 100 mm width, 10mm

Thk., 4 Nos. - SS 316

450 NB, 200 mm Ht, 8mm Thk. Neck. Flange &

Cover 20mm Thk. - MS

WITH SS316 Lining

Ø400mm ID, 450mm Ht., 8mm Thk. Shell., 500mm

OD,400 ID , 25mm

Thk. Flanges -Mild steel

32mm Thk. MS WITH SS 316 Bushing

7.5HP / 1440 RPM Flange Mounted,

Make - C.G.-FLP

Make - ELECON (7.5HP )Out Put RPM

90, Worm Reduction type, Foot Mounted Gear Box.

STUFFING BOX / Single Mechanical Seal as per

requirement.

MS / CI

Seamless Pipes, SCH40. - SS 316

ASA150# Sorf ANSI B 16.5 Flanges -

SS 316 As per Standard

Seamless Pipes, Mild Steel

ASA150# Sorf ANSIB16.5 Flanges –

As per standard

2 Nos. -mild steel with SS 316 pad

plate

4 Nos. Legs Type –mild steel with SS

316 Pad Plate

SS 304-02 No

SS 316 /MS

CHAMPION TEFLON WRAPPED

N/A

N/A

ats of epoxy primer

Potrebbero piacerti anche

- 6 PDFDocumento100 pagine6 PDFKory JenoNessuna valutazione finora

- PSV Sizing Tool API Based Calc Sheets PDFDocumento11 paginePSV Sizing Tool API Based Calc Sheets PDFLucas Farias0% (1)

- Limpet Coil On Dish Design As Per PD5500Documento1 paginaLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENessuna valutazione finora

- Boiler Specification 2Documento3 pagineBoiler Specification 2AbdulBasitNessuna valutazione finora

- Dostoevsky in Moderation - Thomas MannDocumento8 pagineDostoevsky in Moderation - Thomas MannNyetochka100% (3)

- 1803 Hector Berlioz - Compositions - AllMusicDocumento6 pagine1803 Hector Berlioz - Compositions - AllMusicYannisVarthisNessuna valutazione finora

- Cooling Tower ComparisonDocumento4 pagineCooling Tower ComparisonKiran DasNessuna valutazione finora

- Agitator SizingDocumento4 pagineAgitator SizingArbee AquinoNessuna valutazione finora

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocumento2 pagineE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinNessuna valutazione finora

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Documento4 pagineControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986Nessuna valutazione finora

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocumento1 paginaCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNessuna valutazione finora

- Tank Volume CalculationDocumento9 pagineTank Volume CalculationMangesh MandgeNessuna valutazione finora

- Line Sizing Design Basis - General Specification PDFDocumento11 pagineLine Sizing Design Basis - General Specification PDFSaiKumarNessuna valutazione finora

- Process Design Data Sheet C-401Documento2 pagineProcess Design Data Sheet C-401Tej ChoksiNessuna valutazione finora

- EF3e Preint Filetest 06b PDFDocumento5 pagineEF3e Preint Filetest 06b PDFDiego Real Torres Nina100% (1)

- Autoclave ReactorDocumento24 pagineAutoclave ReactorMeredith Villarete100% (1)

- Column Data Sheet Distillation Column (T-2010)Documento12 pagineColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezNessuna valutazione finora

- NOx Scrubbing Technology Breakthrough - Products FinishingDocumento6 pagineNOx Scrubbing Technology Breakthrough - Products FinishingPiyush AgarwalNessuna valutazione finora

- Cortot Edition Chopin Etudes Alexander Technique Facilitate PerformanceDocumento102 pagineCortot Edition Chopin Etudes Alexander Technique Facilitate PerformanceMiguel Angel Aguirre Igoa50% (2)

- Output Summary: SI UnitsDocumento42 pagineOutput Summary: SI UnitsAkhil JoseNessuna valutazione finora

- TBA - AdsorbentDocumento4 pagineTBA - AdsorbentTifano KhristiyantoNessuna valutazione finora

- Boiler Capcity-F&A 100 Deg CDocumento3 pagineBoiler Capcity-F&A 100 Deg CAgeng Firstyan BagaskoroNessuna valutazione finora

- School Grade Level & Quarter Teacher SHS Track Week No. Inclusive Dates Learning Area Scheduled Time 7:30am - 8:30am/ 9:45am-TopicDocumento4 pagineSchool Grade Level & Quarter Teacher SHS Track Week No. Inclusive Dates Learning Area Scheduled Time 7:30am - 8:30am/ 9:45am-Topicjm33% (3)

- Statistics for Process Control Engineers: A Practical ApproachDa EverandStatistics for Process Control Engineers: A Practical ApproachNessuna valutazione finora

- Object PronounsDocumento2 pagineObject PronounsLiz PinedaNessuna valutazione finora

- MONTZ Main CataloqueDocumento69 pagineMONTZ Main Cataloque123Nessuna valutazione finora

- Bulerias by Sabicas PDFDocumento7 pagineBulerias by Sabicas PDFe_saNessuna valutazione finora

- Line Sizing Criteria As Per Different StandardsDocumento4 pagineLine Sizing Criteria As Per Different Standardsadil alameenNessuna valutazione finora

- Medieval Christian Dualist Perceptions and Conceptions of Biblical ParadiseDocumento18 pagineMedieval Christian Dualist Perceptions and Conceptions of Biblical ParadiseDositheus SethNessuna valutazione finora

- Water Treatment Plant Performance Evaluations and OperationsDa EverandWater Treatment Plant Performance Evaluations and OperationsNessuna valutazione finora

- Superheated Steam Condensate TankDocumento4 pagineSuperheated Steam Condensate TankGanesh BhardwajNessuna valutazione finora

- Excel SizingDocumento10 pagineExcel SizingJolteon JuniorNessuna valutazione finora

- PDFDocumento1 paginaPDFdhaktodesatyajitNessuna valutazione finora

- Pressuredrop Calculations by Kern Method SRRDocumento18 paginePressuredrop Calculations by Kern Method SRRrajeev50588Nessuna valutazione finora

- TW6151A - Wake Freq CalcaDocumento2 pagineTW6151A - Wake Freq Calcakkd3Nessuna valutazione finora

- Atlas Copco Scooptram: St2G Diagrams & DrawingsDocumento50 pagineAtlas Copco Scooptram: St2G Diagrams & Drawingsferdy ramosNessuna valutazione finora

- Emergency Scrubber DesignDocumento36 pagineEmergency Scrubber DesignSurajit das0% (1)

- Blending and AgitationDocumento18 pagineBlending and AgitationSivanand SNessuna valutazione finora

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocumento4 pagineWI06-0260 Calculations For Obround Nozzle ConnectionskumarNessuna valutazione finora

- Student Unit Op Lab Manual - Thin Film Evaporator PDFDocumento5 pagineStudent Unit Op Lab Manual - Thin Film Evaporator PDFMuiz MoktarNessuna valutazione finora

- Vent CalculationDocumento4 pagineVent CalculationniteshacharyaNessuna valutazione finora

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Da EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Nessuna valutazione finora

- Project : Agitator Power Calculations for 15L FermenterDocumento4 pagineProject : Agitator Power Calculations for 15L FermenterGunasekaranNessuna valutazione finora

- Power Calculation For AgitatorDocumento12 paginePower Calculation For AgitatorDeepikaNessuna valutazione finora

- Premagopal Goswami - Nityananda Vamsa VistarDocumento204 paginePremagopal Goswami - Nityananda Vamsa VistarPañcama Veda Dāsa100% (1)

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocumento3 pagineSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Heat ExchangerDocumento11 pagineHeat ExchangerMangesh MandgeNessuna valutazione finora

- Bulk Air Eliminator R1Documento1 paginaBulk Air Eliminator R1hydrothermsNessuna valutazione finora

- Blower Datasheet SpecsDocumento2 pagineBlower Datasheet Specspramod_tryNessuna valutazione finora

- Process Design of Solid-Liquid Separators (Project Standards and Specifications)Documento10 pagineProcess Design of Solid-Liquid Separators (Project Standards and Specifications)nabilaNessuna valutazione finora

- Dennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale OperationsDocumento25 pagineDennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale Operationssushant_jhawerNessuna valutazione finora

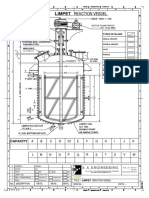

- Limpet Reaction Vessel PDFDocumento1 paginaLimpet Reaction Vessel PDFarajamani78Nessuna valutazione finora

- Design of AgitatorDocumento6 pagineDesign of AgitatorVishalNessuna valutazione finora

- General Arrangement Drawing: Pump DataDocumento1 paginaGeneral Arrangement Drawing: Pump DataJwardNessuna valutazione finora

- Vapor Line Sizing-Mpp6Documento10 pagineVapor Line Sizing-Mpp6Nitin KurupNessuna valutazione finora

- Chemical Engineering DiagramsDocumento1 paginaChemical Engineering DiagramsAngela Te SabordoNessuna valutazione finora

- Chemical Plant Utility - Nitrogen System DesignDocumento10 pagineChemical Plant Utility - Nitrogen System DesignIJRASETPublicationsNessuna valutazione finora

- Condensate & CoolingDocumento111 pagineCondensate & CoolingSantosh KumarNessuna valutazione finora

- Agitated Thin Film Dryer ClaculationDocumento12 pagineAgitated Thin Film Dryer ClaculationakaashNessuna valutazione finora

- Tank DesignDocumento2 pagineTank DesignkamleshyadavmoneyNessuna valutazione finora

- Pipe DimensionDocumento7 paginePipe DimensionLily NurdianaNessuna valutazione finora

- Sludge Thickener Pump Head CalculationDocumento4 pagineSludge Thickener Pump Head CalculationgawtomNessuna valutazione finora

- Heat ExchangersDocumento48 pagineHeat ExchangersRiccat Shio'TangNessuna valutazione finora

- KOCH MBR Brochure Ver.2016Documento8 pagineKOCH MBR Brochure Ver.2016quysuvn88Nessuna valutazione finora

- Pertamina FRP and Ball Valve Specification SheetDocumento3 paginePertamina FRP and Ball Valve Specification Sheetbagus handokoNessuna valutazione finora

- Insulation For SCI ReactorDocumento12 pagineInsulation For SCI ReactorJogender DhayalNessuna valutazione finora

- Index of DEPs Version 28 technical document standardsDocumento46 pagineIndex of DEPs Version 28 technical document standardsMina EliasNessuna valutazione finora

- AtfdDocumento4 pagineAtfdDarshan PatelNessuna valutazione finora

- A11Documento1 paginaA11liviu_dovaNessuna valutazione finora

- Solar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsDa EverandSolar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsM. G. HutchinsNessuna valutazione finora

- P PT Industrial Stainless Steel Filter HousingsDocumento4 pagineP PT Industrial Stainless Steel Filter Housingsliceth.emilio30mpNessuna valutazione finora

- Kings, Farmers and Towns: By: Aashutosh PanditDocumento27 pagineKings, Farmers and Towns: By: Aashutosh PanditIndu sharmaNessuna valutazione finora

- Reading Quiz For U3 (Wrap Up) - Attempt ReviewDocumento4 pagineReading Quiz For U3 (Wrap Up) - Attempt ReviewNancyNessuna valutazione finora

- Advertising in Selling Real Estate by C.C.C. TatumDocumento7 pagineAdvertising in Selling Real Estate by C.C.C. Tatumreal-estate-historyNessuna valutazione finora

- Products ListDocumento9 pagineProducts ListKrishnan Jayaraman0% (2)

- Kevin LynchDocumento3 pagineKevin LynchKevinLynch17Nessuna valutazione finora

- Laser Cut Helicone: Build DNA Sculpture Under 40 CharsDocumento9 pagineLaser Cut Helicone: Build DNA Sculpture Under 40 CharsEawNessuna valutazione finora

- Dear YouDocumento6 pagineDear YouSue SandraNessuna valutazione finora

- La Danse, A Film by Frederick Wiseman 2009Documento5 pagineLa Danse, A Film by Frederick Wiseman 2009gheorghe3Nessuna valutazione finora

- Contemporary Czech Violin Makers 08 2007Documento3 pagineContemporary Czech Violin Makers 08 2007Sergiu MunteanuNessuna valutazione finora

- DokumenDocumento15 pagineDokumennoviaNessuna valutazione finora

- Fourth Finger Base Joint: BasicsDocumento3 pagineFourth Finger Base Joint: BasicsFrancisco Darling Lopes do NascimentoNessuna valutazione finora

- A Drop of Water - Amounts To Life': A Report On Project Boond'Documento8 pagineA Drop of Water - Amounts To Life': A Report On Project Boond'reyazbashaNessuna valutazione finora

- Exploring the Versatility of Reinforced Concrete in Brutalist ArchitectureDocumento17 pagineExploring the Versatility of Reinforced Concrete in Brutalist ArchitectureGaurika GroverNessuna valutazione finora

- Vitreous Enamel Panels: Durable, Versatile Cladding MaterialDocumento24 pagineVitreous Enamel Panels: Durable, Versatile Cladding Materialjoe briffaNessuna valutazione finora

- Architecture of The PhilippinesDocumento20 pagineArchitecture of The PhilippinesMary Rose QuimanjanNessuna valutazione finora

- Lirik Lagu My Love - WestlifeDocumento2 pagineLirik Lagu My Love - WestlifeRafif Rafif100% (1)

- Olives Ocean Discussion GuideDocumento1 paginaOlives Ocean Discussion Guideapi-271982029Nessuna valutazione finora

- SRDocumento17 pagineSRMonika AyuningrumNessuna valutazione finora

- Bài tập rút gọn mệnh đề quan hệ trong tiếng anh có đáp ánDocumento2 pagineBài tập rút gọn mệnh đề quan hệ trong tiếng anh có đáp ánVan HongNessuna valutazione finora