Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Xuper 680 CGS

Caricato da

Arbind RajrishiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Xuper 680 CGS

Caricato da

Arbind RajrishiCopyright:

Formati disponibili

More than 100 years‘ experience in finding solutions for your business.

Xuper 680 CGS

Manual arc welding electrode Application: Joining dissimilar steels

DESCRIPTION OPERATING PARAMETERS

Xuper 680CGS is a highly alloyed manual Preparation

electrode giving very high strength joints with For best results, remove contamination, cracks and worn

excellent resistance to cracking, corrosion and metal from weld area. Prepare joints with a U/V (60°) or X

oxidation. profile (90°).

FEATURES Preheating

Fe Cr Ni rich alloy deposit with an Generally not needed. Preheating depends on the steel's

austenitic structure, strengthened with Carbon Equivalent, the work piece size, thickness and

delta ferrite geometry.

superior dilution tolerance allows use on

a wide range of steels CE < 0.2 preheat not essential

Special rutile basic flux coating for easy CE 0.2 - 0.4 preheat 100-200°C

welding CE 0.4 - 0.8 preheat 200-350°C

CGS - Controlled Grain Structure -

strength and ductility Note that 12-14% Mn steels should never be preheated

spray type metal transfer and the work piece temperature during welding should be

superb weldability for all steels kept below 250°C.

low amperage - easy strike / restrike Welding parameters

useful for repairs where the base material

is unknown

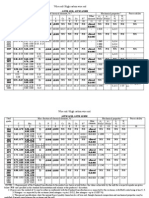

Wire equivalent EnDOtec DO02 Dia. mm 2.5 3.2 4.0 5.0

Current A 45-85 60-110 90-150 145-200

PRINCIPAL APPLICATIONS

Joining and buttering

For difficult to weld steels, including: cast steel, Higher amperages for large workpieces, and maximum

heat-treated steel, high carbon steel, manganese deposition rate; lower amperages for small workpieces,

steel, stainless steel, tool steel and steels of difficult welding positions and minimum dilution. Minimise

unknown composition, plus dissimilar joining. arc length. Max. interpass temperature: 300°C. Remove

Wearfacing slag before each new pass.

Machineable, low friction, work hardening deposit

provides oxidation resistant protection for all of Welding polarity (+) DCEP

the above base materials.

Industrial examples Post-welding treatment

Tool and die repairs, rebuilding gear teeth, Do not use heat treatment. Adjust cooling rate according

repairing cracks in machine casings, buttering to base material and size of workpiece.

layers and repairs on earthmoving and drilling

equipment, and rebuilding worn shafts. Storage and handling

Electrodes are supplied in DryPak containers for optimum

TECHNICAL DATA protection. Unprotected electrodes may absorb moisture,

Mechanical properties in which case redry for 1-2 hours at 200-250°C.

Tensile strength Rm MPa 770-850

Yield strength Rp0.2 MPa >640

Elongation A5 % 25-30

Hardness as welded HV30 240-280

Deposit density g/cm3 ~7.6

Effective yield RE <110 %

Linear expansion 20-300 °C ~13.5 x 10-6

Service temperature <450°C for

(not for sub-zero temperature) joining

Australian Distributor for Castolin Eutectic Products

Offices in Brisbane, Sydney, Melbourne, Perth

Ph 1300 728 422 Fax 1300 728 420

www.smenco.com.au sales@eutectic.com.au

Potrebbero piacerti anche

- John Deere 772d 6wd GraderDocumento6 pagineJohn Deere 772d 6wd GraderyaserattiaNessuna valutazione finora

- Introduction To Probability: Business Statistics: Communicating With Numbers, 4eDocumento52 pagineIntroduction To Probability: Business Statistics: Communicating With Numbers, 4eRetno Ajeng Anissa WidiatriNessuna valutazione finora

- S355 European Standard SteelDocumento7 pagineS355 European Standard SteelmaiquelernNessuna valutazione finora

- Nisshin Cold-Rolled Special Steel GuideDocumento28 pagineNisshin Cold-Rolled Special Steel GuideekopujiantoeNessuna valutazione finora

- Heat Treatment ProcessesDocumento44 pagineHeat Treatment Processesmesa142Nessuna valutazione finora

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Documento5 pagineSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiNessuna valutazione finora

- Tata Steel - YMPRESS S500MC - Data SheetDocumento2 pagineTata Steel - YMPRESS S500MC - Data SheetpnagarajjNessuna valutazione finora

- CIGWELDDocumento244 pagineCIGWELDrodastrid5653100% (1)

- Name: Fatema Saeed Grade Level:: Lesson Plan TemplateDocumento3 pagineName: Fatema Saeed Grade Level:: Lesson Plan Templateapi-340688378Nessuna valutazione finora

- GL DrilTec Catalogue Last VersionDocumento32 pagineGL DrilTec Catalogue Last Versiontoxicity23Nessuna valutazione finora

- Surface Preparation Metallizing ProcedureDocumento6 pagineSurface Preparation Metallizing ProcedureCorrosion FactoryNessuna valutazione finora

- China Structural Steel and Alloy Steel GBT Q345Documento3 pagineChina Structural Steel and Alloy Steel GBT Q345bkprodhNessuna valutazione finora

- Surface Defects in Steel ProductsDocumento41 pagineSurface Defects in Steel ProductsShilaj PNessuna valutazione finora

- Analysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceDocumento5 pagineAnalysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceTanjidul IslamNessuna valutazione finora

- AISI 1018 Mild Low Carbon Steel PDFDocumento3 pagineAISI 1018 Mild Low Carbon Steel PDFFebrian JhaNessuna valutazione finora

- Is 513 Amendment-1Documento2 pagineIs 513 Amendment-1sanjeev00747488Nessuna valutazione finora

- WCC Colmonoy 200 Series - TDSDocumento3 pagineWCC Colmonoy 200 Series - TDSedipson100% (2)

- Weld RepireDocumento91 pagineWeld RepireالGINIRAL FREE FIRENessuna valutazione finora

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocumento2 pagineSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- GB 1591 Q420 Steel PropertiesDocumento6 pagineGB 1591 Q420 Steel Propertiespbp2956Nessuna valutazione finora

- IS 5517 - 1993-Hardening & Tempering GradesDocumento15 pagineIS 5517 - 1993-Hardening & Tempering GradesMohanrajMJ100% (1)

- Quality Alert # 01 Storage of Welding ConsumablesDocumento1 paginaQuality Alert # 01 Storage of Welding ConsumablesGaurav Khamkar100% (1)

- GMAWDocumento12 pagineGMAWsushant47Nessuna valutazione finora

- Welding BisplateDocumento12 pagineWelding BisplateLim Senglin100% (1)

- c40 Carbon Steel Round Bar PDFDocumento2 paginec40 Carbon Steel Round Bar PDFRamNessuna valutazione finora

- Wall Colmonoy Surfacing Alloys Selector ChartDocumento3 pagineWall Colmonoy Surfacing Alloys Selector Chartmp87_ingNessuna valutazione finora

- Esab MKT Price ListDocumento18 pagineEsab MKT Price ListAnik Desai100% (1)

- STEEL 30NiCrMo16 30NCD16 FDMA - 1 - GBDocumento2 pagineSTEEL 30NiCrMo16 30NCD16 FDMA - 1 - GBAdnan ColoNessuna valutazione finora

- Tabla de Referencia de Materiales: Material Reference ChartDocumento2 pagineTabla de Referencia de Materiales: Material Reference Chartsateesh chandNessuna valutazione finora

- High Carbon Wire RodDocumento9 pagineHigh Carbon Wire Rodninganray6316100% (1)

- CRCA Technical Notes - 2018Documento11 pagineCRCA Technical Notes - 2018Sajib Chandra RoyNessuna valutazione finora

- Gantrex Technical Bulletin Summarizes European Crane Rail StandardsDocumento3 pagineGantrex Technical Bulletin Summarizes European Crane Rail StandardsLainhatanhNessuna valutazione finora

- WPQDocumento1 paginaWPQChava TejaNessuna valutazione finora

- AlokJain JindalDocumento76 pagineAlokJain JindalArunprasad Murugesan100% (1)

- Welding ProcessDocumento42 pagineWelding ProcessPankaj KumbhareNessuna valutazione finora

- Iron Carbon DiagramDocumento10 pagineIron Carbon DiagramsivakumarNessuna valutazione finora

- Hot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017Documento8 pagineHot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017raghavendragouda patilNessuna valutazione finora

- BohlerThyssen PDFDocumento386 pagineBohlerThyssen PDFElMacheteDelHuesoNessuna valutazione finora

- Casting, Forming & Welding (ME31007) Lecture NotesDocumento102 pagineCasting, Forming & Welding (ME31007) Lecture NotesramuNessuna valutazione finora

- Astm A148Documento2 pagineAstm A148raghumnNessuna valutazione finora

- Technical Delivery Conditions for Steel FastenersDocumento5 pagineTechnical Delivery Conditions for Steel FastenersDorota HONessuna valutazione finora

- Chemical DetailsDocumento3 pagineChemical Detailsemmas18Nessuna valutazione finora

- Chemical Quality of TMT Bars: View Previous Topic View Next TopicDocumento6 pagineChemical Quality of TMT Bars: View Previous Topic View Next Topicpatrik710Nessuna valutazione finora

- 0803 - John Deere - Casting Repairing InstructionsDocumento4 pagine0803 - John Deere - Casting Repairing Instructionscrazy dNessuna valutazione finora

- Steel Dynamics Bar Book Rev 2 New CoverDocumento194 pagineSteel Dynamics Bar Book Rev 2 New CoverNina LazuardiNessuna valutazione finora

- Is - 814 - 2004Documento31 pagineIs - 814 - 2004sangitaghaisasNessuna valutazione finora

- 4711Documento10 pagine4711Gaurav AgarwalNessuna valutazione finora

- Chemical and Mechanical PropertiesDocumento5 pagineChemical and Mechanical PropertiesAristotle MedinaNessuna valutazione finora

- IS1731 steel flat dimensions tableDocumento2 pagineIS1731 steel flat dimensions tablekaustavNessuna valutazione finora

- Steel Tubes For Structural Purposes Conforming To IS 1161 - 1998Documento2 pagineSteel Tubes For Structural Purposes Conforming To IS 1161 - 1998Ayush TariyalNessuna valutazione finora

- Cromax 42CrMo4Documento3 pagineCromax 42CrMo4ElMacheteDelHuesoNessuna valutazione finora

- Application - Cast Iron RepairDocumento16 pagineApplication - Cast Iron RepairAnonymous L0ChmPGNessuna valutazione finora

- Withdrawal Speed Bott Withdrawal Speed Mould Oscillator Speed RDB Speed 986.7151956324Documento6 pagineWithdrawal Speed Bott Withdrawal Speed Mould Oscillator Speed RDB Speed 986.7151956324Deepak Sharma100% (2)

- Electrodes EnglishDocumento139 pagineElectrodes Englishcostelino72Nessuna valutazione finora

- Aerospace Material Specification: Plating, Nickel General PurposeDocumento8 pagineAerospace Material Specification: Plating, Nickel General PurposeSURYAS63Nessuna valutazione finora

- Steckel Mill 1 PDFDocumento178 pagineSteckel Mill 1 PDFSomnathNaskarNessuna valutazione finora

- Self-shielded electrode for heavy component repairDocumento1 paginaSelf-shielded electrode for heavy component repairAravind rajNessuna valutazione finora

- Thermanit X Stick Electrode for Stainless Steel WeldingDocumento2 pagineThermanit X Stick Electrode for Stainless Steel WeldingMadhusudan YeoleNessuna valutazione finora

- TDS 351do enDocumento1 paginaTDS 351do enMumkoNessuna valutazione finora

- Manufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6Documento1 paginaManufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6yadi_baeNessuna valutazione finora

- EN 1 4835 - 1510 Valbruna Nordic EnglishDocumento2 pagineEN 1 4835 - 1510 Valbruna Nordic Englishnguyenhuutan91Nessuna valutazione finora

- 1564 Fox Ev 85 ElettrodoDocumento1 pagina1564 Fox Ev 85 ElettrodoAminNessuna valutazione finora

- Aalco Metals LTD Stainless Steel 14021 Bar 311Documento2 pagineAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNessuna valutazione finora

- How To Solve AssignmentsDocumento4 pagineHow To Solve AssignmentsHarisNessuna valutazione finora

- Solution of Problem Set 1 For Purity Hydrocarbon Data PDFDocumento4 pagineSolution of Problem Set 1 For Purity Hydrocarbon Data PDFDrumil TrivediNessuna valutazione finora

- Dynamic Analysis of Motor Floor: Structure DataDocumento6 pagineDynamic Analysis of Motor Floor: Structure Datap_ignatiusNessuna valutazione finora

- Caractéristique Dell Latitude E7250Documento3 pagineCaractéristique Dell Latitude E7250Milandou Ahmed TresorNessuna valutazione finora

- V Single Vane Pumps: 1 - "F3" 2 - Pump TypeDocumento14 pagineV Single Vane Pumps: 1 - "F3" 2 - Pump TypeJose Leandro Neves FerreiraNessuna valutazione finora

- Make Your Own Eye Chart!: Interpreting The TableDocumento2 pagineMake Your Own Eye Chart!: Interpreting The TableneuroNessuna valutazione finora

- 4 UIUm 8 JHNDQ 8 Suj H4 NsoDocumento8 pagine4 UIUm 8 JHNDQ 8 Suj H4 NsoAkash SadoriyaNessuna valutazione finora

- Understand The Standardization Protocol For Iot Understand The Concepts of Web of Things. Understand The Concepts of Cloud of Things With Understand The Basic Concepts of Aspect OrientedDocumento2 pagineUnderstand The Standardization Protocol For Iot Understand The Concepts of Web of Things. Understand The Concepts of Cloud of Things With Understand The Basic Concepts of Aspect OrientedShanthi GanesanNessuna valutazione finora

- Tecquipment - Flumes - Data SheetDocumento3 pagineTecquipment - Flumes - Data SheetArthur BritoNessuna valutazione finora

- The Power of TQM: Analysis of Its Effects On Profitability, Productivity and Customer SatisfactionDocumento15 pagineThe Power of TQM: Analysis of Its Effects On Profitability, Productivity and Customer SatisfactionAbid Ahasan100% (1)

- J Gen Physiol-1952-Hershey-39-56Documento18 pagineJ Gen Physiol-1952-Hershey-39-56api-277839406Nessuna valutazione finora

- Unit2.SP - Mill.setting and ImbibitionDocumento15 pagineUnit2.SP - Mill.setting and ImbibitionHari kantNessuna valutazione finora

- EL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENDocumento4 pagineEL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENfederico4thNessuna valutazione finora

- Electrochemical Cleaningof Artificially Tarnished SilverDocumento11 pagineElectrochemical Cleaningof Artificially Tarnished SilverRahmi Nur Anisah Nasution 2003114489Nessuna valutazione finora

- Basic Chemistry Review (Students)Documento16 pagineBasic Chemistry Review (Students)AnilovRozovaNessuna valutazione finora

- Tehandler KatoDocumento15 pagineTehandler KatoWalterNessuna valutazione finora

- Training Seminar ON GSM Held at BSNL: Presented By: Charli Bagga Kriti Rastogi (AEI-08)Documento51 pagineTraining Seminar ON GSM Held at BSNL: Presented By: Charli Bagga Kriti Rastogi (AEI-08)Ankita BharadwajNessuna valutazione finora

- KN Yb 1000Documento13 pagineKN Yb 1000taharNessuna valutazione finora

- CarbonatiteDocumento9 pagineCarbonatiteWWW.1580.L0GN.CFNessuna valutazione finora

- Animal and Plant CellDocumento3 pagineAnimal and Plant CellElmer Tunggolh, Jr.Nessuna valutazione finora

- Electrical Circuit Analysis ProblemsDocumento14 pagineElectrical Circuit Analysis ProblemsMd Rafiqul IslamNessuna valutazione finora

- AerialSolution - 280 - Brochure - LT - New Design - Final - LRDocumento20 pagineAerialSolution - 280 - Brochure - LT - New Design - Final - LRRover DmsNessuna valutazione finora

- Solid angles in perspective: Ω, have a small but essential role in physics. For example, howDocumento8 pagineSolid angles in perspective: Ω, have a small but essential role in physics. For example, howashkarkabeer08Nessuna valutazione finora

- Operation Manual Zoomlion QY40Documento133 pagineOperation Manual Zoomlion QY40Hải Tiến100% (1)

- TIMO Mock 2019 卷P3fDocumento9 pagineTIMO Mock 2019 卷P3fDo Yun100% (1)

- Recurrent Neural Network-Based Robust NonsingularDocumento13 pagineRecurrent Neural Network-Based Robust NonsingularDong HoangNessuna valutazione finora

- Temperarura4 PDFDocumento371 pagineTemperarura4 PDFmario yanezNessuna valutazione finora